10 VEGAPULS 51K … 54K

21750-EN-031222

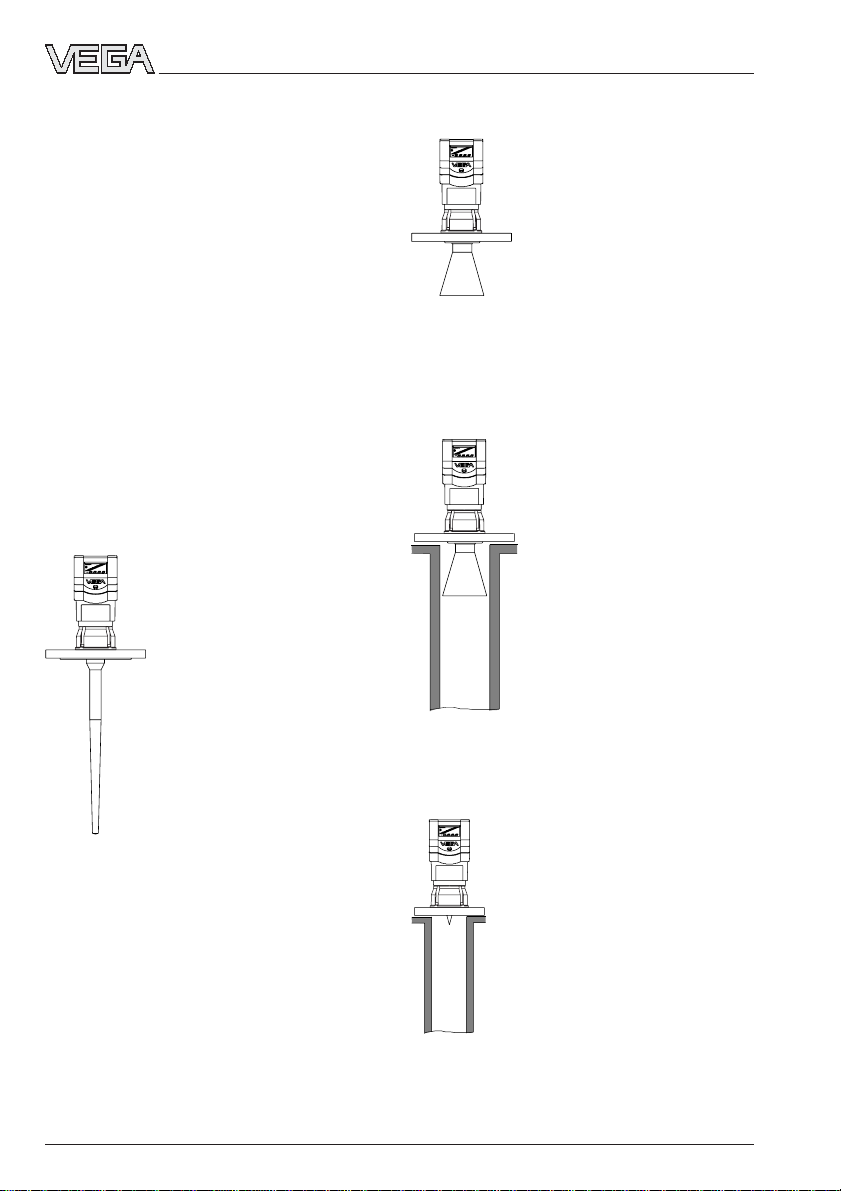

Types and versions

2.2 Antennas

The antenna is the eye of the radar sensor.

The shape of the antenna, however, doesn’t

give a casual observer the slightest clue on

how carefully the antenna geometry must be

adapted to the physical properties of electro-

magnetic waves. The geometrical form deter-

mines focal properties and sensitivity - the

same way it determines the sensitivity of a

unidirectional microphone.

Four antenna systems are available for differ-

ent applications and process requirements.

Beside having its own unique focusing char-

acteristics, each system differs in its chemi-

cal and physical properties.

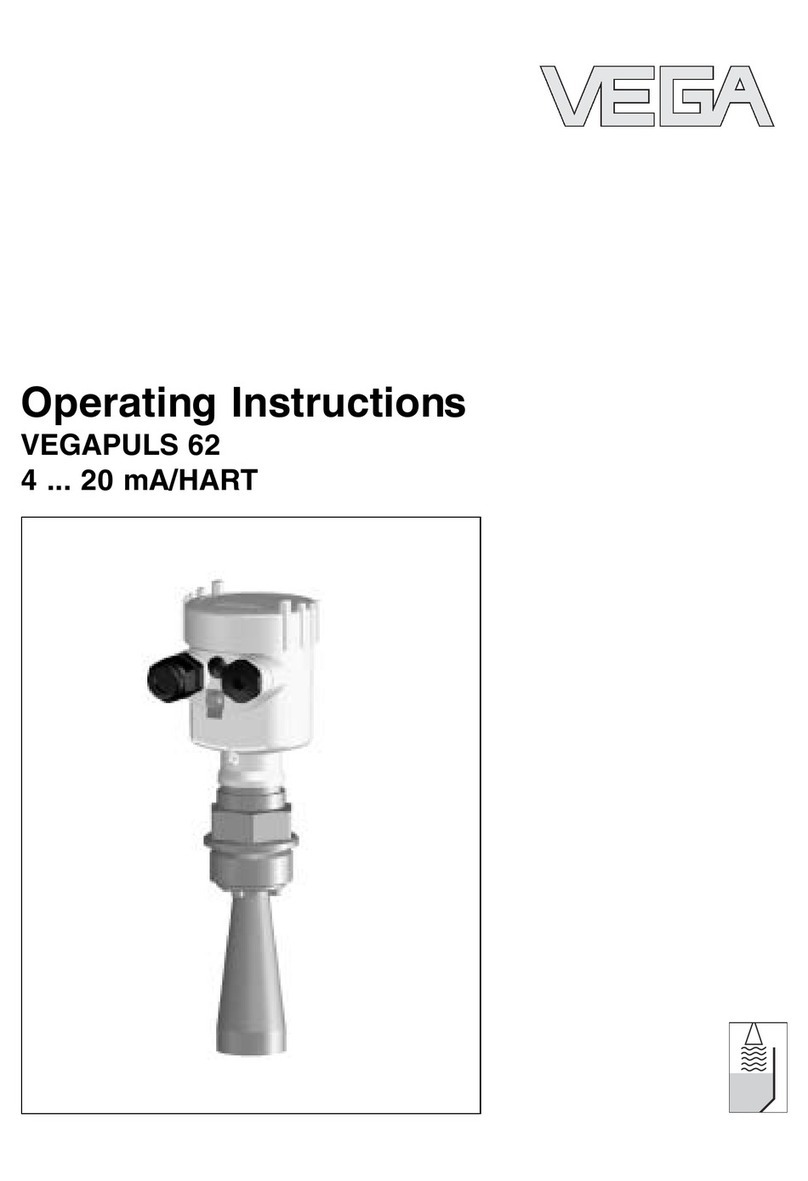

Rod antenna

Rod antennas with high chemi-

cal resistance require only the

very smallest flange diameters

(DN 50). The antenna rod and

the wetted flange parts are

made of PTFE, PP or PPS so

that the rod antenna can be

easily cleaned and provide

resistance to condensation.

The rod antenna is suitable for

pressures up to 16 bar and

temperatures up to 150 °C.

Horn antenna

Horn antennas are well suited

for most applications. They

focus the radar signals very

well. Manufactured of 1.4571

(StSt) or Hastelloy C22, they

are very rugged and are

physically as well as chemi-

cally resistant. They are suit-

able for pressures up to

40 bar and for product tem-

peratures up to 150 °C.

Pipe antenna

The pipe antennas on surge

or bypass tubes only form a

complete antenna system in

conjunction with a measuring

tube (which can also be

curved). Pipe antennas are

especially suitable for prod-

ucts with strong flow or tur-

bulence, or products with low

dielectric constant.

The antenna is available with

or without a horn. Versions

with horn are characterised

by a very high antenna gain.

High measurement reliability

can thus be achieved even in products with

very poor reflective properties.

The measuring tube acts as a

conductor for radar signals.

The running period of the radar

signals changes in the tube and

depends on the tube diameter.

The tube inner diameter must

be programmed in the sensor

so that it can take the altered

running time into account and

deliver accurate level signals.