Vivax Metrotech HL5000 Installation manual

Model HL5000

Elec t roac oust ic Leak Loc at or

Operation Manual

ISO 9001:2000 CERTIFIED

Metrotech has received ISO 9001 Quality Management System

Certification.

Metrotech adheres to the quality standard guidelines of ISO 9001 and ensures quality in its

design/development, production, installation, and servicing disciplines.

© Metrotech Corporation 2006

Metrotech Corporation

3251 Olcott Street

Santa Clara, CA 95054

USA

Tel: 1.800.446.3392; 1.408.734.1400

Fax: 1.408.734.1415

E-mail: [email protected]

Internet: www.metrotech.com

Revision B November 2006

Table of contents

1 Description ..

1

1.1

General . .

1

1.2

Construction .

2

1.3

Technical data . .. .. 2

1.4

HL 5000 Configurations ..

3

1.4.1

HL 5000

-1 .

3

1.4.2

HL 5000

-2 .

3

1.4.3

HL 5000

-3 .

3

1.4.4

HL 5000

-4 .

3

1.4.5

Accessories .. ... 3

2

Getting To Know the HL 5000

. 4

2.1

HL 5000

controls .. 4

2.2

Connection of Components and Accessories .. . .

4

2.3

Battery Compartment .

5

2.4

Automatic Battery Monitoring

6

2.5

Backlight .. 6

2.6

Microphones

6

2.6.1

GM

-50 .. 6

2.6.2

Pam U 40 . 7

2.7

Headphones

8

3 Operation ... ..

9

3.1

Connection and Removal of Attachments ... 9

3.2

Turning the unit On .. 9

3.3

Headphone Volume and Microphone Amplification (Gain) ...

10

3.3.1

Setting the Volume ..

10

3.3.2

Setting the Gain ...

11

3.4

The Main

Screen .

12

3.5

Filter Settiing (HL 5000 Professional)

13

3.5.1

What are Filters? .

13

3.5.2

Filter Selection .

13

3.6

Filter Selection in the Field .

16

3.6.1

Filter Selection A (Ground Microphone GM

-

50,

PAM U 40 with Spike and Rods) ...

16

3.6.2

Filter Selection B: Contact Microphone

(PAM U 40 with Spike or Rods)

16

3.6.3

Leak Detection Process and Filter Selec

tion ..

16

3.7

Mute Button

17

3.8

The Memory Mode ..

18

3.9

Continuous Measurement Mode (HL5000

Professional)

19

3.10

Pipe Locating Using the RSP

-

3 (HL 5000

Profess

ional) ...

20

3.11

Switching off the HL5000

21

4 Troubleshooting

22

4.1

Unit Does Not Switch On

22

4.2

Battery Monitor Does Not Function .

22

4.3

No Sound Can Be Hear

d

22

4.4

Scratching Sounds In the Headphones

22

4.5

Service Center

23

Appendix ..

24

Copyright Notice

25

List of illustrations

Fig 1 :

HL 5000

Control Panel . 4

Fig 2 :

Side view left and right with connections ..

5

Fig 3 :

Base plate with locking screws ... ... 5

Fig 4 :

PAM U 40 with sensor rod .. 7

Fig 5 :

PAM U

40 with magnet

7

Fig 6 :

Headphones .. 8

Fig 7 :

Display at switch on . 9

Fig 8 :

Main Screen w/ Main Menu

10

Fig 9 :

Soft Keys for Setting the Volume ...

10

Fig 10 :

Soft Keys for Gain Adjustment ...

11

Fig 11 :

Current Total and Minimum Leak Sound Values .

12

Fig 12 :

Filter settings .

15

Fig 13 :

Adjusting the lower filter cut

-off frequency

15

Fig 14 :

Adjusting the upper filter cut

-off frequency ...

15

Fig 15 :

Dual Segment Analysis (DSA)

18

Fig 16 :

Memory mode Measurement ..

19

Fig 17 :

Timer ..

20

1

1

Des

cription

1.1

General

The new HL 5000 Leak Locator is designed to facilitate the

implementation of a complete water leak detection program

-

from the preliminary survey, to pre

-

location, to pinpointing.

Although designed with the water utility in mind, the

HL 5000

can also be used for finding leaks in any pipe distribution

network from which pressurized liquid creates sound when

escaping from a leak.

Sound from a water leak is constant; it does not go away.

The HL 5000

utilizes a special feature called D

ual Segment

Analysis (DSA) to simultaneously display both the minimum

constant leak sound value of a leak and the total current sound

value. In addition, the results of each measurement can be

automatically stored for a comparison of leak sound levels

alon

g a series of sequential listening points (see Section 3.8

on Memory Mode, pp 18

-

19).

The HL 5000

is the first leak locator that when in leak

detection mode, utilizes computer

-

enhanced reduction of

extraneous sound. Intermittent impulse sounds/disturba

nces

are automatically suppressed and do not interfere with the

display of consistent, minimum sound values. There are

times, however, when the ability to receive and focus on

impulse sounds are desirable. When using impulse

generating devices (such as Me

trotech s RSP3) to help

locate non

-

metallic pipes, the HL 5000

should be placed

in Pipe Location Mode (see Section 3.10 on Pipe Location

w/RSP3 on p. 20).

2

1.2

Construction

The construction of the HL 5000

is solid. The durable plastic

housing of t

he receiver is water resistant and built to

withstand normal field operation. The comfortably spaced soft

keys on the front of the control panel allow even a gloved

operator to easily navigate between features. The LCD

display is equipped with a backlight

for operation at night or

in other poor lighting conditions.

The HL 5000

is powered by 8 AA batteries that are housed

behind an easily removed cover in the base of the unit.

The multi

-

pin microphone cable connector is designed to

allow a quick, but secu

re, waterproof connection to the

receiver. The headphones are connected via a watertight, ¼

mono instrument plug.

1.3

Technical data

Analysis bandwidth:

0 Hz 4000 Hz

Filter cut

-

off frequencies:

0 70 Hz, 106 Hz, 160 Hz,

240 Hz, 360 Hz, 540 Hz,

800 H

z, 1200 Hz, 1800

4000 Hz

Memory Recordings:

9 dual displays

Continuous Monitoring:

3, 10, & 30 min options

LCD Display:

5.1 x 1.4 in

LCD Illumination:

Backlight

Power Supply 1:

8 x AA batteries, 1.5 Volt

Power Supply 2:

8 x 1.2 V

rechargeable

batteries (option)

Battery Life:

> 35 hrs (battery),

> 15 hrs rechargeable

battery

Storage:

9 measurements

Operating Temperature:

15 to 120 °F

Storage Temperature:

15 to 155 °F

Protection Class

(Operating):

IP 54

Dimens

ions (L x W x D):

8.5 x 3.75 x 4.33 in

Weight: HL 5000

2.6 lbs (with batteries)

Weight: GM

-50

7.7 lbs (w/ carrying handle)

Weight: PAM U

2.2 lbs

3

1.4

HL 5000

Configurations

1.4.1 HL 5000

-1

Includes receiver w/standard software, unive

rsal PAMU40

microphone, cable, 2

-

extension rods, contact spike, tri

-

point

ground plate, hard case and operation manual.

1.4.2

HL 5000

-2

Includes receiver w/standard software, universal PAMU40,

wind protected GM

-

50 microphones, cable, 2

-

extension rods,

contact

point, tri

-

point ground plate, hard case and operation

manual.

1.4.3

HL 5000

-3

Includes receiver w/professional software, universal PAMU40

microphone, magnetic adapter, cable, 2

-

extension rods,

contact point, tri

-

point ground plate, hard case and operation

m

anual.

1.4.4

HL 5000

-4

Includes receiver w/professional software, universal

PAMU40 and wind protected GM

-

50 microphones, cable,

2 extensio

n rods, contact point, tri

-

point ground plate, hard

case and operation manual.

1.4.5

Accessories

GM50 ground microphone

GM50

GM50 magnetic plate

PAM

-W-1-D

PAMU40 microphone

PAM

-U-M

PAMU40 plate

11504

Headphones

158096

Extension rod

VST T-1

Magnetic adapter

110030010

Valve adapter 1.65

AD S

-

42

Valve adapter 0.78

AD S

-

20

Carrying case

11543

4

2

Getting to know the HL 5000

Before using the HL 5000

, it is recommended that you take some

time to become familiar with

the unit and its features.

2.1

HL 5000 Controls

Fig 1 : HL5000

Standard/Pro control panel

2.2

Connection of Components and Accessories

The HL 5000

is designed specifically for use with Metrotech

componen

ts and accessories. Attempting to connect other

headphones or microphones to the equipment may cause

damage to the unit and lead to equipment failure. Fig. 2

illustrates the headphone and microphone connections,

respectively, on the sides of the receiver.

5

Fig 2 : Side view left and right with connections

2.3

Battery Compartment

To access the battery compartment, loosen the two screws

on the underside of the unit and remove the base p

late (Fig.3).

Eight AA batteries power the HL 5000

. When installing or replacing

batteries in the unit, be sure that the positive and negative terminals of

each battery are correctly aligned.

Fig 3 : Battery access plate

6

2.4

Automatic Battery Monitoring

While the HL 5000

is in operation, the battery level is

monitored continuously. The battery symbol in the top right

of the display will begin to flash when there are approximately

4

hours of battery life remaining.

2.5

Backlight

With the equipment on, briefly push the on/off button .

The backlight for the display will be activated / deactivated.

2.6

Microphones

The microphones are connected to the HL 5000

via a multi

-

pin

cable connection on the right hand side of the equipment

(see Fig. 2). There are two microphones available for use

with the HL 5000

: the PAM U 40 Universal/Contact

Microphone and the GM

-

50 Wind

-

Protected Ground

Microphone. The following sections det

ail each of the two

microphones and the various configurations of the PAM U 40.

2.6.1

GM50

The GM

-

50 is an active piezo ground microphone for use

on pavement and other hard surfaces. The microphone

is particularly well shielded from the wind by virtue of its

bell shaped housing and rubber skirt. The carrying

handle/rod, once inserted, is securely locked in place with

a quick, quarter

-

turn to the right. The ability to quickly insert

and remove the handle after placing the microphone is

particularly helpful

when trying to reduce unwanted sound

created by strong winds blowing against the handle.

Important note:

Piezo

-

electric microphones like those in the GM

-

50 and

PAM U 40 provide superior performance but can be

damaged when subjected to impact. When posit

ioning

the microphone, avoid dropping it onto hard surfaces;

instead, carefully place it in position.

7

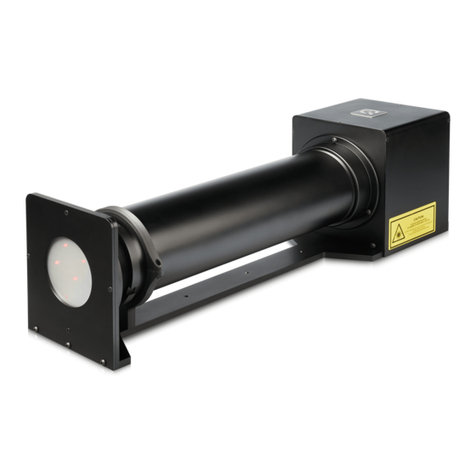

2.6.2

PAM U 40 Universal Microphone

The PAM U 40 is a piezo

-

electric microphone that was

developed primarily as a contact and/or survey microphone.

With th

e use of various adapters, however, it is very effective

in nearly all leak detection situations.

Sensor Rod Configuration:

This configuration allows the operator to quickly

survey the distribution system for leak sound by

touching the tip of the rod to

points of contact like

valves, hydrants, or even the pipe itself. It also

enables the PAM U 40 to serve as an effective ground

microphone by pushing the spike into the soil where

conditions allow it.

Extension rods give the operator the option of

maintai

ning a comfortable, upright position while

working or to reach deeper contact points. They also,

however, can provide greater exposure to wind and

other interfering sounds.

Fig 4 :

PAM U 40 with sensor rod

Magnetic Configuration:

When holding the mic

rophone, even the smallest movements

by the operator can create loud sounds that interfere with the

measurement.

The magnet in this configuration allows the sensor to be

placed on ferromagnetic (metals containing iron are

magnetic) contact points (such as

hydrants and valves) and

remain still during measurement. This configuration provides

excellent transmission of sound vibrations to the sensor

because of the magnets strong connection with the contact

point.

Fig 5 : PAM U 40 with magnet

8

Caution:

Whene

ver possible, grasp and pull the

microphone itself

not the cable

when removing the

microphone from a magnetic contact point. This will help

prevent possible damage to the microphone cable

.

2.7

Headphones

The supplied headphones with ambient sound insula

tion

come standard with the HL 5000

. These electro

-

dynamic

headphones provide excellent reproduction of leak sounds

while blocking out ambient sound to 85 dB.

Fig 6 : Headphones

9

3

Operation

3.1

Co

nnection and Removal of Attachments

Always make sure that the HL 5000

is off when connecting or

removing the headphones or the microphone.

3.2

Turning the Unit On

After attaching both a microphone and the headphones,

press the On/Off button

on the control panel of the

unit. The welcome screen, displaying the current software

version number and the battery status, will appear while the

unit is powering up.

Fig 7 : Display at switch on

After a few seconds, the opening menu appea

rs with the last

equipment settings.

10

Fig 8 : Main Screen with Main Menu

3.3

Headphone Volume and Microphone Amplification (Gain)

The HL 5000

is equipped with separate controls for volume

and gain to accommodate different user preferen

ces across a variety

of leak detection situations.

3.3.1 Setting the volume

The user can set the headphone volume by using the two

soft keys on the far right of the front panel (see Fig. 9).

Note

: Adjusting headphone volume affects

only

the

operator s

ability to hear the sounds that are being processed

by the instrument. Microphone gain (amplification of sound

processed by the unit) is not affected.

Fig. 9: Soft Keys for Setting the Volume

11

3.3.2

Setting the gain

The ampli

fication of the microphone signal, or gain, adjusts

the level of sound passed from the microphone to the

receiver for processing. A high gain setting would allow the

equipment to detect and process far

-

off and/or low

-

level

sounds more easily; close proximi

ty to a leak or loud leak

Fig 10 : Soft Keys for Gain Adjustment

sounds would not require as much amplification and therefore

allow the operator to use a lower gain setting.

Actual pinpointing of a leaks location involves m

easuring the leak

sound level at a number of different points along the line and then

comparing the measurements to one another to determine the point at

which the leak sounds are loudest. Although a high microphone gain

setting (7

-

8) is desirable when in

itially surveying for leak sounds, a

medium gain setting (3

-

5) is recommended when comparing actual

leak sound levels at different points along the line.

Note:

Adjusting the gain (done by using the two soft keys

found on the bottom right of t

he front panel

-

see Fig. 10) will

affect both the displayed sound levels and headphone

volume. The bar over the top of the two buttons (Fig. 10) shows

the gain setting on a scale from 1 (min) to 8 (max).

12

3.4

The Main Screen

When performing leak detection, one of the difficulties faced by

operators is how to identify and measure the sound made by a leak

when other interfering sounds are also present. The HL 5000

utilizes a feature called Dual Segment Analysis (DSA) to diffe

rentiate

between the two types of sounds. Leak sounds, when present, do

not change or go away; they are constant. Other sounds (wind

blowing, passing cars, dogs barking) within range of the microphone

will vary and show changes in volume and intensity or

disappear

altogether. DSA allows the HL 5000 to analyze all the sounds

detected by the microphone and separate those sounds that are

constant and unchanging (like those caused by a water leak) from

those that are caused by elements of the surrounding environment.

The levels of each type of sound are then displayed by separate bar

graphs on the main screen.

The Main Screen (Fig. 11) reveals both the current total sound

level (top bar) and the minimum constant leak sound level

(bottom bar) for all sound frequencies currently selected by the user

(see Section 3.5 on Filter Selection). Measurement of sound levels

takes place when the unit is on and the headphones are not muted.

When the headphones are muted, the unit is placed in stand

-

by

mode and the last measured sound levels remain displayed. When

the unit is returned to measurement mode (un

-

muted) the

measurement cycle begins again and any changes in the two sound

levels are re

-

calculated and displayed.

Fig 11 : Current Tota

l and Minimum Leak Sound Values

13

3.5

Filter Setting (HL 5000 Professional)

3.5.1 What are filters?

One of the characteristics of a sound is its frequency. Technically

speaking, the frequency of a sound is the number of

waves generated

by that sound per cycle. The greater the number of waves per cycle,

the higher the frequency of the sound. In turn, the higher the

frequency a sound has, the higher in pitch that sound will be. Low

-

frequency sounds are low

-

pitched; high

-

frequency sounds are high

-

pitched. Leaks on plastic and PVC lines typically create low

-

frequency sounds and are low

-

pitched to the ear; leaks on copper and

other metallic lines tend to create high

-

frequency sounds and are

high

-

pitched to the ear

.

The

HL 5000 is designed to measure and display sound levels at

frequencies from 0 to 4,000 Hz. On the Filter Menu screen, this broad

spectrum is divided into 9 smaller frequency bands arranged in

ascending order (

0

-

70, 106, 160, 240, 360, 540, 800, 1200, 1

800

-

4000 Hz) and each of these

smaller frequency bands is called a filter.

Any sound that the HL 5000 hears and analyzes is broken down

into the individual frequencies that created the sound, and the process

of selecting specific frequency bands, or fi

lters, for the HL 5000 to

focus on

-

or to ignore

- is referred to as setting the filters.

3.5.2 Filter Selection

While the unit is in listening or measurement mode, go to the filter

selection screen. This is done by pressing the soft key

under

the Filter Menu icon found on the Main Screen.

The 9 vertical bars displayed on the Filter Selection screen (one for

each corresponding filter) show the user how much (or how little) each

individual frequency is contributing toward the overall sound(s) b

eing

processed by the HL 5000 at that moment. The presence or

absence of activity on any particular frequency, or filter, can help the

user decide whether or not to select it for measurement. When a

filter, or group of filters is selected for measurement, three things

happen:

14

1. On the Filter Selection screen, a horizontal bar will be displayed

beneath the selected filter or filters (Figure 12).

2. When the unit is placed in normal Listening Mode (the Main

Screen), Memory, or Continuous Listening Modes, the HL 5000 will

focus on measuring the constant, minimum leak sound levels of only

the frequencies selected by the user on the Filter Selection screen.

Unwanted sounds of interference, such as the hum of power lines, for

example, can be minimized or completely eliminated by not selecting

the filter (in this case, the 0

-

70 Hz filter) associated with the sound.

3. The selected filters/frequency range will be displayed in the upper

right

-

hand corner of the Main Screen.

Sound activity on all the filters will continue to be visible on the Filter

Selection screen (allowing the user to decide when it is appropriate to

change the filter settings), but only sounds generated by the selected

frequencies (filters) will by measured by the HL 5000 when the unit

is in other modes of operation.

Filters are selected or de

-

selected by using the lower (Fig.13) and

upper (Fig. 14) cut

-

off soft keys found underneath of and to the right of

the individual frequency bars, respectively.

When selecting or de

-

selecting filters using the lower cut

-

off,

the user will automatically begin with the lowest selected filter. By

pressing either the left

-

or right

-

arrow soft

keys, the user will be able to

add or remove filters to those already selected.

When selecting or de

-

selecting filters using the upper cut

-

off,

the user will automatically begin with the highest selected filter.

By pressing either the left

-

or right

-

ar

row soft keys, the user will be

able to add or remove filters to those already selected.

15

Fig 12 : Filter settings

Fig 13 : Adjusting the lower filter cut

-

off frequency

Fig 14 : Adjusting the upper filter cut

-

off frequency

16

After the filters have been selected, use the ESC soft key to return to

the main menu.

3.6

Filter selection in the field

Filter selection on the HL 5000 is largely determined by the

type of pipe material the suspected leak is on and whether

the operator is pre-locating or pinpointing the leak. In order to detect

any potential leak sound, an operator may want to use all avai

lable

filters when attempting to pre-locate a leak. When actually

pinpointing the location of the leak, an operator may want to select

only the filter or filters on which the constant minimum leak sound is

most active.

As a general rule, leak sounds on p

lastic pipes (and very large

diameter pipes of any type pipe material) tend to be low

frequency (106

-

540 Hz); leak sounds on metallic and other

high

-

density pipe materials (like asbestos cement) tend to be

higher frequency (360

-

1200 Hz). In addition, b

ecause the

ground itself muffles sound, leak sounds detected with a

ground microphone tend to be lower in frequency than those

detected with a contact microphone placed in direct contact

with the line. The following are two suggested filter settings:

3.6.

1 Filter selection A (Ground microphone GM50, PAM U 40 with

ground plate).

When using a ground microphone, a filter range of 240 Hz

-

540 Hz is recommended.

3.6.2

Filter Setting B: Contact Microphone (Pam U 40 w/ Spike or

Extensi

on Rods).

For measurements directly on the pipe with the sensor spike,

a filter range of 540 Hz

-

1200 Hz is recommended.

3.6.3

Leak Detection Process and Filter Selection

When conducting leak detection in areas where the specific

pipe material is k

nown, an operator may want to set the filters

Table of contents

Other Vivax Metrotech Measuring Instrument manuals

Vivax Metrotech

Vivax Metrotech HL 6000 User manual

Vivax Metrotech

Vivax Metrotech vLoc3-MLA Instruction Manual

Vivax Metrotech

Vivax Metrotech vLoc3-9800 Instruction Manual

Vivax Metrotech

Vivax Metrotech vLoc3-Cam Instruction Manual

Vivax Metrotech

Vivax Metrotech vLocPro2 User manual

Vivax Metrotech

Vivax Metrotech A-frame User manual

Vivax Metrotech

Vivax Metrotech vLoc3 Series User manual

Vivax Metrotech

Vivax Metrotech VM-540 User manual

Vivax Metrotech

Vivax Metrotech vLocPro Series Reference guide