3. CR#2 ~ CR#5: The settings of average times of the signals at CH1 ~ CH4. Range: K1 ~ K20 (default = K10).

Please note that the average time settings at CR#2 ~ CR#5 only need to be written in once.

4. CR#6 ~ CR#9: The average of the signals at CH1 ~ CH4 obtained from the settings in CR#2 ~ CR#5. For

example, if the settings in CR#2 ~ CR#5 is 10, the content in CR#6 ~ CR#9 will be the average of the most

recent 10 signals at CH1 ~ CH4.

CR#10, CR#11, CR#16, CR#17, CR#22, CR#23, CR#28 and CR#29 are reserved.

5. CR#12 ~ CR#15: The present value of input signals at CH1 ~ CH4.

6. CR#18 ~ CR#21: The adjusted OFFSET value of CH1 ~ CH4, representing the analog input voltage or current

when the analog signal is converted into digital value 0.

The adjustable range of voltage: -5V ~ +5V (-4,000LSB ~ +4,000LSB)

The adjustable range of current: -20mA ~ +20mA (-4,000LSB ~ +4,000LSB)

7. CR#24 ~ CR#27: The adjusted GAIN value of CH1 ~ CH4, representing the analog input voltage or current when

the analog signal is converted into digital value 4,000.

The adjustable range of voltage: -4V ~ +20V (-3,200LSB ~ +16,000LSB)

The adjustable range of current: -16mA ~ +52mA (-3,200LSB ~ +10,400LSB)

Please note that: GAIN value – OFFSET value = +800LSB ~ +12,000LSB (voltage) or +800LSB ~ +6,400LSB (current)

When GAIN – OFFSET is small (steep oblique), the resolution of input signal will be finer and variation on the

digital value will be greater. When GAIN – OFFSET is big (gradual oblique), the resolution of input signal will be

rougher and variation on the digital value will be smaller.

8. CR #30: Error status value (See the table below)

Error status Content b15 ~ b8

b7

b6

b5

b4

b3

b2

b1

b0

Abnormal power supply K1(H’1) 0 0 0 0 0 0 0 1

Incorrect analog input

value K2(H’2) 0 0 0 0 0 0 1 0

Incorrect mode setting K4(H’4) 0 0 0 0 0 1 0 0

OFFSET/GAIN error K8(H’8) 0 0 0 0 1 0 0 0

Hardware malfunction K16(H’10)

0 0 0 1 0 0 0 0

Abnormal digital range K32(H’20)

0 0 1 0 0 0 0 0

Incorrect average times

setting K64(H’40)

0 1 0 0 0 0 0 0

Instruction error K128(H’80)

reserved

1 0 0 0 0 0 0 0

Note: Each error status is determined by the corresponding bit (b0 ~ b7) and there may be more than 2 errors occurring at the same time.

0 = normal; 1 = error

9. CR#31: The setting of RS-485 communication address (Range: 01 ~ 255, default = K1).

10. CR#32: The setting of RS-485 communication speed. b0: 4,800bps; b1: 9,600bps (default); b2: 19,200bps; b3:

38,400bps; b4: 57,600bps; b5: 115,200bps; b6 ~ b13: reserved; b14: high/low bit exchange of CRC checksum

(only valid in RTU mode); b15 = 0: ASCII mode; b15 = 1: RTU mode. ASCII data format: 7-bit, Even bit, 1 stop

bit (7, E, 1); RTU data format: 8-bit, Even bit, 1 stop bit (8, E, 1).

11. CR#33: For authorizations on some internal functions, e.g. OFFSET/GAIN tuning. The latched function will

store the output setting in the internal memory before the power is cut off.

12. CR#34: Firmware version of the model.

13. CR#35 ~ CR#48: Parameters for system use.

14. CR#0 ~ CR#34: The corresponding parameter addresses H’4032 ~ H’4022 are for users to read/write data by

RS-485 communication. When using RS-485, the user has to separate the module with MPU first.

a. Communication baud rate: 4,800/9,600/19,200/38,400/57,600/115,200bps

b. Modbus ASCII/RTU communication protocols: ASCII data format (7-bit, Even bit, 1 stop bit (7, E, 1)); RTU

data format (8-bit, Even bit, 1 stop bit (8, E, 1)).

c. Function: H’03 (read register data); H’06 (write 1 word datum to register); H’10 (write many word data to

register)

d. Latched CR should be written by RS-485 communication to stay latched. CR will not be latched if written by

MPU through TO/DTO instruction.

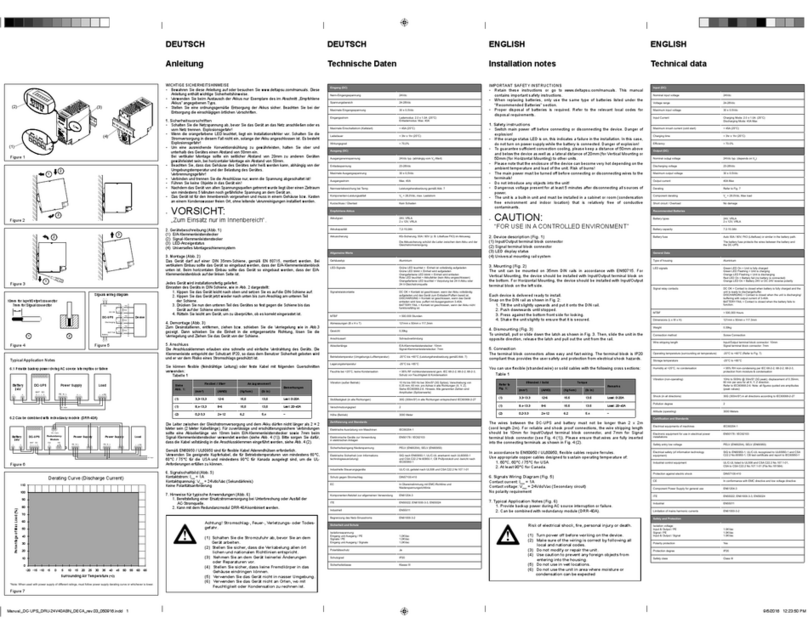

Adjusting A/D Conversion Curve

4.1 Explanation

Voltage Input Mode

+4,000

-4,000

10V

-6V-10V

0

Mode 0

Mode1

CR#1 mode 0 GAIN = 5V (4,000LSB)

OFFSET = 0V (0LSB)

CR#1 mode 1 GAIN = 6V (4,800LSB)

OFFSET = 2V (1,600LSB)

GAIN

The voltage input value when the digital

output value = K4,000

Range: -4V ~ +20V (-3,200LSB ~

+16,000LSB)

OFFSET

The voltage output value when the digital

input value = K0

Range: -5V ~ +5V (-4,000LSB ~ +4,000LSB)

GAIN - OFFSET Range: +1V ~ +15V (+800 LSB ~ +12,000

LSB)

Current Input Mode

+4,000

-12mA-20mA

4mA

0

GAIN

Mode 3

Mode 2

CR#1 mode 2 GAIN = 12mA (2,400LSB)

OFFSET = 4mA (800LSB)

CR#1 mode 3 GAIN = 10mA (2,000LSB)

OFFSET = 0mA (0LSB)

GAIN

The current input value when the digital

output value = K2,000

Range: -8mA ~ +40mA (-1,600LSB ~

+8,000LSB)

OFFSET

The current input value when the digital

output value = K0

Range: -10mA ~ +10mA (-2,000LSB ~

+2,000LSB)

GAIN - OFFSET Range: +2mA ~ +30mA (+400 LSB ~ +6,000

LSB)

The user can adjust the OFFSET/GAIN curves according to the actual needs by changing the OFFSET value

(CR#18 ~ CR#21) and GAIN value (CR#24 ~ CR#27).

LSB refers to “least significant bit”: In voltage input, 1LSB = 10V/8000 = 1.25mV; in current input, 1LSB = 20mA/4,000 =

5μA.

4.2 Program Example

Example 1: Set the OFFSET value of CH1as 0V (= K0LSB) and GAIN value as 2.5V (= K2,000LSB).

X0

K24

H0 K1

K0

K1

M1002

K0

K1

K0

K18 K0

K0

TO

TO

TO

TO

Write H’0 into CR#1 of analog input module

No.0 and set CH1 in mode 0 (voltage input

-10V ~ +10V).

Write H’0 into CR#33 and allow OFFSET/GAIN

tuning in CH1 ~ CH4

When X0 goes from Off to On, write the

OFFSET value K0LSB into CR#18 and the GAIN

value K2,000LSB into CR#24.

Example 2: Set the OFFSET value of CH2 as 2mA (= K400 LSB) and GAIN value as18mA (= K3,600LSB).

X0

K25

H18 K1

K0

K1

H0

K0

K1

K0

K19

K0

TO

TO

TO

TO

Write H’18 into CR#1 of analog input module

No.0 and set CH2 in mode 3 (current input

-20mA ~ +20mA).

Write H’0 into CR#33 and allow OFFSET/GAIN

tuning in CH1 ~ CH4

When X0 goes from Off to On, write the

OFFSET value K400LSB into CR#19 and the

GAIN value K3,600LSB into CR#25.

Trial Operation & Troubleshooting

LED Display

1. When the module is powered for the first time, POWER LED will be on and ERROR LED will be on for 0.5

second. After this, A/D LED will start to flash.

2. When the power supply is normal, POWER LED will be on and ERROR LED should be off. When the

power supply is less than 19.5V, ERROR LED will keep being on until the power supply is higher than

19.5V.

3. When controlled by RS-485, the RS-485 LED on the module will flash after receiving the RS-485

instruction.

4. When the input or output value exceeds the upper bound or falls below the lower bound after conversion,

ERROR LED will flash.

Program Example

K1

K0 K1

K0

K0

K0

M1000

FROM

TO

END

K2

K6

D0

H618

K10

D20 K4FROM

TO

K0

K2

= H6400 D0

M1002

= H6400 D0

Read the model name from K0 and see if it is DVP04AD-H2: H’6400.

If D0 = H’6400, set the input modes: (CH1, CH3) mode 0, (CH2, CH4) mode 3.

Set the average times in CH1 and CH2 as K10.

Read the average of input signals at CH1 ~ CH4 from CR#6 ~ CR#9 and store the 4 data in D20 ~ D23.

Relevant Instructions

API

78

D

FROM

P

Read CR data in special modules

Instruction

Explanation

: No. of special module (m1 = 0 ~ 7) : CR# in special module to be read

: Device for storing read data : Number of data to be read at a time

Program

Example

Read CR#24 of special module No.0 into D0 and CR#25 into D1. Only 2 groups of data are read

at a time (n = 2).

FROM K0 K24 D0 K2

API

79

D

TO P

Write CR data into special modules

Instruction

Explanation

: No. of special module (m1 = 0 ~ 7) : CR# in special module to be written

: Data to be written into CR : Number of data to be written at a time

Program

Example

Use 32-bit instruction DTO to write the content in D11 and D10 into CR#3 and CR#2 of special

module No.0. Only 1 group of data is written in at a time (n = 1).

K0 K2

K1

Remarks

Operand rules

1. : The No. of special modules connected to PLC MPU. No. 0 is the module closest to te

MPU. Maximum 8 modules are allowed to connected to a PLC MPU and they will not occupy

any I/O points.

2. : CR#. CR (control register) is the 49 16-bit memories built in the special module,

numbered in decimal as #0 ~ #48. All operation status and settings of the special module are

contained in the CR.

3. FROM/TO instruction is for reading/writing 1 CR at a time. DFROM/DTO instruction is for

reading/writing 2 CRs at a time.

CR #10 CR #9

Designated CR number

High er 16 -bit

4. Number of groups “n” to be transmitted: n = 2 in 16-bit instructions and n = 1 in 32-bit

instructions mean the same.

D0

D1

D2

D3

D4

D5

CR #5

CR #6

CR #7

CR #8

CR #9

CR #10

D0

D1

D2

D3

D4

D5

Designated CR

16-bit instruction when n=6

32-bit instruction when n=3

M1083 for switching instruction modes in EH2 series models

1. When M1083 = Off, during the execution of FROM/TO instruction, all external or internal

interruption subroutines will be forbidden. The interruptions are allowed only after FROM/TO

instruction finishes its execution. FROM/TO instruction can also be used in an interruption

subroutine.

2. When M1083 = On and an interruption signal occurs during the execution of FROM/TO

instruction, the interruption will be processed first (with a 100us delay) and the execution of

FROM/TO will be stopped. After the interruption subroutine finishes its execution, the

program will jump to the next instructio of FROM/TO. FROM/TO cannot be used in an

interruption subroutine.

The content of this instruction sheet may be revised without prior notice. Please consult our distributors or

download the most updated version at http://www.delta.com.tw/industrialautomation