NKT SuperK EXTREME User manual

SuperK EXTREME

Instruction Manual

High Power Supercontinuum Laser Series

P a g e | 1

This product is protected by intellectual property rights including one or more of the following granted or pending patents:

US6611643; US6796699; US6888674; US6898367; US7123408; US7466885; US7679822; US7787503; DE10313987; DE10331906;

CN101430476; AU2004304019; EP1164400; EP1184701; EP1706788; EP2045643; EP1164406; JP2002098896; US2002006264;

JP2002082286; EP1184701; EP1184701; DE20122782; US2002009260; US2002028044; DE10331906; WO2005006042;

US2006165359; JP2009513994; EP1644765; US2009074023; WO2005062113; NO20063369; JP2007515680; HK1102937;

EP1697793; CN101430476; CN1898597; CN100445858; CA2544871; AU2004304019; EP1706788; WO2005071483; US2008226242;

AT445175; DE10115488; DE10115589; US2009086315; JP2010102345; EP2045643; EP2045642; EP2045641; EP2045641;

DK1184701; DE10115590; DE10115577; DE10115509; DE10115487; DE10115486; AT407381; EP1164400; JP2002055284;

DE20122783; US2005122580; DE10313987; WO2005024482; US2007025662; JP2007504499; EP1714187; DE10340964;

US8000574; US2010040335; WO2008083686; EP2111564; CN101681079; CA2675234; JP2010515940; EP2332892;

WO2010003422; US2011116283; EP2307915; US2011019701; WO2009095022; EP2238655 ; US2010296529; WO2009076967;

EP2223396; WO2009095023; US2010329292;

WO 2010115432; US2008226242; WO2005071483; EP1706788; AT445175; WO2009024490; DE102007039498; EP 2181350;

GB2380812; WO0212931; AU8174101; US2002061176; US6792188; US6972894; WO2014944; AU7960301; US6892018;

GB2384323; AU1494402; GB2394712; US2004179796; WO02072489; US7155097; WO02084350; EP1381894; CN1535389;

CA2443037; JP4203320; US7174078; GB2397135; WO0241050; US7349611; AU2002336075; EP1421420; WO03019257;

JP2005500583; DE60217684; CA2445280; AT352050; AU2002350398; WO03032039; US7327922; EP1442323; CA2445487;

US7221840; US7266275; US7289709; WO2005059612; EP1700146; US6542681; WO0060390; JP2002541508; EP1181595;

CA2368789; AU3550900; US7321712; US7532798; US7245807; AU771646; US6954574; JP4761624; EP1153325; DE60025766;

DE60005486; CN1645174; CN1329755; CN1341221; CN1178079; CA2362997; AU256500; AT316516; AT250772; AU2004202828;

DK1153325; DK1340725; EP1340725; AU767773; EP1385028; US6888992; US6631234; JP2002537574; EP1153324; DE60004638;

DK1153324; CN1185513; CN1341219; CA2362992; AU767773; AT247837; US6990282; WO0142829; EP1236059; AU5439201;

US6853786; WO0142831; EP1236063; AU2192401; GB2380811; WO0210817; AU7573101; US7106932; WO02090277; EP1385796;

GB2403219; WO03080524; US2011121474; US2005238301; CN1649801; CA249760; AU2003222586;

US7346249; WO2004083919; GB2407390; US7224873; CN1143147; US6334019; JP2002506533; GB2341457; WO9900685;

EP0991967; EP1443347; AU8116998; DE0991967; GB0991967; US6603912; AU763796; RU2226705; PL197264; NO20014740;

JP2002541507; HK1046037; EP1166160; DE60029315; CN1353824; CN1192261; CA2368778; AU3827400; AT333103; GB2350904;

US6985661; US6888992; WO03062160; US2006008218; WO03058308; WO03058309; AU2003201996; AU2003201650;

WO03058310; AU2003201638; AU2003201638; GB2389915; WO03093884; AU2003226571; WO2004001461; AU2003236903

WO2004001465; AU2003244812; WO2004057392; AU2003290312; US2005117841; WO0186347; EP1279065; AU53240001;

EP1460460; WO2004053550; AU2003302807; WO2004049025; US2007122095; US2006067632; AU2003281985; WO03078338;

AU2003226893; WO2004019092; AU2003254639; WO03100488; AU2003229545; WO03079074; AU2003226890; WO0239159;

US6856742; GB2384323; AU1494402; CA2334510; DE60217684; DE60025766; GB2408812; GB2386435;

FDA (Food & Drug Administration):

FDA accession number #9912672

Issue: 4.0

Published: November 2011

Author: MDE

Copyright © 2011 by NKT Photonics A/S. All rights reserved. Reproduction or translations of

any part of this work is prohibited.

P a g e | 2

Table of Contents

1General......................................................................................................................................................................3

2Laser Safety ..............................................................................................................................................................4

2.1 General Safety Aspects.....................................................................................................................................4

2.1.1 Basic Operation and Designated Use.......................................................................................................4

2.1.2 Organizational Measures..........................................................................................................................4

2.1.3 Selection and Qualification of Personnel –Basic Responsibilities............................................................5

2.1.4 Safety Instructions Governing Specific Operational Phases.....................................................................5

2.2 Specific Safety Aspects .....................................................................................................................................6

2.2.1 Physical Hazards ......................................................................................................................................6

2.2.2 Personnel Safety.......................................................................................................................................7

2.2.3 Constructive Safety Features....................................................................................................................9

2.2.4 General Safety Features...........................................................................................................................9

2.3 Safety Compliance List......................................................................................................................................9

2.4 Labeling...........................................................................................................................................................10

2.4.1 Labels used on SuperK EXTREME ........................................................................................................10

2.4.2 Label Positions........................................................................................................................................12

2.5 Laser protective goggles..................................................................................................................................13

3Requirements ..........................................................................................................................................................14

3.1 Installation Requirements ................................................................................................................................14

3.2 Operating Conditions.......................................................................................................................................15

4Installation ...............................................................................................................................................................16

5Interface...................................................................................................................................................................20

5.1 Front Panel......................................................................................................................................................20

5.2 Back Panel.......................................................................................................................................................21

5.2.1 Power Inlet and Main Power Switch........................................................................................................21

5.2.2 External Bus............................................................................................................................................22

5.2.3 Output Control.........................................................................................................................................23

5.2.4 Interlock ..................................................................................................................................................24

5.2.5 LEDs.......................................................................................................................................................26

5.2.6 USB.........................................................................................................................................................26

5.2.7 Seed Pulse..............................................................................................................................................26

5.2.8 Gate Out .................................................................................................................................................26

5.2.9 Pulse Monitor..........................................................................................................................................27

5.2.10 NIM Pulse ...............................................................................................................................................27

5.2.11 Modulation Input (Option)........................................................................................................................27

5.2.12 External Feedback (Option)....................................................................................................................28

5.2.13 Optical Output.........................................................................................................................................29

5.2.14 RF-Driver Interface (Option)....................................................................................................................30

5.2.15 Air Outlet.................................................................................................................................................31

6Operation.................................................................................................................................................................32

6.1 Precautions......................................................................................................................................................32

6.2 Turning ON the SuperK EXTREME for the first time .......................................................................................32

6.3 Everyday Operation via the Front Panel..........................................................................................................33

7System Menu...........................................................................................................................................................34

7.1 Operating Mode...............................................................................................................................................35

7.2 Pulse-Picker Ratio...........................................................................................................................................36

7.3 Input Readouts ................................................................................................................................................37

7.4 Status Display..................................................................................................................................................37

7.5 Date and Time.................................................................................................................................................38

7.6 Display Contrast ..............................................................................................................................................38

7.7 Display Backlight .............................................................................................................................................39

7.8 Serial Numbers................................................................................................................................................39

7.9 Firmware Versions...........................................................................................................................................40

8Computer Controlled Operation...............................................................................................................................41

9Supercontinuum Generation....................................................................................................................................42

9.1 Spectrum vs. Output Power.............................................................................................................................42

9.2 Polarization of Output ......................................................................................................................................42

9.3 Pulse-Picker.....................................................................................................................................................43

9.4 Reflection monitor............................................................................................................................................43

9.5 Constant Power and Constant Current mode..................................................................................................44

10 Service & Support....................................................................................................................................................45

10.1 Support............................................................................................................................................................45

11 Literature .................................................................................................................................................................46

12 Electrical and Mechanical Specifications.................................................................................................................47

12.1 System Dimensions.........................................................................................................................................47

12.1 Collimator Dimensions.....................................................................................................................................48

13 Accessories for the SuperK Extreme.......................................................................................................................49

P a g e | 3

1 General

Introduction

Please take the necessary time to read this manual. It contains important

information on safety issues concerning the usage of the SuperK EXTREME laser.

Warning: safety might be seriously impaired if the instructions are not

followed carefully.

This manual covers the SuperK EXTREME laser series, with the product numbers

beginning with S4x2, where x indicates what type of spectrum the system provides.

The SuperK EXTREME comprises a Class 4 laser and only persons who are familiar

with laser safety regulations are allowed to operate any of these systems.

This product is not UL-approved but all safety components are UL-approved.

If you have any questions concerning this product, please do not hesitate to contact

regarding support for the SuperK Extreme.

Description

SuperK Extreme is a range of ultra broadband supercontinuum lasers with the

spectral brightness of a laser and the bandwidth of a lamp –all delivered in a single

mode fiber.

The SuperK supercontinuum laser system and accessories features unrivaled

reliability in an industrial turn-key format with market leading performance. These

high-brightness low-noise supercontinuum sources can be operated with a touch of

a button and requires no warm-up time.

The SuperK EXTREME is a quasi CW single-mode supercontinuum white light laser

with excellent power density. The system is a complete stand-alone unit with

everything required integrated.

The SuperK Accessories product range completes the SuperK system with plug-

and-play filters and fiber delivery systems providing robust filtering and routing

options in an easy-to-use format. All accessories are source-independent, and can

be used with any of the SuperK EXTREME models.

The graphical user interface SuperKontrol 2.0 software makes it very easy to control

the SuperK EXTREME. See the SuperKontrol 2.0 Software Manual for more

information about how to use the graphical user interface.

It is recommended to keep this manual in the area close to the SuperK EXTREME

system, so operators if required can use it as reference book.

P a g e | 4

2 Laser Safety

Never switch on or attempt to operate the SuperK EXTREME before reading,

understanding and fully familiarizing yourself with the contents of this

chapter.

Introduction

This chapter is divided into four sections:

General Safety Aspects

Explains aspects relating to the safe operation of the laser device. See

section General Safety Aspects.

Special Safety Aspects

Outlines the risks specific to working procedures with and on this laser

device. See section Specific Safety Aspects.

Safety compliance list

See section Safety Compliance List.

Overview of safety-relevant labels

Shows the design and describes the safety labels. See section Labels.

Laser goggles.

See section Laser protective goggles.

2.1 General Safety Aspects

2.1.1 Basic Operation and Designated Use

Basic Safety

The SuperK EXTREME has been designed in accordance with state-of-the-art

standards and the recognized safety rules. Nevertheless, its use can constitute a

risk to the user or third parties or cause damage to other material property.

The SuperK EXTREME system and Accessories are not approved nor tested

for use in treatment or diagnostics of human and animals and does not

comply with European, US or Rest of World requirements for medical device

lasers.

Warning: Potential eye and skin burns! Only use the laser in accordance with

its designated use.

The SuperK EXTREME must only be used in technically perfect conditions and in

accordance with its designated use.

Follow the instructions in this manual, and let only safety conscious persons, who

are fully aware of the risks involved, operate the SuperK EXTREME.

Any functional disorders, especially those affecting the safety of the SuperK

EXTREME, must be rectified immediately.

2.1.2 Organizational Measures

Laser Safety Officer

In accordance with the valid national regulations for prevention of accidents, appoint

a responsible person as the Laser Safety Officer (LSO).

His responsibility is to effect the knowledgeable evaluation of laser hazards and to

monitor and enforce their control.

The instruction manual must always be at hand where the SuperK EXTREME is

used. In addition to the operating instructions, observe and instruct the user in all

other generally applicable legal and other mandatory regulations relevant to accident

prevention.

P a g e | 5

Protective

Equipment

These compulsory regulations also deal with the issuing and/or wearing of personal

protective equipment. The necessity of reading the instruction manual applies

especially to persons working only occasionally on the SuperK EXTREME.

Use protective equipment, wherever required by the circumstances or by law.

Warning: Risk of serious injury through incorrect operation! Personnel

entrusted to operate the SuperK EXTREME must have read the instruction

manual and in particular the safety instructions.

Safety Labels

Ensure that all safety-relevant labels are attached to the laser device in accordance

with the label location diagrams in Section Labels and local regulations. Make sure

that these labels are always complete and perfectly legible.

If any labels are missing, immediately inform NKT Photonics A/S. In the event of

safety relevant modifications or changes in the behavior of the SuperK EXTREME

during operation, stop the laser device immediately and report the malfunction to

NKT Photonics A/S.

Never make any modifications, additions or conversions which might affect safety.

This also applies to the installation and adjustment of safety devices.

2.1.3 Selection and Qualification of Personnel –Basic Responsibilities

Qualified Personnel

Make sure that only authorized personnel work on or with the SuperK EXTREME.

Statutory minimum age limits must be observed. Employ only trained or instructed

staff and set out clearly the individual responsibilities of the personnel for operation

and set up.

2.1.4 Safety Instructions Governing Specific Operational Phases

Precautions

Take the necessary precautions to ensure that the SuperK EXTREME is used only

when in a safe and reliable state.

In the event of malfunctions, stop the laser device immediately and lock it. Have any

defects rectified immediately.

Before starting the SuperK EXTREME ensures that nobody is at risk. Brief operating

personnel before beginning special operations, and appoint a person to supervise

the activities. Ensure that the operations area is adequately secured.

P a g e | 6

2.2 Specific Safety Aspects

Specific safety aspects are:

Physical hazards related to the system. See Section Physical Hazards.

Protection of the users of the system against these hazards. See Section

Personnel Safety.

Constructive protective measures against these hazards. See Section

Constructive Safety Features.

Within this classification, the SuperK EXTREME is Class 4 (high power) laser, and

must therefore be regarded as a potential hazard to the human operator. The laser

beam must also be regarded as a potential fire hazard. Class 4 is the most powerful

(and potentially hazardous) category of lasers. Direct and scattered radiation from

Class 4 products is considered an acute hazard to the eyes and skin. Precautions

include eye and skin protection, remote interlocks and warning labels.

2.2.1 Physical Hazards

Warning

The laser beam is very dangerous to the eyes and skin!

The following are hazardous,

Direct radiation-light as it leaves the laser.

Reflected radiation-light which has hit a surface and bounced off.

Diffuse radiation-light, which has hit a surface, bounced off, and scattered.

Light

In case of malfunction the SuperK EXTREME may provide laser radiation with

power levels up to 20 Watt and operating wavelength of from 300 nm up to 3000 nm

is emitted from the output aperture of the SuperK EXTREME. The output is a

collimated exit beam from a fiber delivery cable. The beam diameter of the output is

less than 3 mm. Despite the non-ionizing nature of the operating wavelengths,

damage can still occur to living tissue as a result of heat produced during radiation

absorption. Part of the radiation of the SuperK EXTREME lies outside the visible

range. Suitable beam dumps must be used at all times when the laser product is

operating.

In general, the maximum permissible radiation exposure for the skin is several times

greater than for the eye. Safety measures with regard to the radiation hazard are

therefore mainly based on dangers for the eye. Not only are the direct laser beam

hazardous, but unchecked reflections of laser light also constitute a potential hazard.

P a g e | 7

2.2.2 Personnel Safety

Personnel Protection

The SuperK EXTREME is a class 4 laser.

Warning:

Risk of serious injury! Always wear protective eyewear when there is a chance of

exposure to radiation from the laser. Before putting on the protective eyewear, check

them for any obvious defects. As the filter in the protective eyewear provides

protection for only a narrow band of wavelengths, make sure you are wearing the

appropriate protective eyewear for the laser device in question. Check with your

Laser Safety Officer or other safety personnel for guidance in selecting the

appropriate eyewear.

Radiation Safety

The SuperK EXTREME emits high power visible and near-infrared radiation, which

constitutes a hazard to personnel during periods of operation.

Protective Eyewear

The ANSI (American National Standards Institute) standard for safe use of lasers

requires that a set of protective goggles blocking the appropriate laser wavelength

should be worn while operating or servicing class 4 lasers. However, since the

SuperK EXTREME covers the full visible spectrum with a very high spectral power

density, it is not possible to achieve full protection without totally limiting the visual

brightness through the laser goggles.

NKT Photonics recommends using a combination of several different filter-

technologies (absorption and interference). The IR5D filter from NoIR Laser

Company, LLC is currently the most suitable product available. Full protection is not

achieved, but the alternatives are significantly worse; see section Laser protective

goggles for details.

Clearly label the goggles with an optical density and the specified wavelength. To

avoid confusion, keep these goggles separate from other safety glasses and

personal protective equipment.

Using the wrong type of goggles is dangerous. It can be worse to have improper

eyewear and a false sense of security than to have no eyewear and take

precautions based on the absence of protection. Even if you are wearing protective

goggles, never look directly into the beam; intense laser radiation is capable of

destroying the protective filter.

Warning:

Protective eyewear can only provide partial protection from the hazardous radiation

of a supercontinuum laser source.

Eye Protection

Warning:

Potential eye burns! Only use the laser in accordance with its designated use.

Safety interlocks are only to be overruled by authorized personnel.

The following guidelines describe some of the actions necessary to avoid injury

caused by the laser beam. Always follow these guidelines and take additional

precautions if necessary.

When eyewear is necessary, make sure it has the proper optical density for

the laser wavelength.

All other personnel in the vicinity of the laser to wear protective eyewear.

Permit only qualified personnel to operate the laser.

Never intentionally look directly into any laser beam.

Avoid indirect viewing of direct or reflected laser radiation. Specular

reflections (from reflective surfaces) can be as dangerous as the direct

laser beam. Do not view the beam through optical instruments unless the

optics is designed to filter the laser wavelength.

Take precautions to ensure that there are no reflecting objects in the path

of the laser beam.

P a g e | 8

Do not deviate from standard operating procedures when working with

class 3B and class 4 laser equipment.

Use lasers only in approved applications and locations. Take adequate

precautions to prevent unauthorized personnel from entering the area

where a class 4 laser is operating. Do not use lasers around untrained

personnel. Ensure that all personnel in the area observe proper safety

precautions.

Report all incidents of exposure to your supervisor.

Clearly display warning signs indicating the laser enclosed area with an

additional warning light outside the door.

Adhere to local and national regulations governing the safe use of lasers.

Skin Protection

Warning:

Potential skin burns! Direct and reflected laser radiation can burn exposed skin. Only

use the laser in accordance with its designated use. Safety interlocks are only to be

overruled by authorized personnel.

Although the skin can withstand considerably higher radiation intensity than

the eyes, tissue may be burned to a greater or lesser degree, depending on

the radiation time and the irradiation intensity.

Avoid contact between the skin and the beam, or specular reflections of the

beam. Reflections of the beam may be as dangerous as the beam itself.

Wear appropriate protective clothing to protect the skin whenever

necessary.

Fire Protection

Warning:

Fire hazards! Class 4 lasers are, by definition, fire hazards. The laser beam can

cause flammable materials to ignite or explode. Always keep a fire extinguisher in

the laser area in case a fire occurs.

Because of the high output power from the class 4 laser, a wide range of materials

can be set on fire. Therefore, take appropriate fire prevention measures when the

beam path is open:

Combustible materials may be ignited by the laser beam or by electrical

components inside the laser system. Flammable items must be isolated

from the laser beam and from the laser system.

Paper (circuit diagrams, leaflets, or even posters on the wall), curtains that

are not coated with fire retardant, wooden panels or similar materials can

be easily set on fire by direct or reflected laser radiation.

Use only beam stops made of non flammable materials (not asbestos!).

Many fluids and solvents (e.g. cleaning agents used for maintenance) are

combustible. The intense beam of the laser can ignite vapors from these

materials. Prevent the laser beam from contacting flammable materials

used in the laser area.

Move containers of flammable materials as far from the laser system as

possible and shield them from the beam with opaque materials. Place

these solutions and vapors under no circumstances in the beam path or

near the system.

P a g e | 9

2.2.3 Constructive Safety Features

Safety Features

The laser device is equipped with the following constructional safety features:

Appropriate Class 4 label affixed to laser device enclosure (see section

Labeling).

All parts of the laser where laser radiation may possibly escape are marked

with the appropriate adhesive danger signs (according to IEC 60825).

The SuperK EXTREME is provided with a connector (”Interlock”) on the

rear panel of the laser housing, where an external interlock switch can be

installed. The interlock switch shuts down the laser remotely, for instance, if

a door connected with the switch is opened.

2.2.4 General Safety Features

General Safety

The SuperK EXTREME has key switch controlled laser operation. The laser device

can only be switched on with the key-switch. This prevents inadvertent or

unauthorized starting of the laser. It cannot be operated with the key in the OFF

position and the key cannot be removed in the ON position.

2.3 Safety Compliance List

CE Approval

The SuperK EXTREME is CE-marked and has been tested for FCC and VCCI

compliance as well.

FDA Approval

The SuperK EXTREME complies with FDA part 1040 except for deviations provided

in laser notice 50.

UL and CSA

Approval

The equipment is not UL- or CSA-approved. However, the power supply itself is UL-

and CSA-approved, and all mains wiring (including the power inlet) is enclosed in

the power supply. No voltages outside the power supply are higher than 24 VDC

(nominal). Datasheet and conformity documents for the power supply can be

delivered on request.

P a g e | 10

2.4 Labeling

This section contains a description of the safety labels on the SuperK EXTREME

and shows their location on the equipment. Ensure that all warning labels are affixed

to the system as outlined in this chapter prior to operating the system.

2.4.1 Labels used on SuperK EXTREME

The SuperK EXTREME contains the following labels:

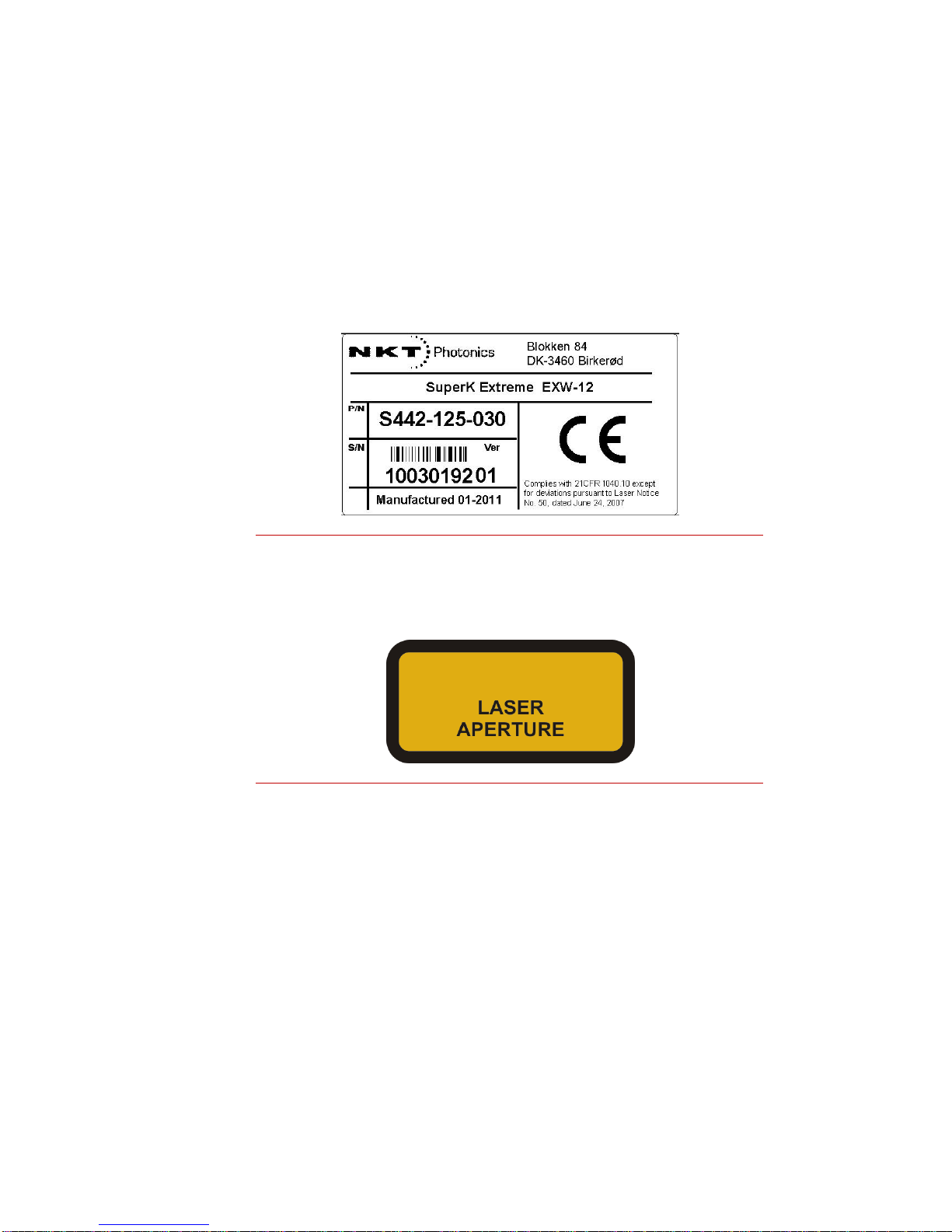

Visible and Invisible Classification label, see figure 2-1.

Laser label, see figure 2-2.

Laser Aperture label, see figure 2-3.

Item label, see figure 2-4.

Laser Aperture sign, see figure 2-5.

Visible and Invisible

The visible and invisible classification label informs about visible and invisible laser

radiation from the SuperK EXTREME system that it is a Class 4 laser product and

exposure to eye and skin must be avoided from both direct and scattered radiation.

Figure 2-1: Visible and Invisible Classification label

Laser Source

The Laser label indicates that SuperK EXTREME is a laser source.

Figure 2-2: Laser label

Laser Aperture

The Laser Aperture label provides information about where the Laser Aperture is

located, what kind of laser emission is radiated from the Laser Aperture and that the

SuperK EXTREME product complies with the IEC 60825-1 standard.

Figure 2-3: Laser Aperture label

P a g e | 11

Item

The Item label provides information about:

the manufacturer of the system (NKT Photonics, Blokken 84, DK-3460

Birkerød)

a short name of the SuperK EXTREME variant, e.g. SuperK EXTREME 80

MHz PP

the product number (P/N) for the actual system, e.g. S442-125-030

the serial number (S/N) for the actual system 8 digits, e.g. 10030192

the design version (Ver), e.g. 01

when the actual system was manufactured, e.g. 01-2011 for January 2011

that the system meets the EU consumer safety and environmental

requirements (CE-mark).

the Laser Notice No. 50,: indicates that the product complies with FDA

requirements.

Figure 2-4: Item label

Aperture Sign

The Laser Aperture sign is attached to the output fiber close to the Laser Aperture

(the collimator). The Laser Aperture sign is to warn users about the high laser

emission from this collimator (Laser Aperture).

Figure 2-5: Laser Aperture sign

P a g e | 12

2.4.2 Label Positions

The positions of safety labels on the back plate and collimator are shown on figure

2-6 and 2-7.

Figure 2-6: Labels on the back of the SuperK EXTREME.

Figure 2-7: Laser Aperture sign on collimator.

P a g e | 13

2.5 Laser protective goggles

As mentioned earlier in this manual, it is not possible to achieve full protection from

laser protective goggles since the SuperK EXTREME covers the full visible

spectrum with a very high spectral power density.

Accordingly, utmost care must be taken when operating this light source

and there is direct access to the full emission of the output fiber. Only

authorized personnel must operate the laser source.

However, significant protection can be achieved by choosing the correct

laser goggles. We recommend using a combination of several different

filter-technologies (absorption and interference). Absorption filters can be

edge filters as well as band pass filters. Only the combination of these

filters makes it possible to solve complex requirements for broadband light

source laser applications. The IR5D filter from NoIR Laser Company, LLC

is currently the most suitable product available. Full protection is not

achieved, but the alternatives are significantly worse.

The Optical Density as a function of wavelength for the IRD5 is shown in the figure

below.

Figure 2-9: Optical Density (OD) as a function of wavelength

Note: More information can be found at: http://www.noirlaser.com/filters/ird5.html

P a g e | 14

3 Requirements

3.1 Installation Requirements

Mechanical Specs

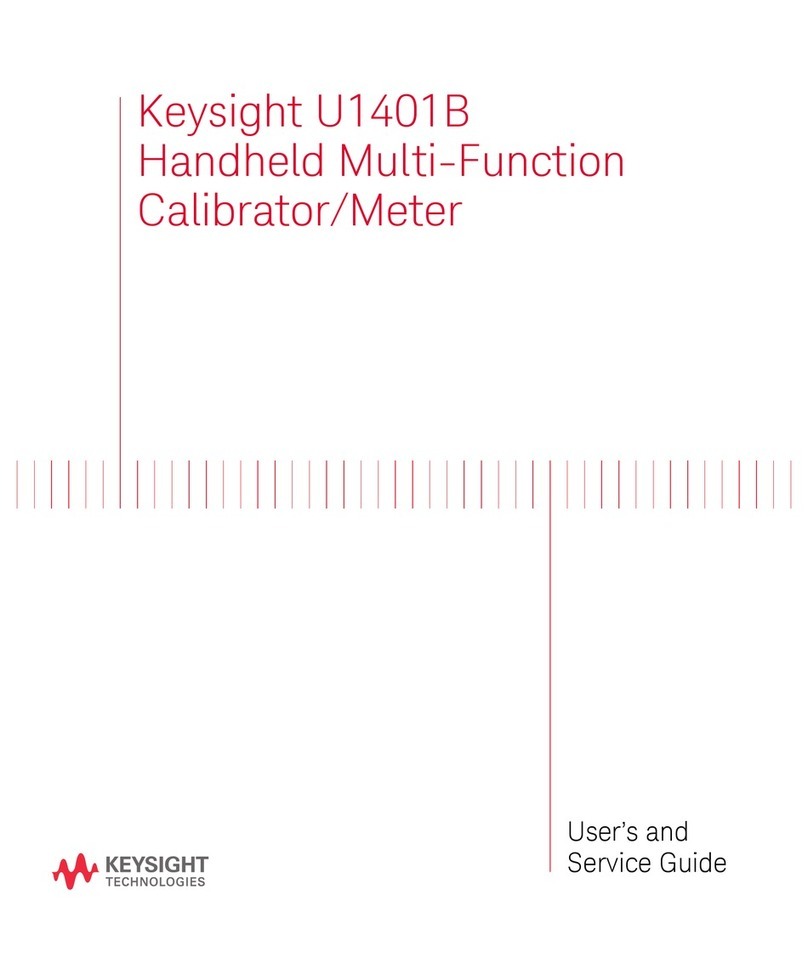

For installation, maintenance and transport the SuperK EXTREME requires

entrances with inside spans of minimum 700 mm

Shipment casing: 610 x 650 x 680 (w x h x d) mm

Total shipment weight including casing and SuperK EXTREME: 33-41 kg

oShipment casing weight: 16 kg

oSuperK EXTREME weight: 17-25 kg

SuperK EXTREME dimensions: 444 x 223 x 377 (w x h x d) mm

Figure 3-1: Transport casing

Ambient Conditions

Allowable operating temperature range: +18 to +30 °C

Protection from dust (Pollution degree 2, Office environment)

Allowable relative humidity: 20 to 80 % (non-condensing)

Vibration should be minimized. An optical table is not needed and the

source can be placed on an ordinary table or on the floor.

Keep a back plate distance to wall or equipment of 100 mm to ensure free

access to all ventilation openings.

P a g e | 15

3.2 Operating Conditions

Facility

Requirements

The SuperK EXTREME is a Class 4 laser product and the operation facility and

conditions need to comply with the following requirements:

CFR21 1040.10 & Laser Notice LN50

IEC / EN 60825-1

Or the SuperK EXTREME should be operated in accordance with local regulations

for a Class 4 laser source.

Warning

Make sure that at all times during system operation the beam path is known

and controlled. Wear suitable protection and make sure everybody in the laser

area is aware of the fact that the system is being operated.

Electrical Supply

Requirements

Supply voltage: 100-240 VAC, 50/60 Hz

The supply connections must be a 3 wire connection with one Phase,

Neutral and Earth connections (standard IEC socket, type C13). Earth

connection must be connected to earth.

Maximum power consumption: up to 400 Watt (dependent on system

variant and accessories)

P a g e | 16

4 Installation

Unpacking the

SuperK EXTREME

Check the shipment case for any visible damage before unpacking the system from

the shipment casing (see figure 4-1).

Be careful not to drop or bump the system while unpacking it from the shipment

casing, as the laser system is shock sensitive and might be activated.

Note

Do not dispose any of the shipment materials as these must be used in case it

is required to return the product. The warranty and service only covers if the

unit is returned in the original packaging and packed according to the

instruction in this manual.

1. Remove the lid of the transport casing.

a. Use torx bit (T20) enclosed in the shipping folder.

Figure 4-1: Side view of shipment casing

b. Unscrew the screws in the top of the box, on the sides of the

shipment casing and remove the lid.

P a g e | 17

2. Remove the cardboard boxes with enclosed manuals, cables, accessories,

etc.

Figure 4-2: Cardboard boxes with manuals, cables, etc.

Note

Do not dispose the shipment materials as these must be used for any further

shipments of the system.

3. Remove the techno foam and open the cardboard box containing the

SuperK EXTREME.

Figure 4-3: Top view of the SuperK EXTREME in the open cardboard box

4. Lift the SuperK EXTREME out of the cardboard box with the techno foam on the

two sides.

Please notice that the system weighs about 20 kg, so be careful when lifting the

system. One person must not lift or carry the system alone. Two persons, one

on each side of the shipping box, can lift up the system from the crate.

5. Carefully place the SuperK EXTREME on the position where it is intended to be

used. Ensure that the system is positioned solidly without risk of falling down

P a g e | 18

before continuing. Remove the techno foam from the two sides by lifting one

side with one hand and removing the foam with the other.

6. Open the plastic bag from the SuperK EXTREME.

Figure 4-4: SuperK EXTREME in plastic bag

Carefully remove the plastic bag without bumping the SuperK EXTREME on the

table. Remove the Silica Gel Desiccant placed on top of the SuperK EXTREME,

which has avoided moisture to get into the system during shipment.

The beam delivery fiber is fixed to the back plate using non-marking Kapton

tape. Remove the Kapton tape from the back plate to free the beam delivery

fiber.

7. The collimator output is equipped with a black protecting holder. The collimator

holder is made out of metal and it is fixed to the back plate of the SuperK

EXTREME with two screws. Do not release the collimator before the SuperK

EXTREME is at its operational position. To release the collimator from the

collimator holder, gently release the two plastic screws on the collimator holder,

see figure 4-6.

Figure 4-6: Collimator holder (A) and collimator (B)

The SuperK EXTREME is now fully unpacked and the set-up procedure can be initiated.

Note

The collimator holder is the recommended protective location for the collimator

when this is not in use. If desired, the collimator holder can be released from the

SuperK by removing the four screws attaching the collimator holder to the back

plate of the SuperK unit.

A

B

P a g e | 19

Warranty Label

It is not allowed to open the SuperK EXTREME. Thus the SuperK EXTREME is equipped

with a warranty label on the top cover, see figure below. The warranty void if the system

is opened.

Figure 4-7: Warranty label

Securing Output

Beam

Before turning on the system please observe the following:

Ensure that the collimator has been removed from the collimator holder.

Ensure that all optical cables are free of kinks, sharp bends and mechanical

damage.

Ensure that the collimator (output aperture) enters an appropriate beam dump

capable of handling the emitted power.

Warning

Make sure the beam path is known and controlled at all times during system

operation. Wear suitable protection and make sure everybody in the laser area is

aware the system is being operated.

Reach Room

Temperature

The SuperK EXTREME is specified to an operating range from +18 to +30 °C.

Immediately after receipt the laser system might have a temperature outside the specified

range. Please allow the system to reach room temperature before starting it up.

Warning

Please ensure that the temperature of the SuperK EXTREME is within the specified

range before starting it up.

Table of contents

Other NKT Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Keysight

Keysight U1401B User's and service guide

Milwaukee

Milwaukee M12 ICAV3 Original instructions

SICK

SICK VMS4400 CV operating instructions

ETS-Lindgren

ETS-Lindgren HI-1501 user manual

Endress+Hauser

Endress+Hauser Proline Prosonic Flow B 200 Brief operating instructions

KROHNE

KROHNE OPTISONIC 3400 Handbook