Safety

SAFETY PRECAUTIONS

-Readtheinstructionmanualbeforeturning on

the machine. Pay close attention and respect

all the operating and safety recommendations

while operating. SHARE THIS INFORMATION

WITHOTHERUSERS.

- Do not operate the machine while of after

drinking alcoholic beverages or medications

which affect your normal condition. Pay

attention to what you are doing and use good

sense.Anylack of attentionwhile operating the

machinecanresultinaseriousaccident.

- The utilization of this equipment in

applications not mentioned in this manual is

considered as unacceptable and is not

authorized by this manufacturer. Adapting or

use of after- market parts can damage the

operation, and endanger the operator, and

maketheguaranteenullandvoid.

- Before turning on the machine, the person in

charge of the operation should be instructed

about how handle it correctly and its safety. To

do this, we advise you to read the instructions

manual carefully. Using the machine correctly

issurelythemostimportantfactorinpreventing

accidents. If you have any queries, see our

department of technical assistance. We have

technicians who have been duly trained to

guideyouwhenevernecessary.

- Before turning on the machine, check to see if

thereareanytoolsorobjectsinsideit.

- Check around the machine before operating

it. Keep animals and spectators away from the

pickuparea.Beespeciallycarefulofchildren.

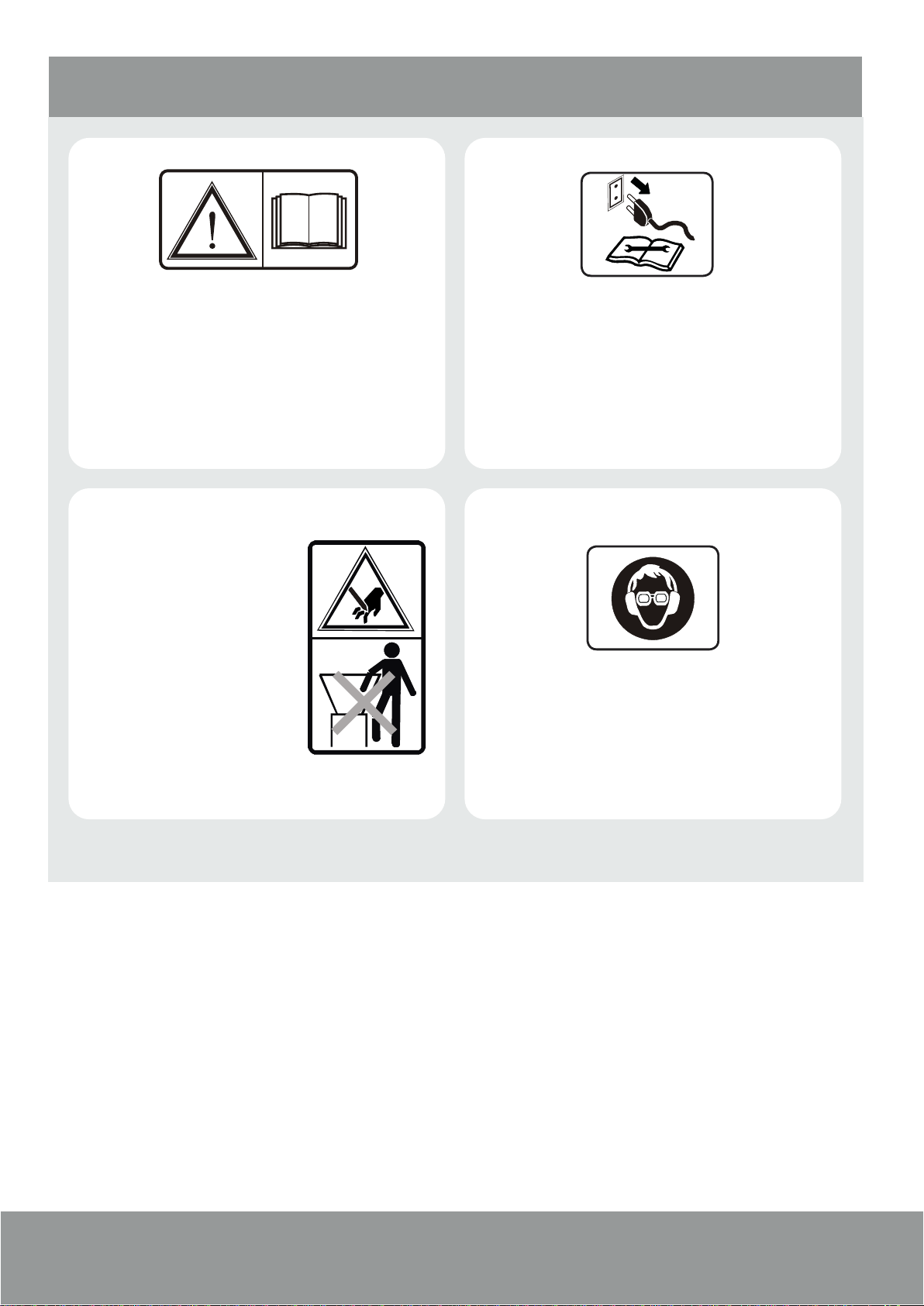

- Wear personal protective equipment - PPE -

whileoperatingthemachine.Exposuretonoise

for prolonged period can cause hearing

damage or loss. Wear earplug and safety

glasses.

- Keep the safety labels in good condition and

legible.Replacethemwhenevernecessary.

- Keep the shielding and protections in the

proper places and do not operate the machine

withoutthembeinginstalled.

- If you notice any abnormality in the operation:

vibration, different noises etc., turn off the

machine immediately. Check and eliminate the

causebeforeturningonagain.

- The utilization of this equipment in

applications not mentioned in this manual is

considered as unacceptable and is not

authorized by the manufacturer. Adapting or

use of after-market parts can damage the

operation, and endanger the operator, and

maketheguaranteenullandvoid.

- Be prepared in case of an accident. Keep a

first-aid kit in an easily accessible location.And

knowhowtouseit.

- Comply with the safety recommendations and

pay attention. Any lack of attention while

operatingthemachinecancauseaccidents.

- Ensure that the surroundings of the machine

areclearbeforestartingit.

- Do not wear large or loose clothes near the

machine and maintain hands, feet and clothes

awayfrommovingparts.

- Never place your hands, or any exposed part

of your body, inside the feeding nozzle, or near

theoutputoftheproduct.

-Donotallowchildrenoranimals to be near the

machinewhenitisworking.

- Never leave the machine when it is

functioning.

8Operation Technical Manual