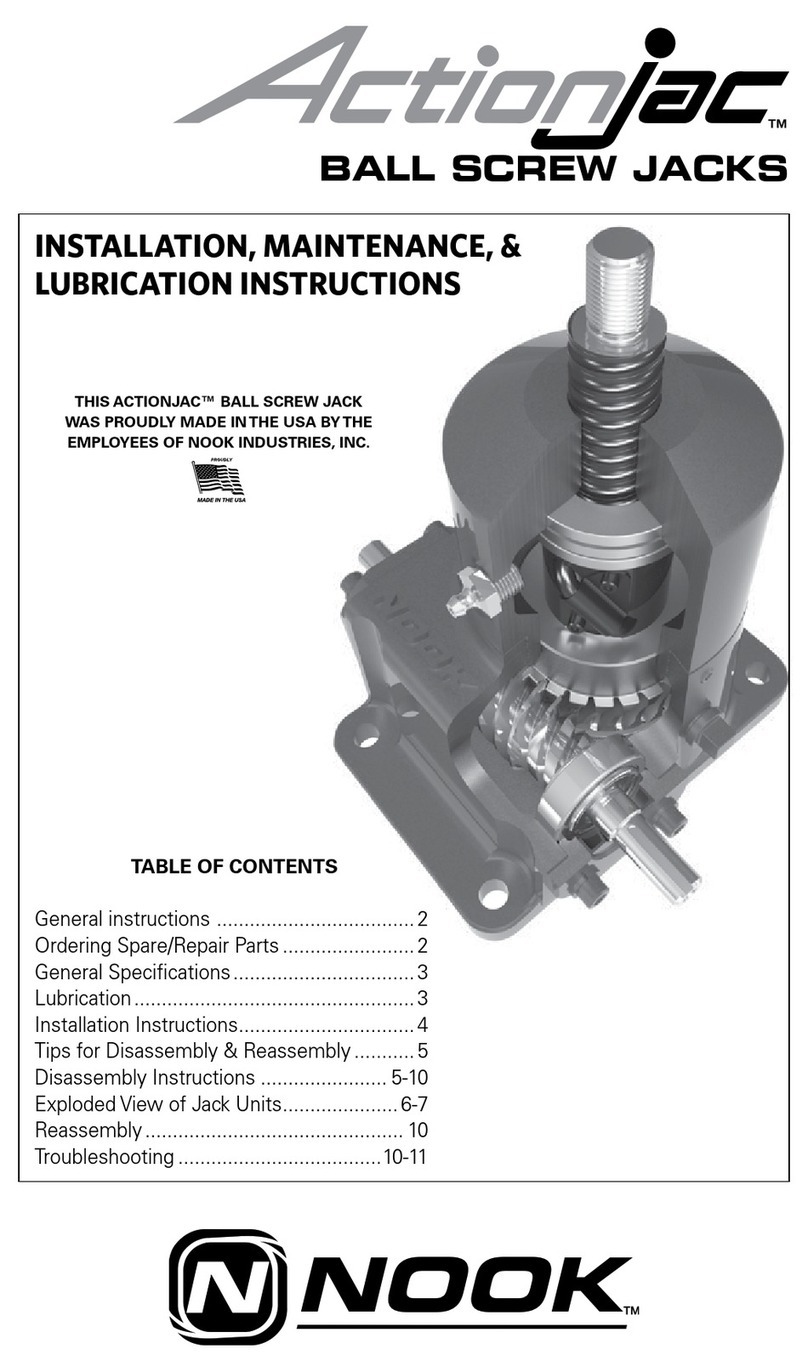

NOOK ActionJac 1-MSJ Installation and operating instructions

MACHINE SCREW JACKS

INSTALLATION, MAINTENANCE, &

LUBRICATION INSTRUCTIONS

TABLE OF CONTENTS

General instructions .................................... 2

Ordering Spare/Repair Parts ........................ 2

General Specifications ................................. 3

Lubrication................................................... 3

Installation Instructions................................ 4

Tips for Disassembly & Reassembly ........... 5

Disassembly Instructions ......................... 5-8

Exploded View of Jack Units..................... 6-7

Reassembly .............................................. 8-9

Troubleshooting ...................................... 9-10

Anti-Backlash Adjustment.......................... 11

THIS ACTIONJAC™ MACHINE SCREW JACK

WAS PROUDLY MADE IN THE USA BYTHE

EMPLOYEES OF NOOK INDUSTRIES, INC.

2 3

CAUTION - The customer is responsible

for providing stops at either end of travel.

Machine Screw Jacks are usually self-lock-

ing. However, self-lowering or creep could

result from vibratory conditions. In these

cases, a brake should be considered.

Overtravel could cause the lifting screw to

become disengaged from the drive sleeve.

GENERAL INSTRUCTIONS

Your Machine Screw Jack is a high quality,

sturdy unit designed to give many hours

of trouble-free service. However, certain

precautions and procedures must be ob-

served in handling, installing and servicing

the unit in order to obtain optimum perfor-

mance.

1. Any apparent or suspected dam-

age to equipment manufactured or

furnished by Nook Industries during

transport from the factory to the user

should be immediately reported to

both Nook Industries and the carrier.

2. Upon delivery all equipment fur-

nished should be carefully invento-

ried against shipping papers to de-

termine whether any shortages exist

in delivered material. Any such short-

ages must immediately be reported

to Nook Industries and the carrier.

3. The installation of most power trans-

mission equipment does not normally

require the services of a factory engi-

neer. These services are not included

in the selling price of the equipment

unless specifically agreed upon in

writing between the seller and pur-

chaser. In applications requiring a

more complex arrangement of com-

ponents, consideration should be

given to the use of a factory engineer

for construction super-vision or check-

out of the installation. These services

are available from Nook Industries by

contacting the Service Department.

4. The Seller’s warranty applies insofar

as the unit is operated within the rat-

ing and service conditions for which

it was specifically sold. The purchaser

must prevent the existence of any

destructive external conditions which

might typically include vibratory loads

due to critical speeds, severe shock

loading, mechanical or thermal over-

loads, or side loads.

5. Adequate installation, maintenance

and safety instructions must be given

by the user to personnel directly re-

sponsible for the installation and op-

eration of the equipment.

6. In the event of malfunction within the

warranty period, the manufacturer

must be informed promptly or, in any

event, within thirty days if it is intend-

ed that the warranty is to covert the

incident.

CAUTION - UNITS ARE NOT MEANT FOR

PERSONNEL SUPPORT. Refer all applica-

tions for potential personnel support to the

factory for approval.

ORDERING SPARE/REPAIR PARTS

This booklet contains general instructions,

operating, maintenance and troubleshoot-

ing instructions for your ActionJac™ Worm

Gear Jack. In the event spare or repair

parts are required, call your local represen-

tative or contact Nook Industries at (216)

271-7900 or 1(800) 321-7800.

Please provide the following information

when requesting spare/repair parts:

• Jack Size &Type Designation (i.e., 2 MSJ)

• Serial Number & Year of Manufacture (lo-

cated on housing nameplate)

• Stroke Length

• Part Description (see pages 6-7)

GENERAL SPECIFICATIONS

The worm gear driven Machine Screw

Jack incorporates an alloy steel worm

which drives a high tensile bronze worm

gear, accurately machined to the high stan-

dards of Nook Industries for maximum

load carrying capacity and uniformity of

motion transmission. All shafts are mount-

ed on heavy duty, anti-friction bearings to

increase operating efficiency of the drive

mechanism. Thrust bearings are provided

to support the rated thrust load of each

unit. Housings are made of high strength

material, well proportioned to handle the

rated thrust and torque loads of each size

unit.

CAUTION - In the absence of internal or

external stops, it is possible to run the lift-

ing screw out of the unit. Your Machine

Screw Jack is NOT equipped with internal

stops unless specifically requested in your

order.

A lifting screw cover is threaded into the

bottom of the unit on the upright model,

or in the top of the unit on the inverted

model, in order to keep the lifting screw

threads free of foreign material.

Depending upon which jack model is pur-

chased, the lifting screw is made of 4140

heat treated steel, 304 or 316 stainless

steel, or a special alloy. The threads of

the lifting screw for all models should be

well lubricated and kept free of grit, dirt, or

other abrasive contaminants. Fabric type

protective boots, or spiral steel protectors,

can be provided as an accessory to protect

the exposed portion of the lifting screw. In

the absence of positive stops, over-travel

may crush protective boots.

CAUTION - Standard units should not be

operated at input speeds over 1,800 RPM

without consulting the factory. Machine

Screw Jacks are designed for a maximum

of two hours intermittent operation per

day. For values higher than two hours per

day, for any continuous operation, or for

repeated operation over any segment of

total travel, consult factory.

LUBRICATION

The jack gearboxes are partially filled with

a lubricant at the factory unless otherwise

specified. Before operating any unit, verify

lubricant presence. All jack housings are

furnished with a grease fitting(s) and/or

pipe plug(s).

Lubricant inspection is recommended at

regular intervals. Once every six months

is satisfactory under normal operating

conditions, unless experience indicates

that regreasing should occur at shorter or

longer intervals. Severe operating condi-

tions such as high duty cycles, high am-

bient temperatures, or contamination will

shorten the lubrication inspection interval.

Lubricate internal jack components utiliz-

ing the grease fitting(s)/Port(s). When ap-

plying grease to the gearbox housing, suf-

ficient grease pressure is required in order

to properly apply grease to the bearing(s)

and worm gear. When applied at the facto-

ry, lubricant is typically applied at 5,000psi.

When utilizing an off-the-shelf, general-

purpose grease gun or auto lubrication

system, care must be taken to ensure

proper amount of lubricant is dispensed.

Only a small amount of lubricant would be

required. The below table is the amount

of lubricant applied at the factory. When

adding lubricant to the jack housing do

not exceed the amount specified. See jack

nameplate for specific lubricant installed in

the gearbox, or consult factory.

The lubricant must not contain any grit or

dirt, abrasives or fillers. It should not pre-

cipitate sediment, nor separate at temper-

atures up to 280°F. The lubricant must also

have resistance to oxidation and must be

non-channeling. For operating conditions

outside these limits, consult factory.

4 5

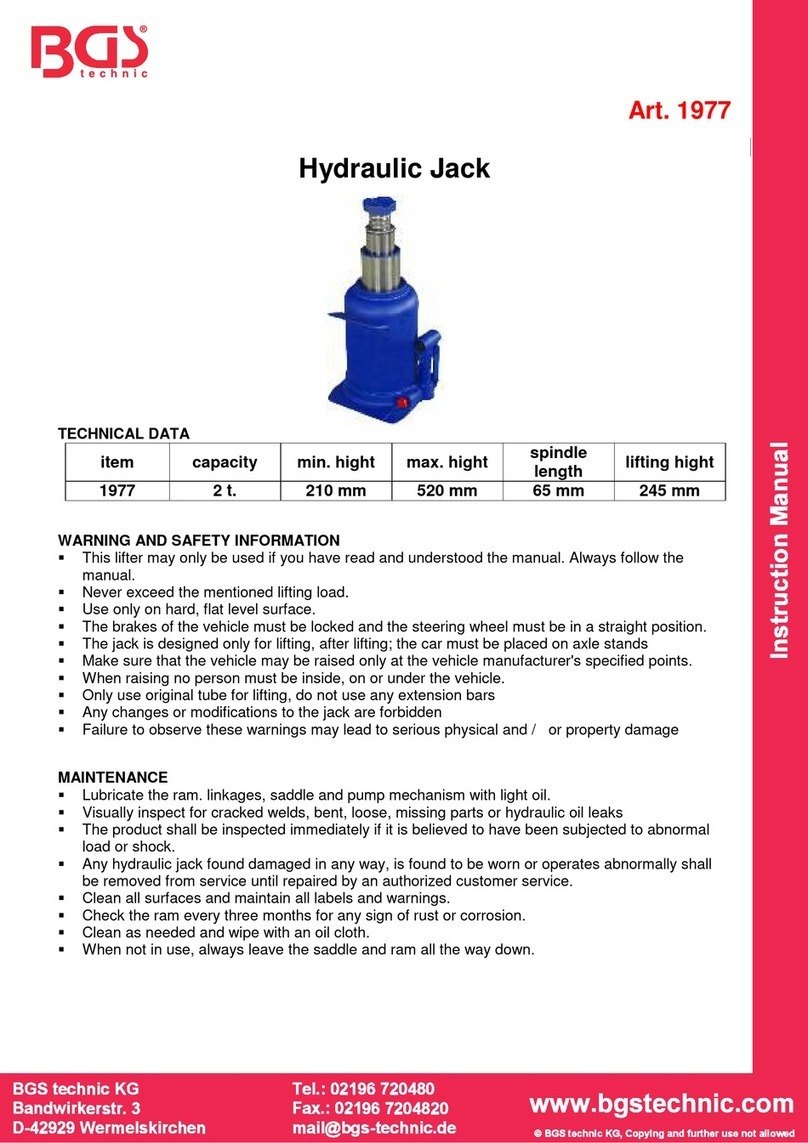

Amount supplied at factory as follows:

Jack capacity Lube [oz.]

MJ 0.8

1 Ton 1. 6

2 Ton 4

2 1/2 Ton 4.5

5 Ton 11

10 Ton 14

15 Ton 15

20 Ton 24

30 Ton 48

35 Ton 48

50 Ton 92

75 Ton 144

100 Ton 256

All units are suitable for intermittent opera-

tion providing that the housing tempera-

ture including ambient is not lower than

-20°F or higher than +200°F. Factory sup-

plied grease in standard units will operate

in this range. Consult factory for available

low-temperature greases when operating

below -20°F.

Lifting screws should be checked periodi-

cally to insure they are adequately lubricat-

ed. This is especially necessary in rotating

units where no lubrication is deposited on

the lifting screw through the jack housing.

CAUTION - The user is responsible to in-

sure lubricant compatibility. If improper

lubricant is used or insufficient lubrication

maintained, this will lead to degraded per-

formance and failure.

INSTALLATION INSTRUCTIONS

1. Be certain that the rating of the jack

exceeds the maximum load that may

be imposed upon it.

2. The foundation for the unit must

be rigid enough to maintain correct

alignment with connected machinery

Torque values for bolting are as follows:

Bolt Size

(in)

Approx.Torque Value

(ft-lb)

1⁄4

6

3⁄8

20

1⁄2

50

5⁄8

100

3⁄4

165

7⁄8

265

1 400

1

1⁄4

830

1

1⁄2

1350

1

3⁄4

2500

2 3650

IMPORTANT -Take up evenly on mounting

bolts to avoid damaging the housing.

9. If operating at the upper limits of the

unit rating, DO NOT STOP the down-

ward travel of the unit by running the

lifting screw attachments or the load

against the housing without check-

ing with Nook Industries, as serious

damage to the internal mechanism

may result. The customer is respon-

sible for providing mechanical stops

and switches for control of the prime

mover. Noneare included unless spe-

cifically quoted by and ordered from

Nook Industries.

CAUTION - If limit switches are furnished

by Nook Industries, they are NOT factory

set. Limit switches should be set by care-

fully moving to the set position by hand or

jogging. Care must be taken to avoid run-

ning lifting screws out of units or crushing

boots.

TIPS FOR DISASSEMBLY

AND REASSEMBLY

CAUTION - Disassembly of the actuator

will void the warranty.

Never perform any work on the jack or as-

and have ample strength to carry the

maximum load.

3. The foundation should have a flat

mounting surface to uniformly sup-

port the jack unit. The opening for the

lifting screw cover (or lifting screw)

that passes through base must be as

small as possible to provide jack sup-

port over the largest possible area.

4. It is extremely important that the jack

be installed so that the lifting screw

is exactly plumb and that all connect-

ing shafting is aligned with the worm

shaft.

5. After precise alignment, each mem-

ber must be securely bolted and if

possible, doweled in place. Doweling

will assure exact repositioning if ever

removed. It is essential that a jack

unit be securely bolted down to its

foundation using bolts of the proper

diameter to fit mounting holes. Bolts

should be S.A.E. Grade 5 or equiva-

lent.

CAUTION - In the case of rotating units it

is essential, for proper alignment and pre-

vention of screw failure, that the load be

attached to the traveling nut only when the

load is in the position of travel closest to

the jack housing

6. After the Jacks, mitre boxes, cou-

plings, etc. are installed and aligned,

there should be no signs of binding or

misalignment.

7. Shaft coupling guards are the respon-

sibility of the customer and are not

provided unless specifically quoted

to and ordered by the customer.

8. Caution must be taken when operat-

ing jack at either extreme of travel. If

possible, hard external stops should

be provided.

sociated transmission equipment (mitre

boxes, couplings, etc.), until absolutely

certain that the prime mover cannot be re-

motely or automatically started. Also make

certain that load cannot affect personnel or

machinery when the Jac, brake, or other

holding devices are removed. Be sure dis-

assembly area is relatively clean to prevent

contamination of parts. Store all machined

parts on wooden blocks or skids to prevent

damage to machined surfaces.

Before starting disassembly, carefully re-

view a typical parts list or certified assem-

bly drawing of the unit.

When removing end caps, be sure to tape

shaft extension keyways and other sharp

edges to avoid damaging oil seals.

NOTES:

1. Be sure to clean and dry all parts be-

fore rebuilding.

2. It is advisable to replace old seals

when the unit is rebuilt.

3. Remove any protective coatings on

replacement parts before installing.

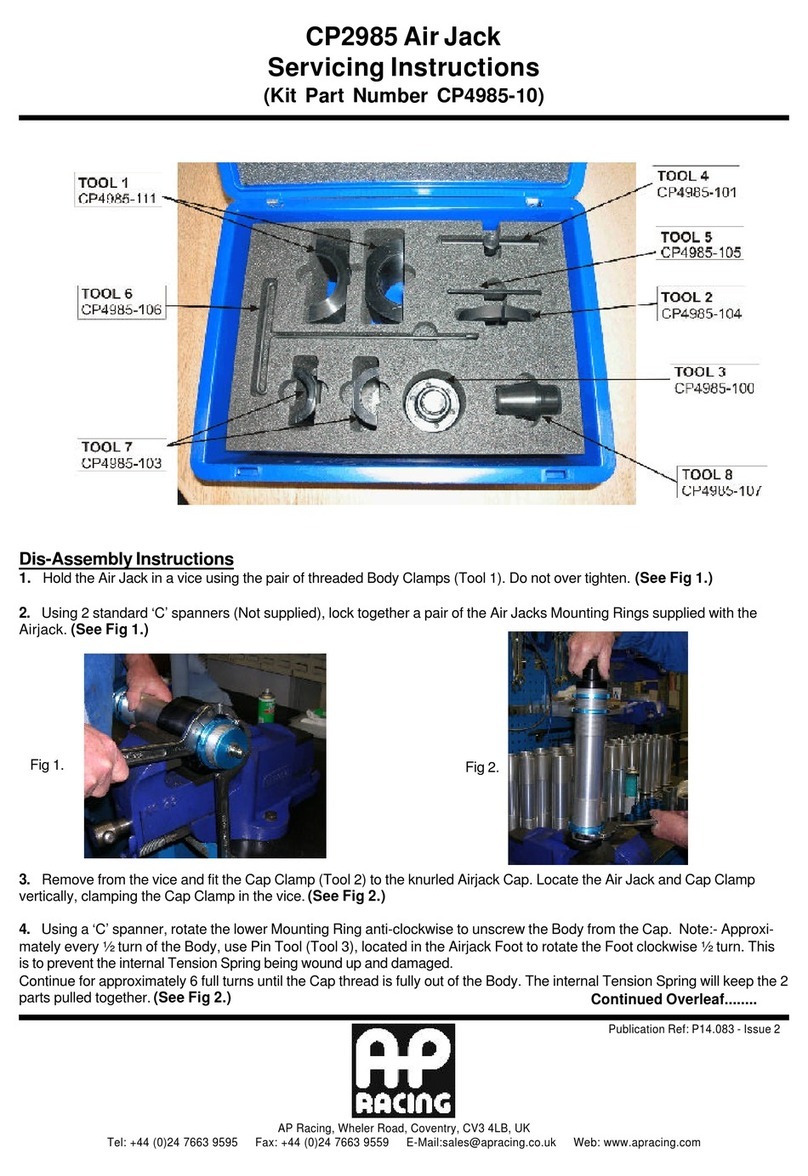

DISASSEMBLY INSTRUCTIONS

1 MSJ through 100 MSJ Models Only

Refer to typical parts, pages 6-7. No MJ

models are serviceable in the field. These

instructions are necessarily general, and

as such, cannot provide for minor details

of construction, which may vary from unit

to unit. For specific questions, consult fac-

tory giving order number and serial num-

ber from unit name plate.

Upright or Inverted Units

Disassembly

1. Unscrew lifting screw cover assem-

bly from unit.

2. Remove protective boot and end at-

tachment from lifting screw, if appli-

cable.

6 7

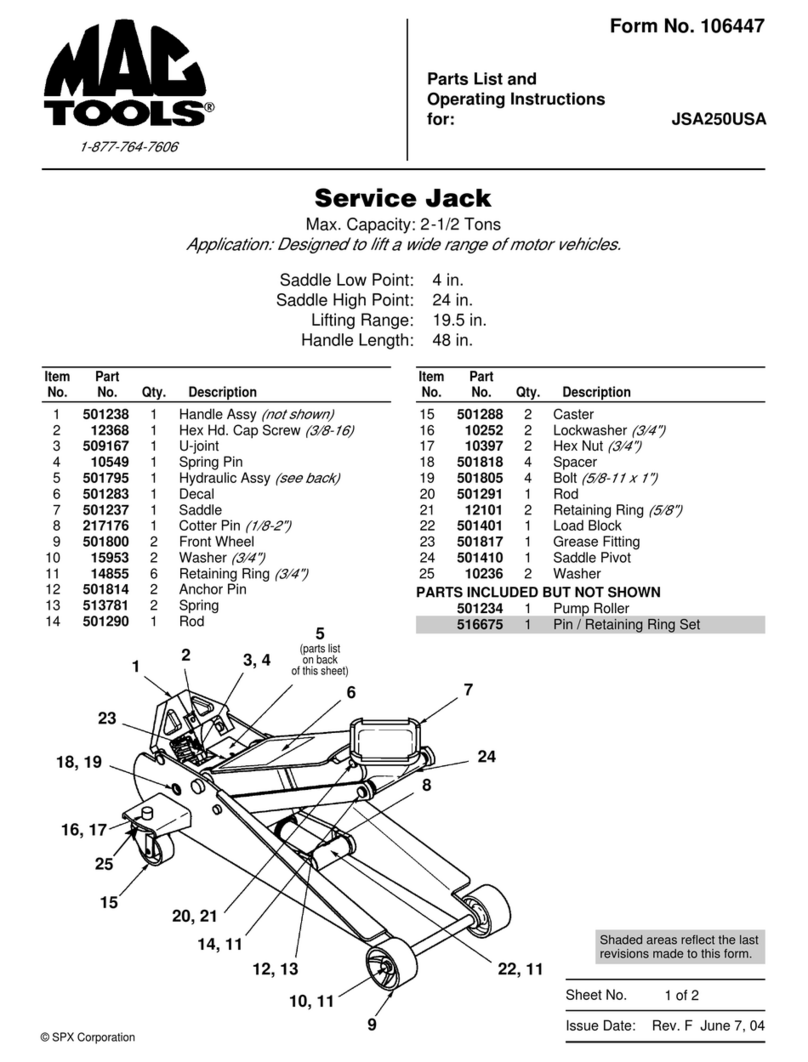

ACTIONJAC™MACHINE SCREW JACK

ALL MODELS 1-MSJ THROUGH 100-MSJ*

EXPLODED VIEW OF A TYPICAL ASSEMBLY

Views are illustrative only. See page 2 for ordering spare/repair parts.

* Models MJ-20 through MJ-200 should not be disassembled. These units arer not serviceable in the field.

KEYED SCREW

DESIGN

ROTATING SCREW

DESIGN

TRANSLATING SCREW

DESIGN

(UPRIGHT ASSEMBLY)

TRANSLATING SCREW DESIGN

(UPRIGHT ASSEMBLY)

Hex Soc.

Set Screw

Hex Soc. Set Screw

Clevis End

Hex Soc.

Set Screw End Cap

Key (special)

Hex Soc.

Set Screw

Cover

Hex Soc.

Set Screw

Top Plate End

Lifting Screw Lifting Screws

Thrust

Bearing

Seal Ring (Rotating Design Only)

Drive Sleeve & Gear

Thrust Bearing

Cover

Travel Nut

Shim

Lifting Screw

Cover

Roller Bearing

Roller Bearing

Oil Seal

Shim

End Cap

Worm Shaft

Lifting Screw

Cover Housing Plug

(Rotating Design Only)

Sealed Bearing

(1 MSJ Only)

Housing Col.

Bushing

Lifting Screw

Hex Soc. Set

Screw

Hex Soc. Set Screw

Grease Fitting

Housing

Cap

(1 MSJ Only)

8 9

3. Unscrew lifting screw from drive

sleeve.

4. Remove socket head set screws in

housing.

5. Unscrew housing cover.

6. Remove end caps on worm shaft as-

sembly.

CAUTION - Handle shims carefully to

avoid damage.

While tapping one end of the worm shaft

with a wooden mallet, turn the worm

shaft. This will loosen the bearing cup to

facilitate removal. (2 MSJ - 100 MSJ only)

7. Remove the worm shaft bearing

cups. (2 MSJ - 100 MSJ only)

8. Drive sleeve and gear assembly

should now lift easily from housing.

9. Worm shaft assembly can be re-

moved if necessary.

NOTES:

1. Bearing cones are press-fitted to worm

shaft. If removal is required use bearing

puller.

2. Removal of the bearings from the drive

sleeves of Jacks equipped with Taper

Roller bearings, may result in their being

damaged.

Rotating Units Disassembly

1. Remove set screws from housing.

2. Unscrew housing cover.

3. Remove end caps on worm shaft as-

sembly.

CAUTION - Handle shims carefully to

avoid damage.

4. While tapping one end of the worm

shaft with a wooden mallet, turn the

8. Drive sleeve and gear assembly

should now lift easily from the hous-

ing.

9. Thrust bearing assembly can be re-

moved if required. (see note 2)

10. Worm shaft assembly can be re-

moved if necessary.

NOTES:

1. Bearing cones are press-fitted to

worm shaft. If removal is required us-

ing bearing puller.

2. Removal of the bearings from the

drive sleeves of Jacks equipped with

worm shaft. This will loosen the bear-

ing cup to facilitate removal.

5. Remove the worm shaft bearing

cups.

6. Drive sleeve and gear assembly can

now be lifted easily from the housing.

7. Thrust bearing assembly can be re-

moved if required. (see note 2)

8. Worm shaft assembly can be re-

moved if necessary.

NOTES:

1. Bearing cones are press-fitted to

worm shaft. If removal is required

use bearing puller.

2. Removal of the bearings from the

drive sleeves of Jacks equipped with

Tapered Roller bearings, may result in

their being damaged.

Keyed Units Disassembly

1. Remove key retaining bolt.

2. By turning worm shaft, drive lifting

screw and key from housing and re-

move key.

3. Remove set screws from housing

and cover.

4. Unscrew housing cover.

5. Remove end caps on worm shaft as-

sembly.

CAUTION - Handle shims carefully to

avoid damage.

6. While tapping one end of the worm

shaft with a wooden mallet, turn the

worm shaft. This will loosen the bear-

ing cup to facilitate removal.

7. Remove the worm shaft bearing

cups.

Tapered Roller bearings, may result in

their being damaged.

REASSEMBLY

Your jack can be easily reassembled by

reversing the procedure as previously

outlined. In reversing disassembly proce-

dures, be sure to pack worm, worm gear,

and all bearings with grease. Also coat all

seal areas with grease. After unit is reas-

sembled, fill with grease, see page 3.

Reassembly may required that one worm

shaft ball bearing be pressed onto worm

shaft after drive sleeve and worm are as-

sembled in the housing.

TROUBLE SHOOTING TIPS

Your ActionJac™ Machine Screw Jack will perform satisfactorily if suggestions described

in this booklet are carefully followed. It is estimated that approximately 98 percent of

Machine Screw Jack failures can be attributed to improper lubrication, misapplication,

and misalignment.

TROUBLESHOOTING CHART

TROUBLE WHAT TO INSPECT ACTION

Worm Shaft Failure 1. Type of Coupling Rigid Couplings can cause

shaft failure. Replace with

coupling will provide adequate

flexibility and lateral float.

2. Coupling Alignment Realign as required.

3. Presence of Excessive

Overhung Load

Check jack for allowable loads.

4. Unit Overload See Housing Failure No.1.

5. Shock Loading Apply coupling capable of ab-

sorbing shock and, if neces-

sary, replace with unit of suf-

ficient capacity. Shock loads

can significantly increase ap-

parent dead weight loads.

6. "Ganging" Units If several units are "in-line", the

worm shaft of the first unit

can assume 300% of the rat-

ed input torque. If this value is

exceeded, you must replace

with a larger unit.

10 11

TROUBLESHOOTING CHART (continued)

TROUBLE WHAT TO INSPECT ACTION

Housing Failure 1. Unit Overload Reduce load or replace with

unit of sufficient capacity.

2. Improper Support Unit should be supported over

entire base area, not just at bolt

hole locations.

3. Uneven Bolting Torque Take up evenly on mounting

bolts.

Bearing Failure 1. Unit Overload See housing failure No.1

2. Excessive Overhung

Load

See worm shaft failure No. 3

3. Coupling Alignment See worm shaft failure No. 2

4. Coupling Lateral

Alignment

Adjust spacing between con-

necting shafts to relieve end

pressure.

5. Bearing Adjustment Bearings must not be pinched.

Adjustable tapered bearings

must be set at proper lateral

clearance. All shafts should turn

freely when disconnected from

the load.

6. Bearing Lubrication Add lubricant if necessary

7. Shock Loading See worm shaft failure No. 5

Drive Sleeve &

Worm Gear Wear

1. Unit overload See housing failure No.1

2. Bearing Adjustment See bearing Failure No. 6.

3. Lubrication Proper levels and grade must

be maintained. See lubrication

page.

Drive Sleeve &

Worm Gear Nut

Wear

1. Unit Overload See housing failure No. 1

2. Alignment Lifting shafts must be perfectly

plumb.

3. Lubrication See Gear Wear No.3

4. Side Load Eliminate side load

Lifting Screw Failure 1. Unit Overload See housing failure No. 1.

2. Alignment See lifting shaft failure No. 2.

3. Side Load Check with Nook Industries

Engineering Department for al-

lowable size load.

ANTI-BACKLASH ADJUSTMENT

The anti-backlash feature is set at the factory and normally does not require further

adjustment. However, as wear develops with extended use, it may become necessary

to adjust lash.

ADJUSTMENT PROCEDURE

1. Loosen Locknut (Item a)

2. Loosen Set Screw(s) (Item c)

3. To reduce backlash, rotate Adjusting Cap (Item a) clockwise until resistance is felt.

(Do not over tighten)

4. Place a reference mark between thread on Adjusting Cap and Housing.

5. Rotate Adjusting Cap (Item A) counter clockwise an amount equal to the A dimen-

sion on the o.d. of the threads. (See chart)

6. Tighten Set Screws.

7. Holding Adjusting Cap (Item a) stationary, tighten Locknut (Item b).

8. Operate jack through entire stroke, checking for tight spots. Note: If jack has been

used only over a portion of its stroke, backlash should be adjusted in the least

worn portion of the screw.

CAUTION - Care should be taken not to overtighten the anti-backlash system in order

to prevent binding or lockup between the drive nut and lifting screw. Overtightening can

cause a destructive heat buildup or failure.

a b c

A

Item Description

a Adjusting Cap

b Locknut

c Set Screw

Jack Model A

1, 2, 2.5-MSJ

7⁄32

5, 10-MSJ 5⁄16

15, 20, 30-MSJ 3⁄8

35-MSJ 1⁄2

50-MSJ 11⁄16

75-MSJ 13⁄16

100-MSJ 1

STATEMENT OF ASSURANCE

Thank you for purchasing another quality product from Nook Industries, Inc.

Every effort has been taken to assure this product was manufactured to the

highest industry standards of quality, precision, and performance.

GUARANTEE

Unless otherwise stated herein, Seller will repair or replace, without charge,

f.o.b. point of shipment, any parts proven to Seller’s satisfaction and upon

Seller’s examination to have been defective in material or workmanship when

furnished to the original purchaser, provided claim is made within five (5)

years after date of shipment of

1

⁄

4

ton to 20 ton jacks or within one (1) year

after date of shipment for jacks 30 tons and larger. Deterioration or wear oc-

casioned by abuse, severe eccentric loading, overloading, chemical or abra-

sive action, or excessive heat shall not constitute defects. Equipment and

accessories not of the Seller’s manufacture are warranted only to the extent

that they are warranted by the manufacturers, and this warranty is applicable

only if the defect was the result of normal use, application, and service, and is

void if the product or any part hereof was tampered with, repaired, or altered

by any person other than the factory or authorized repair station. THERE ARE

NO OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THAT OF

MERCHANTABILITY AND OF FITNESS FOR A PARTICULAR USE.

Under no circumstances shall Seller be liable for any loss of profit or for spe-

cial, consequential, or exemplary damages over and apart from the repair or

replacement of Seller’s part.

This warranty and any controversy or claim arising out of this warranty or

its interpretation, or any breach thereof, which cannot be amicably resolved

between Seller and the original purchaser with sixty (60) days of written no-

tice by the aggrieved party to the other, shall be finally settled by binding

arbitration submitted to the three (3) arbitrators selected from the panels of

the arbitrators of the American Arbitrator’s Association in accordance with

the rules and regulations of the American Arbitrator’s Association sitting in

Cleveland, Ohio, with each party to pay its own cost.

Authorization for return must be received from Nook Industries before return-

ing any equipment for inspection or warranty repair.

WARNING

The equipment shown in this bulletin is intended for industrial use only and

should not be used to lift, support, or otherwise transport human cargo, un-

less you have a written statement from Nook Industries, Inc. that the Jack

unit as used in your application is suitable for human cargo.

4950 East 49th Street / Cleveland, OH 44125

216.271.7900 - 800.321.7800 - fax: 216.271.7020

www.nookindustries.com P-520-9

Rev. 4.0

This manual suits for next models

11

Table of contents

Other NOOK Jack manuals