Nittan CKLD-KPT2 User manual

Instruction Manual

Beam Type Smoke Detector

Thank you for purchasing our product.

Please read through the instruction manual before use.

Keep this manual in an easily accessible place for future

reference.

2

Handling Instructions ·············································· 3

Names of Parts ····················································· 5

Installation ··························································· 7

Wiring Connection ················································· 9

Adjustment of Light Axis (Transmitter and Receiver) ···· 10

Adjustment of Receiving Light Intensity (Receiver) ······ 11

Sensitivity and Response Time ······························· 14

Sensitivity Test ···················································· 14

Compensation and Fault Signal ······························· 15

Sensitivity Compensation ······································· 15

Test Function ······················································ 16

Maintenance ······················································· 17

Indicator ····························································· 17

Specification ························································ 18

Table of Contents

3

For Your Safety

The criteria of the Danger, Warning and Caution markings are as follows.

Warning

There is a risk of endangering the health or life of the user, or

causing a significant damage to the product if the product is

mishandled.

Caution

There is a risk of causing minor injuries, damage to the product,

or a trouble to the product if the product is mishandled.

Action Prohibited

Action Mandated or Directed

Warning

〇Do not get the equipment wet or touch it with a wet hand.

It may cause electric shock or system trouble.

〇Do not use the equipment in a location where operating temperature

exceeds its range (-10 to +50°C) or where explosive gas or corrosive gas

is generated.

It may cause the equipment trouble or fire ignition.

〇Do not use the equipment in a location with high humidity, or where

condensation, steam, or oily smoke is generated.

It may cause electric shock or system trouble.

〇Do not disassemble or modify the equipment.

It may cause electric shock or system trouble.

〇 Make sure to connect to each terminal correctly, according to rated

capacity and polarity.

Otherwise it may cause the equipment trouble or fire ignition.

〇If work at height is involved, make sure to secure scaffolding for safety

to prevent falls.

There is risk of falls or falling objects.

Handling Instructions

4

Warning

〇Make sure to turn the power off before commencing any wiring work.

Otherwise it may cause damage to the equipment.

〇 Avoid installing the product in any location where it can be easily

touched by accident.

It may cause injury.

〇Ensure to fix the product securely.

Otherwise it may cause falling.

Important

1)Notes in installation

・Contact your distributor or contractor for the installation of the product.

・Any work at height must be carried out by no less than 2 persons in order to prevent

falling accidents.

・Use the Remote Station(LP05/LP04) in combination with the Detector.

・Avoid locations where the Receiver is exposed to direct sunlight.

・Avoid locations where the Receiver is exposed to an intense light source (more

than 5000 lux), light beam, or strobe light. Optional shading hood (KLD-14) is also

available.

・Secure the space of approximately 1 square meter around the Detector and the

Remote Station, for maintenance and adjustment after the installation.

・In the event of installation in places where the Detector may be hit by a ball such

as a school gymnasium, use the optional protector (KLD-15).

2)Notes in operation

・Place the monitoring switch of Remote Station back to the normal position. If the

switch is shifted to the monitoring side, normal monitoring is not available.

3)Notes in maintenance

・Antifog coating is applied to both the Transmitter and Receiver lenses. For

cleaning, gently wipe off with a dry soft cloth to avoid damage. Do not use thinner

or other solvents.

Handling Instructions

5

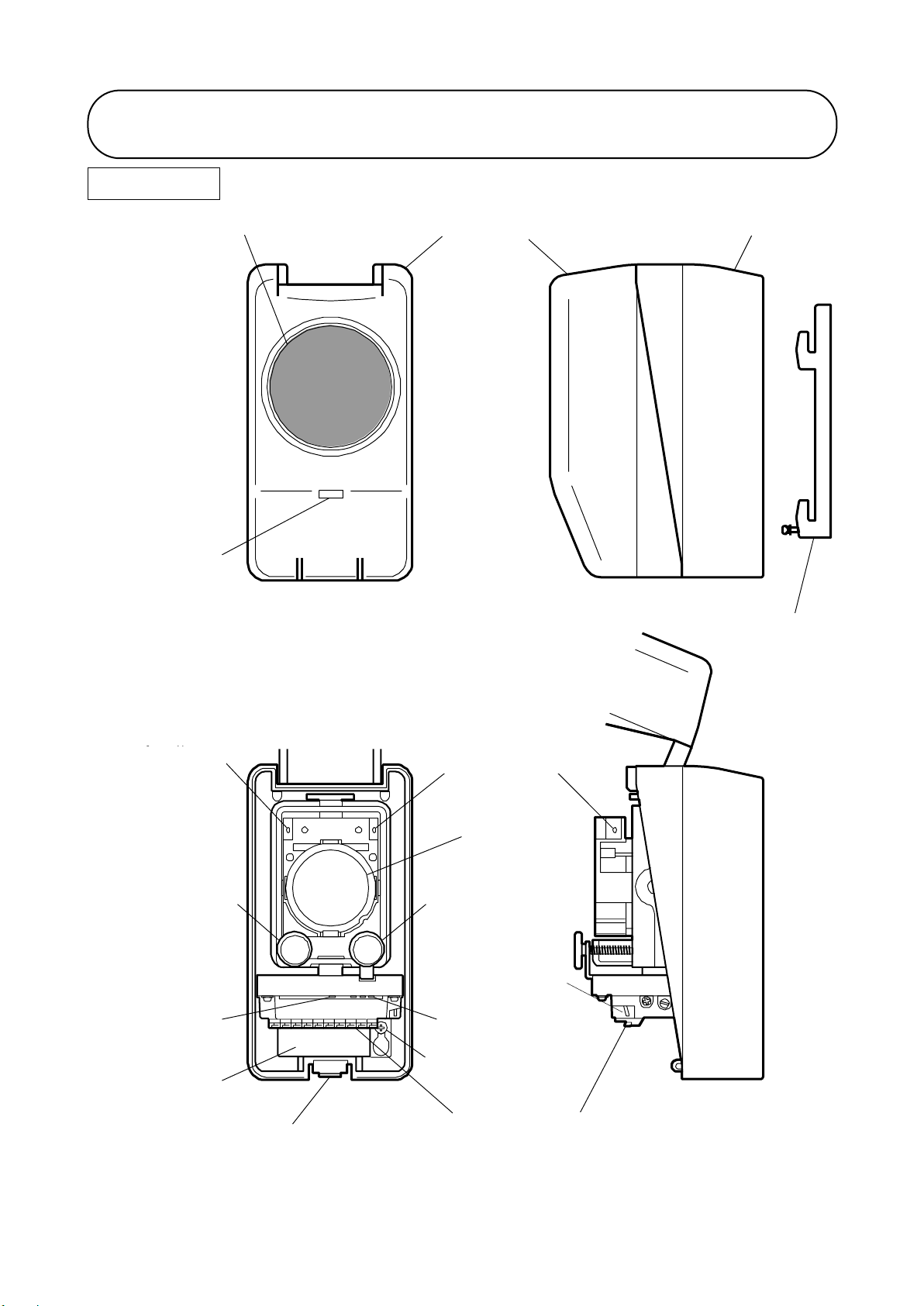

Transmitter Upper figure: Cover closed Lower figure: Cover opened

Names of Parts

Collimation Dial Y

(Vertical)

Lock Tab

Lens

Collimation Hole

Collimation Hole

Wiring Hole

Wiring Terminal

Lens Cover

Cover

Body

Base

Detector Fixing

Screw

Power Indicator

Power Indicator

Collimation Dial X

(Horizontal)

6

Receiver Upper figure: Cover closed Lower figure: Cover opened

Names of Parts

調整スイッチ

Collimation Dial Y

(Vertical)

Lock Tab

Lens

Collimation Hole

Collimation Hole

Wiring Hole

Light Intensity

Indicator

Status Switch

Lens Cover

Cover

Body

Base

Alarm Indicator

Alarm Indicator

Collimation Dial X

(Horizontal)

Wiring Terminal

Detector Fixing

Screw

7

※ベース固定ねじ(なべ小ねじ

M4×10)は別途ご用意くだ

さい。

掛け部

ベース

通線孔

感知器固定ねじ

2

3

4

1※

1. Pay attention to the vertical direction of the Base and fix it to the

wall. (Detector Fixing Screw to be on the bottom).

2. Pull out Wiring cable from the Wiring Hole.

3. Do not tighten the Detector Fixing Screw until the Detector is

mounted onto the Base.

4. Put the Detector onto the Base and slide it downward, as shown

in the figure. Four hooks on the Base are to be slotted into the

slit provided on the back side of the Detector, in order to be

temporarily fixed.

Base Mounting Dimensions (mm)

Installation

Wiring Hole

Base

Detector Fixing Screw

Wiring Hole

Base

Detector Fixing Screw

Hook

※Screws for fixing the base

(Pan-head screw M4x10)

to be prepared separately.

8

5. Press the Lock Tab, open and move the body cover upward. The

cover can be held at 2 positions to make the installation easier.

6. Fasten the Detector Fixing Screw next to the Wiring Hole.

Ensure that the head of the screw is positioned at the specific

position of the main body. Fasten the Detector Fixing Screw to

secure the Detector to the Base. When detaching the Detector,

loosen the Detector Fixing Screw and slide the Detector upward.

〇Set the Status Switch of the Receiver to “CAL” position before

power up.

When the Detector is powered up while the Status Switch is at the

“NORM” position, the Detector may go into alarm.

〇Please be aware that the switch would go back to “NORM”

position when the Detector cover is closed.

〇The mounting method for both the Transmitter and the Receiver

are the same.

Installation

Detector Fixing Screw

Cover holding position 1

Cover holding position 2

Hook

9

Control

Panel I+

F

FL C Lx

LD+Lin Cin Lx

Remote

Station

L

C

T

K

L

C

T

K

SL SC SLSC

Receiver Transmitter

K C L

End of line device

As required

1.Use dedicated Remote Station LP04 or LP05.

2.The number of the Detector and the Remote Station connected to

a zone is 3 sets at maximum for LP04, and 1 set for LP05.

3.In case of using LP05, do not connect any other detector in the

same zone.

4.The line between L and C of the Detector is polarity insensitive.

The other terminals are polarity sensitive.

5.Ensure to connect the EOL device accompanied with the Remote

Station in the line between L and C, and C and K of the Receiver.

6.In case of requirement of taking trouble status of CKLD-KPT2 by

compatible control panel through the remote station, make wiring

“Lx” between panel and remote station, and wiring “K” between

receiver and remote station respectively.

Wiring Connection

Wiring Example

LP05

10

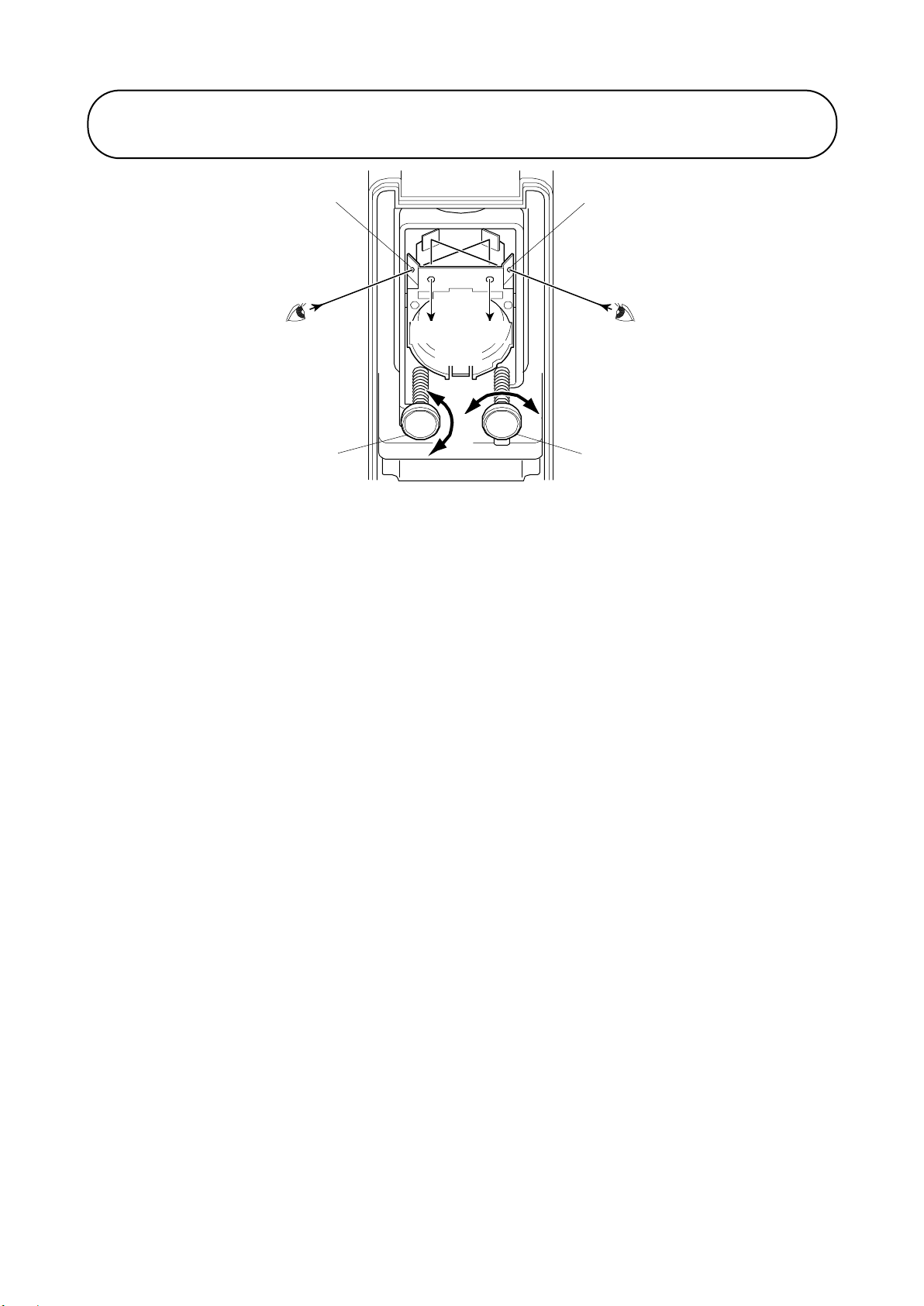

Collimation Dial

Two Collimation Dials X and Y are provided to adjust the light axis.

Look into one of the Collimation Holes provided above the lens to collimate

the opposed unit. Turn the Collimation Dial, until the opposed unit can be

seen in the center of the hole.

Vertical adjustment

Turn the Collimation Dial Y to adjust the light axis in a vertical direction.

The degree range of movement on “Y” dial is plus-minus 10 degrees. One

full turn of dial corresponds to approximately 1 degree change.

Horizontal adjustment

Turn the Collimation Dial X to adjust the light axis in a horizontal direction.

The degree range of movement on “X” dial is plus-minus 10 degrees. One

full turn of dial corresponds to approximately 1.7 degree change.

Adjustment procedure

1.Adjust the light axis of the Transmitter.

2.After the light axis adjustment is completed, close the main cover

immediately.

3.Adjust the light axis of the Receiver.

4.After the light axis adjustment is completed, adjust the receiving light

intensity next.

Adjustment of Light Axis (Transmitter and Receiver)

Collimation Dial Y

Collimation Dial X

Collimation Hole

Collimation Hole

U

D

L

R

Collimation

Axis

11

FIRE

L L C C T K K KC SL SC

LED flickers

while calibration

Monitor for Cal

Lo w O K High

Cal NORM Cal

L

M

S

Alarm Indicator

(Flashing during calibration)

Light Strength Indicator

Distance Selection SW

Light Strength Adjustment VR

Status Switch

〇Ensure that the cover of the Transmitter is closed completely

before adjusting the receiving light intensity.

If the cover is opened, it is not possible to adjust the receiving light

intensity.

1.Confirm that the control panel is powered off (i.e. the Detector is

not powered).

2.Open the cover of the Receiver, and move the Status Switch from

“NORM” to “CAL” position.

3.Turn on the power of the control panel to power the Detector.

Confirm that the Alarm Indicator of Receiver blinks.

4.Set the Distance Selection Switch according to the table below.

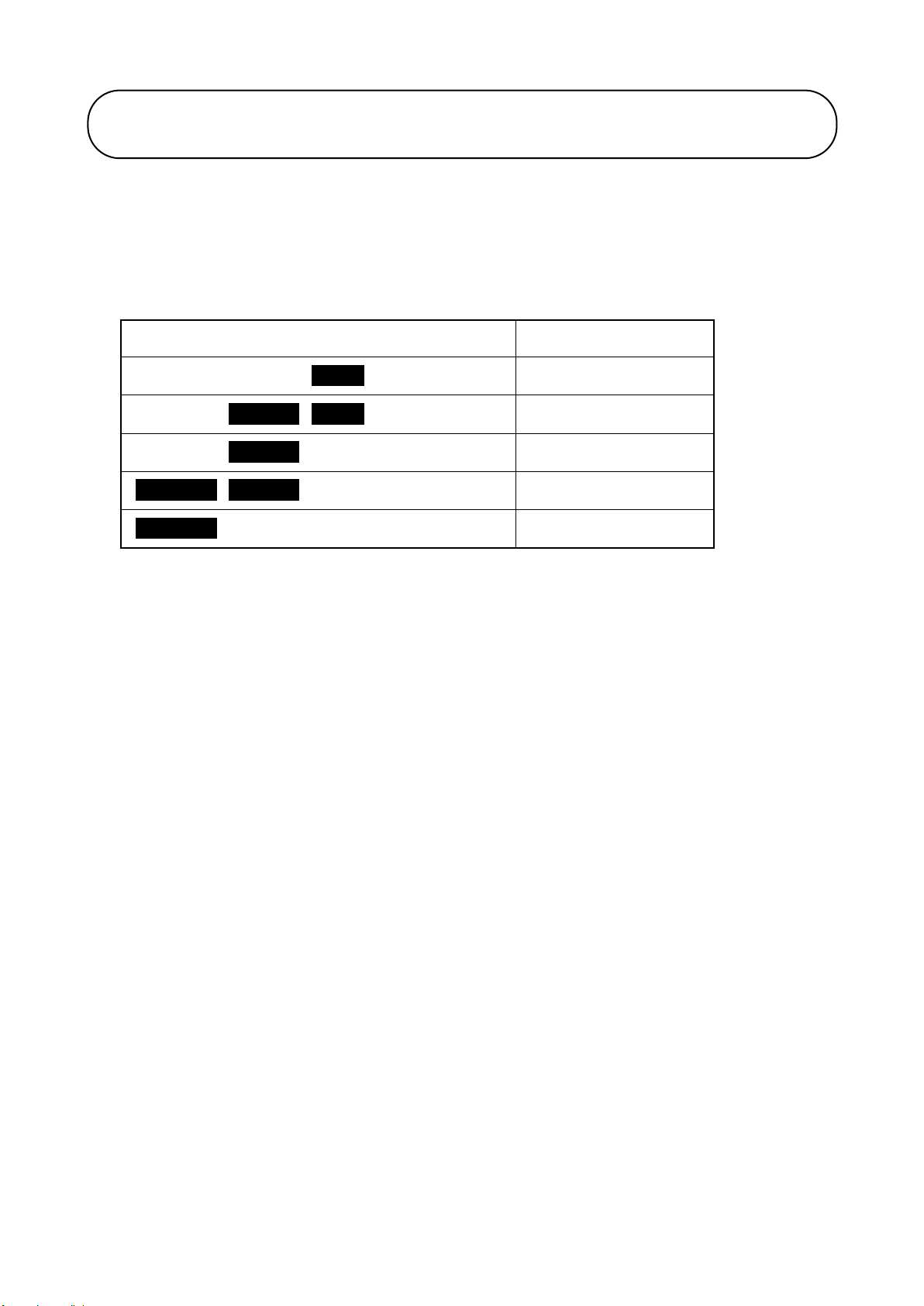

Distance Selection Switch

Distance between Transmitter

and Receiver

Short

5m to less than 15m

Medium

15m to less than 40m

Long

40m to 100m

Adjustment of Receiving Light Intensity (Receiver)

Light Intensity Indicator

Alarm Indicator

Status Switch

Distance Selection Switch

Light Intensity Adjustment Volume

CAL

CAL

12

5.Turn and adjust the Light Intensity Adjustment Volume, looking at

the Light Intensity Indicator, so that only the green indicator

blinks.

Light Intensity Indicator

Light Intensity Level

Orange Green Red ------ Blinking

Too high

Orange Green Red ------ Blinking

Slightly high

Orange Green Red ------ Blinking

Adjusted

Orange Green Red ------ Blinking

Slightly low

Orange Green Red ------ Blinking

Too low

In spite of adjusting the Light Intensity Adjustment Volume to

maximum, if the orange indicator still blinks, the adjustment of light

axis or the setting of Distance Selection Switch may be

inappropriate.

Check the adjustment of light axis and the setting of Distance

Selection Switch.

In spite of adjusting the Light Intensity Adjustment Volume to

minimum, if the red indicator still blinks, the setting of Distance

Selection Switch may be inappropriate.

Check the setting of Distance Selection Switch.

6.Confirm that received light intensity level is adjusted (i.e. only the

green indicator is blinking). Put the Status Switch back to the

“NORM” position, and the adjustment of received light intensity is

completed. Close the cover immediately after the completion.

7.When the Status Switch is back to “NORM” position, the Detector

starts its initialization that takes 3 minutes. The Alarm Indicator of

the Receiver blinks during the initialization. The indicator turns off,

when the initialization completes and the Detector goes back to

the normal monitoring condition.

Adjustment of Receiving Light Intensity (Receiver)

13

8.After adjusting the Detector, the state of detector can be

monitored by using the Remote Station for Beam Detector. For

the details of monitoring, refer to the instruction manual of

Remote Station for Beam Detector LP04/ LP05.

〇Make sure that the voltage between K and C during monitoring is

within the following range, and not the range specified in the

instruction manual of the Remote Station.

Voltage range for monitoring

Approx. 2.08V to 2.23V

〇If the main cover is left open longer than 10 seconds after the Status

Switch has put back to the “NORM” position, put the Status switch

back to “CAL” position and perform the operation from 5. above again.

〇Keep clear the monitoring area (light axis) during initialization.

〇Sensitivity test must not be conducted during initialization. Make sure

that the Alarm Indicator of the Receiver finishes blinking before

sensitivity test.

Adjustment of Receiving Light Intensity (Receiver)

14

The sensitivity of detector (obscuration rate) and response time are

shown in the following table.

Distance between

Transmitter and Receiver

Sensitivity of activation

(central value)

Response

time

5m to less than 15m

30 %

4-10 sec

15m to less than 40m

40 %

4-10 sec

40m to 100m

65 %

4-10 sec

Put the light obscuration filter test unit (NKL-F2), which is sold

separately, just in front of the lens of Receiver to perform Activation

/Non-activation test. Use the filters in the test according to the

following table.

Distance between

Transmitter and Receiver

Activation test

Non-activation test

5m to less than 15m

40 % filter

20 % filter

15m to less than 40m

50 % filter

30 % filter

40m to 100m

80 % filter

50 % filter

Make sure that the Detector is activated within 30 seconds in

Activation test, and is not activated for 2 minutes in Non-activation

test, after placing the filter.

Sensitivity and Response Time

Sensitivity Test

15

1. The Detector performs compensation process for the slow change

of received light intensity which is caused by the contamination of

the lens or shifting of light axis. In the monitoring condition, the

Detector regularly checks if light intensity received by the Receiver

is appropriate. If specified light intensity cannot be received,

compensation process is performed to compensate light intensity.

2. The Detector sends a fault signal (short circuit between K and C)

to the Remote Station, if the light intensity continues to be less

than 43% or more than 130% of the initial value for 12 hours or

more.

Cause of Fault

Countermeasures

Light axis is misaligned

Adjust the light axis and the receiving light

intensity.

(Refer to “Handling Instructions” on page 4)

Lens cover is contaminated

Clean the lens cover and adjust the

receiving light intensity.

(Refer to “Handling Instructions” on page 4)

〇 After readjusting the light axis and the receiving light intensity,

in order to update the internal status of detector, make sure to

restart the detector. Press and hold the reset switch of Remote

Station for 5 seconds or more, after the initial setting is completed

(i.e. when approx. 3 minutes pass after the Status Switch is placed

at the “NORM” position).

(If restarting the detector cannot be easily done, please wait for the

automatic update of internal status, which is performed 20 minutes

after the completion of initial setting)

The sensitivity of detector is compensated also if the received light

intensity is reduced to less than 50 % of initial setting value. If the

received light intensity continuously decreases, the Detector goes

into alarm at the specific sensitivity level.

Compensation and Fault Signal

Sensitivity Compensation

16

The remote test function is supported by using Remote Station for

Beam Detector (LP04/ LP05) to connect the Detector to P-type

control panel. Test is remotely performed by operating the test

switch of the Remote Station. Refer to the Operation Instruction

Manual of the Remote Station for test method.

Test Function

17

Fire alarm systems are essential for providing early detection and

warning in the event of fire in order to save lives and properties and

minimize damage. After installed, periodical maintenance is

necessary to keep the facilities in proper condition.

Important

〇Note in cleaning

Antifog coating is applied to both lenses of the Detector. For cleaning, gently wipe off

with a dry soft cloth to avoid damage. Do not use thinner or other solvents.

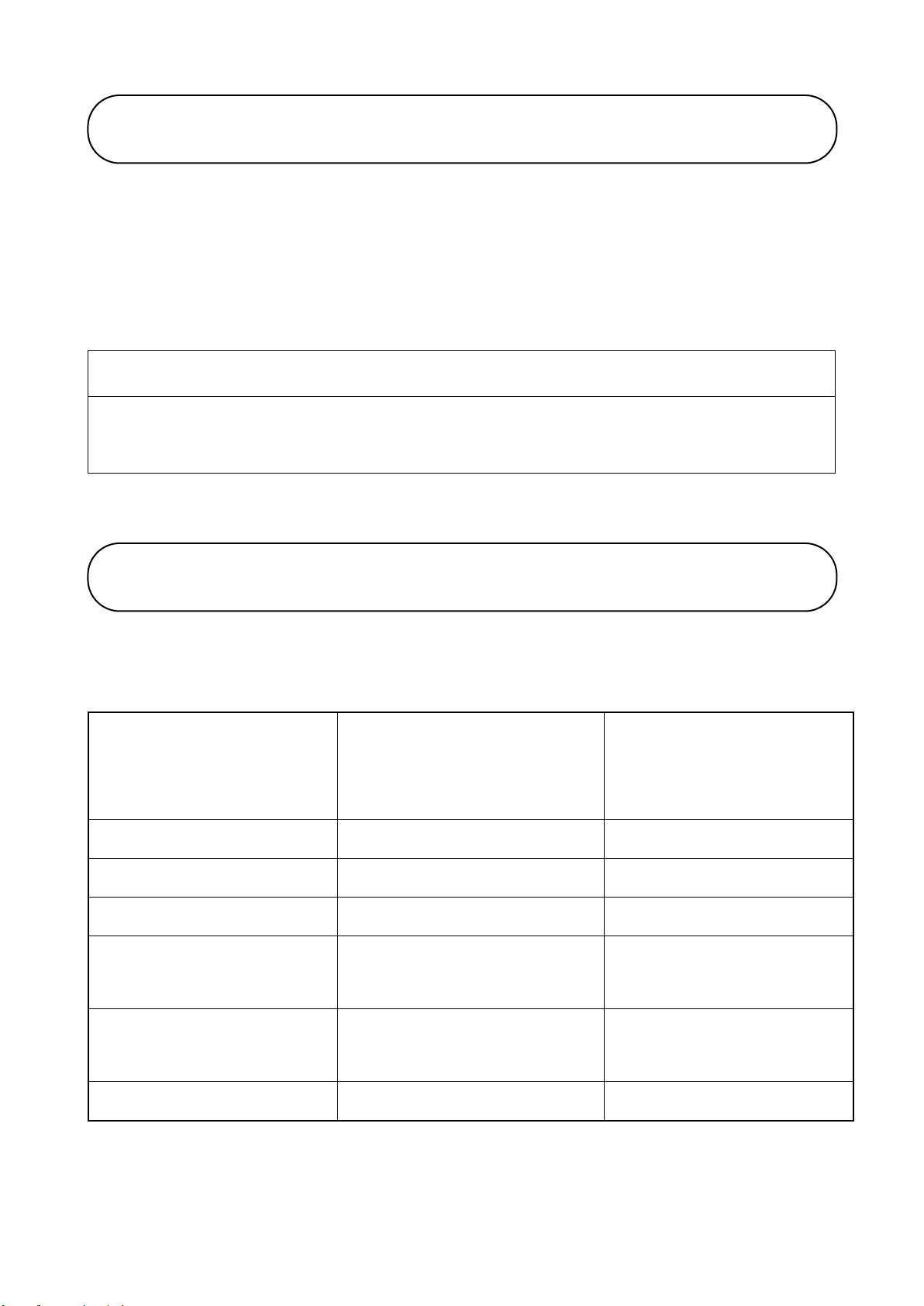

Each state of the indicator of Receiver is as follows.

State of the Detector

Receiver

Light Intensity

Indicator

Receiver

Alarm Indicator

Adjustment

Blinking

Blinking

Normal monitoring

Off

Off

Fire

Off

On

Low received light

(12 hrs or more)

Off

Off

High received light

(12 hrs or more)

Off

Off

No received light

Off

On

Maintenance

Indicator

18

Classification

Beam type smoke detector (with test function)

Model

CKLD-KPT2

Allowable Distance

5m to 100m

Sensitivity

Distance Sensitivity

5m to less than 15m :30%

15m to less than 40m :40%

40m to 100m :65%

Rated Current/ Voltage

L-C:Fire Nominal Voltage DC 24V

Monitoring current 760μA

Alarm current 65mA

K-C:Fault Nominal voltage DC 24V

Alarm current 65mA

T-C:Test Nominal voltage DC 24V

Alarm current 100mA

Indicator

Transmitter:Power Indicator(red LED)

Blinking in the monitoring state

Receiver: Alarm indicator(red LED)

Turning on in the alarm state

Other functions

Adjustment of receiving light intensity

Sensitivity compensation

Fault signal output

Terminal

Transmitter SL & SC (Transmission signal)×1 for each

Receiver L & C (Fire signal)×2 for each

T(Test signal)×1

K(Fault signal)×2

KC (Fault signal)×1

SL & SC (Transmission signal)×1 for each

Compatible control panel

1PM2, 1PM3

Remote Station

LP04/LP05

Temperature & humidity

-10℃ to 50℃

Relative humidity 0% to 95%(no condensation)

Note: This product should not be installed in excessive humid

or condensing conditions.

Weight

Transmitter Approx. 500g (including the base)

Receiver Approx. 520g (including the base)

54-5, 1-chome, Sasazuka, Shibuya-ku, Tokyo 151-8535, Japan

TEL: 81-3-5333-7021 / FAX: 81-3-5333-8615

https://www.nittan.com/english/

Specification

20.11B

Table of contents

Other Nittan Smoke Alarm manuals

Nittan

Nittan EVC-PY-IS User manual

Nittan

Nittan ST-P-AS User manual

Nittan

Nittan EVCA-P User manual

Nittan

Nittan EVC-P User manual

Nittan

Nittan Evolution-Advanced EV-DP User manual

Nittan

Nittan EVA-PYH User manual

Nittan

Nittan ST-P-OM User manual

Nittan

Nittan evolution EVC-P User manual

Nittan

Nittan EVA-PYH User manual

Nittan

Nittan Evolution EVC-DP User manual