NKE PIEZOMETER User manual

USER GUIDE PIEZOMETRE

33-30-077-

Piezomètre_UTI UK

Rev : 3 Page 1/41

nke Tel +33 (0)2-97-36-10-12 Fax +33 (0)2-97-36-55-17 http://www.nke-nstrumentation.com PAGE 1/41

USER GUIDE PIEZOMETRE

33-30-077-

Piezomètre_UTI UK

Rev : 3 Page 2/41

nke Tel +33 (0)2-97-36-10-12 Fax +33 (0)2-97-36-55-17 http://www.nke-nstrumentation.com PAGE 2/41

Sommaire

SOMMAIRE

1.

INTRODUCTION 4

2.

OVERVIEW AND DESIGNATION 6

2.1

« D

ATING

&

S

TORAGE

M

ODULE

»

(MDS) 6

2.2

B

ASE PLATE

7

3.

LANCE ASSEMBLY PROCEDURE 8

3.1

L

ANCE ELEMENT

8

3.2

S

PECIAL TOOLS

9

4.

ASSEMBLY PROCEDURE 10

4.1

B

OTTOM END ASSEMBLY WITH BUS CONNECTION

10

4.2

S

TEP

-1 :

B

OTTOM SLEEVE ASSEMBLY WITH STANDARD TUBE

11

4.3

S

TEP

-2 :

W

INPIEZO CHECK

11

4.4

S

TEP

-3 :

N

EXT SLEEVE ASSEMBLY WITH BUS CONNECTION

11

4.5

MP&T

BUS

–

MDS

CABLE ASSEMBLY WITH BULKHEAD AND FIRST SLEEVE

12

4.6

C

HECK THE OPERATION

12

4.7

O

IL FILLING OF THE TUBE

12

4.8

F

INALIZE WITH A LANCE TUBE

13

5.

SOFTWARE WINPIEZO 14

5.1

P

RESENTATION AND

U

SE

15

5.2

C

OMMUNICATION MODE

15

5.2.1

Vitesse de communication du bus et configuration des Switchs de la carte MDS 15

5.3

I

NSTALLATION

16

5.4

I

NSTALL THE DRIVERS

16

5.4.1

Procedure : 16

5.4.2

Determine the number of the serial communication port . 16

5.5

D

ESIGNATION OF SOFTWARE COM

17

5.6

O

VERVIEW

18

5.7

"MDS

P

ROGRAMMING

"

FUNCTION

18

5.8

S

EQUENCE OF OPERATING MODES FOR THE

MDS

MODULE

19

5.8.1

BOOT mode 19

5.8.2

SYNCHRONIZATION mode 20

5.8.3

BUS mode 20

5.8.4

Le mode double cadences 21

5.8.5

ACQUISITION Mode 22

5.8.6

WAITING mode 22

5.8.7

RECORDING Mode 22

5.8.8

RECORDED Mode 22

5.9

D

ISPLAY THE DATA FILES

23

5.10

CALIBRATION

FUNCTION 24

5.11

D

ESCRIPTION OF COMMANDS

24

5.12

P

ROCEDURE

24

5.13

E

XPORTING THE GRAPH MEASUREMENTS

. 25

6.

COMMUNICATION INTERFACE 26

6.1

D

ESIGNATION OF THE EQUIPMENT

26

USER GUIDE PIEZOMETRE

33-30-077-

Piezomètre_UTI UK

Rev : 3 Page 3/41

nke Tel +33 (0)2-97-36-10-12 Fax +33 (0)2-97-36-55-17 http://www.nke-nstrumentation.com PAGE 3/41

6.2

D

ESCRIPTION OF THE INTERFACE

26

6.3

U

SE WITH

"MDS

MODULE

" 26

6.4

U

SE WITH

"MP&T" 26

1. SHIP CARACTERISTICS 28

1.1.

DECK

(A

FRAME DEPLOYMENT

) 28

2. LANCE INSTALLATION (FROM 6 TO 15M) 29

2.1.

A

FRAME LAUNCHING

–

F

ILLING IN STOP

29

2.2.

P

AY OUT

30

2.3.

C

ALIBRATION STOP

31

2.4.

L

ANCE PENETRATION

32

2.5.

V

ERTICALITY CONTROL

33

2.6.

D

EAD WEIGHT RECOVERY

34

3. LANCE RETRIEVAL (FROM 6 TO 15M) 35

3.1.

R

ETRIEVAL OF PIEZOMETER

35

3.2.

H

OOK UP

36

3.3.

R

ETRIEVAL

37

3.4.

P

IEZOMETER RECOVERY

38

7.

1 MODE YOYO 39

7.1

G

REEMENT

: 39

7.2

P

ROCEDURE DE MISE A L

'

EAU

: 39

8.

SUPPORTING DOCUMENTS 40

8.1

A

SSEMBLY SHEET

41

USER GUIDE PIEZOMETRE

33-30-077-

Piezomètre_UTI UK

Rev : 3 Page 4/41

nke Tel +33 (0)2-97-36-10-12 Fax +33 (0)2-97-36-55-17 http://www.nke-nstrumentation.com PAGE 4/41

1. INTRODUCTION

The piezometer is an instrument that consists of an expendable instrumented lance driven into

the sediment by gravity, based on the principle of a Kullenberg corer, and a retrievable module

that includes data storage and power supply. The sensors in the lance (torque, differential

pressure and temperature) are spaced at predetermined intervals in the lance.

The differential pressure sensors measure the difference between the hydrostatic pressure at the

water/sediment interface and the pressure in the sediment at the sensor via a porous stone filter.

The temperature sensor located as close to the porous stone as possible measures the

temperature of the sediment.

The measurements provided by the pressure/temperature sensors are sampled at regular

intervals.

The data is stored in digital format in a container that also houses the power supply.

After triggering an acoustic release, this container rises to the surface using buoyancy. Surface

tracking is provided by a system that comprises a flag, a beacon and a VHF radio.

The piezometer can be used in "yo-yo" mode, whereby it remains connected to the coring cable,

with a measurement time of a few hours, while the ship remains directly above the station. Once

the measurement is made, the piezometer and its tube are retrieved by heaving the coring cable.

In "yo-yo" mode, the acoustic release system, surface tracking system and trip gear are not

used.

In both modes, a query sent to an acoustic release may provide the tilting angle of the system

after it has sunk into the sediment.

The optional "MDS module" can manage up to two measuring systems at the same pressure

and provides data storage. It also includes an interface for configuration and calibration of the

instrument, as well as an interface to connect the instrument to a potential ocean bottom

observatory, which will provide real time data transmission to the user.

The instrumented lance has "connections" spaced at predetermined intervals, which

accommodate two types of sensors:

- A temperature sensor (CTN) with a measurement range of 0°C to +50°C

- A differential pressure sensor +/- 2 bar

Inclinometers integrated to the module indicate if the system is poorly sunk (e.g. buckling)..

USER GUIDE PIEZOMETRE

33-30-077-

Piezomètre_UTI UK

Rev : 3 Page 5/41

nke Tel +33 (0)2-97-36-10-12 Fax +33 (0)2-97-36-55-17 http://www.nke-nstrumentation.com PAGE 5/41

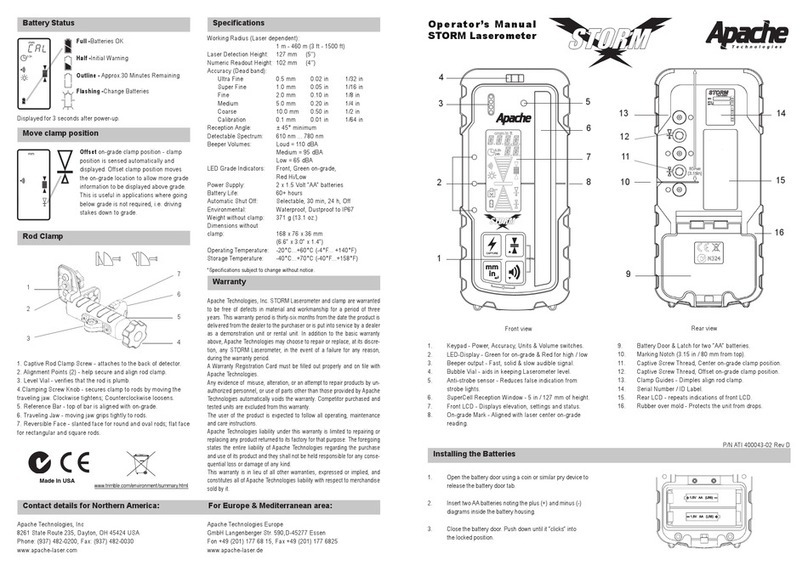

Vue d'ensemble du piézomètre complet

USER GUIDE PIEZOMETRE

33-30-077-

Piezomètre_UTI UK

Rev : 3 Page 6/41

nke Tel +33 (0)2-97-36-10-12 Fax +33 (0)2-97-36-55-17 http://www.nke-nstrumentation.com PAGE 6/41

2. OVERVIEW AND DESIGNATION

2.1 « Dating & Storage Module » (MDS)

The « Dating & Storage Module »integrates a batteries Pack 3S7P LS26500 SG; 10,8V 54Ah

and a « SD Card » which contains different files according:

- File format measure « xml »

- Configuration File « cfg »

- The logger « log »

The position of the container is given by the two inclinometer mounted on the board electronic

board.

USER GUIDE PIEZOMETRE

33-30-077-

Piezomètre_UTI UK

Rev : 3 Page 7/41

nke Tel +33 (0)2-97-36-10-12 Fax +33 (0)2-97-36-55-17 http://www.nke-nstrumentation.com PAGE 7/41

2.2 Base plate

The « Base plate » is equipped with « Cônes »' at the corners and two « mobile tab » that are

used to receive the« Ballast».

In its upper part is integrated « skirt ».mounted on three « silent blocks » where the « MDS »

enclosure via the two postures clamps is fixed.

The «

Bulkhead

» receiving the "arrow" is assembled from beneath using the four bolts M10x30

USER GUIDE PIEZOMETRE

33-30-077-

Piezomètre_UTI UK

Rev : 3 Page 8/41

nke Tel +33 (0)2-97-36-10-12 Fax +33 (0)2-97-36-55-17 http://www.nke-nstrumentation.com PAGE 8/41

3. LANCE ASSEMBLY PROCEDURE

3.1 Lance element

The lance comprises the elements described below:

Bulkhead : Allows the lance to be mechanically

connected to the ballast part of the piezometer. It will

receive the first tube of the lance.

First connecting tube:

Provides the connection between

the bulkhead and the first sensor sleeve.

The tube's length is 75 cm

MP&T Bus – MDS cable

: This cable allows the bus from

the firs

t sensor sleeve to be connected to the MDS

container.

Connection to the container is made via the 8-pin

Subconn connector. Connection to the bus is made via

the 6-pin “Micro-Fit” connector.

Sensor sleeve:

Allows two tubes from the lance to be

connect

ed. It contains the MPT card and the differential

pressure and temperature sensor.

The first sleeve is unique in that is has a 4-

pin connector

and a 6-

pin connector. All others are reversible (identical

4-pin connectors)

Contains 60 ml of oil after oil filling of the system.

USER GUIDE PIEZOMETRE

33-30-077-

Piezomètre_UTI UK

Rev : 3 Page 9/41

nke Tel +33 (0)2-97-36-10-12 Fax +33 (0)2-97-36-55-17 http://www.nke-nstrumentation.com PAGE 9/41

Bus connection

: reversible cable used to connect the

transmission bus. The sizing of these cables depends on

the length of the tubes used to form the lance. A cannula

with a 4-pin Micro-Fit connector is fitted at each end.

Contains 20 ml of oil per metre.

Connecting tube: They are reversible. Currently

available in three lengths (0.75, 1.5 and 3 m)

Equipressure bladder:

Allows a potential lack of oil to

be compensated.

100 ml capacity.

Lance tube : Final element of the piezometer lance.

3.2 Special tools

Vacuum pump: Allows oil filling of the

communication bus.

Beaker: Used to fill the equipressure bladder.

Preferably use a model with a hole at the bottom, a

connecting pipe and a valve..

USER GUIDE PIEZOMETRE

33-30-077-

Piezomètre_UTI UK

Rev : 3 Page 10/41

nke Tel +33 (0)2-97-36-10-12 Fax +33 (0)2-97-36-55-17 http://www.nke-nstrumentation.com PAGE 10/41

4. ASSEMBLY PROCEDURE

To complete the assembly of a piezometer lance, we start from the bottom end of the lance and

finish with the bulkhead, which weighs around 20 kg.

To facilitate the work, arrange the sleeve numbers in the ascending order, starting from the top

end of the lance. The first sleeve with a 6-pin connector will not necessarily bear the lowest

number.

Description of the important steps of the assembly:

4.1 Bottom end assembly with bus connection

•Install the 6 joints on the sleeve using a minimum of grease

•Install the joint on the cannulas of the bus connection using a

minimum of grease

•Connect the card side of the sleeve to the bus connection

•Stow the connector and the wires inside the cannula

•Stow the wires inside the sleeve by rotating it

•Grease and fit the cannula onto the sleeve (two M5 screws)

USER GUIDE PIEZOMETRE

33-30-077-

Piezomètre_UTI UK

Rev : 3 Page 11/41

nke Tel +33 (0)2-97-36-10-12 Fax +33 (0)2-97-36-55-17 http://www.nke-nstrumentation.com PAGE 11/41

4.2 Step-1 : Bottom sleeve assembly with standard tube

•Grease the sleeve on the tube side (grease barrier)

•Check the cleanliness of the tube's inlet and grease it

•Hook a mounting tool to the cannula and insert it inside the

tube

•Once the sleeve / tube assembly is complete, use an M10

screw to secure the assembly

4.3 Step-2 : Winpiézo check

•Connect a data acquisition module at the head of the lance (MDS)

(for more details, refer to chapter Erreur ! Source du renvoi introuvable. to use the

software)

•For this test, the 1st sleeve (6-pin Micro-Fit) must be inserted between the last sleeve and

the data acquisition module

•Using the “Winpiézo” application, ensure the sensor is present on the bus.

4.4 Step-3 : Next sleeve assembly with bus connection

•Repeat step 1.

The only difference involves connecting the side of the sleeve

without the electronic board to the cannula. Use the steel wire to

pull the cannula out of the tube.

•Repeat steps 1, 2 and 3 as necessary

When all the sleeves are assembled and only the first tube

remains to be mounted:

USER GUIDE PIEZOMETRE

33-30-077-

Piezomètre_UTI UK

Rev : 3 Page 12/41

nke Tel +33 (0)2-97-36-10-12 Fax +33 (0)2-97-36-55-17 http://www.nke-nstrumentation.com PAGE 12/41

4.5 MP&T bus – MDS cable assembly with bulkhead and first sleeve

•Assemble the first tube and the bulkhead using 4 M10 screws

•Insert the MPT bus - MDS cable inside the bulkhead/first tube assembly

using the steel wire

•Attach the bus cable to the bulkhead using 2 M6 screws

•Repeat steps 1, 2 and 3

•Place two 100 cm "Tricofuel" hoses on the two water filling cannula fittings.

4.6 Check the operation

•Connect “ The Communication interface MDS” at the head of the lance

•Check the electronic module

•Test all the sensors (nb, temp., Pressure, curve, etc etc)

•Check the order of the sensors

4.7 Oil filling of the tube

Each sleeve contains approximately 6 cl, and 2 cl are required for every metre of diam. 8

Tygon tubing.

The lance may be laid down

- Calculate the volume of oil. (e.g. 10 m lance, 5 sensors: 10*2 + 5*6 = 50 cl)

- Fit an end cannula onto the last sensor sleeve on the lance side (grease + joint)

- Connect the vacuum pump to this cannula (small Tygon hose)

- Place a clamp on the hose of the pump (not tight, close to the cannula)

USER GUIDE PIEZOMETRE

33-30-077-

Piezomètre_UTI UK

Rev : 3 Page 13/41

nke Tel +33 (0)2-97-36-10-12 Fax +33 (0)2-97-36-55-17 http://www.nke-nstrumentation.com PAGE 13/41

•Raise the beaker, connect the hose barb connector of the MPT bus - MDS cable to the

beaker using a diam. 8 Tygon hose

•Close the beaker's outlet valve and fill it with oil

•Place a clamp on the Tygon hose (not tight, close to the

hose barb connector)

•Start the pump to create a vacuum inside the lance for 2

to 3 minutes,

•Open the beaker's valve, check the volume used and add

oil if necessary.

•Once filling is complete,

•Tighten both clamps, on the end cannula side and the

MDS side. Cut the Tygon hoses 3 or 4 cm after the clamp.

•On the cannula side, connect the pre-filled oil bladder;

place a plastic plug on the other..

•Tighten a cable tie on both fittings.

4.8 Finalize with à lance tube

•Grease the sensor sleeve with its 3 joints

•Install à « lance tube" on it

•Secure the sleeves and tubes assembly using M10 screws

•Check the tightness of the screws

Bouchon

tuyau Tygon

Raccord cannelé

USER GUIDE PIEZOMETRE

33-30-077-

Piezomètre_UTI UK

Rev : 3 Page 14/41

nke Tel +33 (0)2-97-36-10-12 Fax +33 (0)2-97-36-55-17 http://www.nke-nstrumentation.com PAGE 14/41

5. SOFTWARE WINPIEZO

USER GUIDE PIEZOMETER

33-30-077-

Piezomètre_UTI UK

Rev : 3 Page 15/41

nke

(33).02.97.36.10.12 Fax (33).02.97.36.55.17.. ..http://www.nke.fr

5.1 Presentation and Use

The "WINPIEZO" software, compatible with Windows XP, provides several functions:

- Configuration of the acquisition system

- Recovery of data recorded

- Calibration of sensors

- Control the operation of the measuring system in real time via the "MDS module"

- File reading and display of corresponding measurement curves.

For testing and calibration, the software connects directly to the measuring system of the "Pressure

and Temperature Modules" (MP&T) without going through the "Dating & Storage Module"

(MDS).

The application includes three pages called "MDS Programming", "MPT Calibration" and "MDS

Files". The latter allows the reading of the recorded files.

The PC and the "Piezometer" communicate through the "Communication interface".

5.2 Communication mode

To communicate with the "Piezometer", the "WINPIEZO" software uses a USB RS422/RS485 serial

communication port.

The installation of this port must be carried out first (see § 3 page 6).

Once the installation is complete, the "Preferences" dialog box of the software needs to be

configured by entering the serial port's number.

To communicate with the MDS module, the communication speed also needs to be set in the

"Preferences" dialog box.

It must be identical to the speed set in the electronic board (via 4 switches) integrated in the "MDS

module".

5.2.1 Vitesse de communication du bus et configuration des Switchs de la carte MDS

Function S1 S2 S3 S4

1200 bps 0 0 0

2400 bps 1 0 0

4800 bps 0 1 0

9600 bps 1 1 0

19200 bps 0 0 1

38400 bps 1 0 1

115200 bps 0 1 1

230400 bps 1 1 1

Autonome 0

Réseau 1

Note: the position of the switches on the "MDS" board is only taken into account when power is applied to the

unit .

USER GUIDE PIEZOMETER

33-30-077-

Piezomètre_UTI UK

Rev : 3 Page 16/41

nke

(33).02.97.36.10.12 Fax (33).02.97.36.55.17.. ..http://www.nke.fr

5.3 Installation

The "WINPIEZO" software does not require any particular installation. Simply copy the executable file (.exe)

WINPIEZO.EXE directly onto the computer.

5.4 Install the drivers

The converter contained in the "MDS communication interface" needs to be installed on your PC in order to

operate.

A CD-Rom with the necessary drivers is provided.

5.4.1 Procedure :

- Run the

« CP210x_VCP_Win_XP_S2K3_Vista

_7.exe » file and wait until the

installation is complete

- Click the « OK » button

- Connect the USB cable to the "MDS

communication interface

- Connect the other end of the cable to a

USB port on your computer.

Once the converter is detected, Windows

displays the following window.

The detection of the converter, Windows

displays the window

5.4.2 Determine the number of the serial communication port .

From Windows "Start" menu, go to :

- Control Panel / System / Hardware tab then Device Manager

- Find the line "Ports (COM & LPT)" and expand the tree structure.

- Note the COM number (e.g. COM5) that corresponds to the converter and fill in the corresponding field

under the "Preferences" tab of the "Winpiezo" software

Caution: you must install the converter before launching the "Winpiezo" software

USER GUIDE PIEZOMETER

33-30-077-

Piezomètre_UTI UK

Rev : 3 Page 17/41

nke

(33).02.97.36.10.12 Fax (33).02.97.36.55.17.. ..http://www.nke.fr

5.5 Designation of software com

Opens the "Preferences" dialog box

Used to configure the serial port's number and MDS communication speed

Used to start the "

MDS module

" detection

Resets the "MDS module"

Formats the SD Card

Used to synchronize the MDS with the PC or DCF 77 clock

Shows SD Card memory usage

Displays the MDS date and time

Calculates the clock drift

Used to detect the "MP&T" modules present on the bus

Used to display the list of "

MP&T

" modules

Resets the bus

Used to

start recording meas

urements

Used to stop recording measurements

Edits the event log

Used to export a file to the PC

Lists the files saved on the SD Card

Used to

update the MDS

Shows battery voltage

Shows the tilting angle o

f the module

Shows the DCF clock status

Runs the self

-

test for the "

MP&T

" modules

Reads the MDS operating mode

Used to print the curve of recorded data

Exports the data file

Exits the

WINPIEZO

application

Opens the MDS configuration window

Shows th

e real time measurements of the sensors present on the bus

Used to import a file from the PC to the SD Card

USER GUIDE PIEZOMETER

33-30-077-

Piezomètre_UTI UK

Rev : 3 Page 18/41

nke

(33).02.97.36.10.12 Fax (33).02.97.36.55.17.. ..http://www.nke.fr

5.6 Overview

5.7 "MDS Programming" function

The "MDS programming" page allows the user to connect to the "MDS module" in order to set up and plan a

measurement campaign using the various commands at his disposal.

Before taking any action, the user must first ask the application to identify the "MDS module". This analysis is

initiated by pressing the "Connect MDS" button.

Once connected, the "MDS module" must successively go through the different steps called "MDS mode"

before it can start recording.

In the bottom left corner of the application, the software provides information on the current operating mode

(e.g. "MDS mode: boot")

.

Information: These steps are necessary for an appropriate setup, for example: prevent recording if

the clock has not been set first.

USER GUIDE PIEZOMETER

33-30-077-

Piezomètre_UTI UK

Rev : 3 Page 19/41

nke

(33).02.97.36.10.12 Fax (33).02.97.36.55.17.. ..http://www.nke.fr

5.8 Sequence of operating modes for the MDS module

5.8.1 BOOT mode

The BOOT mode, which is activated upon detection of the MDS module, allows the user to communicate with

the SD Card and read the event log present on this memory card.

At this stage, only a few actions are possible and necessary to switch to the following mode:

To switch to the next mode, the user must set the "MDS module" clock using the "Synchronization" button

The application offers the choice of synchronizing with the computer's clock or with an external clock under

DCF77 standard.

This mode also allows the user:

- Copy all files present on the SD Card to the PC.

- Show the "MDS module" power supply voltage

- Show the tilting angle of the housing

Read the "MDS module" operating mode

Whatever the mode, these functions are always accessible

BOOT

SYNCH

RONISATION

BUS

ACQUISITION

WAITING

RECORDING

RECORDED

Synchronisation de l’horloge

Détection du bus

Paramètre échantillonnages

Mise en route

Conditions établies

Fin des conditions d’enregistrement

MDS reset

Display MDS

List MDS files

Erase SDCard

SDCard state

Edit MDS config

Synchronize MDS clock

Upload MDS files

Display batterie voltage

Display tilt angle

Dsiplay DCF status

Read MDS mode

USER GUIDE PIEZOMETER

33-30-077-

Piezomètre_UTI UK

Rev : 3 Page 20/41

nke

(33).02.97.36.10.12 Fax (33).02.97.36.55.17.. ..http://www.nke.fr

5.8.2 SYNCHRONIZATION mode

The command required to detect the "MP&T modules" is found under the "synchronization" mode.

The "Detect sensor connected to MDS" button asks the application to find the "MP&T" modules

connected to the bus.

Once the "MP&T" modules are identified, the "MDS module" switches to Bus mode.

This mode offers other possibilitie:

- Adjust the clock by calculating its drift.

- Copy a file to the SD Card

- Update the "MDS module" electronic board

5.8.3 BUS mode

In Bus mode, pressing the button will display the list of "MP&T" sensors connected in a tree structure.

Each sensor is listed according to its rank, with its unique ID number.

Display MDS date

Process MDS driff

Detect sensor connected

Download a file to MDS

Upgrade MDS

Table of contents

Other NKE Measuring Instrument manuals