AUTOMATIC SOFTENERS INSTRUCTIONS MANUAL

AM/T AM/RT AM/V AM/RV AM/METER AM/R METER

s.r.l. - ITALY Page 8 of 15 am_tvm_mi-r1.doc - r.1

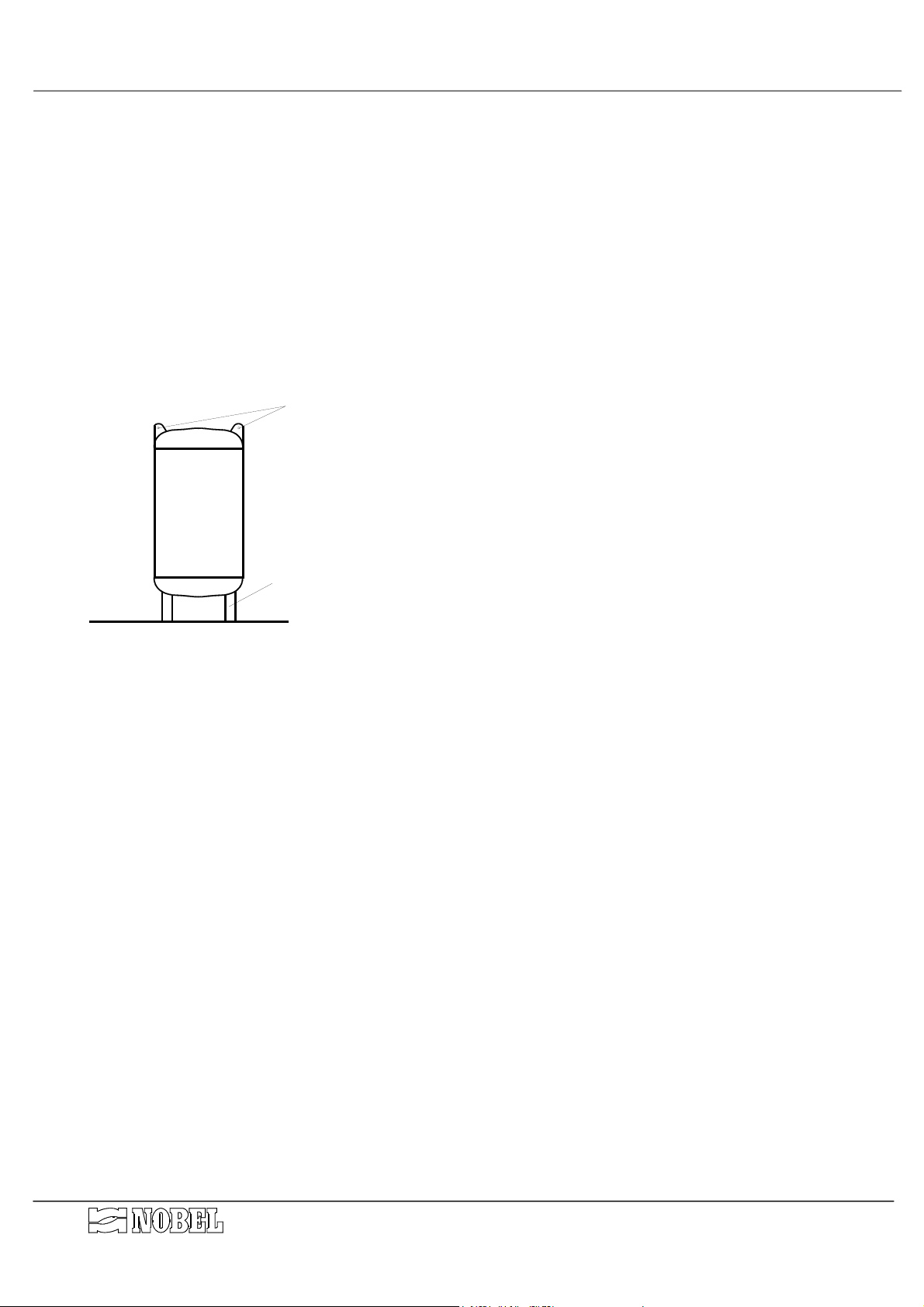

4.5. Hydraulic connections

(see installation and components drawings)

In order to avoid shut-off during maintenance operations, an emergency by-pass line

should be provided

•Connection of inlet fittings

For models AM/R, AM2700 and AM3300 only:complete the line from the untreated water line

to the outlet fitting of the regeneration valve.

For all other AM models:complete the line from the untreated water line to the outlet fitting of

the regeneration valve; connect also the inlet membrane valve V2 to the same water line.

•Connection of outlet fittings :

SERIES /T and /V, models AM/R, AM2700 and AM3300 only:complete the line of the treated

water line to the inlet fitting of the regeneration valve.

SERIES /T and /V, all other AM models:complete the line of the treated water line to the inlet

fitting of the regeneration valve; connect also the outlet membrane valve V1 to the same

water line.

SERIES METER: complete the line of the treated water line to the outlet membrane valve V1.

For models AM/R, AM2700 and AM3300 only the outlet membrane valve is installed

immediately downstream of the outlet fitting of the regeneration valve.

For all other AM models the outlet membrane valve is plumbed at the bottom side of the resins

columns and the outlet fitting of regeneration line is plugged.

•Insert horizontally the pulse sender water meter downstream of outlet connections, (only for

series AM/V, AM/RV, AM/METER and AM/R METER).

•Connect the drain fitting placed on the side of the automatic valve to a floor drain. The gate

valve mounted on the drain fitting will be used to adjust the backwash flow rate.

A common flexible pipe made in plastic or rubber can be used for the drain line downstream

of the gate valve; its size must be equal or larger of the one mentioned on

“CHARACTERISTICS FOR EACH MODEL” table.

It is suggested that the drain line could be inspected in order to check quantity and quality of

drain water, as well as any leakage of resins from the unit.

CAUTION : Do not run the drain line together with overflow line of the brine tank; it will cause

the filling of the brine tank.

•Connect the over-flow fitting of the brine tank to a floor drain, with a line separated from the

drain lines of the vessels. Use proper sized flexible plastic or PVC pipe.

•Complete the line from the brine drawing fitting (on the side of the automatic valve) to the

float valve of the brine tank. For models up to AM 2100, use for the connection the supplied

plastic tubing ø 9.5 (mm); for models AM 2700 and over use ¾" galvanized pipe, or proper

sized PVC or plastic tubing, suitable to withstand the pressure and depressure (0.5 bar

negative).

•run the plastic tubes, already connected to the electronic programmer, to the fittings placed

on the control valves and on the diaphragm valves, according to the numbered sketch.

CAUTION : to avoid any damage of the plastic fittings and parts, it is required to hold all the

piping using adequately sized brackets.

4.6. Electrical wiring connections

•Connect the power feeder of the programmer to a power socket; check that the available

power is correct as listed in technical characteristics (see § 3.2 page 5).

•Connect the DIN plug from the water meter on the socket placed on the side of the

electronic programmer (only for series AM/V, AM/RV, AM/METER and AM/R METER).