NITRON TVT22 User manual

TVT22 FORK CARTRIDGE Installation Instructions

Warnings will be highlighted in boxes like this. This will indicate that your safety is

involved and careful attention should be made to observe these instructions. Severe injury or

fatality may occur if these instructions are not observed.

WARNING

Installation Instructions

This cartridge kit requires special tools and should be installed by an authorised dealer to ensure

optimal function. The front fork is a critical part of the motorcycle and

improper installation could cause serious injury or death.

WARNING

Nitron will not be held responsible for any damage or injury caused through incorrect fitment,

modification or incorrect application of any TVT Fork Cartridge Kits or

related products.

WARNING

If you notice any abnormality in performance or operation, you should stop using the product

immediately and contact Nitron for technical advice.

WARNING

Failure to comply with the installation and maintenance procedures may result in avoidable

damage caused to the shock or motorcycle.

WARNING

Notes and Tips will be highlighted in boxes like this. This will offer important

information regarding procedures or recommendations for ease of installation.

NOTE

Nitron warrant all of its products and accessories against design and material defect for a

period of 1 year from date of purchase. The warranty does not cover any such failure due to

incorrect fitment or use and does not extend to any other part of the motorcycle.

IMPORTANT

Images used in this Instruction Manual are for illustration purposes only, any specific fittings

may differ from your TVT Fork Cartridge Kit.

Please keep the individual specification sheet with the Vehicle Service Manual as this is the

best way to identify your TVT Fork Cartridge Kit.

IMPORTANT

IMPORTANT

2

Introduction

Introduction

Thank you for purchasing a set of Nitron TVT Fork Cartridges. Nitron have invested

heavily in developing the technology, materials and performance of our suspension

components and we are pleased to be able to pass on this experience to our customers. All of our designs

are based on many hours of both real world testing and racing experience. TVT technology has proven to

be extremely versatile and whether you are riding a Superbike on track or adventuring off-road with a Dual

Sport machine you can be sure that your fork cartridge kit has been developed specifically for your needs.

Nitron TVT Adjustable Fork Cartridge Kits offer the same level of improvements in rider control,

performance and comfort that have become the trademark of the Nitron product. The system features a

large bore 22mm shimmed piston which provides significant

improvements in performance over the OEM set up.

Function

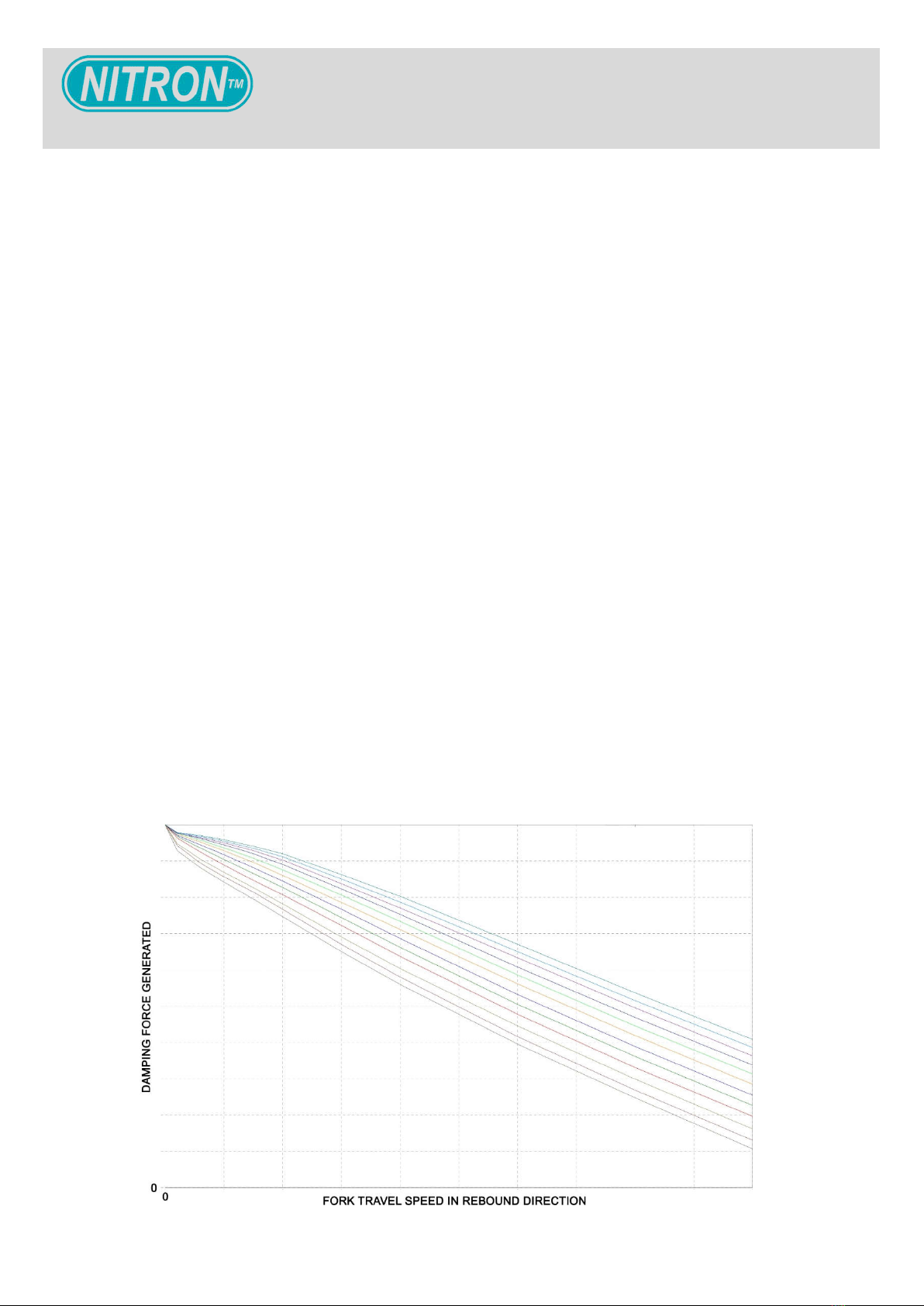

The damping system is divided between each fork leg with the right hand side cartridge controlling the

rebound phase and the left hand side compression. This system allows completely independent damping

adjustment making setup both simpler and quicker. Re-valving is also much quicker particularly when a

change is only required to one side of the damping curve.

For ease of use all adjustments are made from the top of the fork, preload is adjusted via a 14mm hex with

each complete turn of the adjuster resulting in 1mm of additional spring preload from a total of 15 turns.

Damping adjustment is adjusted using the supplied tool by turning the 3mm hex in the centre of the fork cap,

there should be at least 25 clicks of adjustment. Careful attention to the design of the adjustment system

results in not only a broad range of adjustment but the click by click adjustment across the range is very

linear making a setup easier.

3

Introduction

4

Tri-Valve Technology (TVT)

In addition to the main piston in the compression leg TVT cartridges also employ a third piston which gives a

great deal of flexibility when designing the damping curve for a specific application. This piston also utilizes

shims in much the same way as the main compression piston but with this design the shim stack is

preloaded. During slow to medium speed movements of the fork in compression such as braking or through

undulations in the road the damping is created by the main piston. As the pressure in the compression

cartridge reaches a certain point the preload on the second piston will be overcome and oil can now flow

through the TVT ports reducing overall damping for the higher fork speeds.

The main piston in a TVT fork cartridge can be valved to create firmer damping in the low to mid speed

range of compression velocities giving improved brake support and control of weight transfer leading to

improved rider confidence. With a single compression piston design this would normally result in unwanted

high speed damping forces being generated at higher compression velocities such as square edged bumps

and surface irregularities.

On track, professional riders have praised the system describing new found levels of confidence particularly

during high speed , hard edge bumps which combined with hard braking and cornering forces would

normally unsettle a well damped set up. Likewise on the road this system has allowed new levels of

compliance on bumpy poorly surfaced roads.

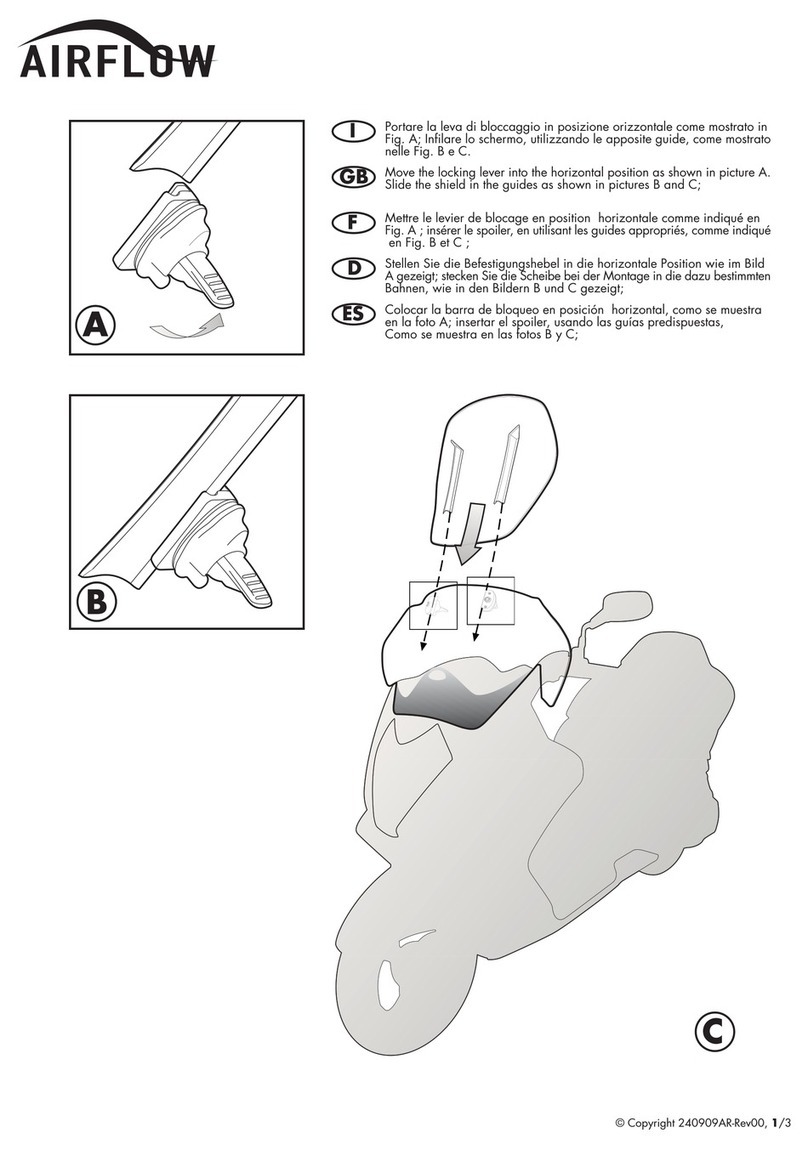

Fork Cartridge Diagram

4

1

2

4

5

6

7

8

9

10

12

13

15

17

18

19

20

21 22

No Description

1. Top Cap

2. Preload Cap

3. Spring Spacer Tube

4. Upper Spring Seat

5. Spring

6. Bump Stop Spacer

Tube

7. Plastic Spacer

8. Bump Stop

9. Lower Spring Seat

10. Cartridge Tube

11. Adaptor

12. Aluminium Lock Nut

13. M10 Lock Nut

14. M10 Washer

15. Piston Rod

16. Adjuster Rod

17. Gland

18. Top Out Spring

19. Piston

20. Base Valve

21. Damping Adjuster

22. Preload Adjuster

16

14

3

11

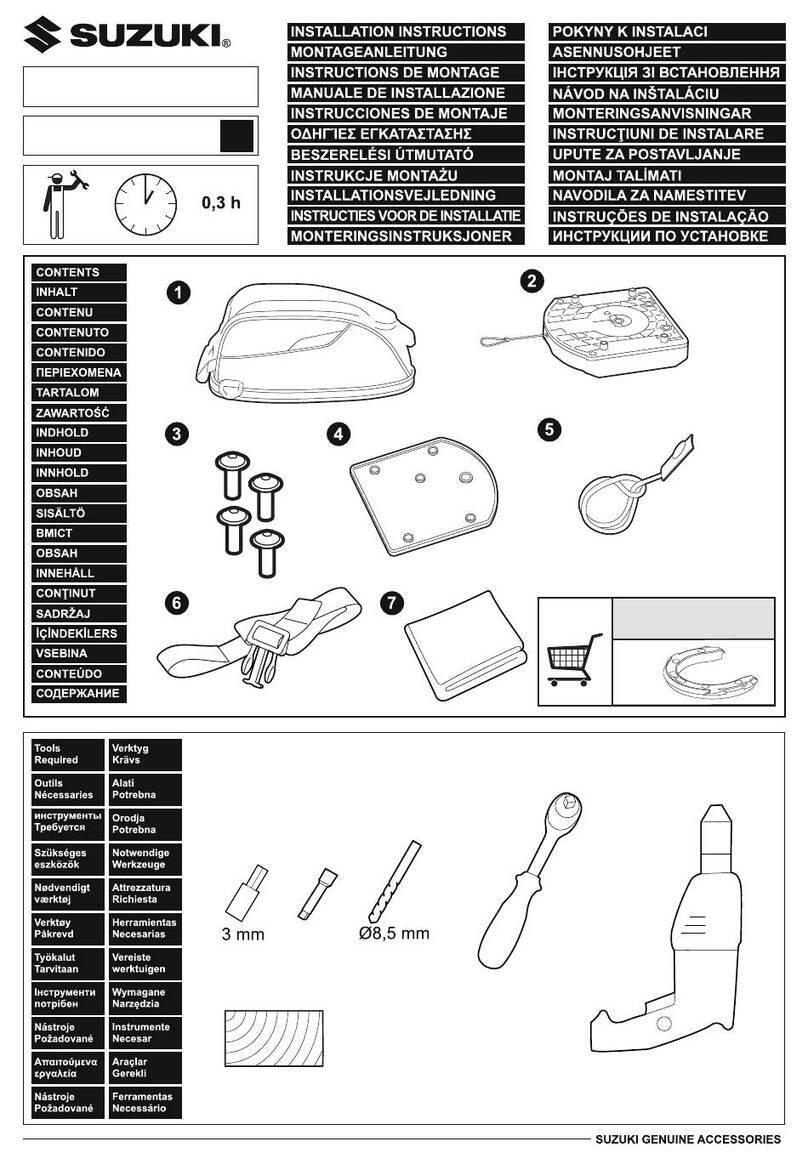

Installation Preparation

6

Installation Preparation

Before commencing with the installation you will need to support the motorcycle with

suitable front and rear stands, ensuring it is on flat, level ground. The front stand should allow the front

wheel to be raised off the floor so it can be removed.

Both fork legs will need to be removed from the motorcycle to perform the installation. It is a good idea to

thoroughly clean the fork legs before proceeding to avoid any contamination later on.

Depending on the amount of use that the fork has had it is recommended to replace the seals and to check

the condition of the bushes. For optimal performance of your fork it is crucial that these are in good condition

and to tolerance. You should also check for any damage to the fork tube coating and if necessary repair or

replace before proceeding any further. Clean the inside of the fork tubes to ensure there is no debris left

inside.

Before removing the fork legs from the yokes loosen the top cap half a turn, this will

make disassembly of the cartridge easier.

NOTE

Do not be tempted to use cheaper and inferior quality seals or bushings as this can

dramatically increase friction in the fork and can even lead to premature wear fork stanchion surface

coatings.

WARNING

Installation Preparation

Description

Piston rod holding plate

Oil level tool

Soft jawed vice

Torque wrench

14mm socket

17mm Spanner X 2

Fork tube removal tool (type ‘C’ installations only – see next page)

Standard Tools Required

Fluids/Grease

Part No. Description

090217 Nitron 02 fully synthetic fork fluid (please see

specification sheet for quantity required)

NTT050473 Molykote 33 White Grease

NTT050476 Loctite 243 Medium Strength Loctite

NTT050477 Loctite 270 High Strength Loctite (type ‘C’ installations

only – see next page)

6

Part No. Description

NTT050392/

NTT050264/

NTT050265.

Fork cartridge top cap tool -33,38 or 41mm PCD.

NTT050268 Piston rod holder.

Refer to the Nitron Fork Tooling Application List for full details.

NOTE

Nitron Specialist Tools

Damper Rod Removal

Damper Rod Removal

Before commencing with the cartridge kit installation if your forks are of the ‘damper rod’ type you will need

to remove these internals from your forks.

Step 1

Undo your OEM top cap and remove the spring and spacer tube if present.

The springs may be under considerable preload so be careful when unscrewing the

top cap to avoid injury. If there is preload adjustment make sure this is backed off first.

WARNING

There will also be a copper crush washer with the bolt, make sure you remove this and

discard it as it may be stuck in the fork bottom.

NOTE

Be careful not to slip and damage the fork tube when removing the dust seal. A plastic

chisel is an effective tool which won’t damage the fork tube.

WARNING

Step 2

Drain the old oil from the fork.

Step 3

Remove the bolt from the bottom of the lower fork tube.

Step 4

The OEM damper rod and top out spring can now be removed.

Step 5

Remove the dust seal.

8

Damper Rod Removal

Step 7

Apply heat around the top of the lower fork tube and then separate the two tubes.

Step 8

Remove the bushes and seals and then part off the very end of the steel tube in a lathe.

Step 9

The OEM damper rod mechanism can then be removed from the fork tube. Remove the bottom out cone

from the very bottom of the lower fork tube.

Step 10

Thoroughly clean the fork tubes. Install the seals and bushes and then insert the inner tube into the outer

tube.

Step 11

Use a seal driver to drive the guide bush and oil seal into place. Replace the circlip and then press the dust

seal back in place.

You are now ready to commence with your cartridge kit installation

Step 6

Remove the circlip.

9

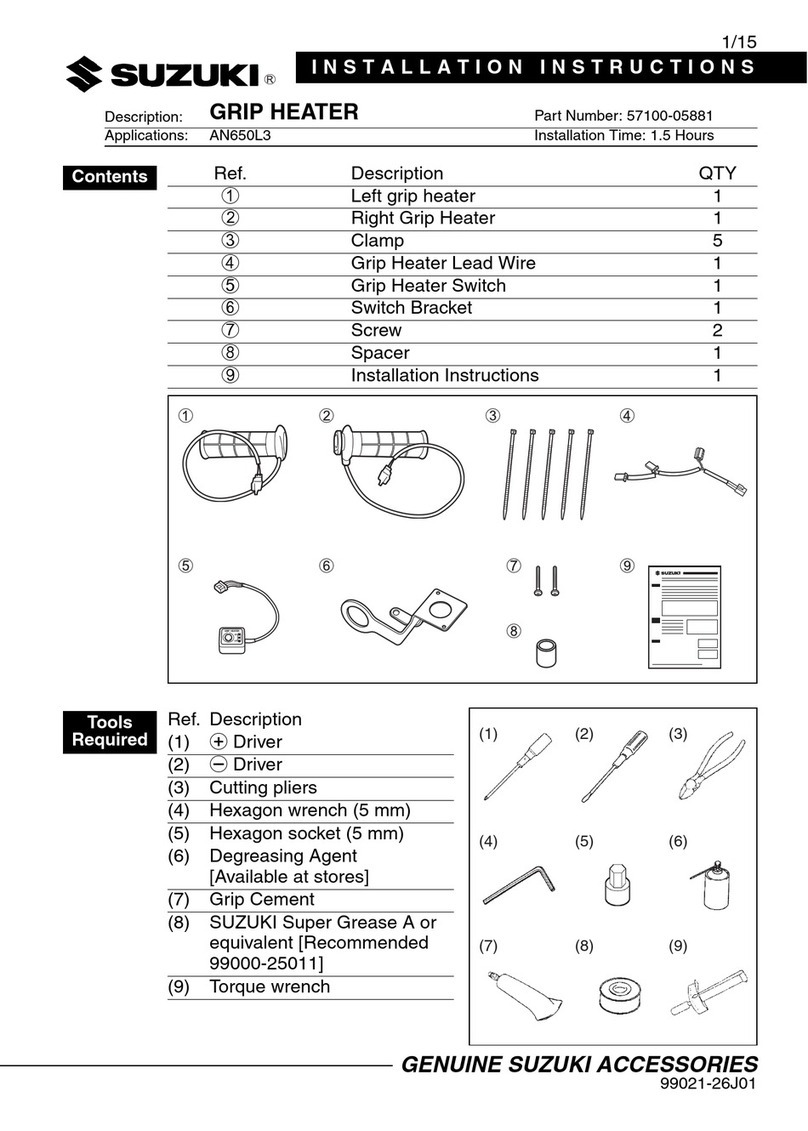

Assembly Instructions

Assembly Instructions

Your cartridge will arrive partially assembled. Unscrew the top cap from the piston rod and then remove the

spring spacer tube, upper spring seat and spring. Remove the two locknuts and washer from the piston rod,

bump stop spacer tube, plastic spacer, bump stop and lower spring seat.

Your cartridge kit splits the functions of compression and rebound damping into separate

fork legs. The rebound cartridge should be installed in the right hand fork leg and the

compression cartridge in the left hand leg. Be careful not to mix the two cartridges up, it is

advisable to work on one fork at a time.

WARNING

Step 1 Install The Cartridge Into The Fork

Install the cartridge into the fork. Apply Loctite 243

medium strength threadlock to the bolt with a new

crush washer and tighten the cartridge to the fork

bottom. Refer to your owners manual for the correct

torque setting.

Step 2 Filling The Fork With Fluid

Pour approximately half of the bottle of suspension

fluid into the fork leg making sure that it easily

covers the top of the cartridge body tube.

For the best damping performance it is essential to use Nitron 02 suspension fluid.

WARNING

10

Assembly Instructions

Step 3 Bleeding Air From The Fork

Work the upper fork tube up and down at least

fifteen times to bleed any air that may be trapped

between the two fork tubes.

Step 4 Bleeding Air From The Cartridge

Work the piston rod up and down at least fifteen

times to bleed the air from the cartridge.

11

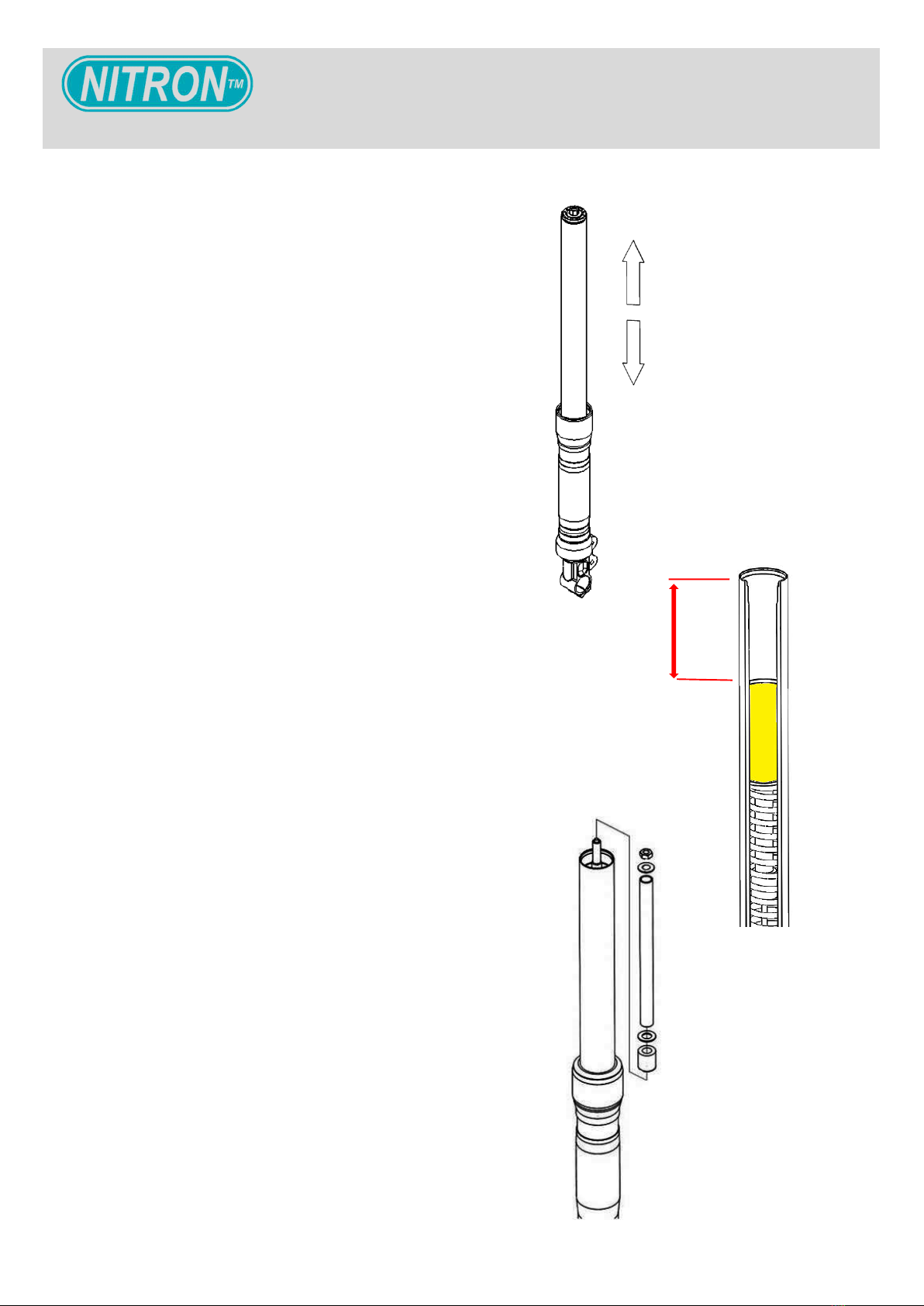

Step 5 Setting The Oil Level (Air Gap)

Push the inner fork tube and the piston rod all the

way down. Using a suitable oil level tool add or

remove oil to obtain the specified oil height (refer to

the specification sheet for your model specific air

gap measurement). The quoted oil height is the

measurement from the upper edge of the fork tube

to the surface of the oil.

Step 6 Lower Spring Seat Installation

Install the lower spring seat onto the piston rod.

Make sure this piece is installed in the correct

orientation.

Step 7 Bump Stop Installation

Install the bump stop, plastic washer, bump stop

spacer tube, M10 washer and M10 locknut.

X

Final Assembly Instructions

Step 8a Setting The Lock Nut

Set the correct position of the lock nut, refer to the

specification sheet for your model specific

measurement. The measurement should be taken

from the end of the piston rod to the top of the lock

nut.

12

Step 8b Setting The Lock Nut

Install the aluminium lock nut and tighten securely

against the steel M10 lock nut.

X

It is imperative that the locknut is in the correct position to ensure the correct function of the fork

cartridge. There should be between 25 and 30 clicks of adjustment, if there are more or less

than this the lock nut is in the wrong position.

WARNING

15

Step 9 Installation Of The Spring Hardware

You are now ready to close the fork. Screw

NTT050268 – piston rod holder onto the end of the

piston rod. Install the spring, upper spring seat,

spring spacer tube and spring preload cap. Pull the

piston rod upwards and then insert a 17mm

spanner through the window in the spring preload

cap. You can now remove the piston rod holder

tool.

Final Assembly Instructions

Step 10 Top Cap Installation

Screw the top cap onto the piston rod. Tighten the

top cap to the piston rod using a 14mm socket to

20N/m. A plastic socket insert is recommended to

prevent marring the aluminium.

Assembly Instructions

14

Step 11 Top Cap Tightening

Remove the 17mm spanner and then pull the inner fork

tube up and screw the top cap into it. Tighten to 10N/m

using the top cap specific tool for your model (see

specification sheet).

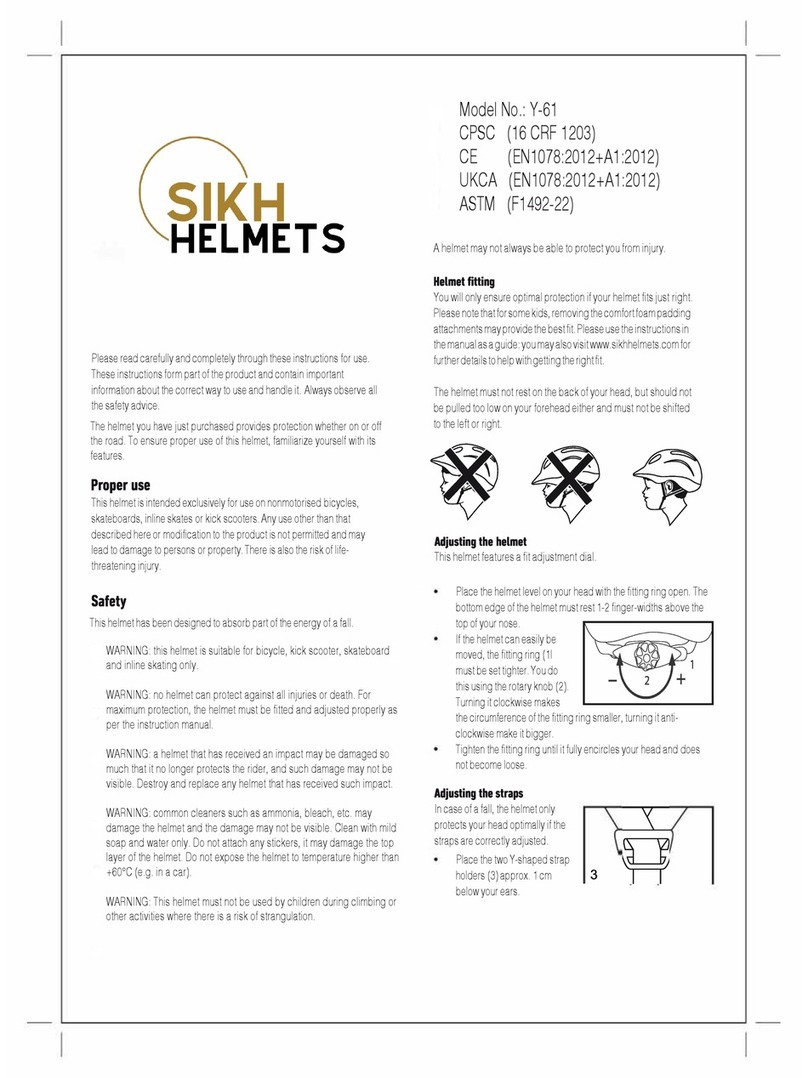

Assembly Instructions

Do not force the adjuster at either end of its adjustment range as this may damage the

internal components.

WARNING

Spring preload is adjusted by turning the 14mm hex,

every complete turn of adjustment equals 1mm of spring

preload. There are 15 turns of adjustment in total and the

setting is referenced as the number of turns from the fully

anti-clockwise position. Adjusting spring preload will

change the amount of initial force required to compress

the springs a given distance in relation to their rate. This

will effectively raise (more preload) or lower (less

preload) the front of the bike thus changing the angle of

the fork and the bikes attitude.

15

Setup

Set the compression and rebound damping adjusters to

the baseline settings specified in your model specific

specification sheet. Adjustment is made by screwing the

adjuster clockwise to its full hard position and then

counting the clicks backwards from this point.

16

Table of contents