NIOSH rpb NOVA 2000 User manual

INSTRUCTION

MANUAL

2

NIOSH CAUTIONS & LIMITATIONS 3

INTRODUCTION 4

RESPIRATORY COMPONENT CONCEPT 5

WARNINGS 6

RESPIRATOR OPERATION 8

SPECIAL OR CRITICAL USERS INSTRUCTIONS BREATHING AIR PRESSURE TABLE 10

SETUP 11

RESPIRATOR USE 12

INSPECTION, CLEANING AND STORAGE 15

PARTS AND ACCESSORIES 17

CONTENTS

Read all instructions and warnings before using this product.

Keep this manual for future reference.

RPB Safety Global Headquarters 2807 Samoset Rd, Royal Oak, MI 48073, USA.

T: 1-866-494-4599 F: 1-866-494-4509 E: sales.us@rpbsafety.com www.rpbsafety.com

RPB Safety Asia Pacic Headquarters 652 Halswell Junction Road, Hornby South 8042

New Zealand. T: +64-3-357-1761 F: +64-3-357-1763 E: sales.nz@rpbsafety.com

www.rpbsafety.com

RPB, advancing your safety and NOVA 2000 are registered trademarks of RPB® Safety

For technical assistance contact our Customer Service Department

Rev: 6

3

1. PROTECTION

CF – Continuous Flow SA – Supplied Air SB – Supplied Air ABrasive Blast

2. CAUTIONS AND LIMITATIONS

A - Not for use in atmospheres containing less than 19.5% oxygen.

B - Not for use in atmospheres immediately dangerous to life or health.

C - Do not exceed maximum use concentrations established by regulatory standards.

D - Air-line respirators can be used only when the respirators are supplied with respirable air meeting the

requirements of CGA G-7.1 Grade D or higher quality.

E - Use only the pressure ranges and hose lengths specied in the User’s Instructions.

J - Failure to use and maintain this product properly could result in injury or death.

M - All approved respirators shall be selected, tted, used and maintained in accordance with MSHA, OSHA,

and other applicable regulations.

N - Never substitute, modify, and, or omit parts. Use only exact replacement parts in the conguration

specied by the manufacturer.

O - Refer to user instruction and/or maintenance manuals for information about use and maintenance of

these respirators.

S - Special or critical User’s Instructions and/or specic use limitations apply. Refer to User’s Instructions

before donning.

RPB Safety

T. 1 866 494 4599 F. 1 866 494 4509 E. info@rpbsafety.com

TYPE CE, CONTINUOUS FLOW, SUPPLIED-AIR RESPIRATOR

THESE RESPIRATORS ARE APPROVED ONLY IN THE FOLLOWING CONFIGURATIONS

National Institute for

Occupational Safety and Health

D

E

P

A

R

T

M

E

N

T

O

F

H

E

A

L

T

H

&

H

U

M

A

N

S

E

R

V

I

C

E

S

•

U

S

A

NV2001

NV2016

4000-01

2015

4000-20

03-501

NV2002

NV2002L

NV2002XL

NV2002HBXL

NV2002HBXXL

NV2025

NV2024

NV2032

2034

2037

NV2027

NV2028

NV2029

2035

2036

NV2021

NV2004

NV2018

NV2031

NV2017

09-800

09-900

19C-363S A/CF/SB NOVA

2000

X

ABCDEJMNOS

19C-422S A/CF/SB NOVA

2000 ABCDEJMNOS

Protection1

RESPIRATOR COMPONENTS

Alternate

Helmets

Alternate

Capes

Alter

nate

Viso

r

Alternate

Lenses

Accessories

TC -

Breathing

Air Tube

Cautions

and Limitations2

M

O

D

E

L

Alternate Flow

Regulator

and Belt

Alternate Quick

Disconnect Alternate Hoses

X

X

X X

X

X X

X

X

X

X X X

X X X

XXX

X X

XXX

X X

X

X

X

X

XXXXX

XXXXX

S

S

NV

NV

NV

NV

4

INTRODUCTION

The RPB® NOVA 2000 SUPPLIED - AIR

RESPIRATOR TYPE CE is specically

designed for use during Abrasive Blasting.

The RPB® NOVA 2000 has been designed

for use in atmospheres NOT IMMEDIATELY

DANGEROUS TO LIFE OR HEALTH, and from

which a user can escape without the aid

of the respirator, or that do not exceed

concentrations allowed by OSHA, EPA and

NIOSH regulations and recommendations.

The RPB® NOVA 2000 is Approved by NIOSH

(TC-19C-363, 19C-422-TYPE CE) to provide

respiratory protection in abrasive blasting

and type CE painting applications. The cape

is designed to protect the wearer’s upper

body from rebounding abrasive.

The RPB® NOVA 2000 is NIOSH Approved

for use with the NV2015, NV2016, 4000-01

Cold Air Tube, 4000-20 Hot Air Tube, and

the 03-501 Climate Control Assembly.

5

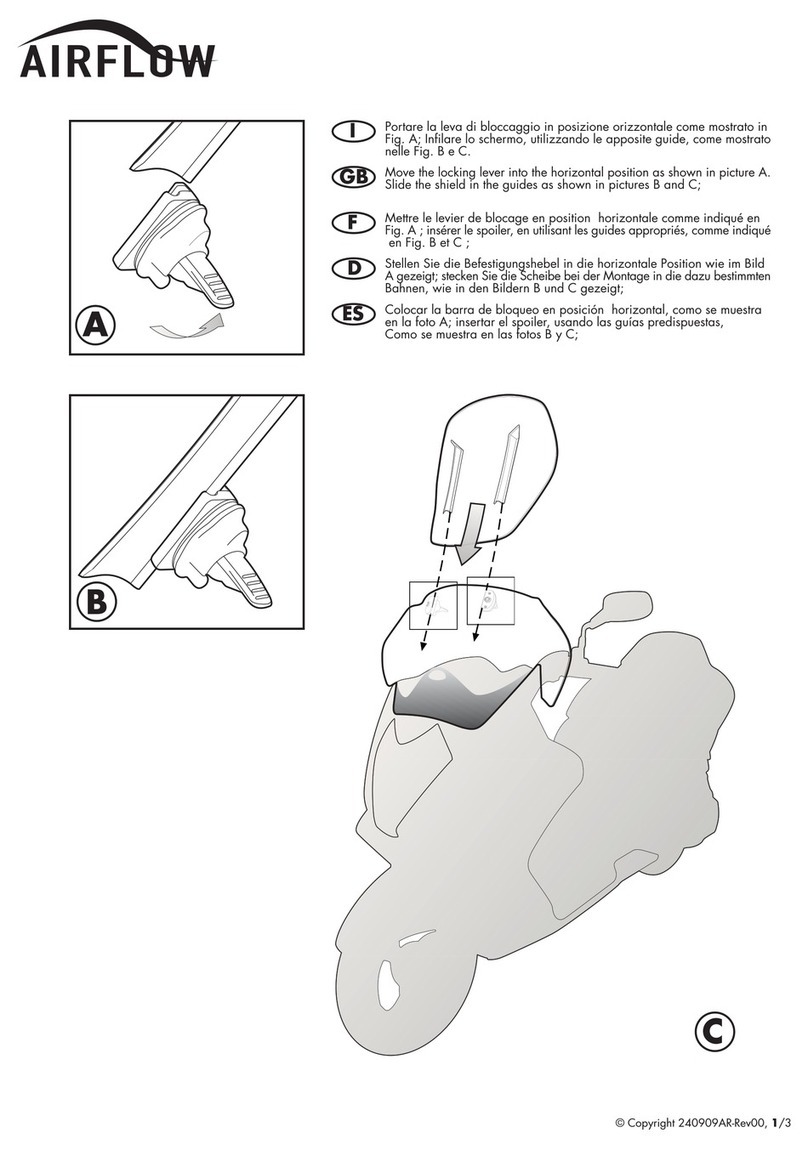

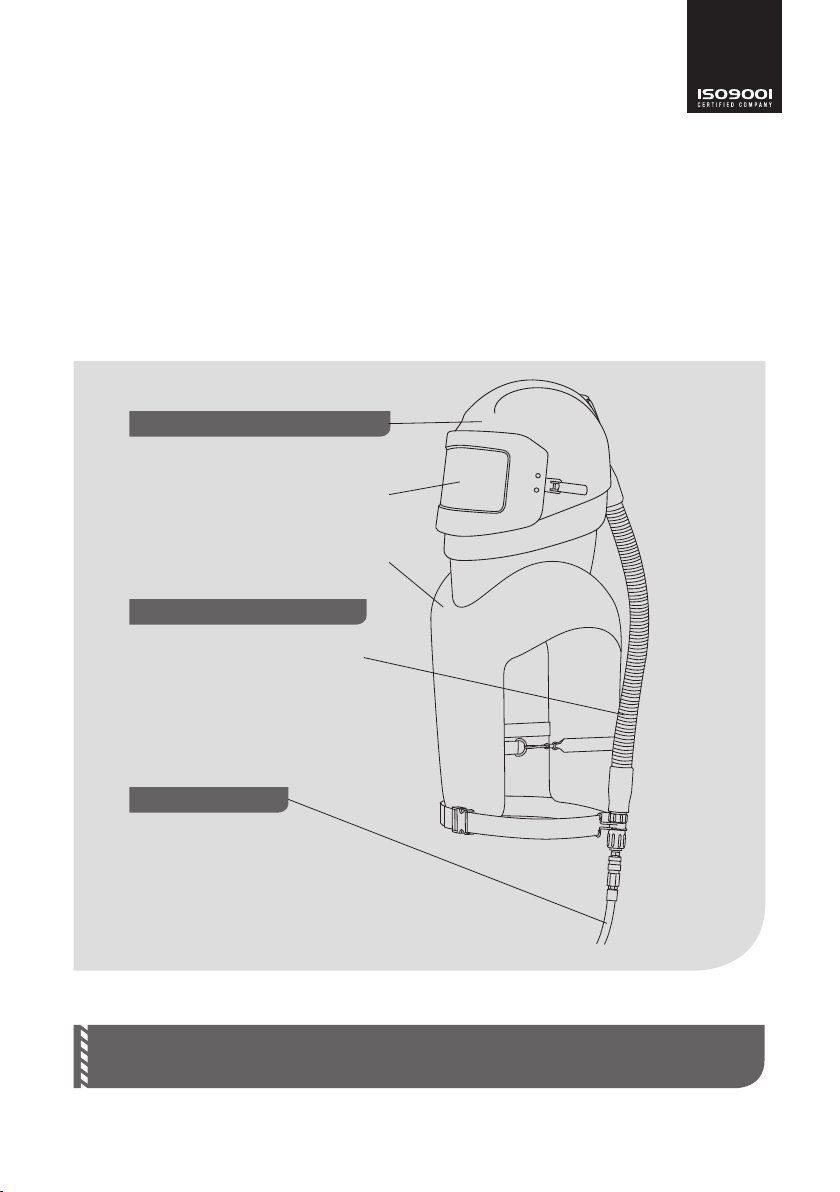

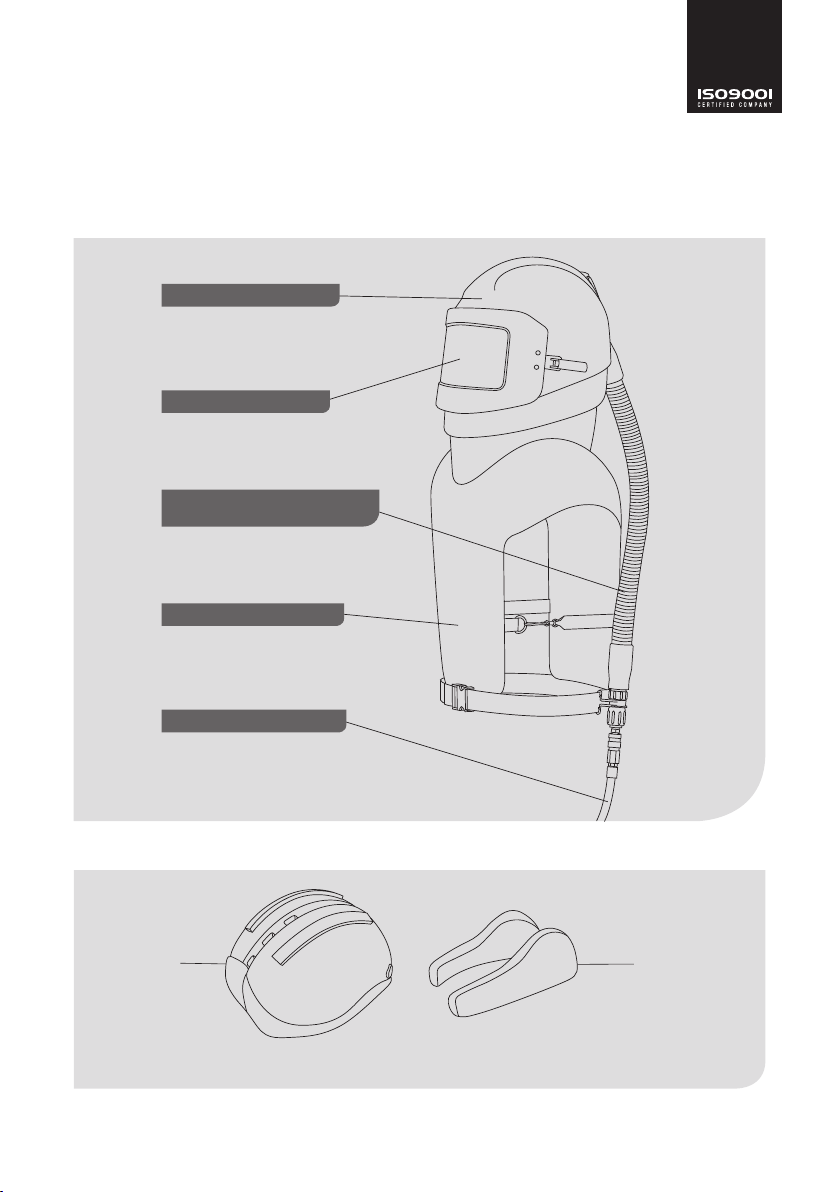

RESPIRATOR COMPONENT CONCEPT

The RPB® NOVA 2000 SUPPLIED AIR RESPIRATOR consists of three main components:

RESPIRATOR HELMET ASSEMBLY, BREATHING TUBE ASSEMBLY, and AIR SUPPLY HOSE. All three

components must be present and properly assembled to constitute a complete NIOSH approved

Respirator.

!WARNING! Failure to use genuine parts and components that are part of the NIOSH

approved respirator assembly will void the approval of the entire respirator assembly.

1. Respirator Helmet Assembly

2. Breathing Tube Assembly

3. Air Supply Hose

Cape

Inner & Outer Lenses

Figure 1.1

6

1. Do not use this respirator until you

have been trained in the respirators

use, maintenance and limitations by

a qualied individual (appointed by

your employer) who has extensive

knowledge of the RPB® Nova 2000

Respirator.

2. Before using this respirator ensure your

employer has determined that airborne

contaminant concentrations do not

exceed those allowed by applicable

OSHA, EPA or NIOSH regulations and

recommendations for continuous-ow

supplied air respirators. Federal law

requires that the employer measures

and monitors airborne contaminant

levels in the work area.

3. DO NOT WEAR this respirator if any of

the following conditions exist:

- Atmosphere is immediately dangerous

to your life or health.

- You CAN NOT escape without the aid

of the respirator.

-Atmosphere contains less than 19.5%

oxygen

- Work area is poorly ventilated

- Contaminants are in excess of

regulations or recommendations

!WARNINGS!

4. Do not modify or alter this respirator.

Use only NIOSH approved RPB® NOVA

2000 components and replacement

parts. The use of non approved parts

voids the NIOSH approval of the entire

respirator assembly.

5. Inspect all components of the respirator

daily for signs of damage or wear

and tear that may reduce the level of

protection originally provided.

6. Do not use abrasives containing silica,

lead, arsenic or sharp glass particles

- use of abrasives containing these

elements could result in serious injury

or death.

7. Do not wear this respirator until you

have passed a complete physical exam

including a lung X-ray conducted by

qualied medical personnel.

8. Improper use of this respirator may

cause injury or death. Improper

use may also cause life threatening

delayed lung diseases such as silicosis,

pneumoconiosis or asbestosis.

7

9. This respirator, when properly tted and

used, signicantly reduces but does not

completely eliminate the breathing of

contaminates by the respirator wearer.

10. Be certain your employer has

determined that the breathing air

source provides at least Grade D

breathable air. The respirator must be

supplied with clean breathable air at all

times.

11. Do not connect the respirator’s air

supply hose to nitrogen, toxic gases,

inert gases or other unbreathable

non Grade D air sources. Check the air

source before using the respirator. This

apparatus is not designed for use with

mobile air supply systems i.e. cylinders.

Failure to connect the supply hose to

the proper air source could result in

serious injury or death.

12. DO NOT use this respirator in poorly

ventilated areas or conned spaces.

Ensure the area is well ventilated and

that the contaminant concentrations

are below those recommended for this

respirator. Follow all procedures for

conned space entry, operation and

exit as dened in applicable regulations

and standards.

13. LEAVE WORK AREA IMMEDIATELY IF:

- Any respirator component becomes

damaged.

- Airow stops or slows down.

- Breathing becomes dicult.

- You become dizzy, nauseous, too hot,

too cold or ill.

- Vision is impaired.

8

RESPIRATOR OPERATION

AIR QUALITY

This respirator must be supplied with clean

breathable air, Grade D or better, at all times.

The RPB® NOVA 2000 does not purify air or

lter contaminants. Breathable air must be

supplied to the point of attachment of the

RPB® NOVA 2000 air supply hose.

Supplied breathing air must at least meet

the requirements for Type 1 gaseous

air described in the Compressed Gas

Association Commodity Specications G.7.1

(Grade D or higher).

AIR SOURCE

Locate the air source in a clean air

environment, always use a lter on the inlet

of your air source. Do not park vehicles

beside your air inlet as this will cause carbon

monoxide to be drawn into your air supply.

Use suitable aftercoolers / dryers with lters

and carbon monoxide alarms to assure clean

breathable air is supplied at all times.

The air should be regularly sampled to

ensure that it meets Grade D requirements.

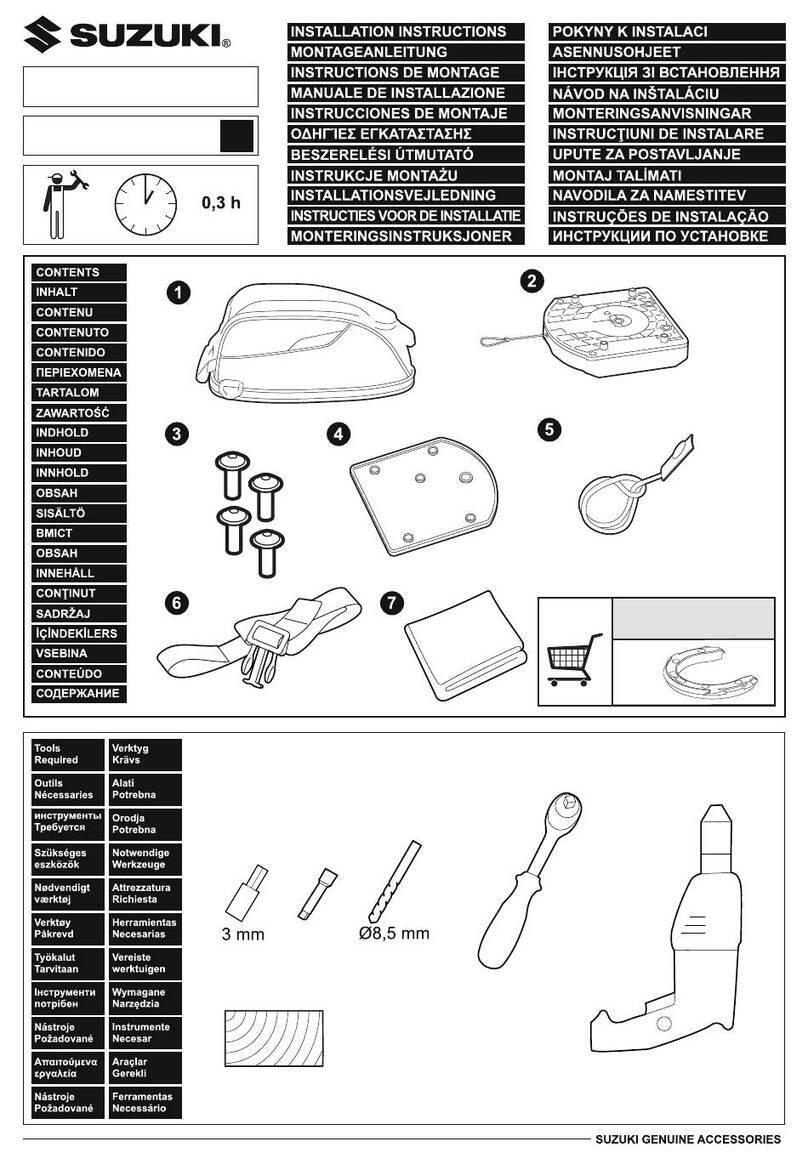

BREATHING AIR PRESSURE

The air pressure must be continually

monitored at the point of attachment

while the air is owing to the respirator.

Air pressure must be read from a reliable

pressure gauge whilst the respirator has air

owing through it.

!WARNING! Failure to supply the respirator

with the minimum required pressure at

the point of attachment for the length

of air supply hose used could result in

contaminants being inhaled as the pressure

in the helmet may become negative due to

peak inhalation ow when working at very

high work rates.

The RPB® NOVA 2000 BREATHING AIR

PRESSURE TABLE on Page 10 denes the

air pressure ranges needed to provide the

respirator with a volume of air which falls in

the required range of 6 - 15 cfm or 170 - 425

lpm.

BREATHING AIR SUPPLY HOSE AND

FITTINGS

NIOSH approved RPB® NOVA 2000 air supply

hoses must be used between the point of

attachment and the respirator breathing air

connection at the wearer’s belt. RPB® NOVA

2000 quick disconnect ttings must be used

to connect the hose lengths together. The

hose sections must be within the approved

length and the amount of sections must be

within the number specied in the Breathing

Air Pressure Table.

9

!WARNING! Make sure you understand the

Breathing Air Pressure Table before using

this respirator.

1. Determine your air source (column 1)

2. Find your breathing tube assembly

(column 2)

3. Be sure your air supply hose is RPB®

Safety NOVA 2000 breathing air hose.

4. Check your RPB® Safety air supply hose is

within the approved length in column 4.

5. Set the air pressure at the point of

attachment within the range specied

in column 6 for your breathing tube

assembly, hose length and amount of

hose sections. Make sure air is owing

through your respirator when setting

the pressure.

10

1.

AIR SOURCE

2.

BREATHING TUBE

ASSEMBLY AND

FLOW CONTROL

DEVICES

3.

AIR SUPPLY

HOSE

4.

SUPPLY

HOSE

LENGTH

5.

MAX

NUMBER

OF SECTIONS

6.

PRESSURE

RANGE

PSIG AIR

Portable or

Stationary

Compressor

NV2021/

NV2016

Flow Control

Valve Assembly

NV2027(100ft)

NV2028(25ft)

NV2029 (50ft)

25

50

100

150

200

250

300

1

2

2

3

4

5

6

28 - 30

28 - 30

30 - 33

33 - 36

36 - 38

38 - 39

39 - 43

Low Pressure

Compressor

or Air Pump

NV2021/

NV2015

Constant Flow

Valve Assembly

NV2035 (50ft)

NV2036 (100ft)

50

100

150

200

250

300

1

1

2

2

3

3

7 - 8

8 - 9

10 - 11

11 - 12

12 - 13

14 - 15

Portable or

Stationary

Compressor

NV2021

03-501

Climate Control Tube

Assembly

NV2027 (100ft)

NV2028 (25ft)

NV2029 (50ft)

25

50

100

150

200

250

300

1

1

2

3

4

5

6

50 - 80

55 - 85

60 - 95

65 - 95

70 - 100

75 - 100

85 - 100

Portable or

Stationary

Compressor

NV2021B/

4000-01

Cold Air Tube

Assembly

NV2027 (100ft)

NV2028 (25ft)

NV2029 (50ft)

25

50

100

150

200

250

300

1

1

2

3

4

5

6

55 - 56

56 - 57

60 - 62

65 - 67

70 - 72

77 - 78

80 - 82

Portable or

Stationary

Compressor

NV2021B/

4000-20

Hot Air Tube

Assembly

NV2027 (100ft)

NV2028 (25ft)

NV2029 (50ft)

25

50

100

150

200

250

300

1

1

2

3

4

5

6

67 - 68

69 - 70

73 - 74

77 - 78

81 - 82

86 - 87

91 - 92

This table lists Air pressure ranges needed to provide the RPB® NOVA 2000 with the volume

of air that falls within the required range of 6 -15 cfm or 170 - 425 lts/min according to U.S.

government regulations.

BREATHING AIR PRESSURE TABLE

SPECIAL OR CRITICAL USERS INSTRUCTIONS

!WARNING! Respirators must be supplied with respirable air meeting the requirements

of CGA G-7.1 Grade D or Higher Quality.

11

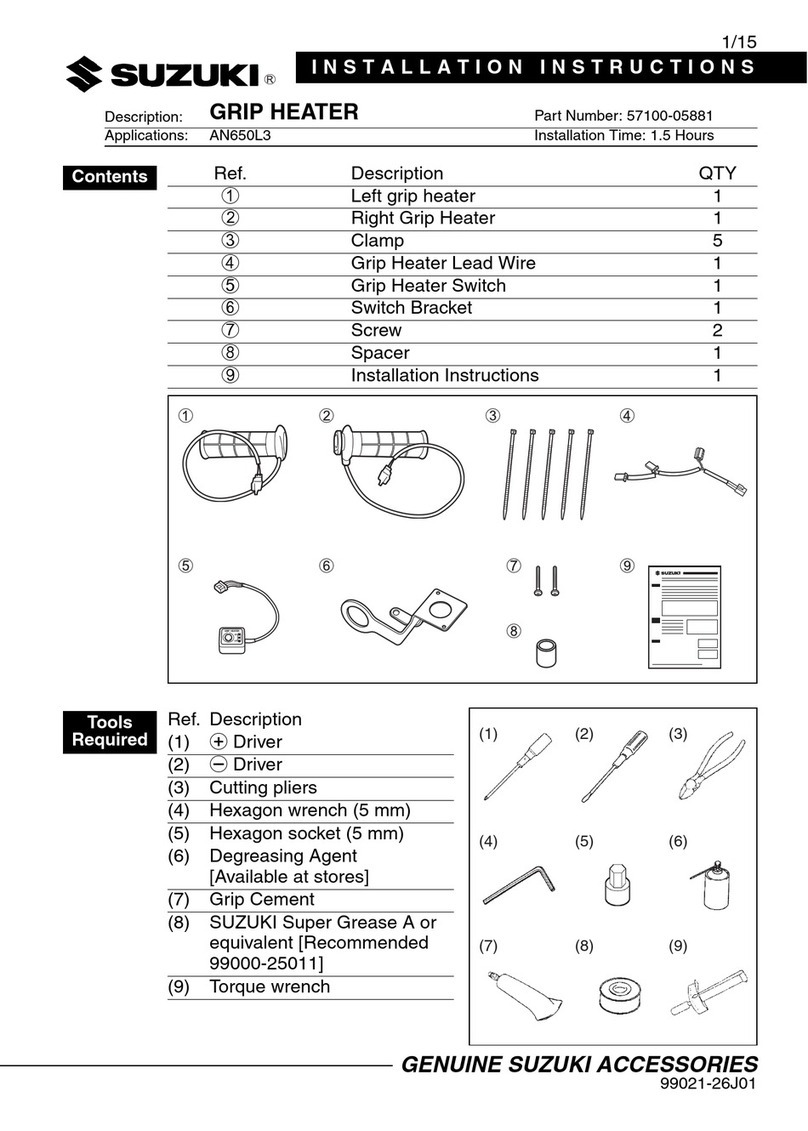

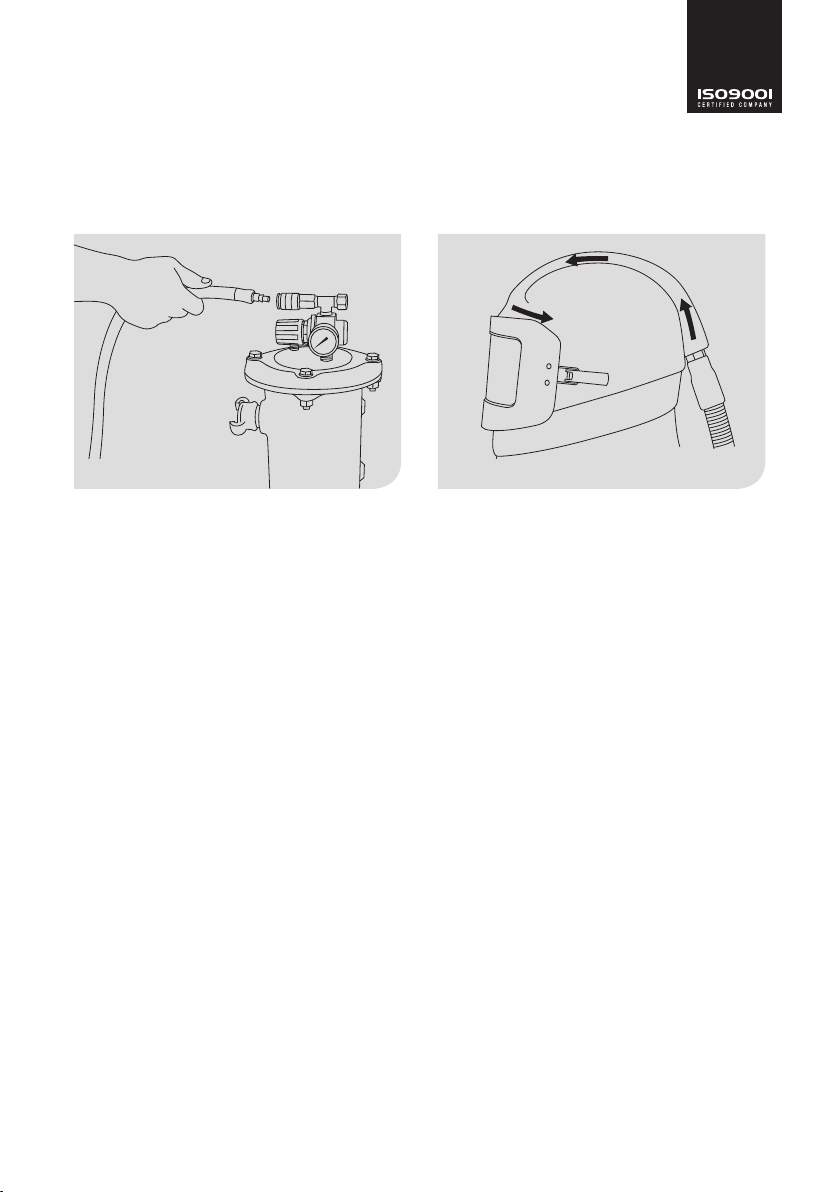

SETUP

NOTE:

Check the hose connections for any air

leaks and tighten if necessary - replace any

worn parts.

With air owing through the respirator

adjust the air pressure at the point of

attachment to the recommended pressure

as specied in the Breathing Air Pressure

Table (page 10).

Connect the RPB® Safety NOVA 2000 Air

Supply Hose to a breathing air source

supplying Grade D or better quality air.

Connect the respirator quick disconnect

tting onto the Air Supply Hose.

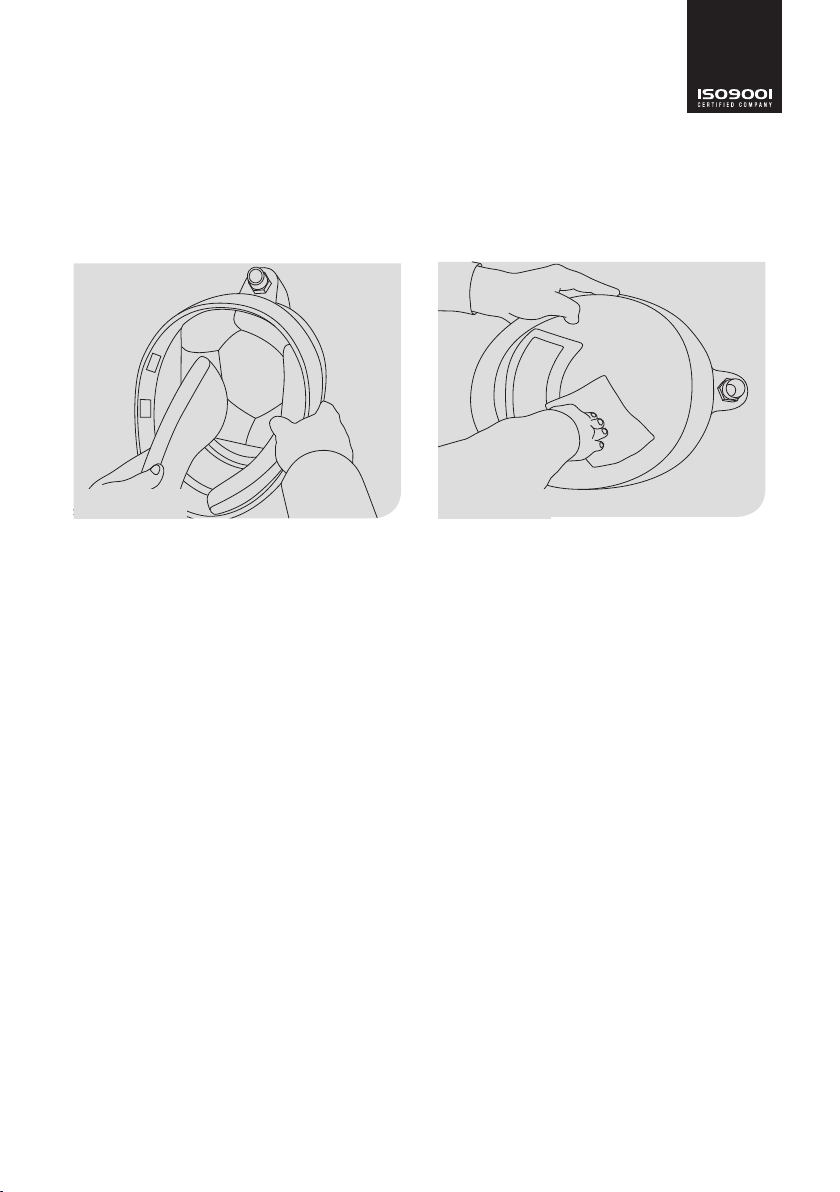

Figure 2.1 Figure 2.2

12

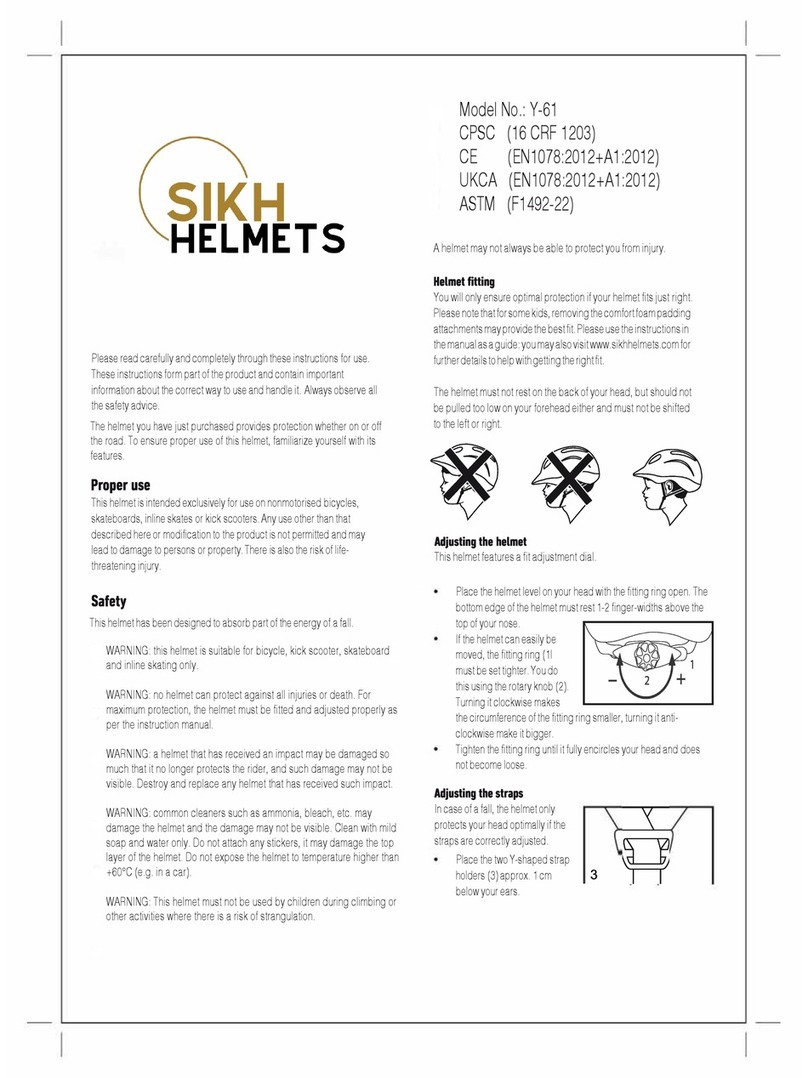

RESPIRATOR USE

Optional tear-o lenses can be used with

the outer lens. It is recommended to use

2-3 tear-o lenses and an outer lens for

extra protection.

Fit an outer lens onto the tabs on the visor,

fold the visor onto the helmet and secure

it with latch, making sure there are no gaps

between the visor and the window frame

gasket.

LENSES

Figure 3.1

Figure 3.3

Figure 3.2

!WARNING! DO NOT use this respirator

without an inner lens in place.

Make sure you have an RPB Safety inner

lens securely tted into the window frame

gasket.

13

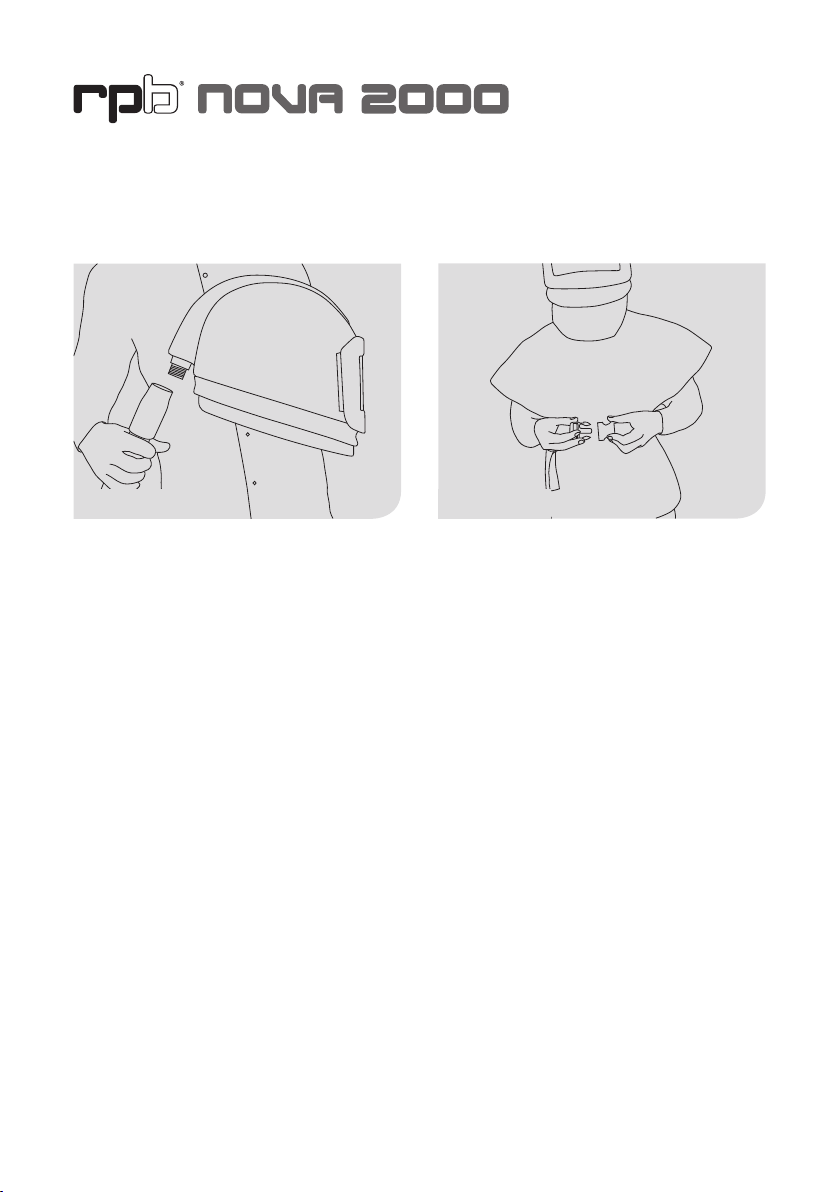

Blast Jackets (NV2002HB Series): Put your

arms through the arm holes then pull the

jacket down around your waist.

With air owing into your Respirator fold

back the cape, open the inner bib and place

your ngers on the inner bib and the side

of the helmet at approximately ear position,

lift the helmet and place onto your head.

Regular Capes: Pull the respirator cape

around your body and fasten the snap

hooks on each side of the cape.

Pull the inner bib around your neck and

adjust the elastic cord to ensure a snug

t around your neck - this helps provide a

barrier to airborne contaminants.

DONNING YOUR HELMET

Figure 3.4

Figure 3.6

Figure 3.5

Figure 3.7

14

RESPIRATOR USE CONTINUED

When attaching the breathing tube to

the helmet, attach the xed end of the

breathing tube hose to the helmet tting

and the loose running nut to the ow

control valve.

When you have nished working leave

the work area wearing the respirator with

air still owing into the helmet. Once

outside the contaminated area remove the

respirator and disconnect the air supply

hose.

!WARNING! NEVER remove your helmet

whilst in a contaminated area or where

blasting is still being performed, as this may

result in serious injury or death.

NOTE:

Re-check the air pressure and adjust

if necessary. With air owing into your

respirator you are now ready to enter the

work area.

Fasten the belt at waist or hip level and

adjust for comfort. Rotate the belt holder

until it is in the hip pocket area.

DOFFING YOUR HELMET

Figure 3.8 Figure 3.9

15

INSPECTION, CLEANING & STORAGE

The helmet linings can be removed and

sponged with warm water and a gentle

detergent, then air dried before retting

into the helmet.

HELMET AND LININGS

The helmet shell and window frame gasket

can be sponged with warm water and a

gentle detergent, rinsed and air dried.

NOTE:

The leather cape must be cleaned with an

approved leather cleaner.

Figure 4.1 Figure 4.2

16

BREATHING TUBE ASSEMBLY

Inspect the breathing tube for cracks or

excessive wear. Check that the ttings are

secured into the hose tightly and aren’t

allowing any air to escape.

Replace the hose as soon as signs of

damage or excessive wear become evident.

Do not remove the foam that is inside the

breathing tube as this helps reduce the

noise levels of the incoming air.

!WARNING! Air leaks will cause a drop

in air ow through the respirator

helmet resulting in less protection from

contaminants.

AIR SUPPLY HOSE

The air supply hoses should be inspected

for cuts, cracks, blisters and signs of

abrasion. Make sure the ttings are

tightly crimped to the hose so that air

cannot escape. Make sure the hose has

not been crushed or kinked. Replace the

hose immediately if there are any signs

of damage. Do not run water through

the inside of the hose. Check the Quick

Disconnect Couplings and blow down with

a duster gun to remove any sand or dirt

that may jam the coupler.

!WARNING! Use only the correct hoses by

for this respirator.

STORAGE

After the respirator components have been

cleaned and inspected place them in a

plastic bag or an airtight container. Store

respirator parts away from excessive heat,

dust, cold, moisture or harmful chemicals.

After use hang the respirator up by the

hand strap, this will help keep the inside of

the helmet free of contaminants.

INSPECTION, CLEANING & STORAGE CONTINUED

17

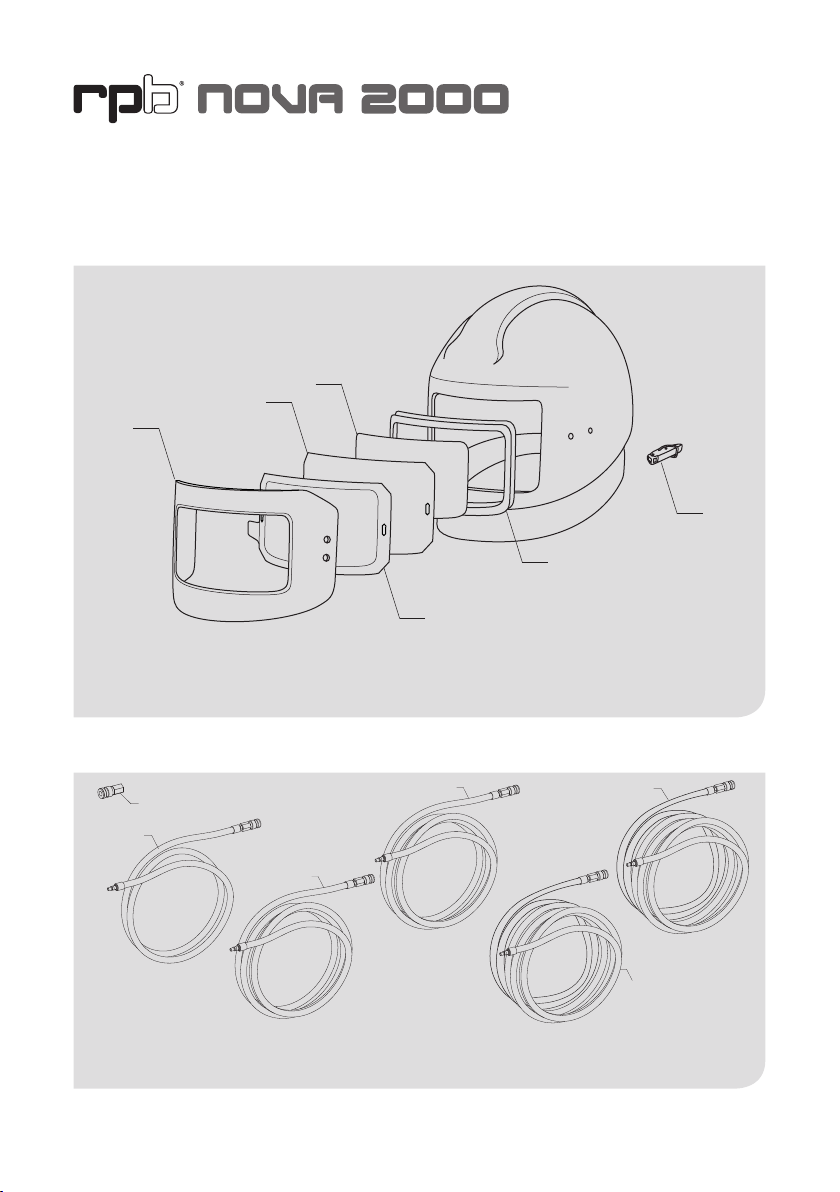

Visor & Lenses - Figure 5.2

Padding System - Figure 5.1

Air Supply Hoses - Figure 5.3

Respirator Capes - Figure 5.5

Breathing Tube &

Flow Control Devices - Figure 5.4

PARTS AND ACCESSORIES

NV2009 Polystyrene Helmet Liner (Sizes S, M & L) NV2010 Sidewings (Sizes S, M & L)

PADDING SYSTEM Figure 5.1

NV2009 NV2010

18

PARTS AND ACCESSORIES CONTINUED

NV2003 Window Frame Gasket

NV2004 Visor with Hinge and Screws

NV2017 Tearo Lens Packet 50

NV2018 Inner Lens Packet 10

NV2031 Outer Lens Packet 50

NV2008 Latch

AIR SUPPLY HOSES Figure 5.3

VISOR AND LENSES Figure 5.2

NV2004

NV2031

NV2018

NV2017

NV2003

NV2008

NV2027 100ft Air Supply Hose

NV2028 25ft Air Supply Hose

NV2029 50ft Air Supply Hose

NV2025 Quick Release Coupler

NV2035 50ft Low Pressure Air Supply Hose

NV2036 100ft Low Pressure Air Supply Hose

NV2025

NV2028

NV2029 NV2027

NV2035

NV2036

19

BREATHING TUBE & FLOW CONTROL DEVICES Figure 5.4

RESPIRATOR CAPES Figure 5.5

NV2002 28¨ Nylon Cape

NV2002XL 38¨ Nylon Cape

NV2002L 28¨ Leather Cape

NV2002HB-XL Blast Jacket Size XL

NV2002HB-XXL Blast Jacket Size XXL

NV2012 Inner Bib

NV2012

NV2002HB-XXL

NV2002HB-XL

NV2002L

NV2002XL

NV2002

NV2021 Breathing Tube

NV2022 Belt

NV2016 Flow Control Valve Assembly - Includes: Flow Control Valve, Belt

NV2015 Constant Flow Valve - Low Pressure

4000-01 Cool Air Tube Assembly - Includes: Cool Air Tube, Belt

4000-20 Hot Air Tube Assembly - Includes: Hot Air Tube, Belt

03-501 Climate Control Assembly - Includes: 03-501, Belt

NV2016

4000-01

03-501

NV2022

4000-20

NV2021

NV2015

AIRLINE FILTRATION

The RPB®RADEX AIRLINE FILTER™ oers

increased capacity, versatility and ltration.

This optional equipment combines the

versatility of either oor or wall mounting

with increased ltration capacity, enabling

customization to meet worker’s needs and

working environments.

AIR TEMPERATURE CONTROL

The RPB®4000-01 Cool Air Tube cools

compressed breathing air coming into

the respirator by up to 30°F while the

RPB®4000-20 Hot Air Tube will heat the

compressed air by up to 30°F. These

maximize worker comfort and increase

productivity in hot or cold climates.

AIR QUALITY MONITORING

The RPB®RADEX CO MONITOR™ helps

ensure worker safety with a unique

traceability feature that monitors and

records carbon monoxide levels, and

temperature. This data that provides

certainty of monitor functioning and can

be stored for up to two years allowing

analysis of plant and eld air quality.

1866 494 4599

www.rpbsafety.com

OTHER PRODUCTS

Table of contents