FHF05 series manual v2204 5/43

Introduction

FHF05 series are the latest standard model for general-purpose heat flux measurement.

Models are available in five dimensions and sensitivities. Significantly thinner and more

flexible, FHF05 series replaces earlier models FHF01 to FHF04. All FHF05 models are very

versatile: they have an integrated temperature sensor and thermal spreaders to reduce

thermal conductivity dependence. It is applicable over a temperature range from –70 to

+120 °C. FHF05 series measures heat flux from conduction, radiation and convection.

Optionally, black BLK and gold GLD stickers are available for every sensor model to

separately determine heat transport by radiation and convection.

All FHF05’s measure heat flux through the object in which it is incorporated or on which it

is mounted, in W/m2. The sensor in FHF05 is a thermopile. This thermopile measures the

temperature difference across FHF05’s flexible body. A type T thermocouple is integrated

as well. The thermopile and thermocouple are passive sensors; they do not require

power.

Multiple small thermal spreaders, which form a conductive layer covering the sensor,

help reduce the thermal conductivity dependence of the measurement. With its

incorporated spreaders, the sensitivity of FHF05 is independent of its environment. Many

competing sensors do not have thermal spreaders. The passive guard area around the

sensor reduces measurement errors due to edge effects and is also used for mounting.

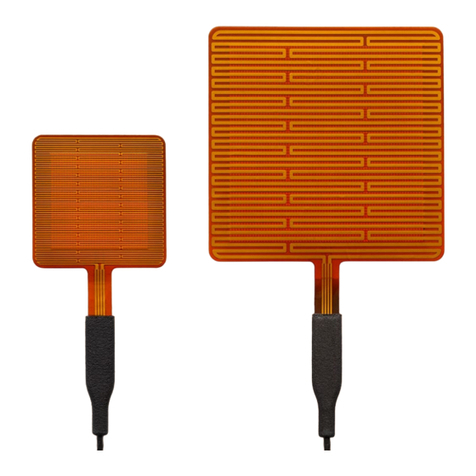

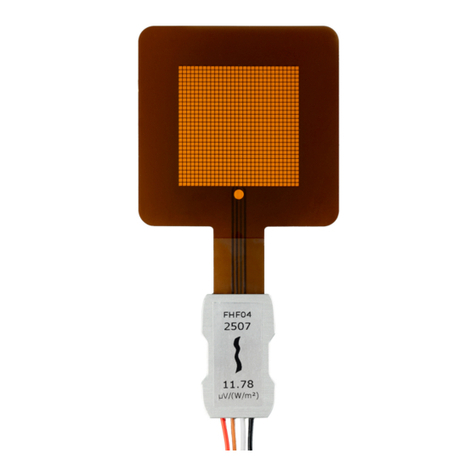

Figure 0.1 Model FHF05-50X50 foil heat flux sensor with thermal spreaders: thin, flexible

and versatile

Using FHF05 series is easy. It can be connected directly to commonly used data logging

systems. The heat flux in W/m2is calculated by dividing the FHF05 output, a small voltage,

by the sensitivity. The sensitivity is provided with FHF05 on its product certificate.

All FHF05’s have unique features and benefits: