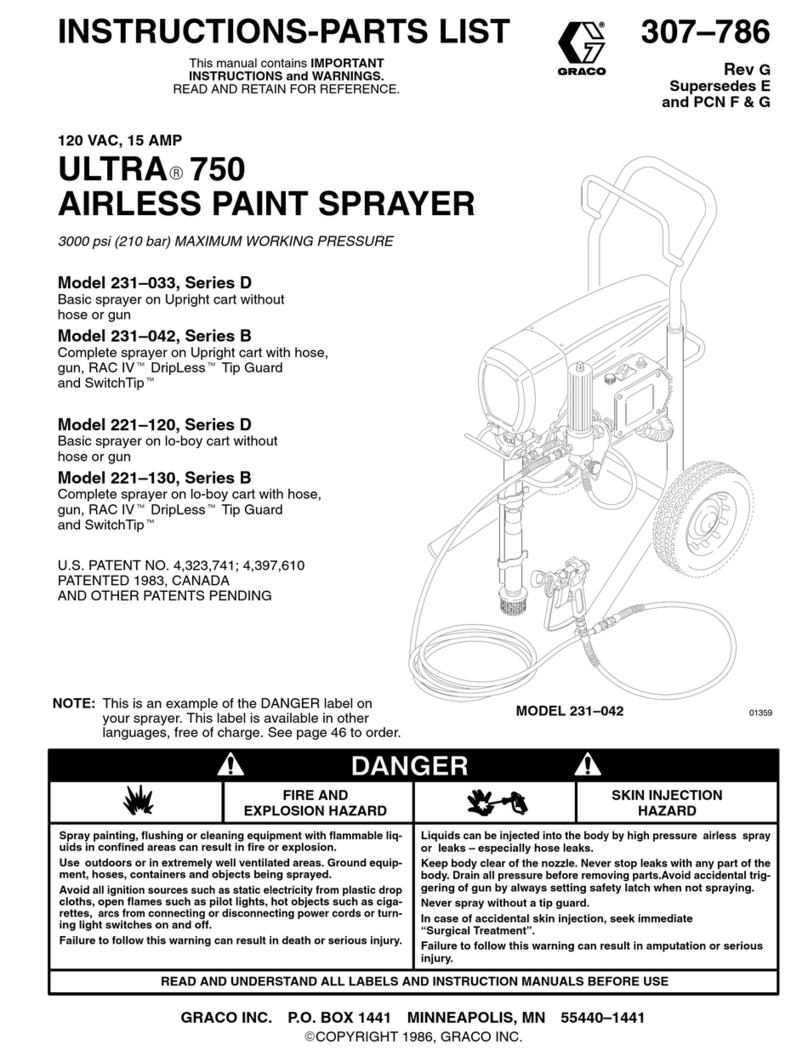

Setup

Supplied Components

Refer

to Fig. 2.

WARNING

A red-handled bleed-type master air valve (35) and

a fluid drain valve (D) are supplied. These accesso

-

ries help reduce the risk of serious injury

, including

fluid injection and splashing of fluid in the eyes or

on the skin, and injury from moving parts if you are

adjusting or repairing the pump.

The bleed-type master air valve relieves air trapped

between this valve and the pump after the valve is

closed. T

rapped air can cause the pump to cycle

unexpectedly

. Locate the valve close to the pump.

The fluid drain valve assists in relieving fluid pres

-

sure in the displacement pump, hose, and gun.

T

riggering the gun to relieve pressure may not be

sufficient.

The red-handled bleed-type master air valve

(35)

is required in your system to relieve air trapped

between it and the air motor when the valve is

closed (see the

WARNING

above). Be sure the

bleed valve is easily accessible from the pump, and

is located

downstream

from the air filter/regulator

(41).

With a wrench, loosen and remove the

female air

line coupler (38).

Screw it onto the main air hose

(A). Leave the mating coupler (37) attached to the

air filter/regulator (41).

The

air filter/regulator (41)

controls pump speed

and outlet pressure by adjusting the air pressure to

the pump. It also removes harmful dirt and mois

-

ture from the compressed air supply

. Locate close

to the pump, but

upstream

from the bleed-type

master air valve (35).

The air manifold (47)

provides ports for connect

-

ing lines to air-powered accessories.

The air relief valve (48)

opens automatically to

prevent overpressurization of the pump.

The air line lubricator (43)

provides automatic air

motor lubrication.

The fluid filter (7) or surge tank

includes a 60

mesh (250 micron) stainless steel element to filter

particles from the fluid as it leaves the pump. It

includes the

fluid drain valve (D),

which is re

-

quired in your system to relieve fluid pressure in the

hose and gun (see the

WARNING

at left).

The suction hose (8) and tube (11)

allow the

pump to draw fluid from a 19 liter (5 gallon) pail (E).

Two fluid shutoff valves (9)

are supplied at the

fluid filter outlets. Attach the fluid hose (103) to one

of the valves. Keep the other valve capped and

closed at all times unless you are using a second

hose and gun.

Connect the Suction Hose

Apply

thread sealant to the suction hose (8) and screw

it into the bushing (5) at the pump’

s fluid intake. Screw

the suction tube (1

1) onto the other end of the hose.

Connect the Fluid Hoses and Gun

NOTE:

Models 238–257 and 238–266 include a Hose

and Gun Kit (101), which supplies fluid hoses, a spray

gun, and connecting parts (ref. nos. 102–106). If you

supply your own fluid hoses and gun, be sure they are

properly sized and pressure-rated for your system.

Use only electrically conductive hoses.

1.

Connect the main fluid hose (103) to one fluid

shutof

f valve (9) at the fluid filter (7) outlet.

2.

Screw the coupling or nipple (105) onto the other

end of the main fluid hose (103).

3.

Screw the short whip hose (104) onto the coupling

or nipple (105).

4.

Screw the whip hose (104) onto the gun swivel

(106).

5.

Screw the gun swivel (106) onto the fluid inlet of

the spray gun (102).

Assemble Models 238–257 and 238–266

1. Assemble

the fluid hoses and gun as explained in

the preceding paragraph.

2.

Mark the date of assembly on the designation

plate (107) and install the plate as shown on its

separate instruction sheet.