Table of contents

Table of contents ............................................................................................................................ 2

Introduction..................................................................................................................................... 3

Power supply.................................................................................................................................. 4

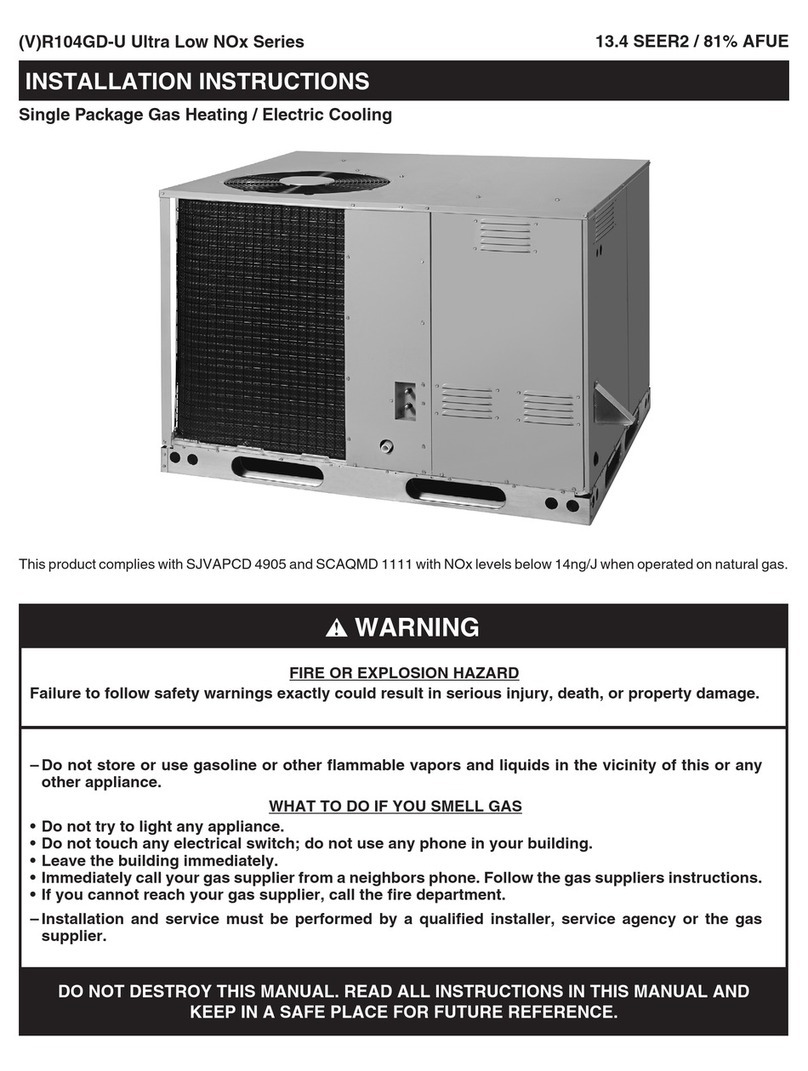

Assembly of Comfort ...................................................................................................................... 5

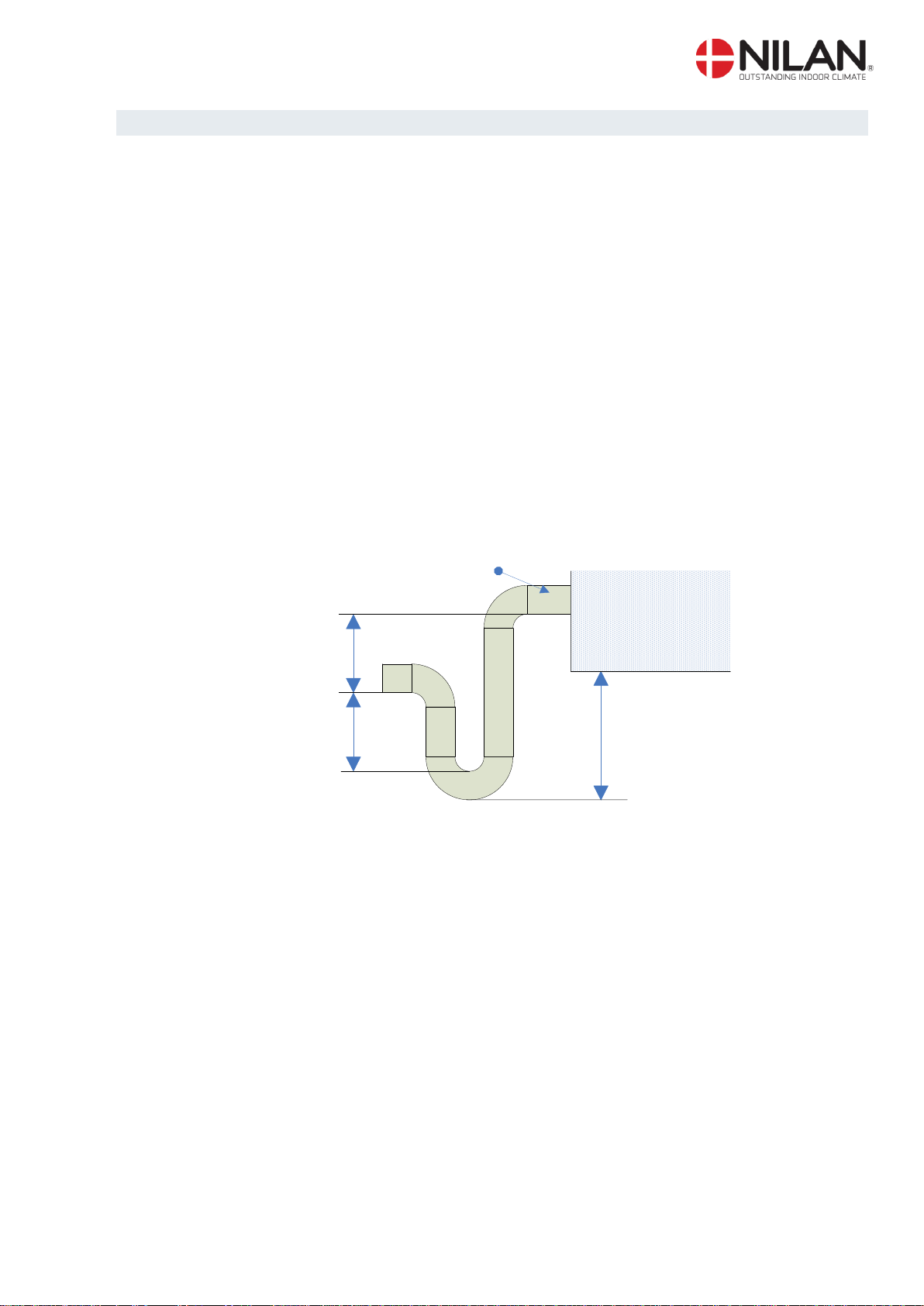

Condensation drain / water seal ..................................................................................................... 6

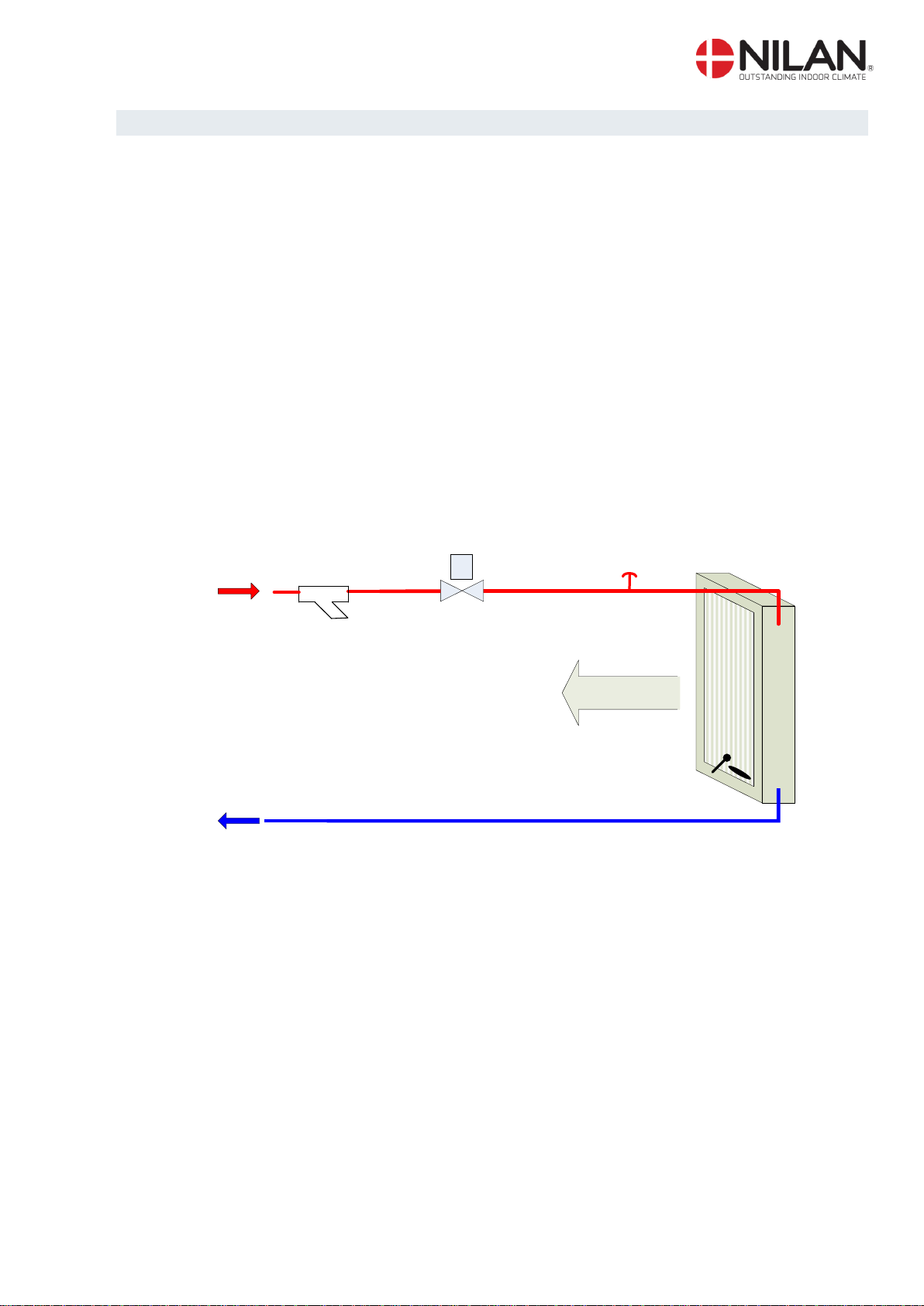

Heating surface, water.................................................................................................................... 7

Heating surface, electrical (retrofitting) ........................................................................................... 9

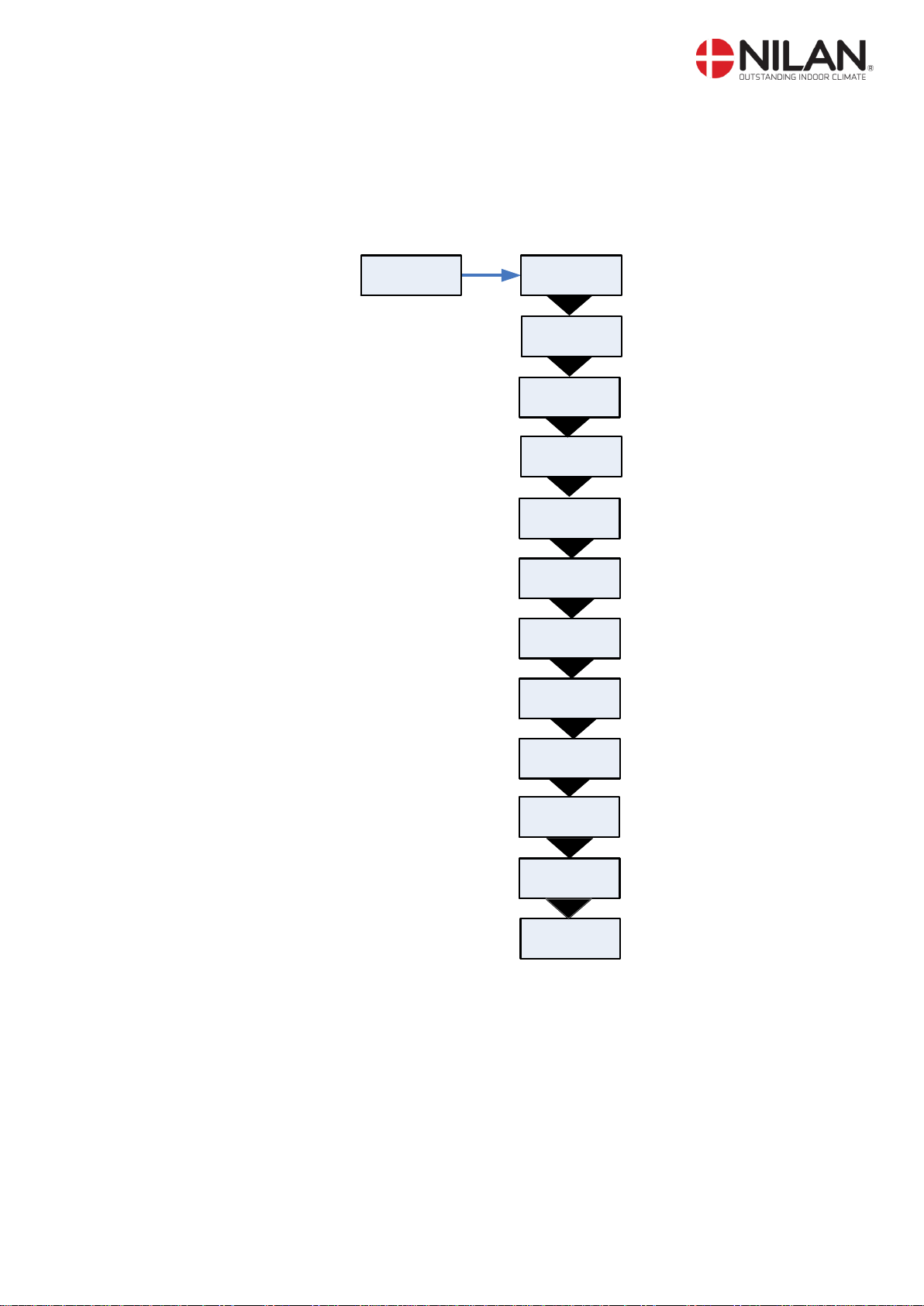

Activating the service menu ...................................................................................................... 10

Heating surface......................................................................................................................... 11

Air quality.................................................................................................................................. 12

Air exchange............................................................................................................................. 13

Defrost...................................................................................................................................... 14

Temp. control............................................................................................................................ 15

Inlet control............................................................................................................................... 16

Room control ............................................................................................................................ 17

Re-start..................................................................................................................................... 18

Preset....................................................................................................................................... 19

Manual...................................................................................................................................... 20

Modbus..................................................................................................................................... 21

Datalog ..................................................................................................................................... 22

System dimensions ...................................................................................................................... 23

Accessories/spare parts ............................................................................................................... 25