NOCRY NRT-128AC User manual

Rotary Tool Kit

Instruction Manual

We've worked very hard on making this manual useful, simple and understandable.

Please read it carefully, and keep it safe inside your rotary tool kit for future reference.

1

WHAT'S INSIDE THIS MANUAL

THE ABC'S OF POWER TOOL SAFETY 4

Basics of your work area safety 5

Basics of electrical safety 5

Basics of personal safety 6

Basics of servicing your power tools 7

THE ABC'S OF ROTARY TOOL SAFETY 8

Basics of safe rotary tool use 8

Grinding, cutting and sanding safety 9

Polishing safety 11

Wire brushing safety 11

TECHNICAL SPECIFICATIONS 12

All rotary tool parts 13

INCLUDED ATTACHMENTS & THEIR PURPOSES 14

INCLUDED ACCESSORIES & THEIR PURPOSES 17

Carving and engraving accessories 17

Cutting accessories 17

Grinding and sharpening accessories 19

Cleaning and polishing accessories 20

Sanding accessories 21

Drilling accessories 23

Adjustment accessories 23

HOW TO USE YOUR ROTARY TOOL 24

How to switch the rotary tool on or off 24

How to select and adjust the speed 24

Recommended speed settings for carving and engraving 24

Recommended speed settings for cutting 25

Recommended speed settings for grinding and sharpening 26

Recommended speed settings for cleaning and polishing 26

Recommended speed settings for sanding 27

Recommended speed settings for drilling 27

2

How to attach and change accessories with the collet nut kit 28

How to attach and change accessories using the chuck 30

How to adjust the chuck for different size accessories 30

How to fit a cutting or sanding disc 31

How to fit a felt wheel 32

How to fit a sanding band 33

How to install the flexible driver 34

How to attach an accessory to the flexible driver 35

How to set up the rotary tool stand 36

How to attach the handle for precision work 36

How to attach and use the cutting set 37

How to attach and use the sanding/grinding guide 37

How to attach and use the sharpening guide 38

How to replace the motor brushes 39

CLEANING AND MAINTENANCE 39

Cleaning 39

Maintenance 40

Responsible ways of disposal 40

ROTARY TOOL LIABILITY 4 0

WARRANTY 4 1

HOW TO CONTACT NOCRY 42

3

THE ABC'S OF POWER TOOL SAFETY

Please, please read all safety warnings and instructions - they're pretty

reasonable. We don't mean to sound dramatic, but neglecting the warnings and

instructions may actually result in electric shock, fire, and/or serious injury easier

than you might think. There's other - better ways to get your adrenaline going.

Also, save this manual for future reference . Reviewing it once in a while in

between rotary tool uses and before instructing others won't hurt either - in fact,

we strongly recommend it. If someone else is going to be operating this tool, make

sure they have read and understood all the information in this manual prior to

handling your rotary tool. Makes sense, right?

To clarify, the following safety instructions refer to all of your mains-operated

power tools (the tools with a power cable), and to your battery operated tools (the

tools with batteries and without a power cable). In addition to these, we've listed

the specific safety instructions relevant to your new NoCry rotary tool in the next

chapter - take a look at those as well.

✔

✔

✔

✔

Don't force the tool. No one is fond of having to do something they're forced

to do - same goes for your power tools. Do not overload them, and use the

right one for the job. A suitable power tool will do a thousand times better

and safer job than one that wasn't exactly designed for the task at hand.

Do not use a malfunctioning tool. If the switch doesn't turn on and/or off,

it's a pretty clear sign to not use the power tool and to get it repaired or

replaced.

Disconnect the tool from the power source and/or the battery pack before

making any adjustments, changing accessories, or putting it in storage.

This way, you'll ensure it will not turn on accidentally.

Keep your power tool away from others. Store it away from children and do

not allow anyone unfamiliar with your power tool or this manual, to operate

it.

4

✔

✔

✔

To keep your power tools well-maintained, regularly check if any parts are

misaligned, damaged or broken, or if there's anything else that might affect

their performance. If you notice anything odd, definitely bring the power tool

for repair BEFORE using it.

Keep your cutting tools sharp and clean. Cutting tools that have been

carefully maintained and have sharp cutting edges will jam less and be easier

to control. If you think that more injuries are caused by sharp tools than dull

ones, you'd be surprised.

Use the accessories and attachments as intended. On pages 14-23, we've

listed all accessories & attachments that come with your rotary tool, and

their purpose. Stick to that list.

Basics of your work area safety

✔

✔

✔

Keep your working area clean and well illuminated. Accidents are much

more likely to happen in messy, dirty, or dark workspaces - accidents that are

super easy to avoid with basic upkeep.

Do not operate your power tools in dusty or explosive areas, such as in the

presence of flammable liquids or gases, for a very simple reason - power

tools create sparks which may ignite the dust or fumes. Not the kind of

fireworks we want.

Keep children and bystanders away. Distractions can easily cause you to

lose control, so consider operating your power tools as your alone time. You'll

catch up with everyone later, when you've made some progress with the

project.

5

Basics of electrical safety

✔

✔

✔

✔

✔

✔

Do not modify the plugs, and make sure they match the outlet to reduce

your chances on getting an electric shock. Also, adapter plugs and earthed

(grounded) power tools are a really bad combo.

Do not abuse the cord. The cord isn't the reason you're having a bad day -

and it won't be, if you won't use it for carrying, pulling, or unplugging the

power tool, and will keep it away from heat, oil, sharp edges, and moving

parts.

Avoid body contact with earthed or grounded surfaces such as pipes,

radiators, stoves, and refrigerators.

When working outside, use an extension cord meant specifically for

outdoors use. It's going to be much more convenient, and will reduce the risk

of an electric shock.

Do not expose the tool to rain and wet conditions. Search “water and

electricity don't mix” on YouTube, and you'll see why.

If damp conditions are unavoidable , use a residual current device (RCD)

protected supply.

Basics of personal safety

✔

✔

Common sense is the best protection, isn't it? Stay alert - watch what

you're doing, exercise common sense, and do not operate your power tools

when you're tired or under the influence of drugs, alcohol, or strong

medications. It takes a split second of inattention to get into major medical

bills that could have easily been avoided.

To avoid unintentionally starting the tool, make sure the power switch is in

the off-position before connecting the tool to a power source and/or battery

6

✔

✔

✔

✔

✔

pack, or before picking up or carrying the tool. Also, learn to never carry

power tools with your finger on the power switch.

Remove any adjusting key or wrench before turning your power tool on. A

wrench or a key left attached to a rotating part of a power tool will ruin your

day real fast.

Do not take unnecessary risks by trying to reach areas that are obviously

too far away to reach safely. Keep proper footing and balance at all times -

it'll help you keep control in unexpected circumstances, would it be the

power tool slipping out of your hands, or someone deciding it would be fun to

attempt to pull a jumpscare on you in your workshop.

Don't underestimate the power of safety gear. No one has ever felt sorry

about using safety glasses, gloves, dust masks, non skid safety shoes, hard

hats, and/or hearing protection when operating power tools. But there's A

LOT of people who feel sorry they didn't. On that note…

Dress appropriately. Your power tools strongly prefer clothing and

accessories that are tight on your body. Do not wear loose clothing or

jewelry, keep your hair, clothing and gloves away from moving parts, and

you'll never have to experience your power tools trying to rip them off you.

Dust safely. If you're using a specific device for dust extraction and

collection, ensure that it's connected and used properly.

Basics of servicing your power tools

✔

Find a qualified repair person who only uses replacement parts identical to

the original to service and repair your power tools. This will ensure that the

safety of the power tool is maintained, and there will be no unpleasant

surprises. Pro tip: Take this manual with you to the service point, just in case.

7

THE ABC'S OF ROTARY TOOL SAFETY

These are the basic precautions you should take before, during, and after working

with your NoCry rotary tool to not end up crying over your medical bills, destroyed

workshop, or a lifeless tool. We've tried to keep it real and understandable, but if

you have any questions, feel free to let us know at wecare@nocry.com .

Basics of safe rotary tool use

✔

✔

✔

✔

✔

Keep your hands far enough from the rotating parts and cutting

attachments. If those attachments and accessories can be effectively used

on glass, metal, and other hard materials, just imagine what they could do to

your digits.

Secure the workpiece. We're not underestimating you, but a workpiece

secured with suitable clamps or in a vice is much more likely to be steady and

stay in place than one held by a hand.

Do not use third-party accessories (such as grinding discs) with the

maximum rated speed below 35,000 RPM. The power of the rotary tool will

most likely tear them apart and scatter them everywhere. Imagine a piece of

rough sandpaper hitting your face at 100mph - not the most pleasant of

experiences. And while we're on the topic...

Do not use accessories or attachments other than the ones recommended

in this user manual. We've included quite a wide variety of add-ons to get

everything done. But if you do wish us to consider adding another one, let us

know at wecare@nocry.com , and we'll see what we can do (we already tried

adding a can opener - it was a bad idea).

When the power supply is interrupted (for example, in case of a power

failure or when the mains plug is pulled), immediately set the on/off switch

to the “off” position to prevent uncontrolled restarting.

8

✔

✔

✔

✔

✔

If you absolutely must have children in the working area, make sure they're

closely supervised by another (responsible) adult and do not interfere with

your work.

Find out if there are any utility lines hidden in the work area. Use suitable

detectors or call the local utility company for assistance. It's totally worth it -

only imagine the level of booms and ouchies that coming in contact with

electric lines, damaging a gas line, or penetrating a water line can bring.

Make sure that everyone using your rotary tool kit or servicing it is

acquainted with this manual. The exception to the rule are children and

infirm people - they shouldn't be using your rotary tool even if they

remember every word written here.

Are you familiar with the accident prevention regulations and general

rules of occupational health and safety in force in your area? No? The

sooner you get acquainted, the sooner you can start using your rotary tool

there.

Do not underestimate the power of personal safety equipment. It'll make

your life way easier and better. Without goggles or safety glasses, you risk

damage to your eyes. Without an effective dust mask, you risk damaging

your lungs. Without a pair of noise-reducing earmuffs, you risk impairing

your hearing. In short - eye, head, ear, hand, foot, and respiratory

protection is a must when operating your rotary tool.

NB! NoCry Work & Safety Gear and the manufacturer shall not be liable for any

changes made to the tool, nor for any damage resulting from such changes.

Grinding, cutting and sanding safety

✔

Do not position your hand in line with or behind the rotating disc. The

kickback would most likely cost you your hand.

9

✔

✔

✔

✔

✔

✔

✔

To avoid damaging the discs and bits, only use accessory types that are

included in your rotary tool kit, and only use them for the recommended

applications. For example, do not grind with the flat surface of a cut-off disc -

it's intended for peripheral grinding, and applying side force may cause the

disc to shatter.

Only use undamaged mandrels that are of correct size and length to reduce

the possibility of cutting and sanding disc breakage.

Do not “jam” the cut-off disc, apply excessive pressure, or attempt to

make an excessively deep cut. It over-stresses the disc, increasing the risk

of it catching your hand or fingers. Your rotary tool will do the job like a hot

knife on butter even without additional effort on your part - save the energy

for showing off the finished work.

If the disc is binding or interrupting a cut for no reason, switch the rotary

tool off in the middle of the cut and hold it in the cut motionless until the disc

comes to a complete stop. Then and only then remove it from the cut,

investigate the cause of the disc binding and make it right before getting

back to work. On that note...

You can switch the rotary tool off, but do not restart it with the disc still in

the material. Instead, let the disc reach full speed in the air, and then

carefully re-enter the cut.

Use extra caution when making a “pocket cut” into existing walls or other

blind areas. The protruding disc may cut gas or water pipes, electrical wiring,

or objects that can cause kickback and other issues you don't want.

Use support underneath any workpiece - especially the larger ones. Large

workpieces tend to sag under their own weight, so, to minimize the risk of

disc pinching and kickback, it's best to place the support panels under the

workpiece near the line of cut and near the edge of the workpiece on both

sides of the disc.

10

Polishing safety

✔

This one is pretty straightforward: Do not allow any loose portion of the

polishing wheel to spin freely. Tuck away or trim any loose polishing wheel

strings, so they can't entangle your fingers or snag on the workpiece.

Wire brushing safety

✔

✔

✔

Be aware that the brush throws wire bristles even during ordinary

operation. So do not overstress the wires by applying excessive load to the

brush. It might also be useful to keep in mind that they can easily penetrate

light clothing and/or skin.

Allow the brush to run at operating speed for at least one minute before

using it. During this time, no one is to stand in front of or in line with the

brush to not get hit with the loose bristles and wires that are discharged

during the run-in time.

During use, direct the discharge of the spinning wire brush away from you

to avoid the small particles and tiny wire fragments become embedded in

your skin at high velocity.

11

TECHNICAL SPECIFICATIONS

NoCry Rotary Tool NRT-128AC

Voltage

120V ~ 60Hz

Rated power

1.4 Amps

No load speed

8,000-35,000 RPM

-1

Collet/Chuck diameter

Ø1/8 in

Weight

1.58 lb

Protection class

回/II

12

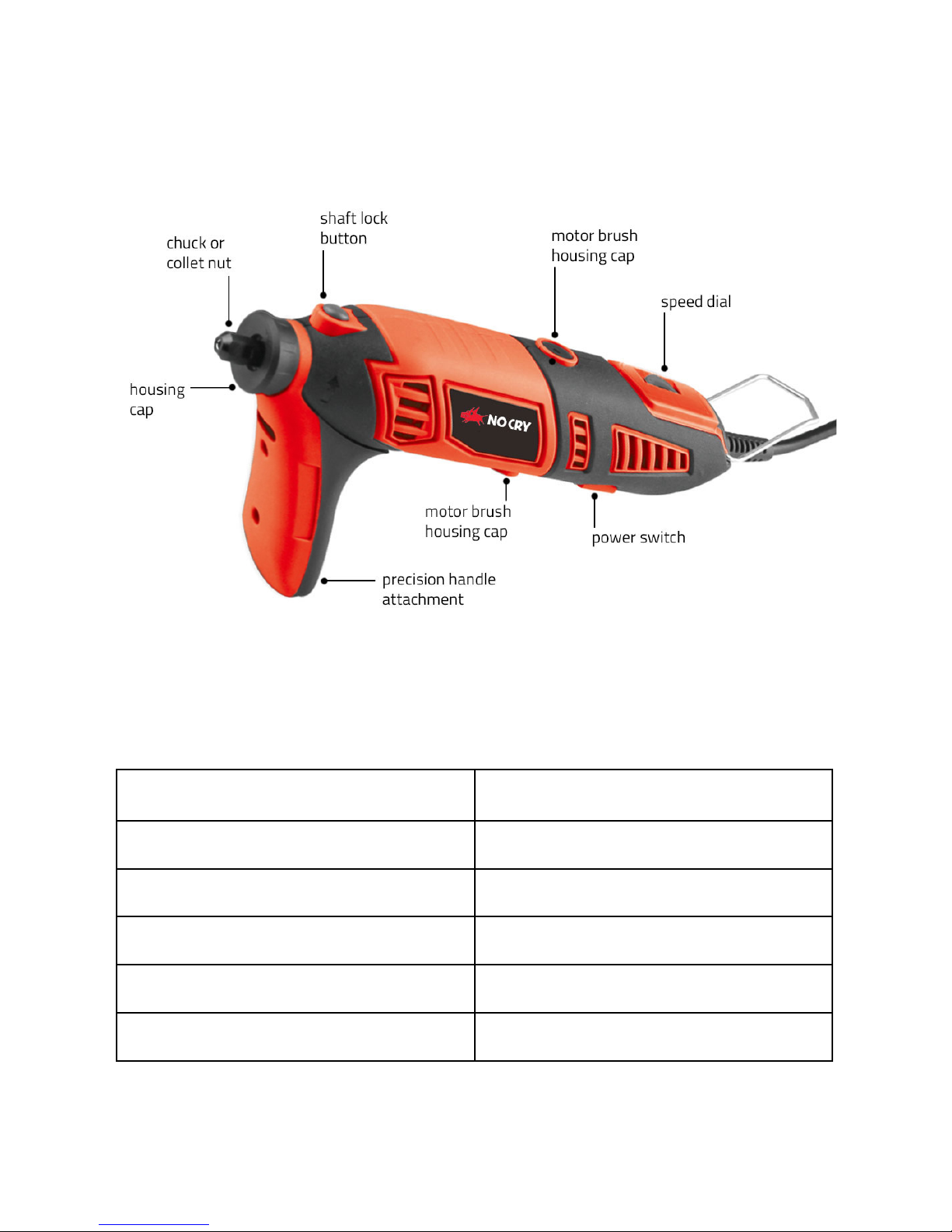

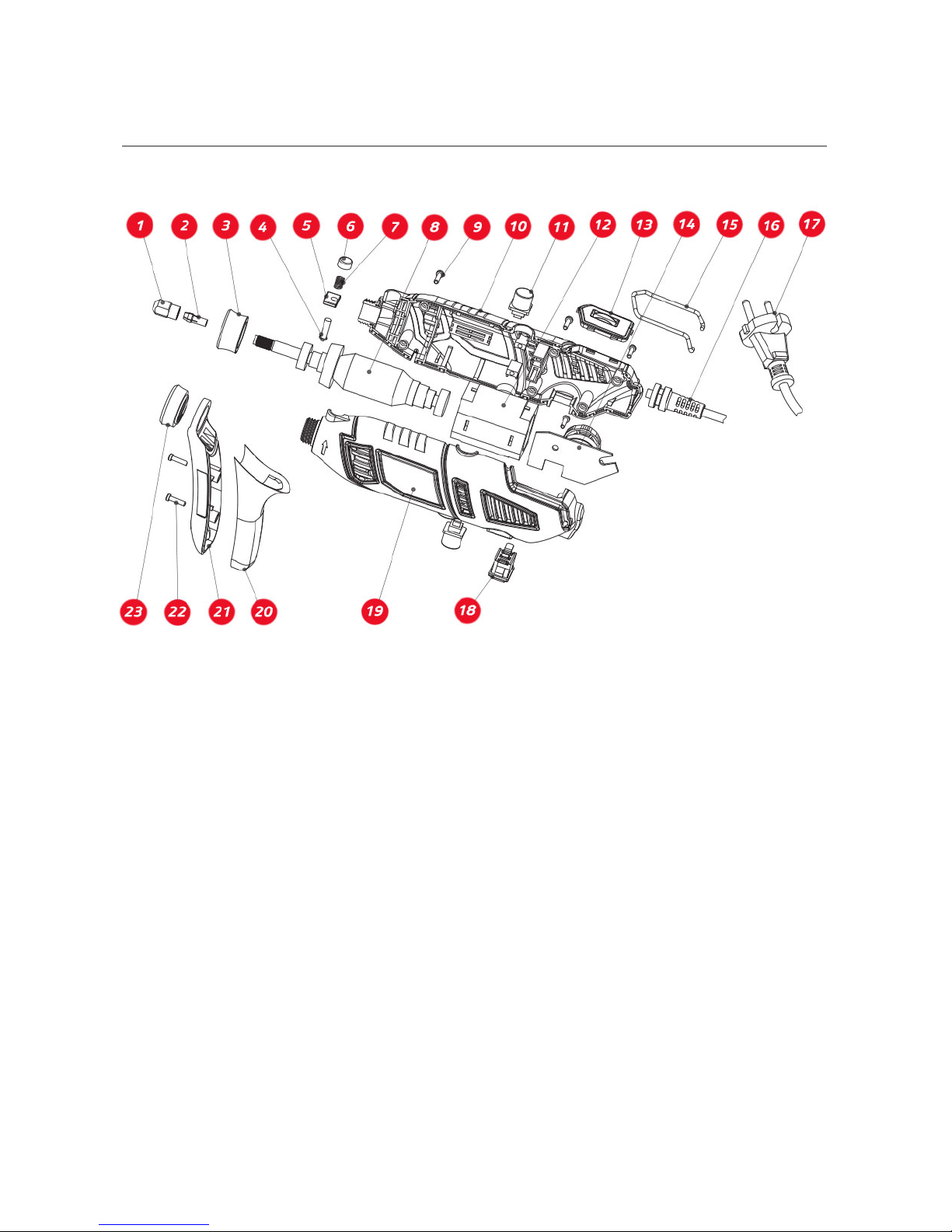

All rotary tool parts

1Collet nut. 2Collet. 3Housing cap. 4Shaft lock. 5Gasket. 6Shaft lock button.

7Spring of the shaft lock. 8Rotor. 9Screw. 10 Right body. 11 Carbon brush.

12 Stator. 13 Speed dial. 14 Circuit board. 15 Hanger. 16 Cord sleeve. 17 Plug.

18 Switch. 19 Left body. 20 Right handle. 21 Left handle. 22 Handle screws.

23 Housing cap.

13

INCLUDED ATTACHMENTS & THEIR PURPOSES

These attachments will help you get the most from all the different accessories

that come with your rotary tool kit (you can find the accessories list on pages

17-23). Here are the attachments we've included in the package - note that the

images are not to scale:

1 CHUCK

The adjustable chuck is a godsend for when you

want to quickly and easily change between

almost all rotary tool accessories, as the grip

can be easily adjusted for shanks with a

diameter of up to 1/8in. Find our tips on installing

and using it on page 30.

1 COLLET NUT SET

The most precise and secure way to hold an

accessory at high speeds. The collets come in 3

sizes (Ø1/8in, 3/32in and 1/16in) to ensure the

tightest fit for your chosen accessory. It's not as

straightforward to use as the adjustable chuck, but

still pretty simple - see the instructions on page 28.

1 FLEXIBLE DRIVER

Perfect for when you need to use the rotary

tool in hard to reach places, or for finesse work

- like when cutting or engraving. Find the steps

for installing and using the flexible driver on page

34.

14

1 ROTARY TOOL STAND

The stand is used to hold the rotary tool up for

maximum mobility when using the flexible

driver. If you can't immediately recognize it,

know that it consists of a table clamp and an

adjustable height rod, and comes disassembled

in the box - find our tips on setting it up on page

36.

1 PRECISION HANDLE SET

This is the key to doing any sort of precision

work with your rotary tool - it redistributes the

weight of the tool to your palm for improved

balance, which is oh-so important for those

precision projects. When looking for it in the

box, keep in mind that the set consists of the

precision handle and the narrow housing cap.

Find tips on attaching and using it on page 36.

1 CUTTING SET

The cutting guide with adjustable depth and the

3 drill bits together allow for a sturdy and

controlled cut with maximum visibility. Look for

the set-up instructions on page 37, and speed &

material recommendations - on page 25.

Pro tip: The drill bits can also be used

independently from the cutting guide, to help

you get the most from the kit.

15

1 PIVOT LIGHT

Even though you won't be using your rotary tool

in dark conditions, sometimes, a little extra light

is necessary for detailed work. The set-up is

pretty simple - replace the housing cap with the

pivot light, and you're good to go.

1 SHIELD

This bad boy provides additional protection by

redirecting sparks and debris while cutting,

grinding, sanding, and polishing. Just replace the

housing cap with the shield, and don't worry -

it's compact enough to not disturb your work.

A SANDING/GRINDING GUIDE

The platform provides stability and enhanced

control during edge sanding and sharpening.

Interested? Find the set-up & use instructions on

page 37.

1 SHARPENING GUIDE

Use the guide with the grinding stones and

sanding bands to sharpen all blades, such as

shears, hoes, lawn mower blades, shovels etc.,

at the optimal angle. Find our tips on using it with

your rotary tool on page 38, and the speed &

material recommendations for sharpening - on

page 26.

16

INCLUDED ACCESSORIES & THEIR PURPOSES

The below listed accessories, used with the appropriate attachments, are the key

to gettings things done with your rotary tool. Note that the images may not be to

scale.

We'd love to keep up with your projects - share the process (and the finished work)

with us sometimes via Instagram with the hashtag #nocrygear, on our Facebook

page, or via email to wecare@nocry.com .

Carving and engraving accessories

Pro tip: A useful accessory to use with these accessories is the flexible driver, which

provides extra level of control and mobility. See our tips on installing it on page 34.

7 DIAMOND-TIP BITS, Ø1/8in

Covered with diamond particles, these bits are

made to be used on harder materials for fine

detail work, engraving, carving, touch-up, and

finishing. Which materials exactly, you ask? See

our material & speed setting guide on page 24,

and if you need help setting up, find our tips on

pages 28-30.

1 HSS CUTTER, Ø1/8in

Use the HSS cutter for shaping, hollowing,

grooving, slotting, and making tapered holes in

a variety of materials - see our material & speed

setting recommendations on page 24. For set-up

instructions, flip over to pages 28-30.

17

Cutting accessories

36 BLACK CUT-OFF DISCS, 15/16 x 1/64in

These black cut-off discs cut along their edge

for a nice, sharp, thin cut in tougher materials

like plastic and metal (might have some

difficulties with really tough reinforced metals

though). See our tips on attaching them on page

31, and in case you're wondering about the

materials they can cut, and at which speed setting

- our guide is right there on page 25.

1 CUT-OFF & SANDING DISC MANDREL, Ø1/8in

This mandrel's main task is to attach the cut-off

and sanding discs to your rotary tool - see how

on page 31.

1 HSS CUTTER, Ø1/8in

The HSS cutter can not only be used as a

carving tool, but together with the tile cutting

guide, it becomes great for cutting various

metals, woods and plastic (hence the name) in a

manner similar to spiral saw blades in any

direction - see our material & speed setting tips

for cutting with the HSS cutter on page 25. To find

set-up instructions, flip over to pages 28-30.

18

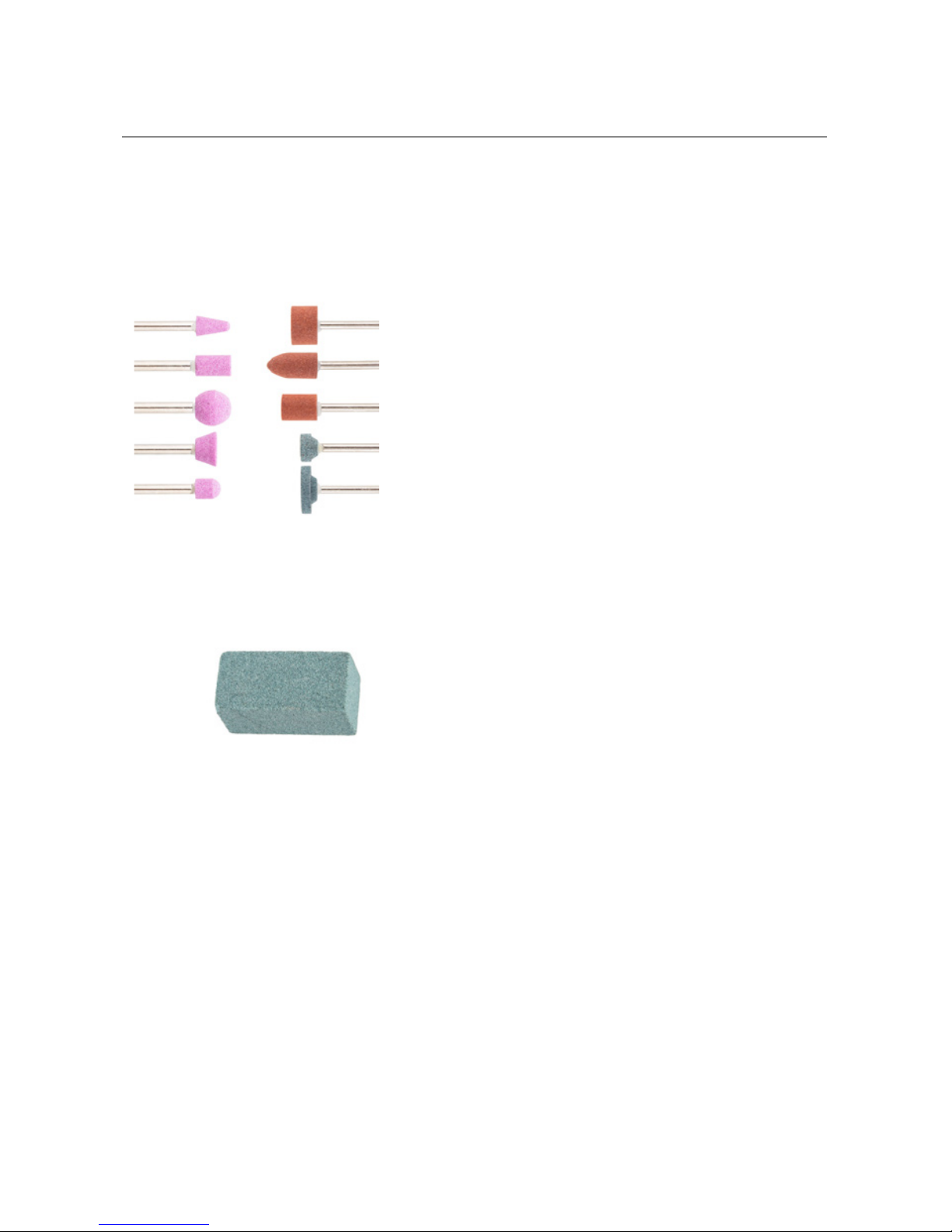

Grinding and sharpening accessories

The grinding and sharpening accessories are probably among the most useful in

the kit, as they are perfect for those practical, everyday money-saving DIY jobs like

sharpening tools, mower blades, and even boat propellers, and smoothing,

grinding and cleaning a variety of materials around the house and garden.

5 PINK, 3 BROWN & 2 GREEN GRINDING

STONES, Ø1/8in, 120 grit

The different colors aren't just for fun

(otherwise we'd have made all the stones red,

obviously). The brown and pink ones are

aluminum oxide stones, while the green ones -

silicon carbide, and all colors have different

applications. See our tips on which materials to

use them on, and at which speed setting on page

26. For installation instructions, flip over to pages

28-30.

1 GREEN WHET STONE

Grind your grinding stones against this little

fella, and it'll bring them back to life in no time.

If necessary, you can also reshape your grinding

stones with this.

19

Other manuals for NRT-128AC

1

Table of contents

Other NOCRY Power Tools manuals