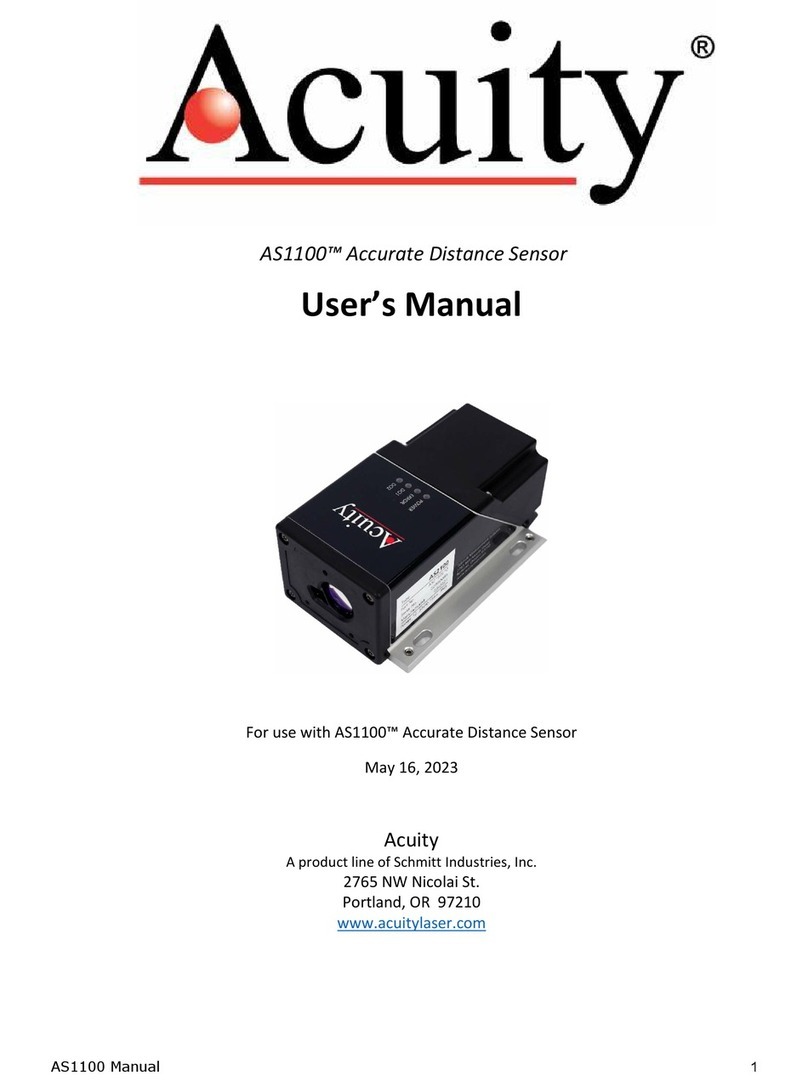

Nittan Sensortec ST-PY-AS User manual

Technical Manual: ST-PY-AS - 000026 (Changes are subject to DCRN)

The ST-PY-AS is elegantly designed, low profile fire

sensor which is aesthetically pleasing, thus enabling it to

blend unobtrusively into modern working environments.

Section 1 - INTRODUCTION

The ST-PY-AS is an attractively-styled, low profile photoelectric

sensor for use with Nittan ‘AS' protocol control panels.

ST-PY-AS features:

• Low profile, stylish appearance

• EEPROM Addressing (Handheld Programmer)

• Low monitoring current

• Supplied with protective dust cover

• Patented OMNIVIEWTM 360° LED fire alarm indicator

• Remote indicator output

• Compatible with UB-4 and STB-4SE bases

• Polarised terminals

• Optical sensor, detecting visible particles of combustion

Section 2 - SENSOR MODELS

The ST-PY-AS photoelectric sensor has two terminals for connection

onto the two wire loop. The remaining terminal provides a switched

current sink function which operates when the sensor goes into

alarm condition, suitable for the operation of an auxiliary function

such as a remote indicator. Terminal 3 (RIL) is limited to 2mA.

Section 3 - BASE MODELS

A variety of bases are available for use with the ST-PY-AS sensor. It is

important to use the correct base for each application. The available

base models are:

i) UB-4 base: for standard use with ST-PY-AS series sensor.

ii) STB-4SE base: Similar to UB-4 base, except deeper.

CONTENTS:-

Section 1

Introduction Page 2

Section 2

Sensor Models Page 2

Section 3

Base Models Page 2

Section 4

Installation Page 3

Section 5

Maintenance &

Cleaning Page 3

Section 6

Technical

Specifications Page 6

Section 7

Environmental

Parameters Page 6

- Temperature Page 6

- Humidity Page 6

Section 8

EMC Page 6

Section 9

Address Setting Page 7

Section 10

Connections Page 8

Section 11

Dimensions Page 8

Section 12

Disposal Page 9

Section 13

ROHS Compliance

Statement Page 9

sensortec

sensortec

2

Ref No: NISM/STPYAS/02 Date: 16.04.09 Issue: 2

• sensortec • ST-PY-AS • analogue addressable photoelectric sensor

instruction manual

www.acornfiresecurity.com

www.acornfiresecurity.com

Technical Manual: ST-PY-AS - 000026 (Changes are subject to DCRN)

Section 4 - INSTALLATION

In normal use, the ST-PY-AS sensor will be installed at ceiling level.

Pass the field wiring through the cable hole in the centre and from

the rear of the base. Offer up and affix the base to the ceiling or

conduit fitting with screws via the base mounting holes. Connect

the field wiring to the base terminals, as detailed on page 8

making sure the wiring does not obstruct fitting of the sensor

head. Fit the sensor head by inserting it into the base and turning

clockwise until the notch in the sensor's rim aligns with base

locking screw. The OMNIVIEWTM 360° LED alarm indicator permits

visibility from any angle.

Note: The address must be set before the sensor is fitted into place.

Fit the plastic dust cover supplied over the sensor to keep out dust

etc, until the system is commissioned. If the dust cover is not fitted

and the environment is slightly dusty, such as when building work is

being completed, for example, problems of false alarms are likely to

occur after commissioning unless cleaning of the sensor is

undertaken. At commissioning, the dust cover should be removed

and discarded.

NOTE: THE PLASTIC DUST COVER MUST BE REMOVED FROM THE

SENSOR IN ORDER FOR THE SENSOR TO FUNCTION CORRECTLY.

Section 5 - MAINTENANCE AND

CLEANING

Maintenance

The ST-PY-AS sensor is a high quality product engineered for

reliability. If proper preventative maintenance is not carried out,

there is a likelihood of malfunction, including false alarms.

Servicing:

Servicing of the system should be carried out in accordance with

the requirements of BS5839 Part 1, Fire Detection and Alarm

Systems for Buildings: Code of Practice for System Design,

Installation and Servicing.

Ref No: NISM/STPYAS/02 Date: 16.04.09 Issue: 2

• sensortec • ST-PY-AS • analogue addressable photoelectric sensor

instruction manual

sensortec

sensortec

3

www.acornfiresecurity.com

www.acornfiresecurity.com

Technical Manual: ST-PY-AS - 000026 (Changes are subject to DCRN)

The maintenance procedures described below should be conducted

with the following frequency:

One month after installation: Routine Inspection and every 3

months after.

Every 6 months: Operational Test.

Every 12 months: Functional Test and Cleaning.

All above frequencies of maintenance are dependent on ambient

conditions.

Routine Inspection

i) Ensure the sensor head is secure and undamaged.

ii)Check the smoke entry apertures are in no way obstructed.

iii)Ensure that the surface of the sensor's outer cover is clean. If

there are deposits due to the presence of oil vapour, dust etc, then

the sensor should be cleaned in accordance with the cleaning

instructions detailed later in this manual. It may be advisable to

ensure that such cleaning is conducted regularly in future.

iv)Ensure that no equipment which may generate excessive heat has

been installed in the vicinity of the sensor since the last routine

inspection. If such equipment has been installed, then you should

notify the Fire Safety Officer or other competent authority that its

presence may cause false alarms.

v) Ensure no equipment which may generate combustion products or

fine airborne particles has been installed in the vicinity of the

sensor since the last routine inspection. If such equipment has been

installed, then you should notify the Fire Safety Officer or other

competent authority that its presence may cause false alarms.

Ref No: NISM/STPYAS/02 Date: 16.04.09 Issue: 2

• sensortec • ST-PY-AS • analogue addressable photoelectric sensor

instruction manual

sensortec

sensortec

4

www.acornfiresecurity.com

www.acornfiresecurity.com

Technical Manual: ST-PY-AS - 000026 (Changes are subject to DCRN)

Operational Test:

The purpose of the Operational Test is to confirm the sensor’s

correct operation in response to a smoke condition.

Take any necessary precautions at the control panel to limit the sounding

of the alarm sounders/bells and any fire service summoning device.

To test the optical sensor, introduce a discrete amount of smoke into

the detector head, e.g. using a 'No Climb - Solo' smoke test head.

Check that the sensor gives an alarm condition within 15 seconds.

Check the LED indicator on the ST-PY-AS sensor illuminates and any

remote indicator LED fitted also illuminates.

After the sensor has given the alarm condition, reset the sensor

from the control panel. It may be necessary to allow a short time to

elapse before resetting the sensor, to allow any residual smoke from

the test to disperse.

iv) Before proceeding to the next sensor, ensure that the sensor just

tested does not re-operate due to the presence of residual smoke.

Functional Tests:

The functional test checks the sensors operation. These detectors

may be returned to our factory for Functional Testing.

Cleaning

Note: The sensor head should NOT be disassembled.

i) Carefully remove the sensor from its base.

ii) Use a soft, lint-free cloth, moistened with alcohol, for sticky

deposits, to clean the plastic cover.

iii) Using a soft bristle brush (e.g. an artists paintbrush) carefully

brush between the vanes of the case in a linear motion away

from the apertures on the plastic case.

iv) Ensure that no debris is left on or around the case once cleaning

is complete.

v) If the unit needs further cleaning or is damaged or corroded,

please return the complete detector to Nittan (UK) Ltd. for service.

Ref No: NISM/STPYAS/02 Date: 16.04.09 Issue: 2

• sensortec • ST-PY-AS • analogue addressable photoelectric sensor

instruction manual

sensortec

sensortec

5

www.acornfiresecurity.com

www.acornfiresecurity.com

Technical Manual: ST-PY-AS - 000026 (Changes are subject to DCRN)

Section 6 - SPECIFICATION

Model Reference: ST-PY-AS

Computer Reference: F14C82100

Sensor Type: Optical smoke sensor

Sensitivity: 3.9%/m

Operating Current: Quiescent: 500µA

Fire alarm (LED On): 5.5mA

Standard: EN54 Part 7:2000

Mass: 105g (excluding base)

Charging Time: 20 seconds

Ambient Temperature

Range: -10°C to +55°C

IP Rating: 41

Certified to standard:

CE Certificate 0832-CPD-0749

LPCB Certificate 842A/03

Section 7 - ENVIRONMENTAL

PARAMETERS

Temperature Considerations:

Over the range from -10°C to +55°C.

Humidity:

Relative Humidity of up to 95%, measured at 50 deg. C., non condensing.

Section 8 - EMC

Installation

The installation shall be in accordance with the regulations either of

the approval body for an approved system, or otherwise, to the

national code of practice/regulations for the installation of the fire

alarm system, e.g. BS 5839 part 1.

Electromagnetic Compatibility (EMC)

On a site where there is an unusually high level of potential electrical

interference, e.g. where heavy currents are being switched or where

high levels of R.F. are prevalent, care then must be taken in the type

and routing of cables. Particular care should be given to the

separation of zone wiring from the cable carrying the interference.

Ref No: NISM/STPYAS/02 Date: 16.04.09 Issue: 2

• sensortec • ST-PY-AS • analogue addressable photoelectric sensor

instruction manual

sensortec

sensortec

6

www.acornfiresecurity.com

www.acornfiresecurity.com

Technical Manual: ST-PY-AS - 000026 (Changes are subject to DCRN)

Section 9 - PROGRAMMING THE

ST-PY-AS USING THE

MTM PROGRAMMER

1) Insert batteries, 2x9v PP3. and switch on Power Switch.

2) The LCD will show “Ver 1.0D”, and Power LED will light after the

LCD will blank (to save power).

3) Plug ST-PY-AS into base, and press “Search” button

4) LCD displays “WAIT….”

5) Then current address “xxx”, and Type “O” (for Optical for

example), and prompts for address to be entered.

6) Press “UP” or “DOWN” Button.

7) A Single press increments (or decrements) by 1, holding the

button down speeds up the increment (or decrement) change.

8) Select the desired address, and press “Set”

9) LCD displays “WAIT….”, then new address , Type and “OK”

(and beeps)

10)Remove detector and repeat from step 3

11)If no keys are pressed for 1 minute, the programmer will power

down into a power saving mode (LCD goes blank). It will be

necessary to press “Search” or switch the Power Off and back

On again.

Ref No: NISM/STPYAS/02 Date: 16.04.09 Issue: 2

• sensortec • ST-PY-AS • analogue addressable photoelectric sensor

instruction manual

sensortec

sensortec

7

www.acornfiresecurity.com

www.acornfiresecurity.com

Technical Manual: ST-PY-AS - 000026 (Changes are subject to DCRN)

Section 10 – CONNECTIONS

Section 11 – DIMENSIONS

Ref No: NISM/STPYAS/02 Date: 16.04.09 Issue: 2

• sensortec • ST-PY-AS • analogue addressable photoelectric sensor

instruction manual

sensortec

sensortec

8

If +ve supply derived from loop, RIL must be LED type

UB-4 / STB-4SE Bases

RIL must be 6v, 2mA max

Auxiliary terminal RIL current limited to 2mA. If the +ve supply for the auxiliary equipment is taken from the

loop, care must be taken to not cause corruption of the data protocol by excessive current draw.

15mm

33mm

Ø104m

27 mm

43 mm

20 mm

41 mm

4.5 mm

9 mm

2.8 x 6mm

GRUB SCREW

15 mm

104.5 mm

www.acornfiresecurity.com

www.acornfiresecurity.com

Ref No: NISM/STPYAS/02 Date: 16.04.09 Issue: 2

• sensortec • ST-PY-AS • analogue addressable photoelectric sensor

instruction manual

sensortec

sensortec

9

Section 12 - DISPOSAL

This symbol on the ST-PY-AS indicates that this product must not be

disposed of with household waste. Instead, it is your responsibility to

dispose of your waste equipment by handing it over to a designated

collection point for the recycling of waste electrical and electronic

equipment. The separate collection and recycling of your waste

equipment at the time of disposal will help to conserve natural

resources and ensure that it is recycled in a manner that protects

human health and the environment. For more information about

where you can drop off your waste equipment for recycling, please

contact your local city office or your household waste disposal service.

Section 13 - ROHS COMPLIANCE

STATEMENT

(RoHS compliant and lead-free)

This product complies with the RoHS (Restriction of Hazardous

Substances) directive.

This product complies with the RoHS (Restriction of Hazardous

Substances) directive which restricts the use of six hazardous

materials in the manufacture of electronic and electrical equipment.

This product complies with the European Union RoHS (Restriction of

Hazardous Substances) directive 2002/95/EC which restricts the use

of the following six hazardous materials in the manufacture of

electronic and electrical equipment.

• Lead (Pb)

• Hexavalant Chromium

• Mercury (Hg)

• Cadmium (Cd)

• Polybrominated biphenyls (PBB’s)

• Polybrominated diphenyl ethers (PBDE’s)

www.acornfiresecurity.com

www.acornfiresecurity.com

Table of contents

Other Nittan Accessories manuals

Popular Accessories manuals by other brands

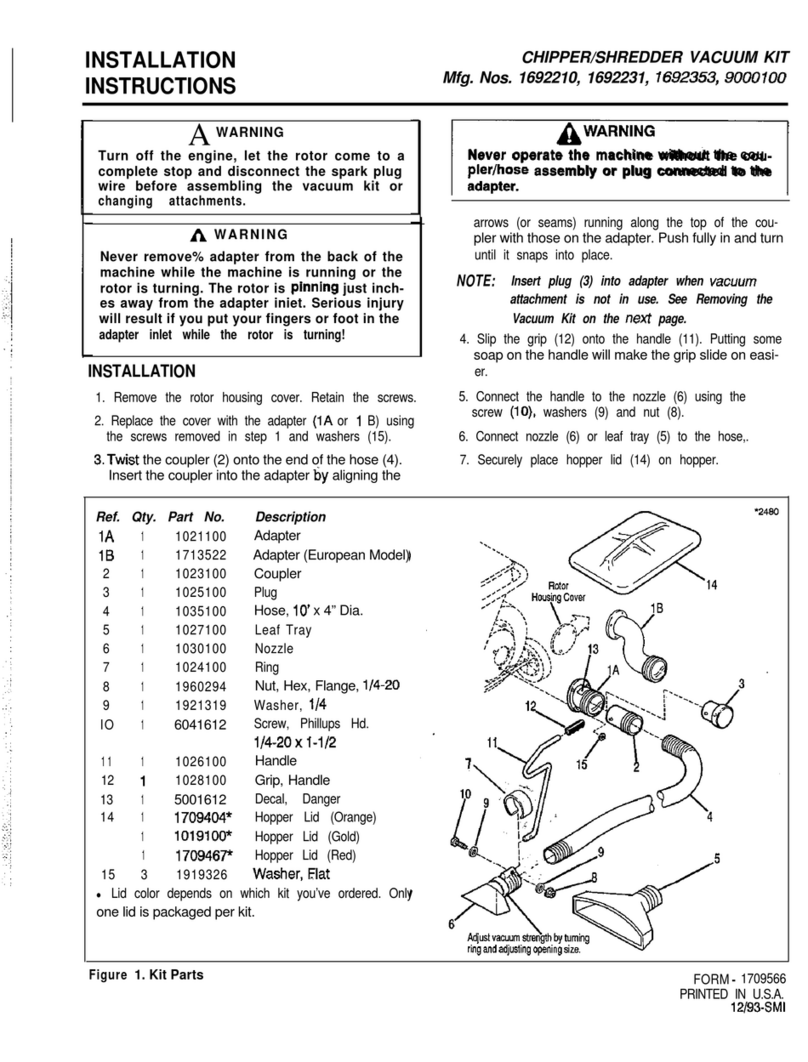

Snapper

Snapper 1692210, 1692231, 1692353, 9000100 installation instructions

Oregon Scientific

Oregon Scientific HWI0002 user manual

Waters Industries

Waters Industries SUNCATCHER SW-9374 manual

Bogen

Bogen PEQ1R install guide

TE Connectivity

TE Connectivity LGA4189 instruction sheet

X-lander

X-lander X-pram Q manual