I

T

Ta

ab

bl

le

e

o

of

f

C

Co

on

nt

te

en

nt

ts

s

§

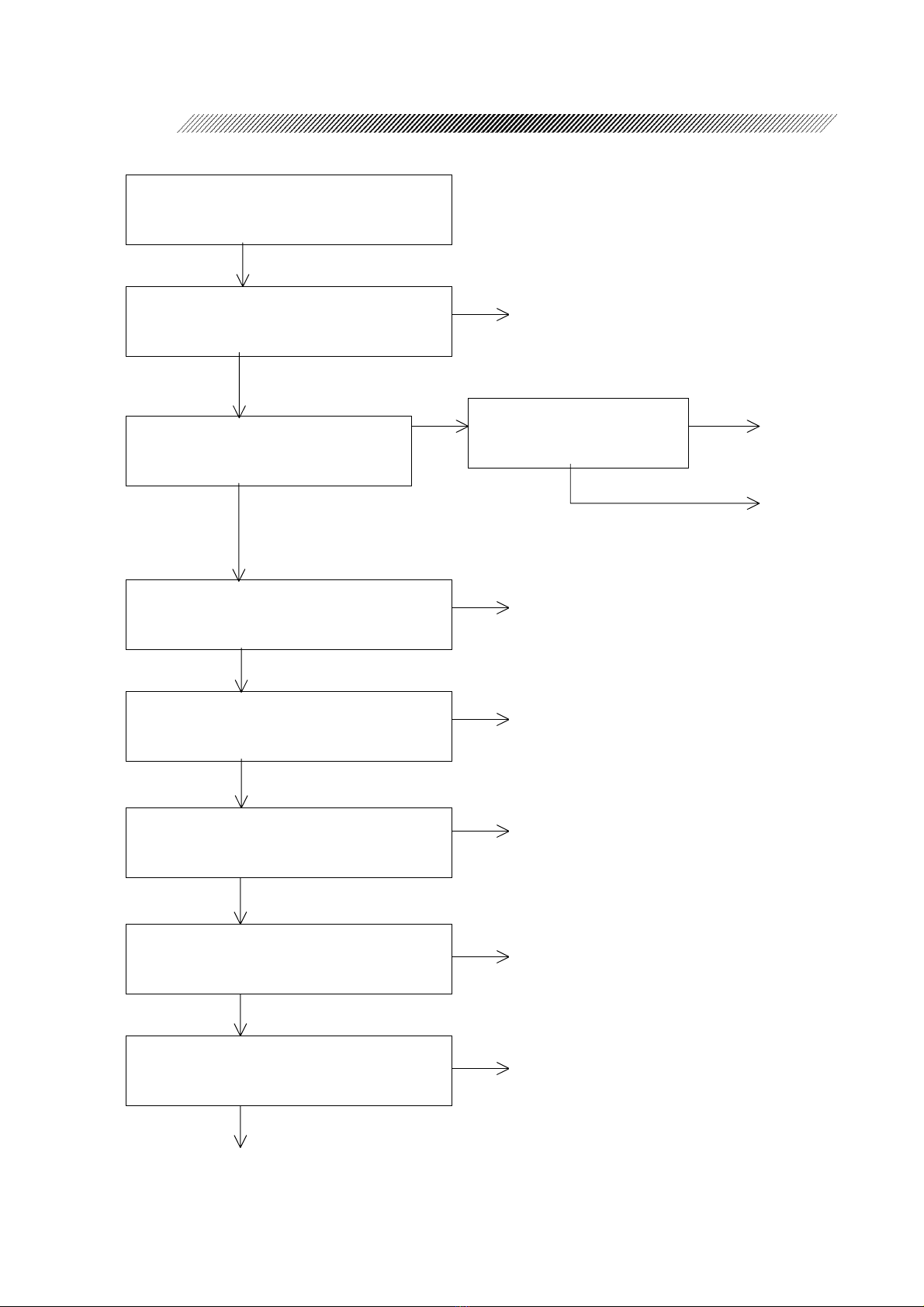

1 INTRODUCTION.........................................................................................................1-1

§

2 CAUTIONS ...................................................................................................................2-1

§

3 TROUBLESHOOTING ...............................................................................................3-1

§

4 SUB TROUBLESHOOTING ......................................................................................4-1

4.1 The Initialization does not Start................................................................................4-1

4.2 The Motor does not Work.........................................................................................4-2

4.3 The Motors do not Stop. ...........................................................................................4-3

4.4 The Projection Lamp does not Go On. .....................................................................4-4

4.5 The Chart Image is Partly Blocked...........................................................................4-5

4.6 The Chart Brightness is Unsuitable. .........................................................................4-6

4.7 The Chart Brightness is Uneven. ..............................................................................4-8

4.8 The Chart Image is not Clear....................................................................................4-9

4.9 The Chart Image does not Change as Operated by the Remote Control. ...............4-10

4.10 The Polarized Chart does not Disappear...............................................................4-11

4.11 The LED does not Go On. ....................................................................................4-12

§

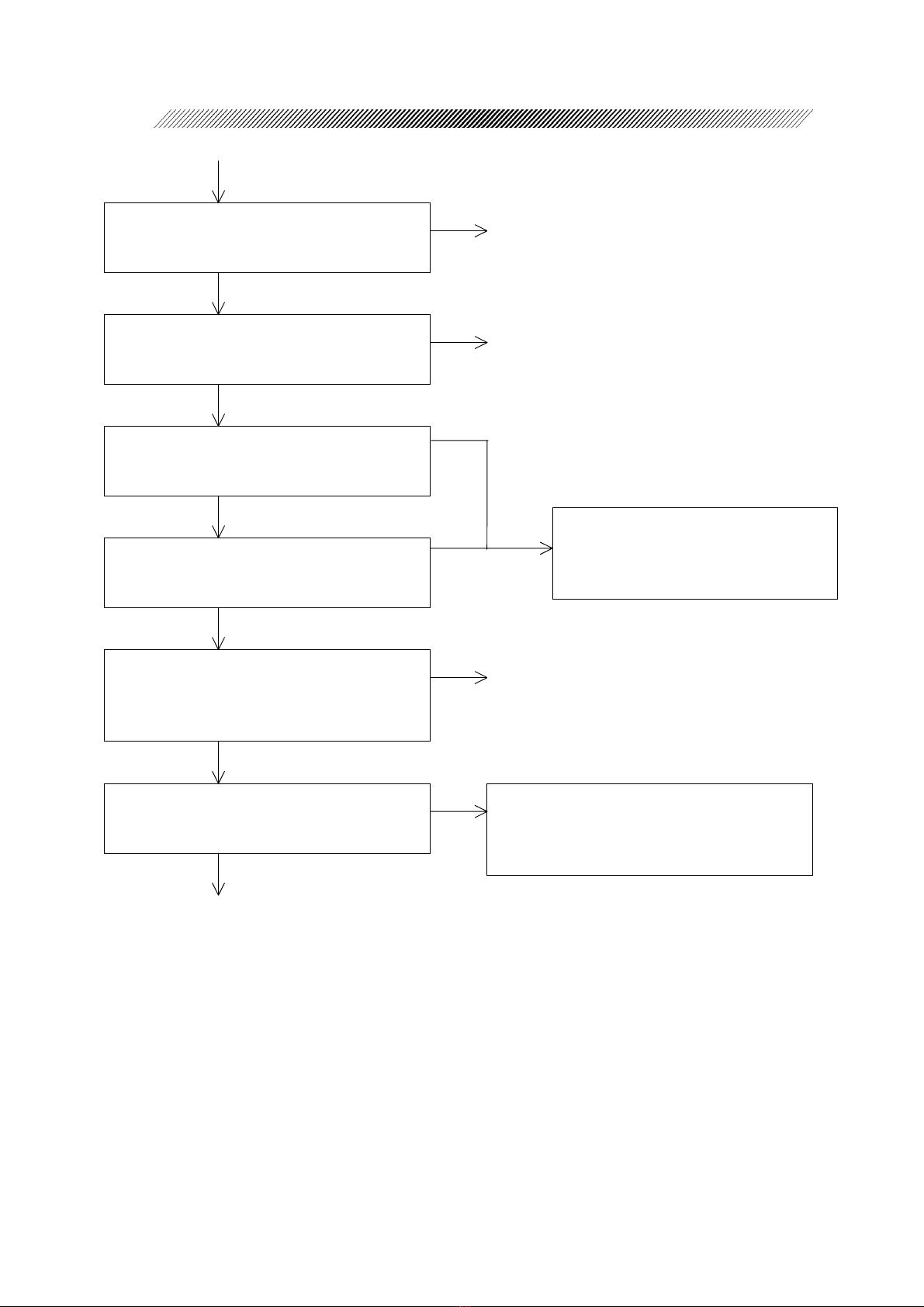

5REPLACEMENT .........................................................................................................5-1

5.1 How to Remove the Covers ......................................................................................5-1

5.2 Replacement of the Circuit Boards ...........................................................................5-3

5.2.1 Replacement of the BA01 board......................................................................5-3

5.2.2 Replacement of the BA02 board......................................................................5-4

5.2.3 Replacement of the BA14 board......................................................................5-4

5.3 Replacement of the Sensors......................................................................................5-5

5.3.1 Replacement of the chart sensor ......................................................................5-5

5.3.2 Replacement of the mask sensor......................................................................5-6

5.4 Replacement of the Chart Motor...............................................................................5-7

5.5 Replacement of the Chart ASSY ..............................................................................5-9

5.6 Replacement of the Mask Motor and Mask ASSY.................................................5-11

5.7 Replacement of the Bottom Cover ASSY (Power LED)........................................5-13

5.8 Replacement of the Power Switch ..........................................................................5-13

Page