Nittan Sensortec ST-H-AS User manual

06

NISM/STHA/06

DATE:

PAGE:

No:

ISSUE:

of

16

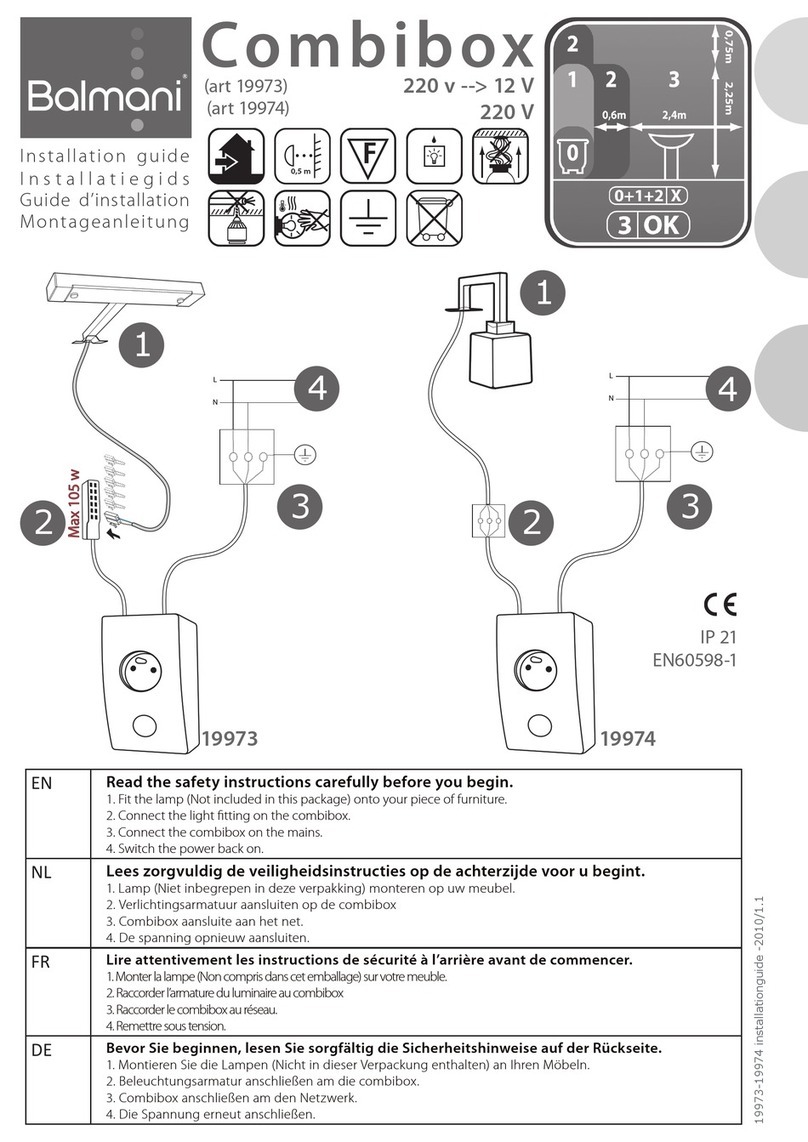

ST-H-AS SENSORTEC

ANALOGUE-ADDRESSABLE

HEAT SENSOR

INSTRUCTION MANUAL

NOV 2006

NITTAN (UK) LTD - BRINGING STYLE INTO FIRE DETECTION SYSTEMS

The new ST-H-AS analogue addressable smoke sensor forms part of a

brand new range of analogue addressable fire detectors from Nittan (UK)

Ltd called SENSORTEC-ANALOGUE.

The ST-H-AS together with the ST-I-AS and ST-P-AS are all low cost,

elegantly designed, low profile fire sensors which are aesthetically

pleasing, thus enabling them to blend unobtrusively into modern work-

ing environments.

The SENSORTEC analogue addressable range all feature the very lat-

est technological advancements increasing reliability and performance

are all compatible with our existing 'AS' protocol and are compatible with

leading analogue addressable panel manufacturers.

SENSORTEC-ANALOGUE...........

From world leaders in SENSOR TECHNOLOGY

comes SENSORTEC.........

www.acornfiresecurity.com

www.acornfiresecurity.com

06

NISM/STHA/06

DATE:

PAGE:

No:

ISSUE:

of

26

ST-H-AS SENSORTEC

ANALOGUE-ADDRESSABLE

HEAT SENSOR

INSTRUCTION MANUAL

NOV 2006

Section 1 - INTRODUCTION

TheST-H-ASisanattractively-styled,lowcost,low

profile heat sensor for use with Nittan 'AS' protocol

control panels. This sensor is identical in function to

ourTCA-AS/TCA-AS2LRsensorandcanthereforebe

used as a direct replacement.

ST-H-ASfeatures:

*Lowprofile,stylishappearance

* Low monitoring current

* Integral LED fire alarm indicator

*Remoteindicatoroutputonstandardmodels

*CompatiblewithRB-3/RB-6Bases

* Compatible with existing 'AS' protocol

* Flashing LED to indicate sensor is being polled

CONTENTS:-

Section1 - Introduction - Page 1

Section2 - SensorModels - Page 3

Section3 - BaseModels - Page 3

Section4 - Installation - Page 3

Section5 - Maintenance&

Cleaning - Page 3

Section6 - Specifications - Page 4

Section7 - Environment

Parameters:- - Page 4

- Temperature - Page 4

- Humidity - Page 4

Section8 - EMC -Page4

Section9 - Sensitivity - Page4

Section10 - AddressSetting - Page5

Section11 - Dimensions - Page6

www.acornfiresecurity.com

www.acornfiresecurity.com

06

NISM/STHA/06

DATE:

PAGE:

No:

ISSUE:

of

36

ST-H-AS SENSORTEC

ANALOGUE-ADDRESSABLE

HEAT SENSOR

INSTRUCTION MANUAL

NOV 2006

Section 2 - SENSOR MODELS

The ST-H-AS heat sensor is supplied, as standard,

withthreeterminals.

The ST-H-AS has the facility to activate a remote LED

indicatororauxiliaryfunction,as standard.

TheterminalsontheST-H-ASsensorheadare

configuredasfollows:-

Terminal 3 = -VE 3 mA aux output

Terminal 1 = Sig + (+VE) positive in/out

Terminal 6 = S- (-VE) negative in/out

Section 3 - BASE MODELS

STB-4Base:having4terminals,forstandard

usewithST-P-ASsensorincludingtheauxiliary

outputfunction.

Section 4 - INSTALLATION

In normal use, the ST-H-AS heat sensor will be

installed at ceiling level. Pass the field wiring through

the cable hole in the centre and from the rear of the

base. Offer up and affix the base to the ceiling or

conduit fitting with screws via the base mounting

holes. Consider visibility and orientation of the sen-

sor'sintegralalarmLEDindicatorwhenmountingthe

base. Connect the field wiring to the base terminals,

as detailed on page 5 making sure the wiring does not

obstruct fitting of the sensor head. Fit the heat

sensor head by inserting it into the base and turning

clockwise until the notch in the sensor's rim aligns

with base locking screw.

Section 5 - MAINTENANCE AND

CLEANING

Maintenance&Servicing:

Generally, it should not be necessary to dismantle the

heat sensor since there is no internal chamber which

mayrequirecleaning. Theheatsensing element and

holder may be kept clean by gentle brushing with a

clean, dry, soft brush for dry deposits. For sticky

deposits, the brush may be moistened with a little

alcohol. If the plastic outer cover becomes dirty, this

may be removed and cleaned in the same manner as

described above for the outer covers of smoke

sensors. When replacing this cover, make sure that

the led indicator locates properly in the hole in the

outercoverbeforepushingthe outercoverhome,

otherwisetheledwillbecomedamaged.

Servicing of the system should be carried out in

accordance with the requirements of BS 5839 Part 1,

Fire Detection and Alarm Systems for Buildings: Code

of Practice for System Design, Installation and Servic-

ing.

Themaintenanceproceduresdescribedbelowshouldbe

conductedwiththefollowingfrequency:

Onemonthafterinstallation:- RoutineInspection

andevery3months

after.

Every6months:- OperationalTest

Every12months:- Functionalcleanand

Test

Allabovefrequenciesofmaintenancearedependenton

ambient conditions.

RoutineInspection

i) Ensurethe sensor head is secure and undamaged.

ii) Ensure the surface of the sensor’s outer cover is

clean. If there are deposits due to the presence of oil

vapour, dust etc, then the sensor should be cleaned in

accordancewiththecleaninginstructionsdetailedlater

in this manual. It may be advisable to ensure that such

cleaningisconductedregularlyinthefuture.

iii)Ensurenoequipmentwhichmaygeneratehigh

temperatures has been installed in the vicinity of the

sensor since the last routine inspection. If such equip-

ment has been installed, then you should notify the Fire

Safety Officer or other competant authority that it’s

presence may cause false alarms.

OperationalTest

The purpose of the Operational Test is to confirm the

sensor’scorrectoperationinresponsetoaheatcondi-

tion.

i) Take any necessary precautions at the control panel

to limit the sounding of the alarm sounders/bells and

anyfireservicesummoningdevice.

ii)Introduceheat using a heatgun/hairdryerwhichhas

been designed especially for testing heat sensors.

iii) After the heat sensor has given the alarm condition,

reset the sensor from the control panel. It may be

necessary to allow a short time to elapse before reset-

ting the sensor, to allow any residual heat from the test,

todisperse.

www.acornfiresecurity.com

www.acornfiresecurity.com

06

NISM/STHA/06

DATE:

PAGE:

No:

ISSUE:

of

46

ST-H-AS SENSORTEC

ANALOGUE-ADDRESSABLE

HEAT SENSOR

INSTRUCTION MANUAL

NOV 2006

Ultrasonic Cleaning

This method may be used to good effect for the re-

movalof contamination from the outer cover only, after

theyhavebeendismantledfromthesensor. However,

care must be taken in selection of the solvent so as

not to cause damage to the plastic and insect screen.

The solvent supplier should be consulted as to it’s

suitability.

Undernocircumstancesshouldthefullyassembled

heatsensorbecleanedwithoutdisassemblyasthis

maycausedamagetothespecialtreatmentapplied

tospecificcomponentswithinthesensor.

Section 6 - SPECIFICATION

ModelReference: -ST-H-AS

ComputerReference: - 81200

SensorType: Lowmassthermistor

OperatingCurrent: - 200

µ

amps

firealarm (LEDon)

3.2mA

SignalCurrent: - 50mAnominal

Sensitivity: - EN54 Part 5

Class A2

Mass: - 101g(excludingbase)

ChargingTime: - 20seconds

AmbientTemperature

Range: - -10deg.Cto

+50deg.C

Section 7 - ENVIRONMENTAL

PARAMETERS

TemperatureConsiderations:

Over the range from -10 Deg. C. to +50 Deg. C..

Humidity:

Relative Humidity of up to 90%, measured at

50deg.C.,noncondensing.

Section 8 - EMC

Installation

The installation shall be in accordance with the regula-

tionseitheroftheapprovalbody foranapproved

system, or otherwise, to the national code of practice/

regulations for the installation of the fire alarm system,

e.g. BS 5839 part 1.

ElectromagneticCompatibility(EMC)

On a site where there is an unusually high level of

potentialelectricalinterference,e.g.whereheavycur-

rentsarebeingswitchedorwherehighlevelsofR.F.are

prevalent, care then must be taken in the type and

routing of cables. Particular care should be given to the

separationofzonewiringfromthecablecarryingthe

interference.

Section 9 - SENSITIVITY/THRESHOLDS

HeatSensorPerformanceGraphs:-

1E

1C

18

16

14

10

0C

06

02

00

0E

12

1A

04

0A

08

2C

26

2A

28

24

22

-20 -10 10 20030 40

TEMPERATURE/DEG.C

40 50 60 70 80 90 100

2E

30

32

34

36

38

3A

3C

3E

TYP.

TYP.

ANALOGUE VALUE (HEX)

ANALOGUE VALUE (HEX)

TEMPERATURE/DEG.C

PerformanceGradetoEN54Part5:- (Hex)

Class A2 (nominal 66 degrees C) 30

Fault : 00

www.acornfiresecurity.com

www.acornfiresecurity.com

06

NISM/STHA/06

DATE:

PAGE:

No:

ISSUE:

of

56

ST-H-AS SENSORTEC

ANALOGUE-ADDRESSABLE

HEAT SENSOR

INSTRUCTION MANUAL

NOV 2006

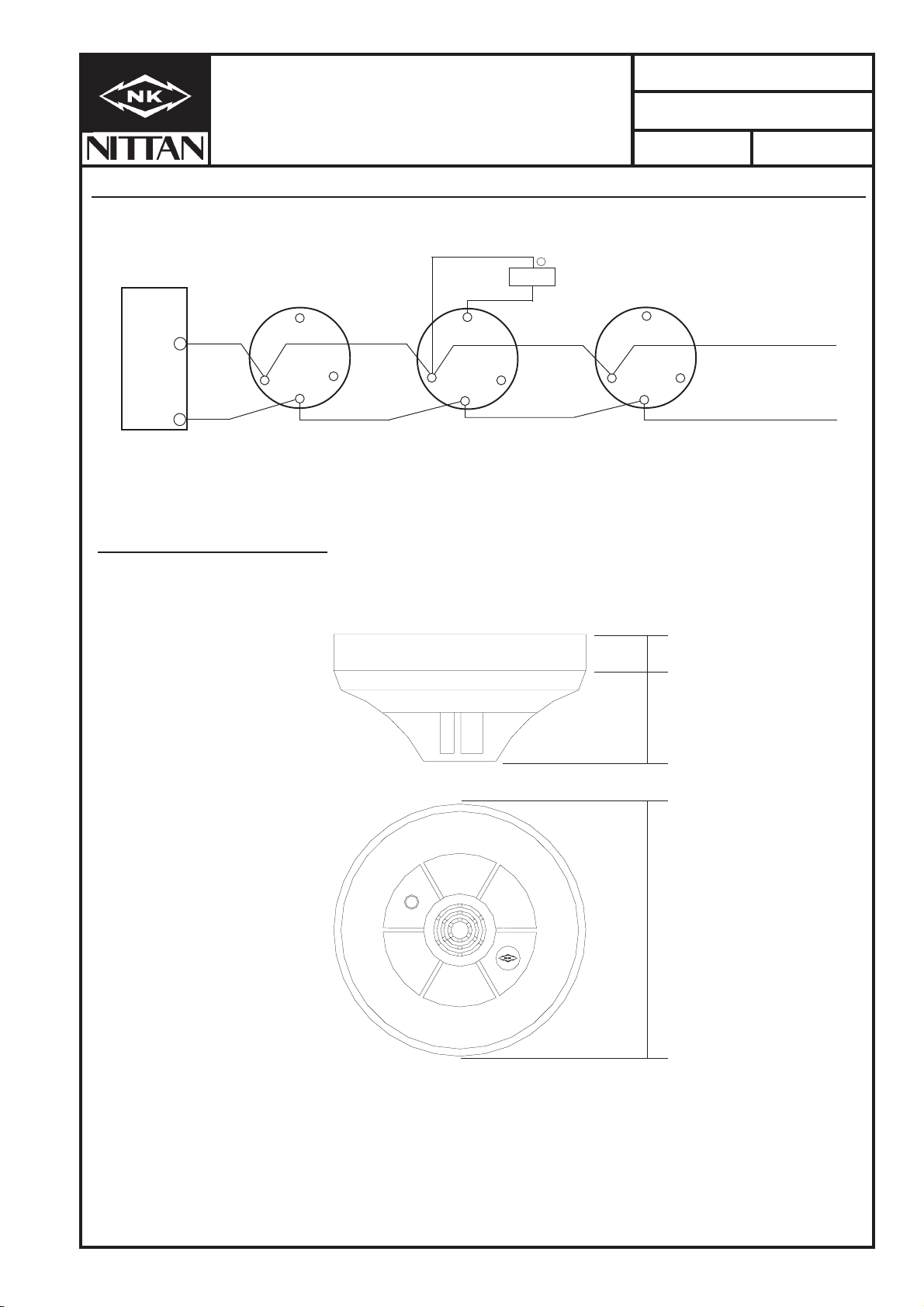

Section 10 - ADDRESS SETTING:-

NITTANDIL SWITCHSETTINGSFORSENSORTECMODEL TYPES:ST-I-AS,5000/IONST-P-AS,

5000/OP,ST-H-AS,5000/TEMP.

WARNING:ConnectonlytoNITTAN (UK)LTD suitableandcompatibleanalogue-addressablecontrol panels.

If in doubt, check with control panel manufacturer.

DIL SWITCH SETTINGS - ALL SENSOR MODELS

Hold the sensor so that the product label can be correctly read. Set each digit on the appropriate eight switches

accordingtotheaddressrequired.

64

8

16

32

4

1

=On

2

On

128

Rear of ST-H-AS Sensor and Address Switch Setting (DIL Switch)

Above switch setting set to address 12.

=Off

Off

64

8

16

32

4

1

=On

2

On

128

Above switch setting set to address 26.

=Off

Off

64

8

16

32

4

1

=On

2

On

128

Above switch setting set to address 95.

=Off

Off

64

8

16

32

4

1

=On

2

On

128

Above switch setting set to address 126.

=Off

Off

64

8

16

32

4

1

2

On

128

OFF

RIL REMOTE LED 3mA MAX.

SER. No. _________________________________

0004572

ST-H-AS

STOCK No. 81200

HEAT SENSOR

SET ADDRESS PRIOR TO USE

AFFIX LABEL TO SEAL ADDRESS WINDOW

DISASSEMBLY WILL VOID WARRANTY

CLASSA2

EN54PT.5

AMBIENTTEMP:-10Deg.C~+90DegC..

RATING: 24Vd.c.,

0.2mANORMAL,

3.5mAALARM

MADE IN UK

USEONLY

WITH

NITTAN

PROTOCOL

NISM/WFM/O2

NITTAN (UK) LTD

www.acornfiresecurity.com

www.acornfiresecurity.com

06

NISM/STHA/06

DATE:

PAGE:

No:

ISSUE:

of

66

ST-H-AS SENSORTEC

ANALOGUE-ADDRESSABLE

HEAT SENSOR

INSTRUCTION MANUAL

NOV 2006

Section 9 - CONNECTIONS (Also suitable for ST-I/ST-P-AS smoke sensors)

Section 10 - DIMENSIONS

STB-4base

_65

33

65

6

3

5

11

STB-4base

LED

1

+

STB-4base

+

SIG+

S-

Low current LED 3mA max.

(STA-R1).

loopreturnto

controlpanel

15mm

49mm

104mm

www.acornfiresecurity.com

www.acornfiresecurity.com

Other Nittan Accessories manuals