INTRODUCTION

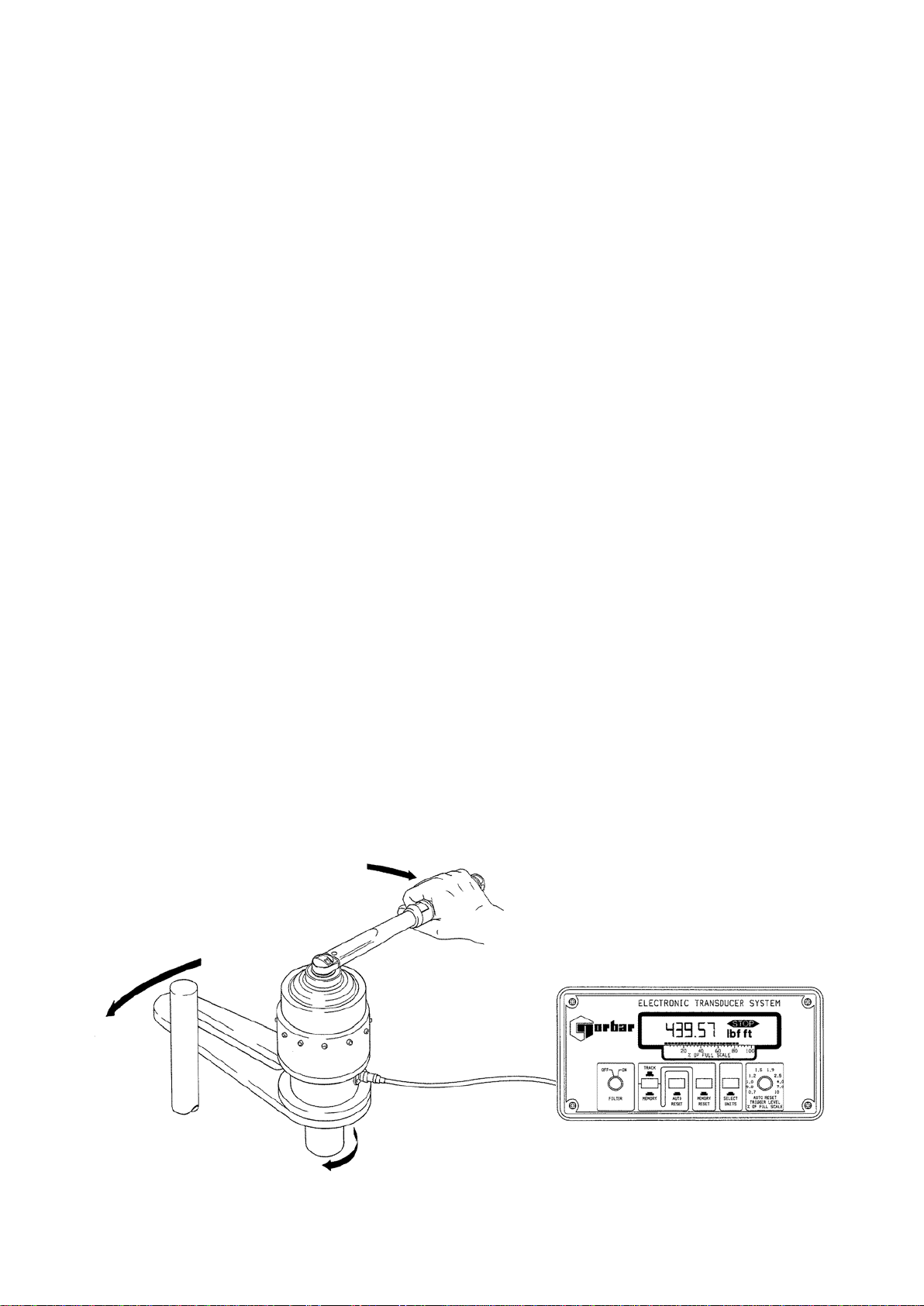

The ETS Annular Torque Transducer comes with its own matching amplifier module and shares the same

serial and model number. Transducers can be calibrated in either N∙m, lbf∙ft or lbf∙in as standard, but other

units of Torque are available i.e. cN∙m, dN∙m, Kgf∙cm and Kgf∙m.

The transducer torsion tube is made from heat treated stainless steel on to which are bonded strain gauges

which are wired to form a Wheatstone bridge. The strain gauges vary their resistance in direct proportion to

the Torque applied. The small change in resistance causes a change in voltage across the bridge that is

then amplified by the amplifier module.

The amplifier module is calibrated to each transducer and at it’s heart is an Instrumentation Amplifier.

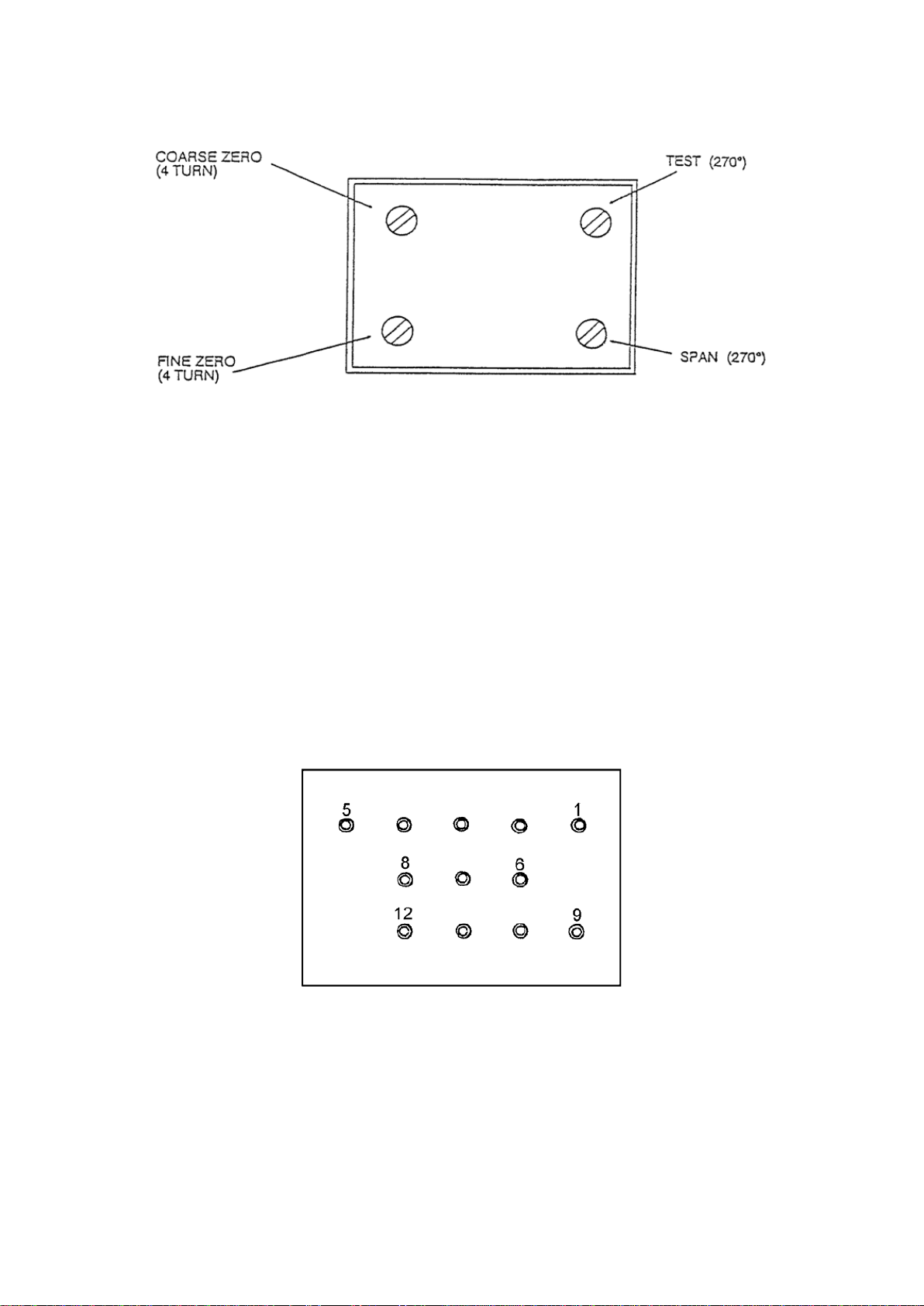

Housed within the amplifier module are the bridge balance potentiometers, gain setting potentiometer and

bridge test potentiometer along with the range and decimal point coding resistors. The whole is potted in

silicon rubber within a plastic shell.

The amplifier operates from supplies of a +/- 10v and a constant current of 20mA which is delivered to the

bridge via the zero network. The output voltage from the amplifier is fed to the internal circuitry of the ETS.

SPECIFICATIONS

Accuracy: See calibration certificate supplied with transducer.

Amplifier Output: 1.0000 volts Full Scale Defection for N∙m.

1.3558 volts Full Scale Defection for lbf∙ft.

1.1299 volts Full Scale Defection for lbf∙in.

0.9807 volts Full Scale Defection for Kgf∙m

Amplifier Power Requirement: +/- 10v D.C. Regulated.

Constant Current: 20mA +/- .01 mA

Operating Temperature Range: -10ºC - +50ºC

Storage Temperature Range: -20ºC - +70ºC

Temperature Co-efficient: <+/- 0.01%/ºC. Full Scale Defection on zero

<+/- 0.03%/ºC. Full Scale Defection on span

Maximum Working Overload: 120% of rated capacity

Absolute Maximum Torsion: 150% of rated capacity

NOTE: If equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment could be impaired.