NKE DualSense HeatPro User manual

User Manual

NKE DualSense HeatPro

Note

Check delivery for possible damage caused by transport without delay. Should

damage be detected, please inform carriers immediately.

As our products are subject to continuous improvement, we reserve the right

to make changes to this document.

INDUCTION HEATING 5

Operating conditions 5

SAFETY GUIDELINES 6

Safety precautions 7

Safety instructions 8

Safety features 9

INSTALLATION 10

Scope of delivery 10

Unboxing 10

Installation process 11

SETTING UP THE WORKPIECE 12

Choosing the yoke 13

Positioning the magnetic temperature probe(s) 14

OPERATION 15

Temperature Mode, using one sensor 16

Ramp Mode 17

Temperature Mode, using two sensors 18

Time Mode 19

User menu 20

MAINTENANCE 21

MALFUNCTION 22

Adjusting the yoke 22

Errors 23

SPECIFICATIONS 24

Dimensions 24

Workpiece dimensions 25

Technical data 26

Additional information 27

Electrical drawing 28

1

2

3

4

5

6

7

8

CONTENTS

4

5

1

NKE DualSense HeatPro induction heaters are used to heat rolling bearings. Other

metal components forming a closed circuit such as bushings, shrink rings, pulleys

and gears can also be heated. This will facilitate mounting where an interference t

is required.

Our range of standard heaters are designed to heat the workpiece to a maximum

temperature of 240ºC (464°F). Always place the temperature sensor on the

workpiece to check the heating cycle. When heating an object using Time Mode, the

heating cycle must be checked using an external temperature meter.

CAUTION

Bearings generally should only be heated to a maximum temperature of 120ºC

(248ºF). Do not use induction heaters for bearings or workpieces with dimensions

outside the ranges specied in this manual. Do not switch off the heater with the

main switch while heating cycle is running.

The heater is designed to be used in an industrial environment with an ambient

temperature of 0°C to 40°C (32°F to 104°F) and an atmospheric humidity between

5% and 90%, non-condensing. The induction heater is intended for indoor use only.

INDUCTION HEATING

OPERATING

CONDITIONS

6

SAFETY GUIDELINES

2

The operating instructions should always be followed when using an induction heater.

NKE Bearings shall not be held liable for damages caused by improper handling or

by use which does not comply with the designated purpose. Prerequisites for the

operator: He/she must be authorised for use of the heater and must be familiar with

the safety precautions.

In order to prevent danger or damage to the induction heater or workpiece, follow

these guidelines:

`All repairs must be carried out by an ofcial NKE Bearings distributor.

`Use original spare parts only.

`Protect the heater from water or very high humidity.

`Protect the heater core and yokes against corrosion, damage and deformation.

`Only preheat bearings to max. 120°C (248°F).

`To ensure proper operation of the device, it is important to provide the device

with the latest software updates. A description can be found in chapter 5 -

OPERATION, page 20 - USER MENU.

7

SAFETY

PRECAUTIONS

`Since a magnetic eld 4&5 is generated by the induction heater, people wearing

a pacemaker 1or other implant device 2should not work or be in the immediate

vicinity of the device. Other sensitive equipment such as wrist watches, magnetic

carriers, electronic circuits, etc. 3might also be affected. The safety distance is

0.5 meters (19”).

`Use protective gloves as protection against burns to hands. The gloves delivered

are suitable for use up to temperatures of 150°C (302°F).

`Hot surface, avoid contact 6.

`Do not operate an induction heater in areas where there is risk of explosion.

`Wear safety shoes 8.

1. 2. 3. 4.

8.7.

6.5.

8

`The user should have an appreciation of the contents of this user manual, and

be familiar with safe workshop practices.

`Follow the user manual at all times.

`Ensure that the induction heater operates at the correct supply voltage. If the

heater is not supplied with a plug, changes should only be made by a suitably

qualied electrician.

`Do not use or store the heater in humid environments. The heater is designed

for indoor use only.

`Use proper handling equipment, appropriate for the weight of the workpiece

and/or yoke. Never support components with a metal cable or have any hanging

in the proximity of the magnetic eld. Extremely high currents can flow through

the cable causing it to heat up quickly, resulting in a risk of burning.

`Do not place any metal objects near the yokes and poles.

`Place heater on a stable, horizontal surface.

`Keep a minimum distance of 1 meter (38”) to surrounding objects.

`Use only in well ventilated areas.

`Do not heat objects containing oil, grease or similar substances. Prevent

possible generation of fumes and smoke.

`Do not inhale fumes or smoke from heated parts.

`Do not move or lift heater when warm after heating cycle.

`Do not touch the heater core during heating cycle.

SAFETY

INSTRUCTIONS

9

Should an error occur during the heating process, the induction heater will

automatically stop. The corresponding error will be displayed on screen. In the case

of user error, the display indicates what steps are to be taken to correct the problem.

More information about the types of errors can be found in chapter 7 - ERRORS.

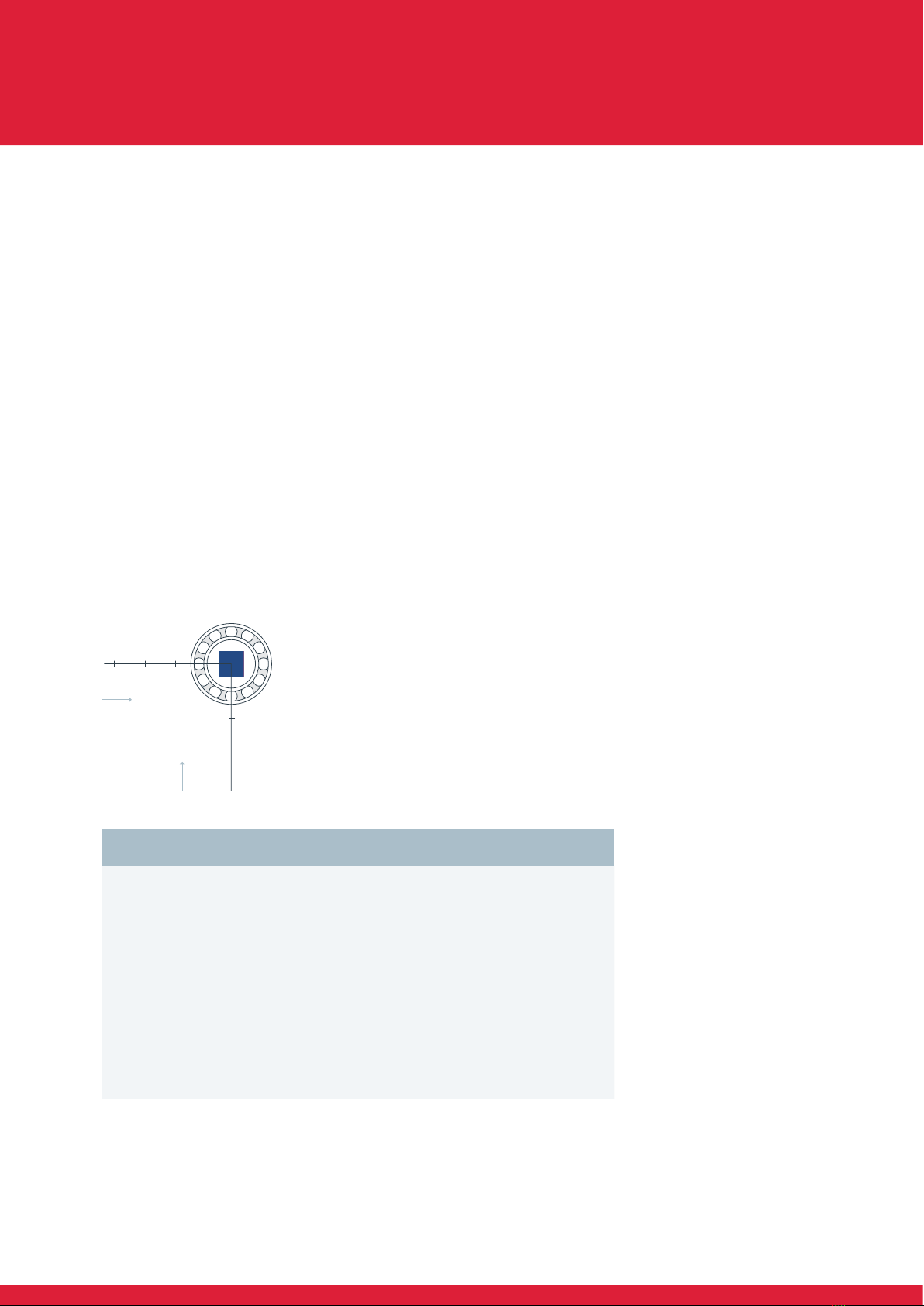

An induction heater produces an electromagnetic eld within a coil to transfer energy

to a workpiece. The table below shows values of the flux density in microTesla

(µT). These measurements can be used as a guide conforming to local regulations

regarding the maximum time exposure to magnetic elds. Different congurations

may give different values. It is impossible to provide

values for all combinations as the variety of bearing

types in combination with the different yokes is

large.

Total 50Hz RMS eld for magnetic measurement results. Max. magnetic flux in safe

exposure area, according to the German BG 11 Regulations is 423 µT.

SAFETY

FEATURES

MP1x 81 249 283

MP2x 16 34 74

MP3x 1 11 28

MP1y 156 181 185

MP2y 27 24 78

MP3y 9 9 41

Measurement position (cm) B-eldtotal (µT)

MP2x

60

MP1x

30

MP3x

90

30

60

90

MP1y

MP2y

MP3y

X

(cm)

Y

(cm)

MNKE DualSense HeatPro 400 500 600

10

INSTALLATION

3

SCOPE OF

DELIVERY

Contents of the box

1. NKE DualSense HeatPro 400 / 500 / 600

2. Yoke(s)

3. Temperature probes

4. Heat-resistant gloves

5. User Manual

6. Quickstart guide

Note

The NKE DualSense HeatPro 400 comes with yokes 10, 14, 25, and 40 included.

NKE DualSense HeatPro 500 includes yoke 50 and NKE DualSense HeatPro 600

includes yoke 70.

Follow the instructions specic for this heater on the supplied Quickstart guide. If

the Quickstart guide is not included in this box, please contact your distributor. The

induction heater must always be transported in the original box, thus also on return

to the manufacturer/distributor.

UNBOXING

11

Turn main switch from 0 to 1. The device will emit a short

beep and the touchscreen display will show the main

menu. The induction heater is now ready for use.

INSTALLATION

PROCESS

Ensure that supply voltage and current meet the specications. These can be found

on the type plate at the back of the induction heater.

Each induction heater is provided with a plug, but there are

a large number of plug types. Should the plug not t your

power supply, a suitable plug must be afxed by a qualied

electrician. Voltages may differ for customized devices.

Insert the plug into a shockproof wall socket and then

connect the device to mains electricity.

Phase Neutral Ground

Voltage

115V Green/YellowWhite

Black

230V Green/Yellow

BlueBrown

Phase X / L1 Phase Y / L2 Ground

Voltage

460-575V Green/Yellow

400-440V Green/Yellow

Black (USA) Black (USA)

Brown Blue

Brown

Black (USA)

Blue

Black (USA)

400 / 500

400 / 500

600

600

12

SETTING UP THE WORKPIECE

4

`Use appropriate hoisting equipment for heavy components and yokes. Manual

lifting of heavy objects is a common cause of injury.

`Wear safety shoes during these procedures.

`The weight of the work-piece should not exceed the maximum weight as shown

in chapter 8 - WORKPIECE DIMENSIONS. Exceeding these limits may result in

catastrophic equipment failure and may also lead to personal injury.

`Ensure there is no contact between the mains cable and the workpiece. Damage

to the cable may result in electrocution.

`Never support components with a metal cable and avoid metal cables hanging

in the proximity of the magnetic eld. Extremely high currents can flow through

the cable causing it to heat quickly, resulting in risk of burning.

The workpiece can be set up in two different ways and must never touch the housing.

Small objects are to be heated in a vertical position.

VERTICAL HORIZONTAL

13

`Choose largest possible yoke which ts the diameter of the workpiece. Position

the workpiece onto the yoke and place the yoke with the machine milled surface

on the poles of the heater core.

`Always make sure that the workpiece avoids direct contact with the housing of

the heater.

`When a heating cycle is completed, always wear heat-resistant gloves. The

maximum temperature of the workpiece on a standard induction heater is

240°C (464°F).

`Always treat yokes carefully. Falling, bumping, etcetera can damage the yoke

and/or cause personal injury. Always store the yoke safely immediately after use.

CHOOSING

THE YOKE

14

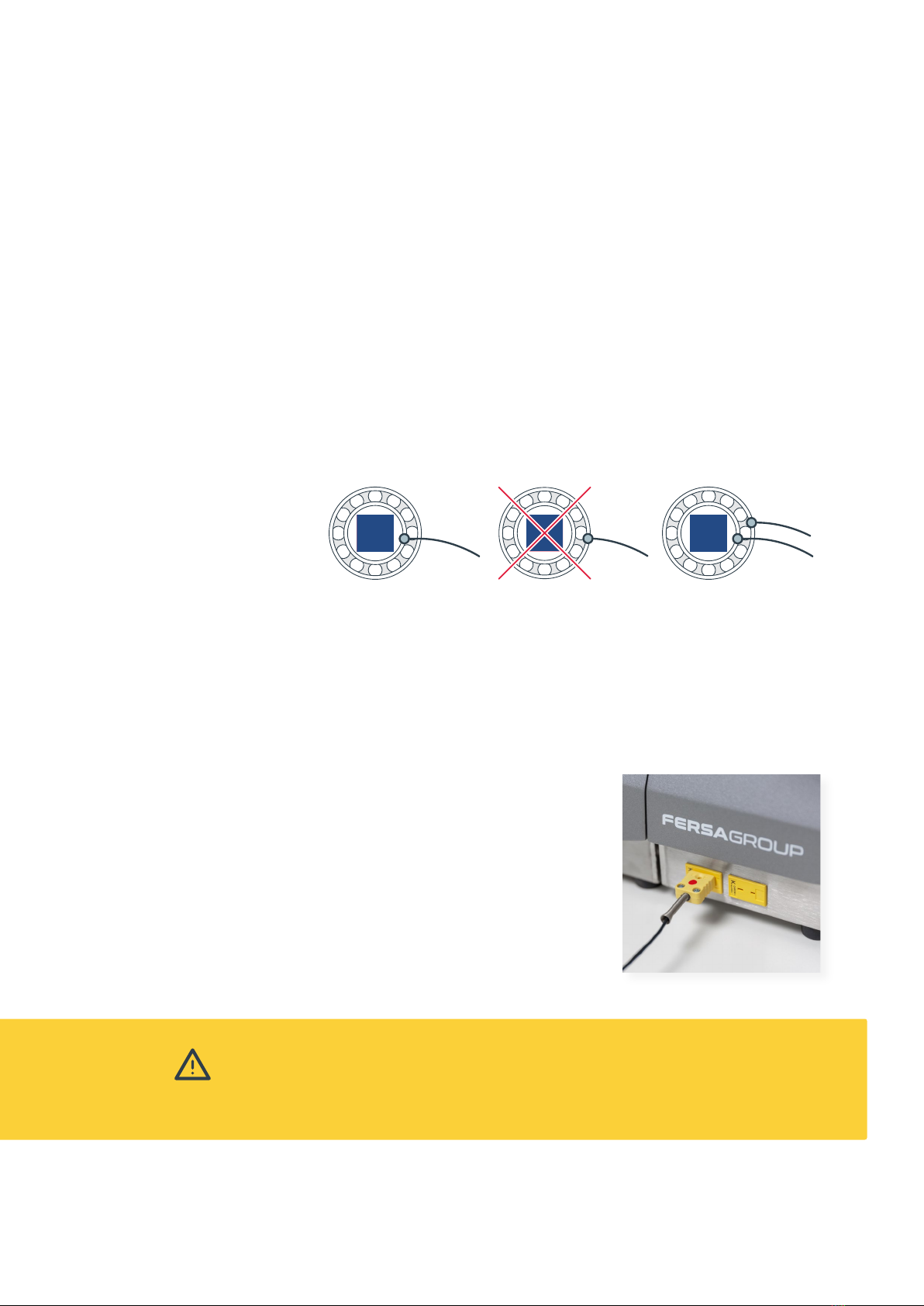

`Always use the magnetic temperature probe (hereafter referred to as the

‘probe’) for heating in Temperature Mode or Ramp Mode.

`Place the probe on the workpiece, close to the bore. Make sure that the surface

used for the probe is free of grease and/or oil.

`If the induction heater has two probes: place one close to the bore and the other

on the outer ring.

`Our standard probes are suitable for operation up to a maximum temperature of

240°C (464°F). The connection between magnet and probe will break above the

maximum temperature. If this occurs when operating in Temperature Mode, the

heater will turn itself off as the probe will fail

to register any increase in the temperature

over a set period of time. Probes for higher

temperatures are optional.

`Connect the probe by inserting the plug into

the socket at the front of the heater, with the

red dot facing upwards.

POSITIONING

THE MAGNETIC

TEMPERATURE

PROBE(S)

Treat the probe with care. It is a valuable part of the heater and can easily be

damaged through careless handling. After use, we suggest that it be placed on the

side of the vertical pole.

CAUTION

15

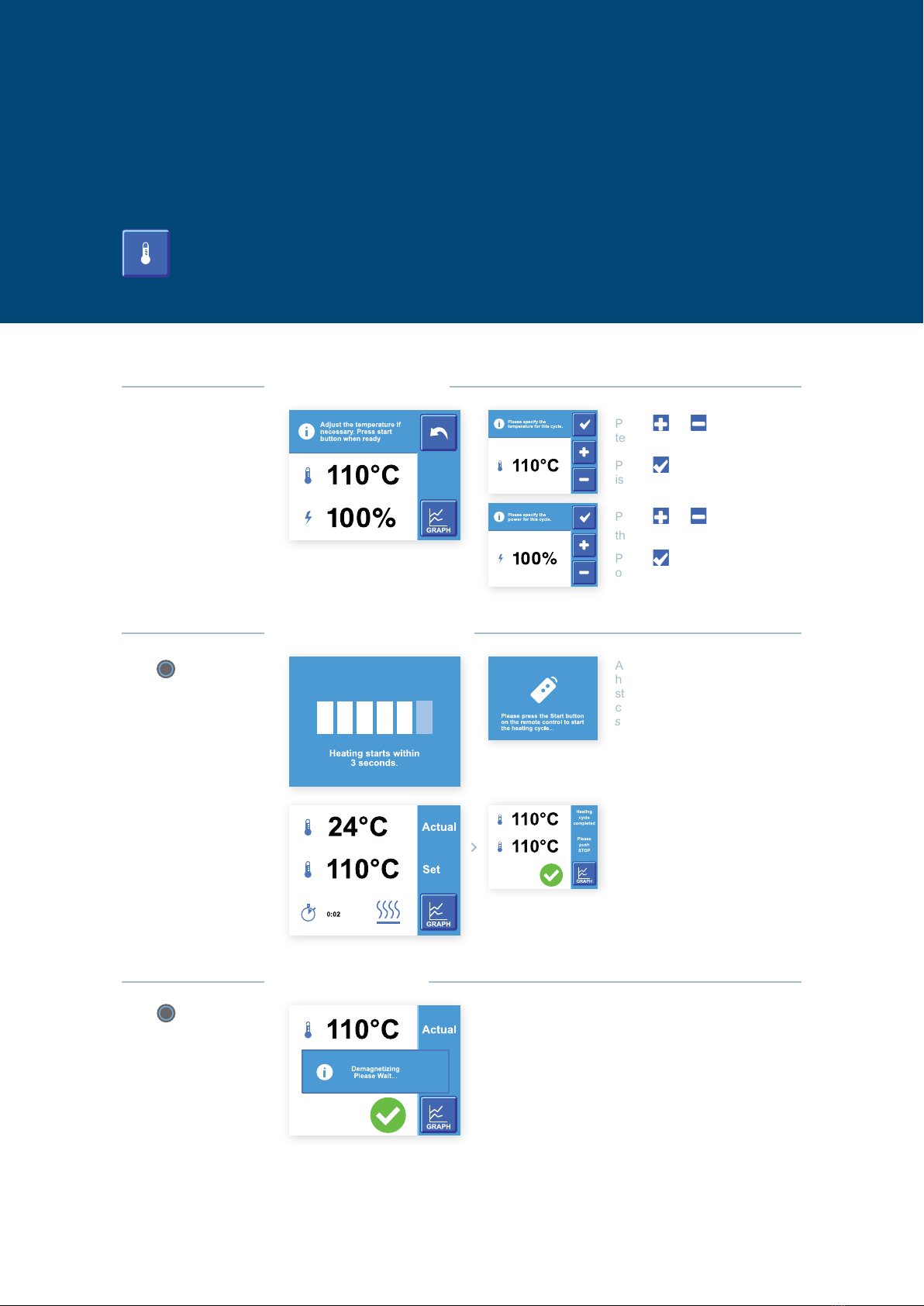

When the induction heater is turned on, the homescreen can show up to four buttons

with different modes; Time Mode is always available. Temperature Mode (with 1

sensor) and Ramp Mode will be enabled when one sensor is inserted.

An extra Temperature Mode (with 2 sensors) will be enabled when a second sensor

is inserted.

The start/stop button is used for starting heating cycles in one of the modes, or to

stop a heating cycle at any time.

When a heating cycle is complete, or stopped prematurely, the program will return

to the main screen of the heating mode. A graph can be requested with the graph

button .

Every mode has three stages:

1. Preparation - The user can change the temperature and/or time.

2. Heating process - The induction heater starts the heating cycle.

3. Completion - The heating cycle has ended.

OPERATION 5

16

Press to start the

heating cycle and stand

at a safe distance.

There is a 5 second

countdown before the

cycle starts.

When the preset

temperature has been

reached the heater will

hold that temperature.

Press to stop the

heating cycle.

The induction heater will

now demagnetize.

Hereafter it will return to

the rst screen.

Alternatively, to start the

heating process, press the

start button on the remote

control. Remote control is

sold separately.

1. PREPARATION

2. HEATING PROCESS

3. COMPLETION

Press or to change the

temperature (max. 240°C).

To change the

temperature press A, to

change the max. power

output press B.

Otherwise proceed to

step 2.

Press when the temperature

is set.

TEMPERATURE MODE, ONE SENSOR

Press or to change

the max. power output.

Press when the max. power

output is set.

A

B

17

Press to start the

heating cycle and stand

at a safe distance.

There is a 5 second

countdown before the

cycle starts.

When the preset

temperature has been

reached the heater will

hold that temperature.

Press to stop the

heating cycle.

The induction heater will

now demagnetize.

Hereafter it will return to

the rst screen.

Alternatively, to start the

heating process, press the

start button on the remote.

Remote control is sold

separately.

1. PREPARATION

2. HEATING PROCESS

3. COMPLETION

Press or to change the

temperature (max. 240°C).

Press or to

change the time.

To change the

temperature press A, to

change the heating time

press B.

Otherwise proceed to

step 2.

Press when the temperature

is set.

Press when the time is set.

RAMP MODE

A

B

18

Press to start the

heating cycle and stand

at a safe distance.

There is a 5 second

countdown before the

cycle starts.

When the preset

temperature has been

reached the heater will

hold that temperature.

Press to stop the

heating cycle.

The induction heater will

now demagnetize.

Hereafter it will return to

the rst screen.

Alternatively, to start the

heating process, press the

start button on the remote.

Remote control is sold

separately.

1. PREPARATION

2. HEATING PROCESS

3. COMPLETION

Press or to change the

temperature (max. 240°C).

Press or to change

the Δtemperature.

To change the

temperature press A

To change the Δ

temperature press B.

Otherwise proceed

to step 2.

Press when the temperature

is set.

Press when the temperature

is set.

35

35

TEMPERATURE MODE, TWO SENSORS

A

B

19

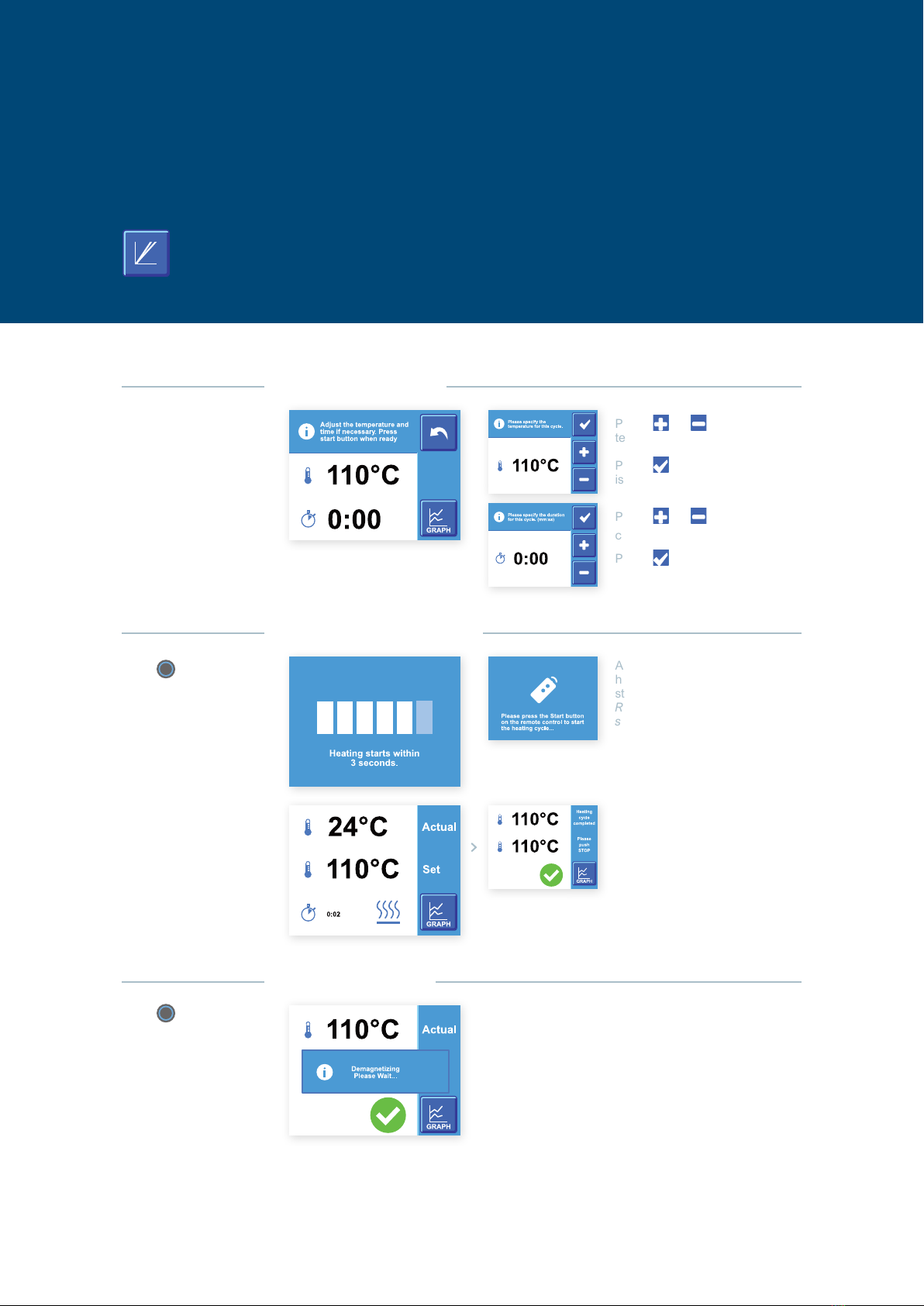

Press to start the

heating cycle and stand

at a safe distance.

There is a 5 second

countdown before the

cycle starts.

Press to stop the

heating cycle.

The induction heater will

now demagnetize.

Hereafter it will return to

the rst screen.

Alternatively, to start the

heating process, press the

start button on the remote.

Remote control is sold

separately.

TIME MODE

1. PREPARATION

2. HEATING PROCESS

3. COMPLETION

Press or to change

the time (max. 99:59).

To change the heating

time press A.

To change the max.

power output press B.

Otherwise proceed to

step 2.

Press when the time

is set.

Press or to change

the max. power output.

Press when the max. power

output is set.

A

B

20

USER MENU The user menu can be accessed by pressing the start/stop button for 8 seconds.

Within this menu the user can view and/or change the following settings:

Calibration Sensor 1

The temperature of sensor 1 can be set if it

is calibrated incorrectly.

Calibration Sensor 2

The temperature of sensor 2 can be set if it

is calibrated incorrectly.

Start Delay (5)

When the user starts the heating process

there will be able to get to a safe distance.

The factory set delay is 5 seconds.

Date Format (DD/MM)

The Date Format can be set to Day/Month or

Month/Day.

Screensaver (0)

The settings for the screen saver can be

set here, ranging from off (0) to a certain

number of minutes.

Time (HH:MM)

The current time can be set here. This

information will be used when datalogging

the heating cycle.

Date (MM/DD)

The current date can be set here. This

information will be used when datalogging

the heating cycle.

Year (YYYY)

The current year can be set here. This

information will be used when datalogging

the heating cycle.

Time Format (24:00)

The Time Format can be set to 24:00 or AM/

PM.

Temp. Hold Hysteresis (5°F)

The max. temperature difference before the

heater starts heating again can be set here.

Auto Sensor Select (On)

When this setting is turned on the heater

can recognize the difference between

Sensor 1 and Sensor 2 and assign the order

automatically.

Time Range (MM:SS)

The Time Range can be switched between

MM:SS (minutes and seconds) and HH:MM

(hours and minutes). This Time Range

setting will be applied to the available

range when using Time Mode.

Exit (Discard Changes)

Any recent adjustments will

be discarded and the user returns to the

homescreen.

Update Firmware GUI

When a USB drive (containing an update

for the User Interface) is inserted this

option will show. Press and follow the on-

screen instructions to update the heater.

Update Firmware PWR

When a USB drive (containing an update

for the Powerboard) is inserted this option

will show. Press and follow the on-screen

instructions to update the heater.

Update Languages

When a USB drive (containing an update

for texts) is inserted this option will show.

Press and follow the on-screen instructions

to update the Fonts and Texts.

Cur. Version GUI

The current version of the User Interface is

shown here.

Cur. Version PWR

The current version of the Powerboard is

shown here.

Number of Cycles

The Number of Cycles shows the amount

of heating cycles for the induction heater.

Heating Timer

The Service Counter shows the total time

(all heating cycles added together) for the

induction heater.

Reset to Factory Settings

Each user setting will be reset

to its original factory values.

Languages

The languages of the heater can be changed

to English, Spanish, German, and French.

Default Temperature (230°F)

The default temperature can be set. The

factory set temperature

is 110°C (230°F).

Temp. Hold (On)

Temperature hold can be turned on or off.

During pendulation the heater will heat to

the set temperature and cools down by 3°C,

then heats again to the set temperature, etc.

Temp. Hold Duration (5:00)

The duration of the temperature hold can be

set. With the factory set duration of 5:00 min

the heater pendulates indenitely.

Completion Signal (On)

The buzzer can be turned on or off. When

on the heater will buzz when it reaches the

set temperature. The factory set value is ‘on’.

Temperature Unit (°F)

The temperature unit can be changed

to Celsius or Fahrenheit. The factory set

temperature unit is Celsius, Fahrenheit in

the USA.

Maximum Temp. Delta (90°F)

The maximum adjustable temperature

difference between the two sensors can

be set.

Remote Control (Off)

The remote control function can be turned

on or off. Remote control is sold separately.

U0

U1

U2

U3

U4

U5

U6

U7

U8

U9

U10

U12

U13

U14

U15

U16

U17

U18

U19

U20

U22

U24

U26

U27

U28

U29

U30

U31

U32

Table of contents

Other NKE Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Futech

Futech Gyro GS user manual

Lenntech

Lenntech Testomat 2000 PO4 operating instructions

Keller

Keller LEO1-Ei manual

Smart Storm

Smart Storm Universal Smart Meter instruction manual

Optical dimensions

Optical dimensions Lasercheck 6212C Operations and Specification Manual

Datcon

Datcon PQRM5300 33 U I Series instruction manual