4.Insta llation

lllill

4.1 Unpacking

After unpacking ,please check carefully to ensure the cable ,gearbox,

and motor shell are not damaged ,and check whether the number of

the following items is correct .Every hoist should be equipped with

the following standard accessories.

1.Chain bag One

2.Control cable 3 Meter

3. Push button One

4.2 Voltage

A

Note

If the voltage of power supply is over or less 10% than standard voltage

to operate hoist under the abnormal voltage will result in motor damage ,

hence , before operation , be sure to confirm whether the voltage of power

supply is within the standard range.

4.3 Installation

A

Warning

It is forbidden to link the power supply before the completion of installation

4.3.1 Before installing the hoist, please confirm the whole upper hook assembly

has been firmly assembled to the hoist body (ensure the chain connection

pin is installed properly).

Remarks :If

the hoist is equipped with electric trolley, the first step (to separate

the upper hook from the hoist body) can be omitted ,it is only required

to install the hoist between two side plates of trolley, and lock the upper

hook.

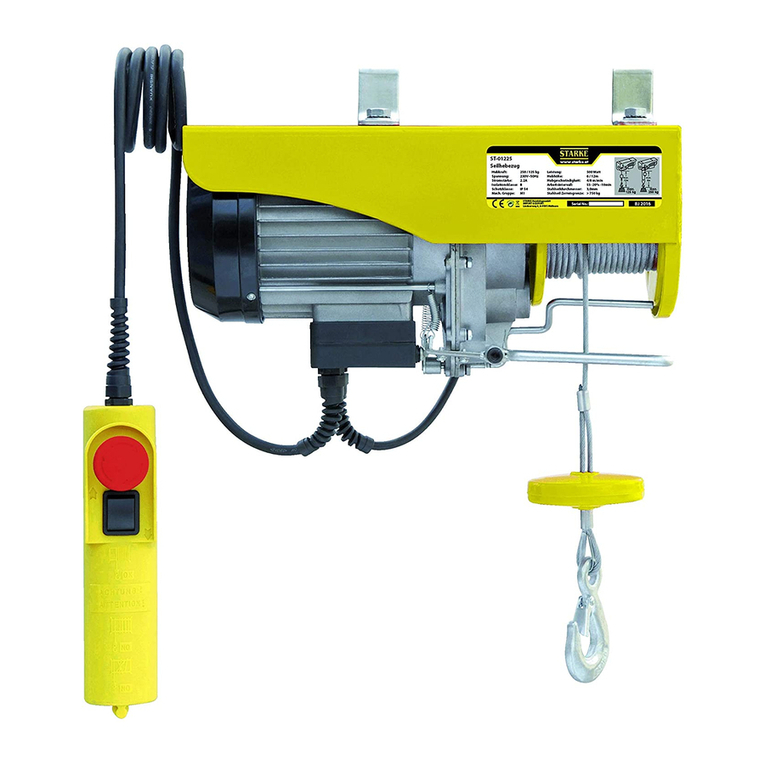

4.3.2 Assemble chain bag (Fig.4.1)

4.3.3 Link the power supply and operate the push button, the procedure should be

performed by professional trained person .(Fig.4.2)

(Fig.4.1)

lm-1.Sm

Power cable pulley

R ST

Electrical box Contactor

0

WON

�OFF

··· ................................ red

Earth

·································· black

(yellow and green or green)

(Fig.4.2)

4.3.4 Operation test

(a) Press the(!) push button to lower the hoist until the limit spring touches the limit switch,

and the motor will stop automatically .

(b) Press the(t)button until the chain are totally in chain bag and the motor stops.

(c) Test the function of the emergency stop switch (if the emergency stop switch is selectively

purchased )Press button(!) or (j), and press the emergency stop switch at the same time to

check whether the hook can stop immediately . When the emergency switch is pressed ,there

will be no response when any other button is pressed .Finally ,turn the emergency switch in

clockwise and it will bounce back to the original position .When it bounces back, the hoist

can be operated again ,if any of the above -mentioned tests is abnormal , it is required to

check the distribution circuit and the self-locking of the emergency switch .

(d) Check the direction of chain .All welding points should be of the same direction .(Fig 4.3).

The operation can not be utterly proper unless all the welding points of chain are in the

same line. .. __