NO DIG VM500 User manual

VM500

Vacuum Excavation System

Directional Boring Mud Slurry Clean-Up

Pot oling to Locate Buried Utilities

Valve Box, Catc Basin, Manway Cleanout

1

Owners Manual

Table of Contents

Important................................................................................................................................ 3

Safety Precautions – Summary..............................................................................................4

Towing................................................................................................................................4

Parking & Set-up.................................................................................................................4

Operating En ironment.......................................................................................................4

Operating Water Blaster......................................................................................................4

Operating Vacuum Sucker..................................................................................................4

Emptying Storage Tank......................................................................................................4

Machine O er iew.................................................................................................................. 5

Operating Principles...............................................................................................................6

Operating Instructions............................................................................................................7

Towing the Vacuum Exca ator...........................................................................................7

Parking and Set-Up.............................................................................................................9

Operating En ironment.....................................................................................................10

Operating Vacuum Exca ator...........................................................................................11

Operating Water Blaster....................................................................................................15

End of Day (Shift) Ser icing of the Vacuum Machine........................................................17

Trouble Shooting Guide........................................................................................................18

Determining Tank Fill Le el..................................................................................................19

Daily (Shift) Pre-Start Checklist............................................................................................20

Pre-Start – Towing............................................................................................................20

Pre-Start – Operational Set-Up.........................................................................................20

Pre-Start – Water Blaster..................................................................................................20

Pre-Start – Vacuum Exca ation........................................................................................21

Pre-Start – Collection Drum Emptying..............................................................................21

Operational Risk Assessment...............................................................................................22

2

Important

Read all safety precautions and instructions carefully before operating this equipment. Refer

to specific instructions on how to tow, set up, operate and empty the Spoil Tank. The

machine must only be operated by an adult person who has both the physical and mental

capacity to do so.

Ensure that the machine is shutdown prior to trying to perform any maintenance tasks on it.

Whilst this machine has a wide ariety of capacities it is not intended to be used for any of

the following purposes: -

Water blasting or acuum exca ation of any strongly acidic or alkaline solids or

liquids;

Vacuum exca ation of materials such as asbestos fibres or other similar hazardous

materials;

Vacuum sucking of any flammable or combustible liquid or solid where the mixture of

a high quantity of air may lead to either a combustible or explosi e atmosphere;

Vacuum exca ation of “contaminated wastes” such as human or animal effluent, food

grease traps etc. as the machine is not designed or licensed to perform such tasks;

Water blasting of people or animals or water blasting near where people or animals

are likely to walk or stand.

Warranty co erage for the machine is in accordance with the Australian Consumer

Guarantee under the Competition and Consumer Act 2010 (the "Act"). As such, no warranty

co er is pro ided to damage caused to the machine by operator error or omission or from

incorrect towing or ehicular accident. Refer to correct operating instructions detailed in this

manual.

With correct operation, maintenance and care, the VM500 Vacuum Exca ator is designed

for many hours of operating use. If it does not function correctly, please consult the fault

finder list for potential causes and remedies. If that fails to resol e the issue, please contact

our maintenance department for assistance.

_________________________________________________________________________

Model No: _______________

Serial Number: _______________

Purchase Date: ____ / ____ / 20__

Original Purchaser: _______________

3

Safety Precautions – Summary

The following safety precautions must be obser ed with the VM500 Vacuum Exca ator: -

Towing Parking & Set-up

The towing ehicle must ha e:-

A two (2) tonne towing capacity;

50mm tow ball.

Standard trailer electrical

connections.

Maximum Towing Speeds: -

80 km/hr on sealed roads;

60 km/hr on unsealed / rough roads.

Before dri ing off: -

Attach safety chains;

Raise and stow trailer jockey wheel;

Release handbrake & stow wheel

chocks.

When parking and setting up: -

Do not park on a tilt angle greater

than 20 degrees lean angle in any

trailer direction;

Apply the trailer (and if attached, the

ehicle) park brake;

Lower the trailer jockey wheel;

Install wheel chocks.

Do not park in a situation that will: -

Cause a traffic hazard;

Interfere with other workplace

machines;

Be hazardous to pedestrians.

Operating Environment Operating Water Blaster

The exhaust gases from the machine

engine are toxic. Hence: -

Do not operate in a fully

or partially enclosed building such

as a warehouse or building

basement, unless sufficient fresh air

is a ailable

The noise from the operating machine is

high, therefore: -

Do not operate in areas at time

where noise restrictions apply.

Whilst water blasting, do not blast: -

Any person or animal with the water

blast;

Too close or at an angle to the

ground in a manner that produces a

lot of blow back.

Do wear: -

Fully enclosed footwear;

Long trousers;

Sealed safety glasses or goggles.

Operating Vacuum Sucker Emptying Storage Tank

Whilst acuuming, Do Not: -

Bring the end of the suction nozzle

into contact with a person’s skin;

Plunge suck into either a liquid or

solids as the suction action will stop;

Collect acidic, alkaline, flammable

or combustible materials or

controlled waste.

Do: -

Suck up material dislodged by the

water blaster;

At a maximum, only half co er the

end of the suction hose nozzle.

Prepare for storage tank emptying by: -

Positioning trailer in suitable dump

location;

Drain liquids first by drain al e.

Open the dump door by: -

Unlocking the door whilst the

acuum pump is still on;

Stand clear and turn off acuum

pump. Door will swing open by

itself.

Wash out tank with water blaster.

4

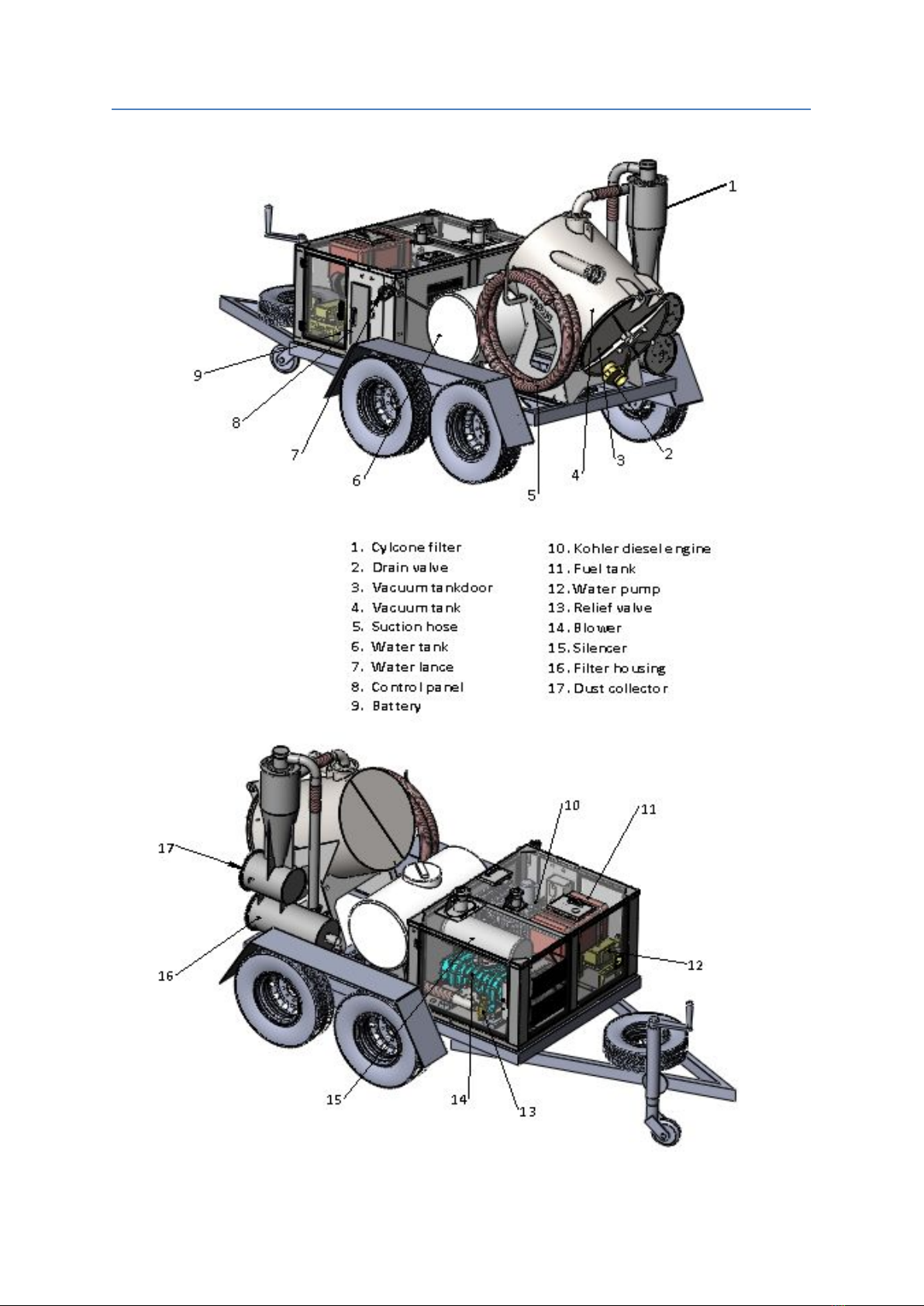

Machine Overview

5

Operating Principles

The Vacuum Exca ator works on the principle of air elocity in order to produce suction at

the end of the hose nozzle. Therefore if the end of the suction hose is fully plunged into

either a solid or liquid no air flow will occur and there will be no suction.

The acuum system uses a 3 stage filtration system in order to filter dirt from the air stream.

Firstly solid or liquid material is drawn into the air stream at the end of the suction hose and

tra els to the collection tank. Due to a sudden change in olume in the tank, the air speed

dramatically drops and the solid or liquid material falls out of the air stream into the collection

tank.

Second filtration is by cyclone to remo e any course dust particles.

Then the third and final stage remo es dust from the airstream ia a cartridge type air filter.

Air flow through the whole air circuit is important to ensure that suction is maintained. It is

critical not to o erload the filters in the air stream circuit. This is best achie ed by not sucking

dry material into the machine. Therefore always use water to break up the ground to be

sucked away by using the in-built water blaster.

The “No-Dig” action of the machine is achie ed by firstly wetting, loosening and breaking up

tight hard ground with the water blaster and then sucking away the loosened ground with the

acuum hose. The machine is primarily designed as a two person operation where one

person is performing the water blasting operation whilst the other is acuuming away the

loosened material.

The primary design intent of the machine is to loosen and suck away ground and small rocks

around buried ser ices or in tight work areas.

The machine is not designed or intended to for acuuming toxic or hazardous material. In

case of accidental contact with toxic or hazardous material use appropriate dumping and

clean out procedures.

6

Operating Instructions

Towing the Vacuum Excavator

Task Step Key Points

Trailer

inspection

1. Complete a trailer

inspection using the

checklist on the right.

ACTIVITY

Check that the following items on

the trailer: -

Any obvious damage to the

trailer structure

The tyres are correctly inflated

The wheel nuts are tight

The handbrake is operational

The safety chains are in good

order

All trailer lights are in good

condition

The wheel chocks are available

DANGER!!!

Do not tow the trailer if any

faults are found.

Towing vehicle

inspection

1. Complete a towing ehicle

inspection using the

checklist on the right.

ACTIVITY

Check that the following items on

the towing vehicle: -

Minimum towing capacity of 2T

50mm tow ball hitch with safety

chain connection rings

Trailer lights connection

Correct vehicle tow height for

the trailer

DANGER!!!

Do not tow the trailer with an

undersized towing capacity

ehicle.

Connect Trailer

to towing vehicle

1. Raise the trailer tow hitch

to abo e the height of the

ehicle tow ball.

Wind the jockey wheel handle in order to

raise the trailer hitch to be just slightly

higher than the trailer tow ball.

2. Position tow ball under the

trailer tow hitch.

Either back the ehicle or mo e the trailer

into the correct position. Be aware that the

trailer is ery hea y and difficult to mo e.

Apply hand brake on towing ehicle.

3. Lower the trailer hitch onto

the ehicle tow ball.

Wind the jockey wheel handle in order to

lower the trailer hitch onto the towing

ehicle tow ball. Remember to open the

trailer tow ball hitch to allow the ball to

fully engage with the hitch.

Secure tow ball hitch and lock out.

7

Task Step Key Points

4. Stow the jockey wheel. With the trailer correctly connected to the

trailer, release the jockey wheel clamp

and swing the jockey wheel 900 to ensure

it is clear of road.

5. Connect the safety chains. Connect the safety chains on the trailer to

the connection links on the towing ehicle

tow hitch.

6. Connect the electrical

connections.

Connect the trailer electrical connections

to the towing ehicle and check for correct

brake light and indicator light operation.

7. Stow wheel chocks. Collect the wheel chocks from the ground

and stow in brackets on the trailer.

8. Release the trailer

handbrake.

Operate the trailer handbrake le er and

ensure that the brakes are released.

DANGER!!!

Ensure that the re ersing arm is

returned to open position to

enable the trailer brakes to auto

operate.

Towing Trailer 1. Test ehicle / trailer

brakes.

If possible on a flat good road surface,

test that the towing ehicle can brake and

hold the Trailer

DANGER!!!

If the towing ehicle is ha ing

trouble being able to brake with

the load of the Vacuum machine

trailer then do not tow further.

2. Tow at a safe road speed. NOTE

The Vacuum Exca ator and

trailer ha e poor aerodynamics

and when the drum has contents

in it, it has a high centre of

gra ity

Only tow the VM500 Vacuum Machine

trailer at the following maximum speeds: -

80 km/hr on good sealed roads.

60 km/hr on unsealed or poor

condition sealed roads.

If strong cross winds or slippery roads,

reduce speed to a lower safer speed.

3. Trailer o erride brakes will

assist in braking the trailer.

REMEMBER!!!

The trailer is fitted with override

brakes that will assist in the

overall braking effort but can

produce jerks in stop-start traffic

8

Parking an Set-Up

Task Step Key Points

Positioning the

Trailer for

operation

1. Position trailer with towing

ehicle.

Use the towing ehicle to position the

Vacuum Machine in the correct location.

2. Install o erride-brake

locking latch if re ersing.

Prior o re ersing the trailer into position it

is necessary to swing the re ersing lea er

on the trailer hitch into position to pre ent

trailer brakes engaging whilst re ersing.

3. Check for reasonably

le el surface. No greater

than 200 lean angle.

Both the engine and the blower ha e

lubricating oil sumps in them. If the trailer

is parked at an angle of greater than 200

then oil star ation and equipment damage

can occur.

4. Apply towing ehicle and

trailer park brake.

Apply towing ehicle handbrake from

inside the ehicle and then apply the

trailer hand brake.

5. Install trailer wheel chocks Collect trailer wheel chocks from the

trailer and position under the trailer

wheels in the direction of most likely trailer

mo ement.

6. Lower jockey wheel. If detaching the towing ehicle from the

trailer, release the jockey wheel bracket,

swing down 900. Wind down jockey wheel

until it is touching the ground.

7. Disconnect the trailer from

the towing ehicle if

required.

The Vacuum Machine trailer can remain

attached to the towing ehicle or detached

if required.

ACTIVITY

If you wish to detach the towing

vehicle then: -

Disconnect the electrical

connection

Disconnect the safety chains

Release tow ball on trailer tow

hitch

Wind up jockey wheel until the

tow hitch clears the tow ball

Drive towing vehicle away

9

Operating Environment

Task Step Key Points

Check for

adequate fresh

air in operational

area

1. Check that the operating

area has adequate fresh

air.

DANGER!!!

DO NOT operate the Vacuum

Machine in an enclosed or mostly

enclosed building, tank or

underground basement without

providing adequate fresh air to

the operator’s position

Note The engine exhaust

gases are toxic.

ACTIVITY

If used in an operating area

where fan forced fresh air is

provided to the operator’s,

ensure that they also wear a gas

monitor for: -

High levels of Carbon

Monoxide and Carbon Dioxide;

Low levels of Oxygen

Operating Noise 1. Both the engine and

blower make loud

industrial noise.

Consider the impact of the operating

noise of the Vacuum Machine if used in

an area near residential, office or

shopping areas.

Also some planned work locations may

ha e night time noise restrictions.

10

Operating Vacuum Excavator

Task Step Key Points

Perform pre-

start check

1. Perform pre-start check of

the trailer engine and

blower.

ACTIVITY

Complete the Engine and Blower

pre-start check list section of the

Vacuum Excavator

Lay out suction

hose

1. Set up the suction hose

and connect to the

collection drum.

Unroll the suction hose from the machine

and lay it out on the ground. Ensure that it

is not forced around tight corners that will

damage the hose.

Attach the suction hose to the collection

drum using the Camlock fittings.

REMEMBER!!!

The suction hose is heavy duty

and heavy to lift Best performed

as a two person operation

Start the engine 1. Start the engine in order

to pro ide power to dri e

the blower.

ACTIVITY

Start the trailer engine by: -

Turn the battery isolator on

Rotate Emergency Stop to off

(out) position

Check for adequate fuel and

turn fuel lever to half

If petrol engine set the choke if

the engine is cold

Turn and hold the ignition key

in the “on” position until the

engine starts Let go of the key

If the engine is cold, allow it to

warm up for several minutes

When the engine is warm, bring

the operating speed up to full

speed

Vacuum

Excavation

1. Wear correct Personal

Protecti e Equipment

(PPE).

The combined operation of water blasting

and acuum exca ation can generate

blow back of high elocity particles.

The operator and persons nearby shall

wear: -

Face shield;

Ear plugs or muffs;

Industrial clothing or o eralls;

Closed in footwear.

2. Two Person operation NOTE

The removal of ground material

using the Vacuum Excavator is

best performed as a two person

team

One person operates the water

blaster, whilst the other the

vacuum hose / nozzle

11

Task Step Key Points

3. Initial ground breaking. First operate the water blaster from a

distance to wet the ground or completely

wet it with a garden hose. This will

minimise dust generation.

As the ground becomes wetter, bring the

water blaster nozzle closer to the ground

surface, but not too close to cause

extensi e splash back.

When loose ground is produced by the

water blaster, acuum it away with the

acuum hose nozzle with a maximum of

50% of the nozzle in the material.

DO NOT plunge the nozzle completely

into the ground as this will result in loss of

acuum and thus no material remo al.

REMEMBER!!!

DO NOT suck dry dusty ground

material, otherwise the machine

dust filters will become clogged

resulting in reduced or no

suction

4. Working the exposed

face.

When the initial section of material has

been remo ed, it will form an edge.

It is best for the water blaster operator to

blast and break away the exposed edge

whilst the acuum hose operator sucks

away the loosened material.

Reduced suction 1. Operator notices reduced

or no suction.

ACTIVITY

If reduced suction is noticed,

check the following: -

Suction nozzle is completely

covered Remove whatever is

covering the nozzle DO NOT

plunge the complete nozzle in

solids or liquids

Blocked suction hose A large

object may have lodged in the

suction hose and a blockage

has built up around it Shut

down the engine, remove the

suction hose and remove

blockage

Engine speed has dropped or

stopped Check if the engine

has run out of fuel

Full collection drum Empty the

drum

Blocked filter Shut down the

machine, remove and clean the

filter

Added length of suction hose

Reduce suction hose length to

standard supplied length

12

Task Step Key Points

Shutting down

the Vacuum

Excavator

1. Shut down water blaster. Switch off the water pump on the control

panel in order to stop the water blaster.

2. Empty the suction line. Lay the suction hose down with the nozzle

completely open to allow any material in

the suction hose to be sucked into the

collection drum.

3. Shut down engine.

(Lea e it on if material

discharge is going to

occur at current work

location)

Lower the engine speed to idle. After 10

seconds at idle, turn the ignition key to the

off position.

Emptying the

storage drum 1. Choose the discharge

location.

The material storage drum can be

emptied at the work location or towed to a

different location.

NOTE

If the trailer is going to be towed

to a different location for

emptying, always following the

towing instructions detailed

earlier in this manual

Also stow water blasting and

suction hoses as detailed below

2. Decide on liquid or solid

material release.

Dependent on what has been sucked into

the storage drum; choose a liquid release

instead of a solid release.

3. Mainly or initial LIQUID

release.

ACTIVITY

If mainly or initially a LIQUID

release then:-

Return the engine to idle and

switch off

Move to the rear of the

collection drum and slowly

open the gate valve and allow

the liquid to drain

4. Mainly SOLID material

release.

ACTIVITY

If mainly SOLID material release:

Ensure that the engine is at full

speed in order to achieve full

suction

Move to the rear of the

collection drum and unscrew

the central door handle until it

is completely released As long

as suction is being maintained,

the door will remain closed

Whilst no person is standing in

front of the door, return to the

engine, reduce the speed to

idle then switch it off

The drum door should open by

itself and the solid material

should discharge

13

Task Step Key Points

5. Washing inside of the

collection drum.

Use the water blaster to wash out any

remaining material.

NOTE

Do not water blast the rubber seal

at the end of the drum, otherwise

the seal can become damaged

and prevent correct vacuum seal

for the next operation

DANGER!!!

Do not enter the inside of the

collection drum without following

correct Confined Space entry

procedures

6. Lea e collection drum

door open to allow drum

to dry out.

If desired the drum door can be left open

to allow it to dry out.

DANGER!!!

Ensure that no member of the

public can access the open drum

Closing the

drum door

1. Correct body position The drum door is best closed by standing

directly behind the middle of the door.

2. Push the door shut. Using one foot lodged in the discharge of

the discharge al e, push the door shut

and engage the door locking handle.

DANGER!!!

Be aware of the pinch point area

between the door and the drum

Keep all hands and fingers clear

of this area

3. Fully close the door with

the locking screw.

When the locking screw is engaged, the

door can be fully closed by winding the

locking handle in until it is tight.

Packing up

hosing

1. Disconnect and pack

away suction hose.

Disconnect the suction nozzle from the

suction hose and stow it

The suction hose can remain connected

to the tank and coil up hose on the

pro ided hook.

REMEMBER!!!

The suction hose is heavy duty

and heavy to lift Best performed

as a two person operation

2. Disconnect and pack

away water blaster.

Disconnect the water blaster gun from the

hose and stow it.

Wind up the water blaster hose onto the

hose holding area.

14

Operating Water Blaster

Task Step Key Points

Perform a pre-

start check

1. Perform pre-start check of

the water blaster.

ACTIVITY

Complete the Water Blaster pre-

start check list section of the

Vacuum Excavator

Lay out pressure

hose and attach

water gun

1. Set up water pressure

hose and gun.

Uncoil water pressure hose from the

machine and lay it out on the ground.

Ensure that no kinks are made in the

hose.

Attach the water gun to the end of the

hose using the quick connect fittings.

Start the engine 1. Start the engine in order

to pro ide power to dri e

the high pressure water

pump.

Start the trailer engine as detailed in the

“Vacuum Exca ation” operating

instructions. Allow the engine to warm up.

Bring engine speed up to full.

Water Blasting 1. Wear correct Personal

Protecti e Equipment

(PPE).

The operation of water blasting can

generate blow back of high elocity

particles.

The operator & persons nearby shall

wear: -

Face shield

Ear plugs or muffs

Industrial clothing or o eralls

Closed in footwear

2. Engage the water pump

ia the control panel.

Engage the water pump by switching the

electric clutch to the “On” position on the

control panel.

3. Operate the trigger on the

water gun.

Operate the trigger on the water gun to

commence blasting operations.

4. Water blast at the correct

angle to exposed face.

The water blasting action will work best if

performed at a slight angle from the

ertical and “biting” away slowly from the

exposed face.

5. DO NOT water blast

people or animals.

DANGER!!!

Water blasting can cause injury

to persons

DO NOT water blast any part of a

person’s body or use it to wash

6. Do not run water pump

dry.

Always ensure that there is adequate

water in the water tank prior to operation

of the water blaster. Damage will occur to

the water pump if it is run dry.

7. Shut down water pump

when water blasting has

been completed.

If no further water blasting is going to

occur for a period of time, shut down the

water pump by switching the electric

clutch to the “Off” position.

Damage will occur to the water pump if no

flow occurs for an extended period of

time.

15

Task Step Key Points

Completed

Water Blasting

1. Switch off water pump. When water blasting has been completed,

switch water pump to the “Off” position.

2. Disconnect water Lance Disconnect the water blasting gun from

the hose using the quick connect

coupling.

Stow water blasting gun on trailer.

3. Stow water blasting hose. Wind up and stow the water blasting hose

on the trailer. Ensure the hose is not

kinked whilst stowing it.

16

En of Day (Shift) Servicing of the Vacuum Machine

Task Step Key Points

End of day

(shift) servicing 1. Shutdown and if required

isolate the engine, using

battery isolator.

DANGER!!!

The machine drive engine must

be shut down If required by your

worksite, switch off battery

isolator and lock it out prior to

performing any servicing tasks

2. Clean the blower pre-

filters

The blower is protected by a cyclone pre-

filter and final cartridge filter.

3. Cleaning cyclone filter. Remo e the co er door & place to one

side. The chamber may ha e some

collected dust.

Sweep the dust out with a brush.

If this chamber has a lot of dust in it, the

suction work has been performed “too

dry”. Next time use more water.

Replace the co er door.

4. Cleaning filter cartridge. Remo e co er door & place to one side.

Remo e the cartridge filter and at a

separate location either blow it clean with

compressed air (max pressure 100 kPa)

or wash it with a garden hose. Do not use

the water blaster.

If washed allow the filter to dry before

reinstalling.

NOTE

DO NOT bang filter cartridge on

ground to clean it, as it will

damage the filter and potentially

cause damage to the blower

5. Reinstall filter cartridge. When the filter cartridge is clean and dry,

reinstall into the chamber and replace the

co er door.

6. Refill the water tank. For most work tasks the water tank has

sufficient quantity of water to last one

waste tank fill.

Refill the tank with water as required. Only

use clean water to fill the tank and do not

add any detergents etc.

Check and if necessary clean the water

filter.

7. Refill engine fuel tank. For most work tasks the fuel tank has

enough fuel to last one day or shift.

Refill the fuel tank with the correct fuel at

the end of the working day.

8. Conduct a general

condition check.

Conduct a general condition check of the

machine looking for oil leaks, damaged

hoses, flat tyres etc.

17

Trouble Shooting Guide

If your Vacuum Machine fails to function correctly, refer to the following table for potential

issues and solutions.

Symptom Cause Solution

1. Engine does not turn

over.

a) Low or dead battery

b) Corroded or bad connections

c) Faulty ignition switch

d) Faulty starter motor

e) Seized blower

a) Charge or replace battery

b) Clean or replace connections

c) Replace ignition switch

d) Replace starter motor

e) Clean out or replace blower.

2. Engine does not start

a) Emergency Stop pressed in

b) Battery Isolator

c) Empty uel tank

d) Fuel line disconnected

e) Dirty uel ilter

) Faulty uel pump

g) Faulty spark / glow plugs

h) Faulty ignition coil

a) Release Emergency Stop

b) Open Battery Isolator switch

c) Re ill uel tank

d) Connect uel line

e) Replace uel ilter

) Replace uel pump

g) Replace spark / glow plugs

h) Replace ignition coil

3. Engine lugs or stalls

a) Empty uel tank

b) Engine speed too low

c) Vacuum relie blocked or set

too high

d) Air ilter blocked

a) Re ill uel tank

b) Increase engine speed to 3600 RPM

c) Clean relie area or readjust relie

setting

d) Clean or replace air ilter

4. No water pressure

a) Water pump not switched on

b) Water tank empty

c) Water ilter blocked

d) Water nozzle blocked

e) Air in water system

) Water pump not turning

g) Blocked water supply hose

h) Faulty water pump

a) Switch on water pump

b) Re ill water tank

c) Clean or replace water ilter

d) Clean or replace nozzle

e) See #8 below

) See # 7 below

g) Clean or replace hose

h) Replace water pump

5. Low water pressure

a) Water ilter partially blocked

b) Air in the water system

c) Leak in the water system

d) Water pump turning too slow

e) Incorrect nozzle size or worn

out nozzle

a) Clean or replace water ilter

b) See #8 below

c) Repair leak

d) See #7 below

e) Replace with correct or new nozzle

6. Water pressure

fluctuates up and

down

a) Air in the water system

b) Leak in the water system

c) Water ilter partially blocked

a) See #8 below

b) Repair leak

c) Clean or replace water ilter

7. Water pump not

turning or turning too

slowl

a) Engine speed too low

b) Water pump rozen

c) Faulty water pump

a) Increase engine speed to 3600 RPM

b) Thaw out pump

c) Replace water pump

8. Air in water s stem a) Cracked ilter housing

b) Loose itting(s)

a) Replace ilter housing

b) Tighten ittings

For further assistance, please call No Dig Equipment Ser ice Department on (08) 9493 0642.

Our technician will be pleased to assist you with your questions

18

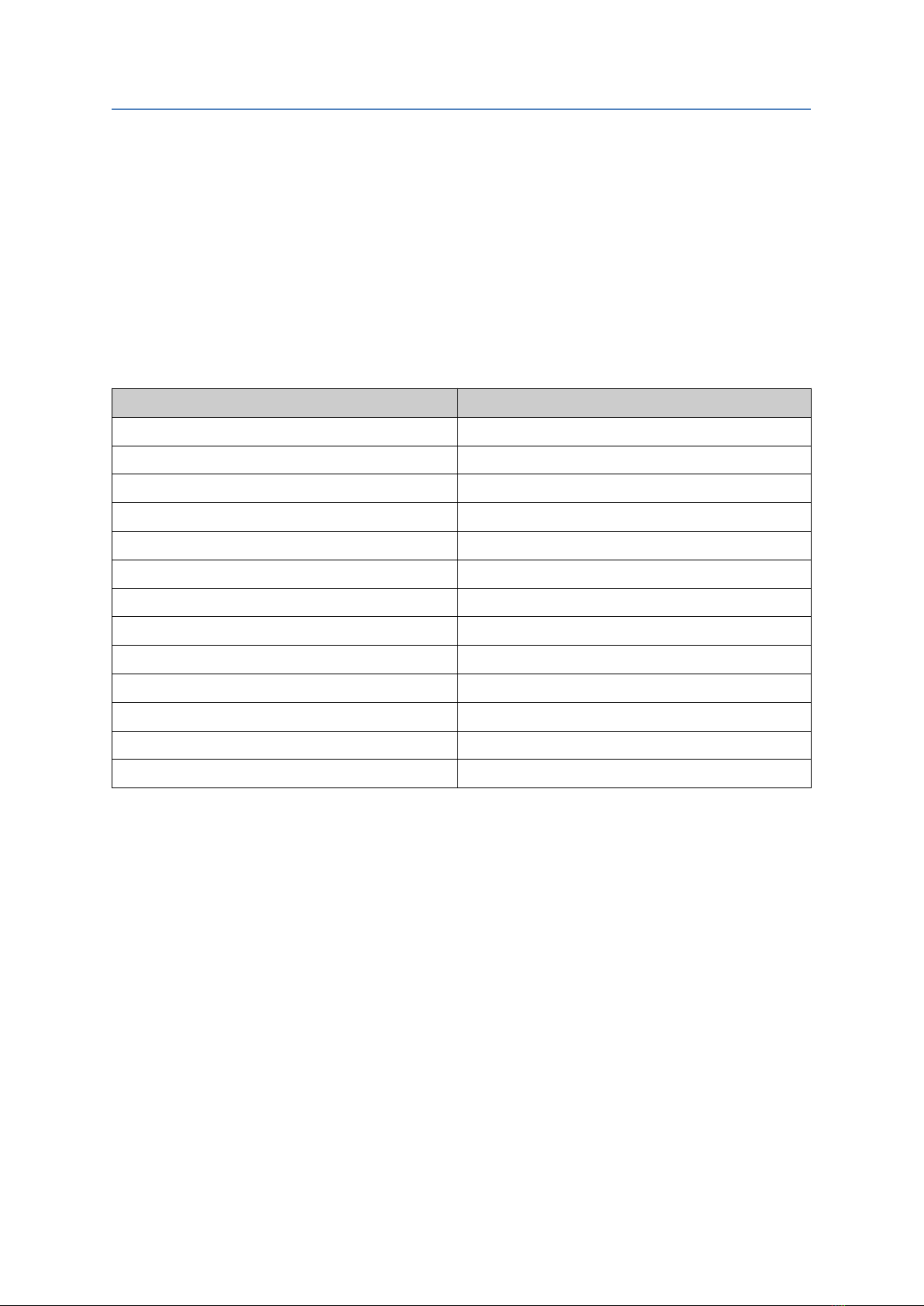

etermining Tank Fill Level

Note: applicable to trailer units only.

The VM500 is designed as a potholing machine and its general operation is suck and dump.

It can be used to cart spoil but caution must be exercised to ensure the trailer is not

o erloaded. Use the reference chart below to help determine how full of arious materials

the acuum tank can be without o erloading the trailer.

Exceeding the maximum fill le el will o erload the trailer.

To use this chart, first find the material being exca ated, if the material being exca ated is

not listed, select material with similar density. Then determine the maximum fill le el.

Material Maximum Vacuum Tank Fill Le el

Wood Chip 100%

Leaf / grass waste 100%

Water 100%

Drill Mud high water contents 100%

Sand 100%

Earth loose 100%

Limestone 100%

Asphalt 100%

Granite / Road Base 100%

Pindan / Iron Ore based mud 100%

Gra el 100%

Shale, rip rap. 100%

19

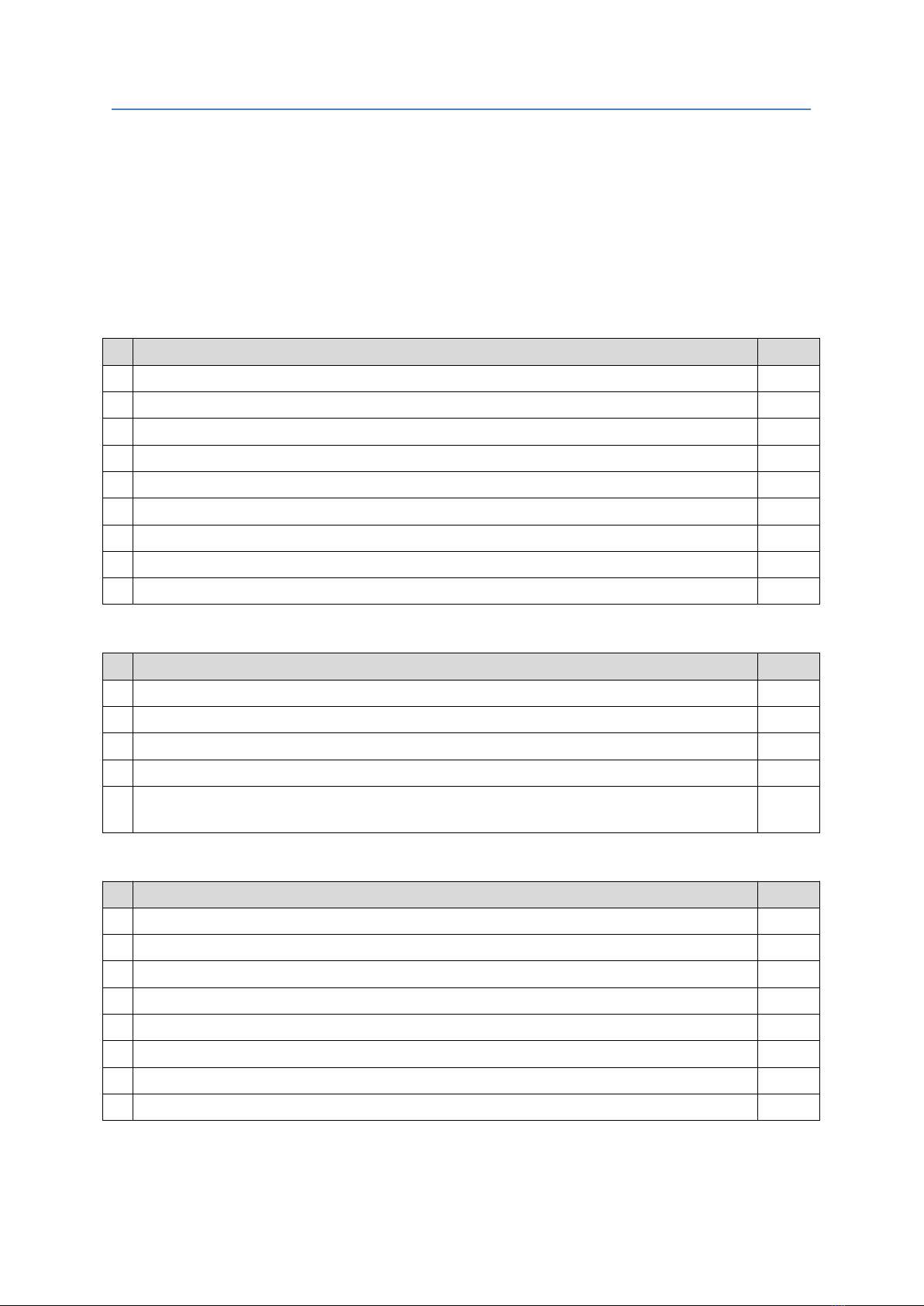

aily (Shift) Pre-Start Checklist

The following two page checklist should be used at the start of each working day (shift)

rele ant to the area(s) of the Vacuum Machine that will be used during the working day. A

rele ant section of the checklist may be filled out prior to the area of the machine being

used.

Vacuum Machine Location ______________________________ Date: __________

Pre-Start – Towing

# Pre-Start Check Requirement Initials

1 Check general condition o the trailer – no damage or protruding items – drum door closed.

2 Check tyres are correctly in lated and no visual damage to them.

3 Check wheel nut tightness – Tight turning the heavy trailer can cause the wheel nuts to loosen.

4 Check that the towing vehicle has a minimum o two (2) tonne towing capacity.

5 Check that towing vehicle has a standard diameter 50mm tow ball.

6 Connect trailer to vehicle – Check sa ety chains are secured and electrical connections made.

7 Check or correct operation o all trailer lights.

8 With vehicle handbrake applied, check that trailer handbrake is released & revering link removed.

9 Stow jockey wheel and wheel chocks correctly.

Pre-Start – Operational Set-Up

# Pre-Start Check Requirement Initials

1 Check that trailer handbrake is applied and wheel chocks installed.

2 Ensure that trailer operation angle does not exceed 20 degrees in any direction.

3 Check that the operational environment is not in an enclosed or partially enclosed building.

4 Plan where the removed material will be dumped.

5 Check that the planned material to be removed is not acidic, caustic, combustible, lammable,

toxic or hazardous material such as asbestos etc.

Pre-Start – Water Blaster

# Pre-Start Check Requirement Initials

1 Check that the water tank has su icient water in it.

2 Check or correct oil level on the water pump – look at sight glass.

3 Check the condition o the water pressure hose – no damage or kinks

4 Check the condition o the water blaster wand & nozzle. Do not inspect whilst connected to hose.

5 Check that the quick connect unctions correctly.

6 Visual checks or water leaks in hoses rom water tank to pump.

7 Clean water ilter i required.

8 Operator is competent to use the water blaster.

20

Table of contents

Popular Utility Vehicle manuals by other brands

Toro

Toro 07252 Workman 1100 Operator's manual

Nilfisk-Advance

Nilfisk-Advance City Ranger 3500 Operator's manual

Taylor-Dunn

Taylor-Dunn ET-015-00 Operation, t roubleshooting and replacement parts manual

Vermeer

Vermeer S650TX Operator's manual

Cushman

Cushman Trackster 898002 Operator's manual

Komatsu

Komatsu D61EX-24 Operation & maintenance manual

Roketa

Roketa GK-13 Owners manual, assembly guide, and parts list

Ingersoll-Rand

Ingersoll-Rand Club Car CARRYALL 710 LSV ELECTRIC Operator's manual

ACG

ACG MOKE NEV 2016 owner's manual

TOMCAR

TOMCAR Utility Vehicle Service manual

Selecta

Selecta TC3080PL Assembly instructions

TYCROP

TYCROP SmoothFlow SF3 owner's manual