NORD-LOCK Boltight Typhoon+ User manual

Typhoon+ Hydraulic

Bolt Tensioners

USER MANUAL

Health & Safety Instructions 4Operating Instructions 8Maintenance & Storage 25 Technical Information 27

Boltight Limited

Tel: +44 4(0) 1922 669 222

www.nord-lock.com/boltight

FOREWORD

Thank you for choosing Boltight hydraulic bolt tensioning equipment.

Before using the equipment you are advised to study this manual carefully.

Boltight Limited is an ISO 9001:2015 company and our bolt tensioning equipment has

been designed to comply with the European Pressure Equipment Directive and the UK

Pressure Equipment Regulations and is CE marked and UKCA marked respectively. The

pressures and forces involved with the use of this equipment are high and it is

therefore imperative that users of the equipment read and understand the operating

manual, paying particular attention to the safety information in Section 1.

COPYRIGHT STATEMENT & DISCLAIMER

This Health & Safety, Operating and Maintenance Manual has been prepared by Boltight Limited. All material in this manual is the

property of Boltight and is subject to Copyright. No part of this manual may be copied or reproduced without prior written consent.

Please note that the scope of this document covers the safety, operation and maintenance instructions concerned with the

equipment supplied ONLY. Safe handling, usage and storage of this equipment on customer applications and installations is the

responsibility of the customer. This document should only be considered a part of the customer’s wider procedure for installation

of plant and therefore Boltight cannot accept any responsibility for any actions arising as a result of misuse of this equipment.

The contents of this manual may periodically be subject to alteration. Boltight reserves the right to alter or modify this

manual without prior notification.

Further copies of this manual can be downloaded from the website www.nord-lock.com/boltight

CONTENTS

SECTION 1 – HEALTH & SAFETY INSTRUCTIONS 4

1.1 Safety notes 4

1.2 European Pressure Equipment Directive 5

1.3 Using quick connectors 5

1.4 Hoses 6

1.5 Hydraulic bolt tensioning tools 7

1.6 Personal protective equipment (PPE) 7

SECTION 2 – OPERATING INSTRUCTIONS 8

2.1 Main Component Parts 9

2.2 Recommended practices 9

2.3 Tensioning a bolt 10

2.4 De-tensioning a bolt 17

2.5 Simultaneous bolt tensioning 23

SECTION 3 – MAINTENANCE & STORAGE 25

3.1 Storage 25

3.2 Maintenance 25

3.3 Parts List 26

SECTION 4 – TECHNICAL INFORMATION 27

4.1 Oil pressure calculations 27

4.1 Pressure load graphs 27

SECTION 1 – HEALTH & SAFETY

INSTRUCTIONS

1.1 SAFETY NOTES

Hydraulic bolt tensioning tools are very powerful and capable of inducing very high

bolt stresses. This equipment will give many years of safe tensioning when used in

accordance with these instructions.

Anyone using hydraulic bolt tensioning equipment must be properly trained to use the

equipment and must take adequate steps to ensure their own safety and the health

and safety of others where bolt tensioning operations are being performed. Boltight

can offer training courses either at its UK base or on site anywhere in the world.

Please read the manual before attempting to use the equipment. Do not use the

equipment if you are not already an experienced user of hydraulic bolt tensioning

equipment. Your attention is particularly drawn to the notes in RED.

When using hydraulic bolt tensioners, loads of many

hundreds of tonnes or even thousands of tonnes can

be induced. If the bolt material is incorrect or faulty

or the tool is incorrectly installed, the broken bolt

could be propelled at high speed along the axis of

the bolt. This is a very rare occurrence. If there is a

failure, anyone standing near the bolt tensioning tool

or in line with the axis of the bolt during the

tensioning operation will suffer critical, possibly

fatal, injury. It is therefore essential that anyone

operating this equipment is properly trained and

takes every precaution to ensure that nobody is

allowed to stand, work or stray near to or in line with

the axis of any hydraulic bolt tensioning tool during

the bolt tensioning operation.

At no time should anyone allow any part of their

body to be positioned over the bolt tensioning tool,

whilst the pressure is rising or when it is

pressurised. In the case of studbolts with nuts at

each end it is important that nobody stands in line

with the long axis of the bolt at either end during

the tensioning operation.

Do not approach a bolt tensioning tool whilst it is

being pressurised. Remember a damaged bolt or

tool is most likely to fail at this critical time. When

the operating pressure has been reached, approach

a pressurised bolt tensioning tool only for as long as

it takes to turn the permanent nut always keeping

away from the axis of the bolt and the bolt

tensioning tool.

Bolt Tensioning tools MUST always be used with a

hydraulic pump which has a pressure limiting

device. Always check that the pump stall pressure

is set at or below, the maximum working pressure

for the tool being used.

Clear all personnel from the area where the bolt

tensioning operation is to be performed. Position

the pump a safe distance away from the bolt

tensioning tools. Set up barriers and warning signs,

or make other adequate arrangements to prevent

unauthorised personnel from accidentally straying

into the bolt tensioning area.

Never leave a pressurised bolt tensioning tool

unattended. Keep the bolt tensioning tools under

pressure for the minimum time necessary to

complete the bolt tightening job. The tools should

only be used as a bolt tensioning tool. DO NOT use

the tools as hydraulic jacks or for any other purpose.

Take care when handling the tools. Large tools may

be heavy and require the use of lifting equipment.

The bridge and load cell of the larger tools are not

held together. The load cell and bridge are easily

taken apart.

Do not try to tighten a leaking hydraulic connection

when it is under pressure. First release the pressure

then repair the leak.

4HEALTH & SAFETY INSTRUCTIONS IBOLTIGHT – TYPHOON+ USER MANUAL

1

4

2

5

3

6

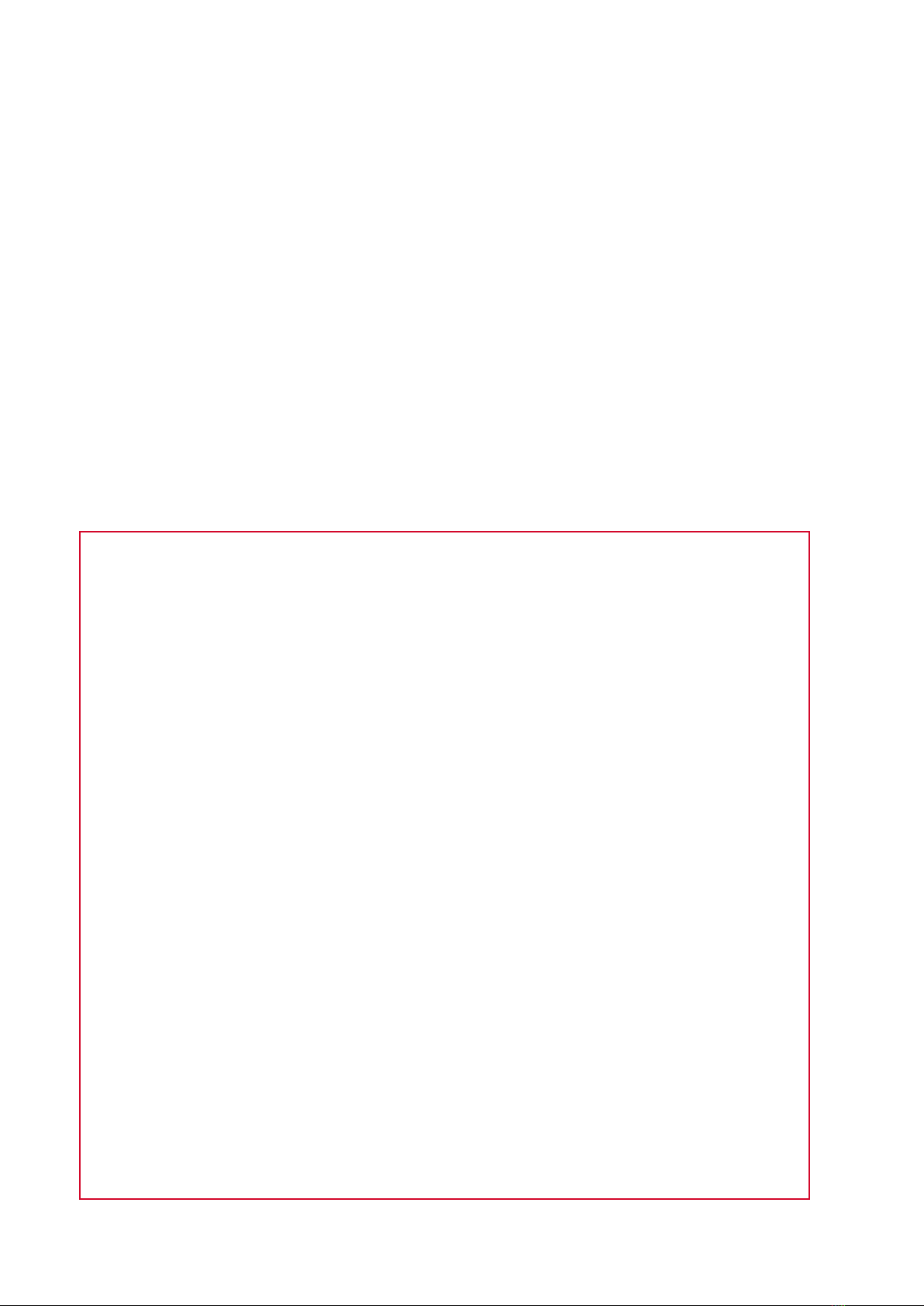

DO NOT pressurize the connectors

when they are disconnected.

Check that there is no pressure in

the system before attempting to

connect or disconnect the couplings.

1.2 EUROPEAN PRESSURE EQUIPMENT DIRECTIVE

The Typhoon+ range of hydraulic bolt tensioners are designed to operate at pressures up to 1350 bar

with Group 2 liquid (hydraulic oil ISO 32 or ISO 46) with a volume less than 10 litres. This equipment

aligns with:

• Category 1:- 2014/68/EU European Pressure Equipment Directive

• Category 1:- UK Pressure Equipment (Safety) Regulations 2016.

Under these regulations the equipment must therefore:

a) be safe;

b) meet the essential safety requirements covering design, manufacture and testing;

d) be accompanied by adequate instructions for use;

e) be marked to identify the manufacturer and CE marked and the UKCA mark respectively.

The regulations call for pressure equipment to be pressure tested at 1.43 times the maximum pressure.

However the regulations recognise that in some cases this may be harmful or impractical. Due to the

very high bolt stresses developed, it is impractical to pressure test the equipment at 1.43 times the

maximum pressure. It would also be harmful to the seals if the equipment was tested at these

pressures. All equipment has been tested to 1.1 times the maximum pressure where appropriate and a

test certificate has been issued.

1.3 USING QUICK CONNECTORS

To connect the quick connect coupling and nipple, first check there is no pressure in the system.

Pull back the shroud by hand and push the coupling onto the nipple. When together, release the

shroud which will spring back to connect the coupling and nipple together. The coupling should

now be locked using the safety locking sleeve (SLS). To disconnect, again check there is no

pressure in the system. Pull back the shroud by hand, and pull the coupling and nipple apart. Once

apart release the shroud.

Pull the shroud into the retract position Insert the nipple into the coupling whilst

the shroud is in the retract position

Allow the shroud to spring back into the

forward position

Check the red line is not visible – if red

line is visible the connection is not safe

to use

To close the safety locking sleeve (SLS)

push the shroud forward to the back of

the collar and rotate – release to lock

This image shows the SLS in the locked

position – this joint is now safe to use

5BOLTIGHT – TYPHOON+ USER MANUAL IHEALTH & SAFETY INSTRUCTIONS

1.4 HOSES

Boltight supply flexible hydraulic hoses which have a small plastic core tube surrounded by multiple high

tensile steel spiral windings. The outside of the hose is molded with a coloured plastic coating. Most hoses

also have a clear plastic cover which provides additional protection against damage when in use. Each hose

is identified with a serial number. All hoses are pressure tested and test certificates are issued.

Three types of hose are available which are identified by the colour of the molded plastic coating beneath the

clear plastic cover. The maximum working pressure for the hose is sometimes marked on the outside of the

coloured plastic coating; however this is the working pressure of the hose ONLY and not the hose ASSEMBLY.

The maximum working pressure of a hose assembly is often limited by the pressure rating of the quick

connect couplings and/or the fittings on the end of the hose. Although the hose may be capable of operating

at higher pressures the limit you must observe is shown below along with the minimum bend radius.

COLOUR MAX WORKING PRESSURE MIN BEND RADIUS

GREEN 1000 bar 95 mm

BLUE 1500 bar 130 mm

RED 2500 bar 200 mm

Hoses are fitted with self sealing quick connect couplings at one or both ends.

If in doubt contact your representative for further information.

— Discard and do not use any hose that does not

have an identifying serial number.

— Discard and do not use any hose that shows

any sign of damage:

-to the coloured molded plastic coating;

-where the spiral windings are exposed;

-where the spiral windings are damaged

or broken;

-where there is damage to the swaged

metal ends;

-do not allow any hose to be kinked

or knotted.

— Hoses which have been kinked or knotted will

have suffered damage and must be discarded.

— Do not allow heavy objects to fall on, rest on, or

roll over the hoses.

— Do not allow hoses to be subjected to

temperatures higher than 60°C.

— Discard and do not use any hose which has

been subjected to heat or fire.

— Do not bend the hose tighter than the minimum

bend radius of the hose or it will be kinked.

— Do not exceed the maximum working pressure

of the hoses.

— Only use the hoses for their intended purpose –

for use with Boltight hydraulic equipment.

— After use check the hoses for damage, wipe to

remove dirt and oil, refit dust caps and prepare

for storage.

— When not in use store the hoses in a safe place

where they cannot easily be damaged.

— Do not mix the coloured hoses. The end fittings

/quick disconnect couplings have different

pressure ratings.

— Never move hose end connectors or quick

disconnects from one colour hose to another.

— All Boltight tools are marked with maximum

operating pressure - ensure tools are

compatible with the hoses you are using.

— Never use the hoses as a handle to carry or pick

up the bolt tensioning tools.

YOU MUST OBSERVE THE FOLLOWING HEALTH & SAFETY

INSTRUCTIONS WHEN USING HYDRAULIC HOSES:

6HEALTH & SAFETY INSTRUCTIONS IBOLTIGHT – TYPHOON+ USER MANUAL

1.5 HYDRAULIC BOLT TENSIONING TOOLS

This can be found etched directly onto the tensioner, on

the general assembly drawing for the tensioner or the

pressure vs load graph. The bolt being tensioned may

have a maximum load less than that generated by the

tensioner at maximum working pressure. The operator

needs to confirm and check what the maximum

pressure is for the particular application being

tensioned. See Section 4 for more information.

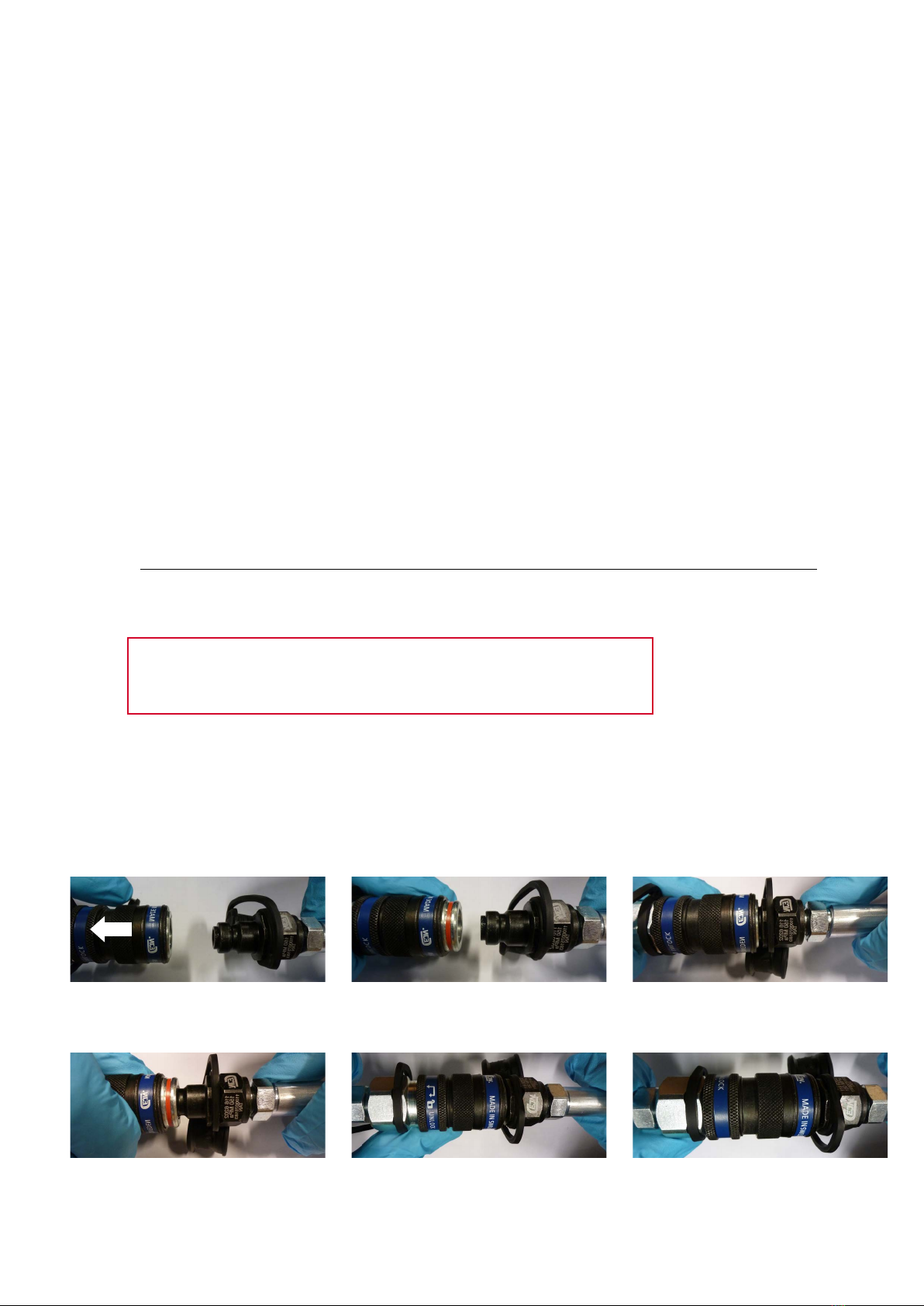

Maximum pressure Do not exceed the maximum working

pressure.

The operator is alerted that

maximum stroke has been

achieved by the indicator ring

which is mounted in the shaft

of the puller bar.

When the tool reaches

maximum stroke -when this

indicator is visible to the

operator, the operator should

stop the pump and tighten the

nut. No further benefit is

gained by increasing the

pressure at maximum stoke

as the bolt cannot be

stretched any further.

See Section 4 for more

information on pressure vs

initial bolt stress graph. The

tooling has been issued with a

pressure/load certificate.

Never exceed the tested load

or pressure, whichever is

lower.

1.6 PERSONAL PROTECTIVE EQUIPMENT (PPE)

This equipment includes (but is not limited to):

— eye protection;

— gloves;

— overalls;

— hard hat;

— steel toe-capped boots or shoes;

— any other site specific PPE required.

When using bolt tensioning tools the operator

should ensure that they are wearing the

correct Personal Protective Equipment (PPE).

<= Maximum

> Maximum

CORRECT AND SAFE

WRONG AND DANGEROUS

Indicator ring visible. Stop the pump.

Indicator ring not visible. Stroke available.

7BOLTIGHT – TYPHOON+ USER MANUAL IHEALTH & SAFETY INSTRUCTIONS

SECTION 2 – OPERATING INSTRUCTIONS

Introduction

A hydraulic bolt tensioner is simply an annular jack with a hollow bore. Much like a jack, a

hydraulic pushing force is generated, however instead of lifting a heavy object the force is

transferred into stretching a bolt. To allow the transfer of force into the bolt a hydraulic

tensioner utilises a threaded puller, bridge and nut rotating socket to effectively transfer and

lock in the tensioned load within a joint.

Unlike conventional tightening methods bolt tensioning does not use torque and does not

require any forceful turning of the nut or bolt, like impact wrenches, flogging spanners or

hydraulic torque wrenches. All of these methods have one common limitation, FRICTION.

Friction accounts for up to 80% of the energy lost when torque tightening a joint, giving only

20% transferable energy for bolt tension.

Bolt tensioning tools can be grouped together to enable multiple bolts to be tightened

simultaneously, to the same high and accurate pre-load. This is particularly useful when

compressing gaskets in pipeline or pressure vessel flanged connections. The high load

developed from the multiple bolt tensioning tools, is evenly distributed around the joint causing

the gasket to flow into the surface irregularities of the flange giving a much better seal.

Flexible hoses with self sealing quick connect couplings are used to group the bolt tensioning

tools together to form a hydraulic ring main. The ring main and tensioning tools are

pressurised using an air driven pump working from a compressed air supply or an electric

pump.

IMPORTANT NOTICE

The tools feature a safe failure mechanism. In the event that the fatigue life of the tool expires, it

has been engineered to fail safely and remain in-situ upon the bolt, posing no threat to adjacent

personnel or equipment.The maximum tool pressure cycle is indicated with the tool technical data.

A record of pressure cycles should be kept and the tool returned for puller replacement before

reaching this limit. A cycle counter can be fitted to the tensioner, to assist with quantifying the

number of cycles the tool has experienced.

The tools are subjected to a one-off pressure test prior to despatch, and a test certificate issued to

certify this. PLEASE NOTE this is not tested at the maximum operating pressure and it is strongly

advised that the tool is NEVER operated above its maximum. Re-testing is not required during its

working life, even after fitting new seals. If the user wishes to conduct a pressure test, the

tensioner should returned to the manufacturer for recertification.

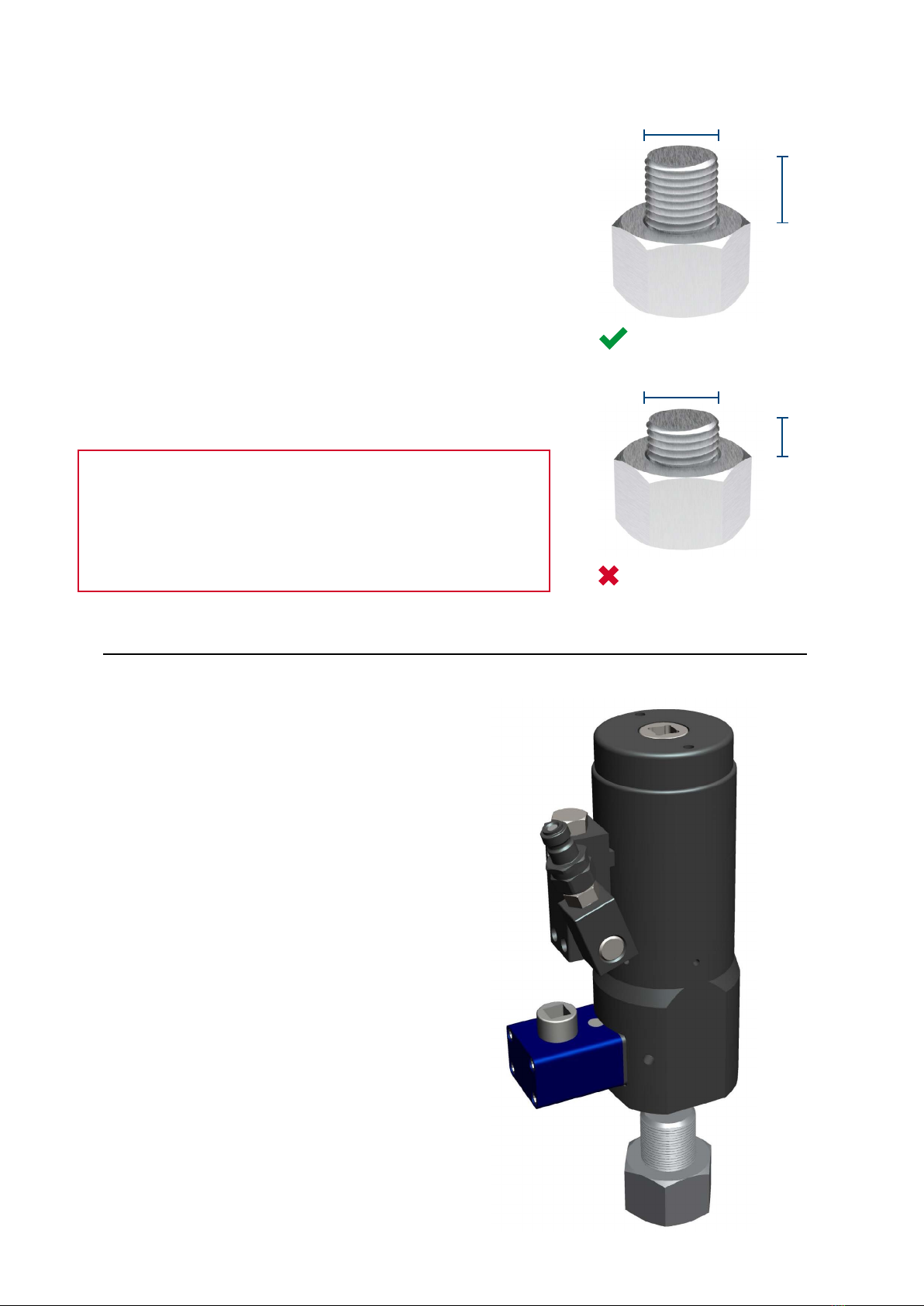

Tool Description

The pressure equipment covered by this operating manual is a Typhoon+ Multi-Stage hydraulic

bolt tensioning tool. The Typhoon+ multi-stage range has been engineered to provide

maximum load capacity under minimal radial envelope conditions.

A multi-stage bolt tensioning tool comprises axially-stacked interlocking load cells (each

comprising a body, piston and inner/outer seal), a common central puller (comprising a

reaction nut and 1/2” drive socket), a spring retraction system and interconnecting bridge. The

bridge incorporates a gear-driven nut rundown mechanism for convenience, also incorporating

a ½” drive socket. The tensioner incorporates a mechanical anti-overstroke protection facility,

and also features a maximum stroke indicator. The load cells are pressurised simultaneously

via a radially mounted manifold block of vertical CEJN 116 nipple configuration.

The different sizes of multi-stage tools have different maximum strokes. Refer to the

information in Section 4 to confirm the maximum stroke, operating pressure and maximum

force for the equipment.

The tensioner must not be modified by any type of machining and no attachment can be made

to the tools by any form of welding or brazing.

8OPERATING INSTRUCTIONS IBOLTIGHT – TYPHOON+ USER MANUAL

1

2

3

4

6

2.1 MAIN COMPONENT PARTS

1 Hydraulic load cells

A multi-stage bolt tensioning tool comprises axially-stacked

interlocking load cells (each comprising a body, piston and

inner/outer seal), a common central puller (comprising a

reaction nut and 1/2” drive socket) and a spring retraction

system.

The load cells are pressurised via a radial manifold block,

using a CEJN 116 high pressure nipple. Within the tensioner,

the hydraulic load cells are interlocked for simultaneous

pressurisation and are supported by the bridge.

2Spring actuated piston

The tool features a spring actuated piston return facility. The

spring retraction system comprises heavy duty springs, which

are contained within the spring cap. The spring system should

not require attention during the working life of the tool. When

the pressure within the tool is returned to zero the spring force

will retract the pistons fully back into the outer bodies.

3 Seals

Each cell is fitted with red polymer lip seals with an anti-

extrusion ring.

4Bridge

The bridge incorporates a spring-loaded gear-driven nut

rundown mechanism for convenience, also incorporating a ½”

square drive socket.

5 Gear Driven socket

The gear driven socket within the bridge has been designed to

interface snugly with the across flats dimensions of nuts as

supplied by the customer, and nut rundown following

pressurisation is achieved by rotating the gear driven socket.

This is performed via the ½” square drive socket located at the

top of the gearbox. This gearbox and geared socket

mechanism can also be utilised to unwind nuts during de-

tensioning procedures.

6Nut and Bolt

Tensioners can be used with standard hex nuts, large width

hex nuts, round nuts or special nuts. The correct tool must be

selected in accordance with the application.

An extra length of thread must protrude through the nut for the

tensioner to screw onto and apply the bolt tension. The length

of the bolt is very important. Details are given in Section 2.3

Step 1. NOTE: Good quality bolts and nuts will make the

tensioning operation quicker and more accurate.

2.2 RECOMMENDED PRACTICES

To obtain the best results from your hydraulic bolt tensioning equipment you should carefully follow the

operating instructions given in the following pages. You should also observe the instructions given below.

DO NOT Do not try to pressurise the hydraulic tensioner unless it is properly seated on its bridge, the bridge

is in full contact with the application and the puller bar has been correctly engaged onto the bolt to be

tightened or released else the tensioner may be damaged beyond safe or repairable use.

9BOLTIGHT – TYPHOON+ USER MANUAL IOPERATING INSTRUCTIONS

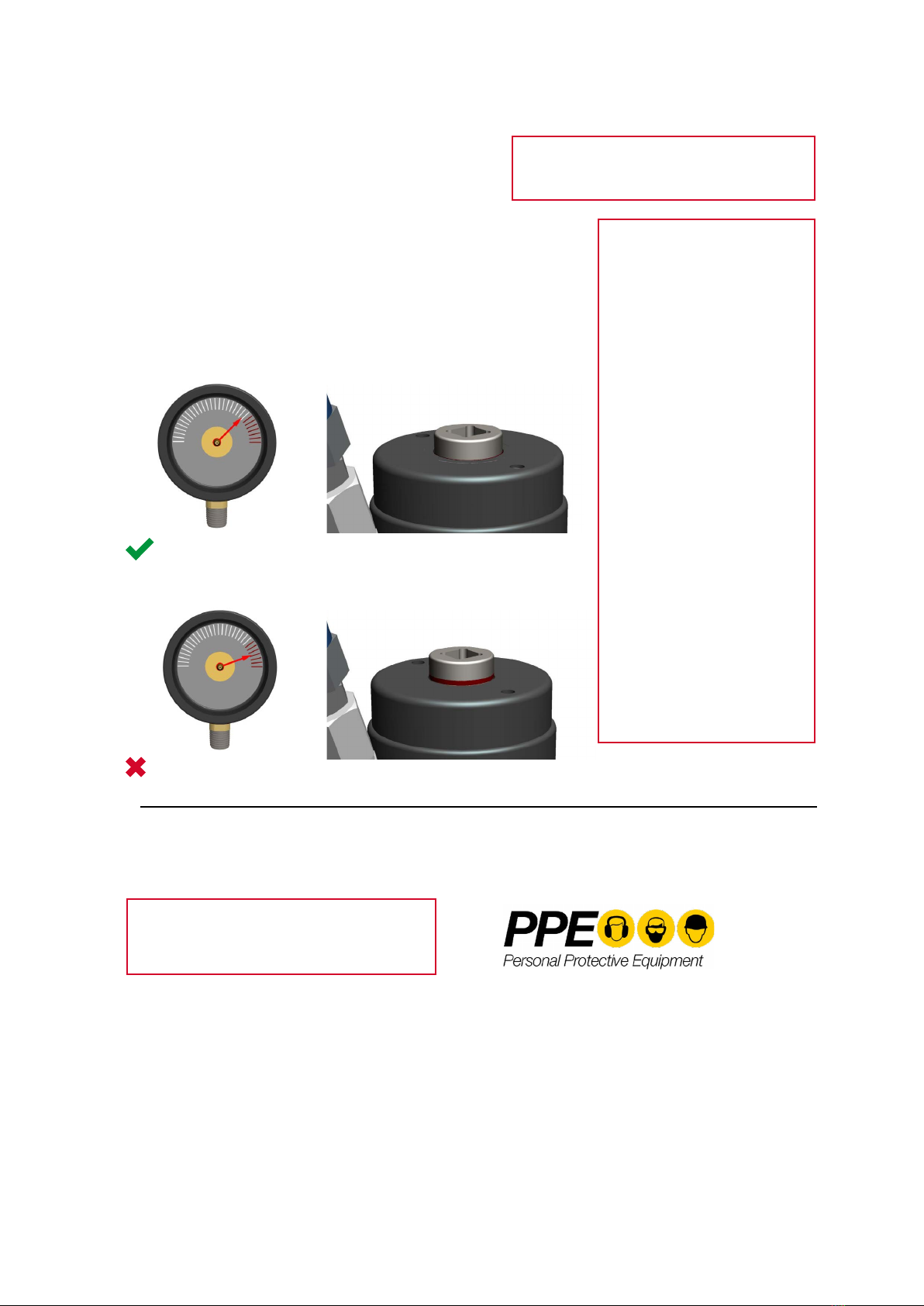

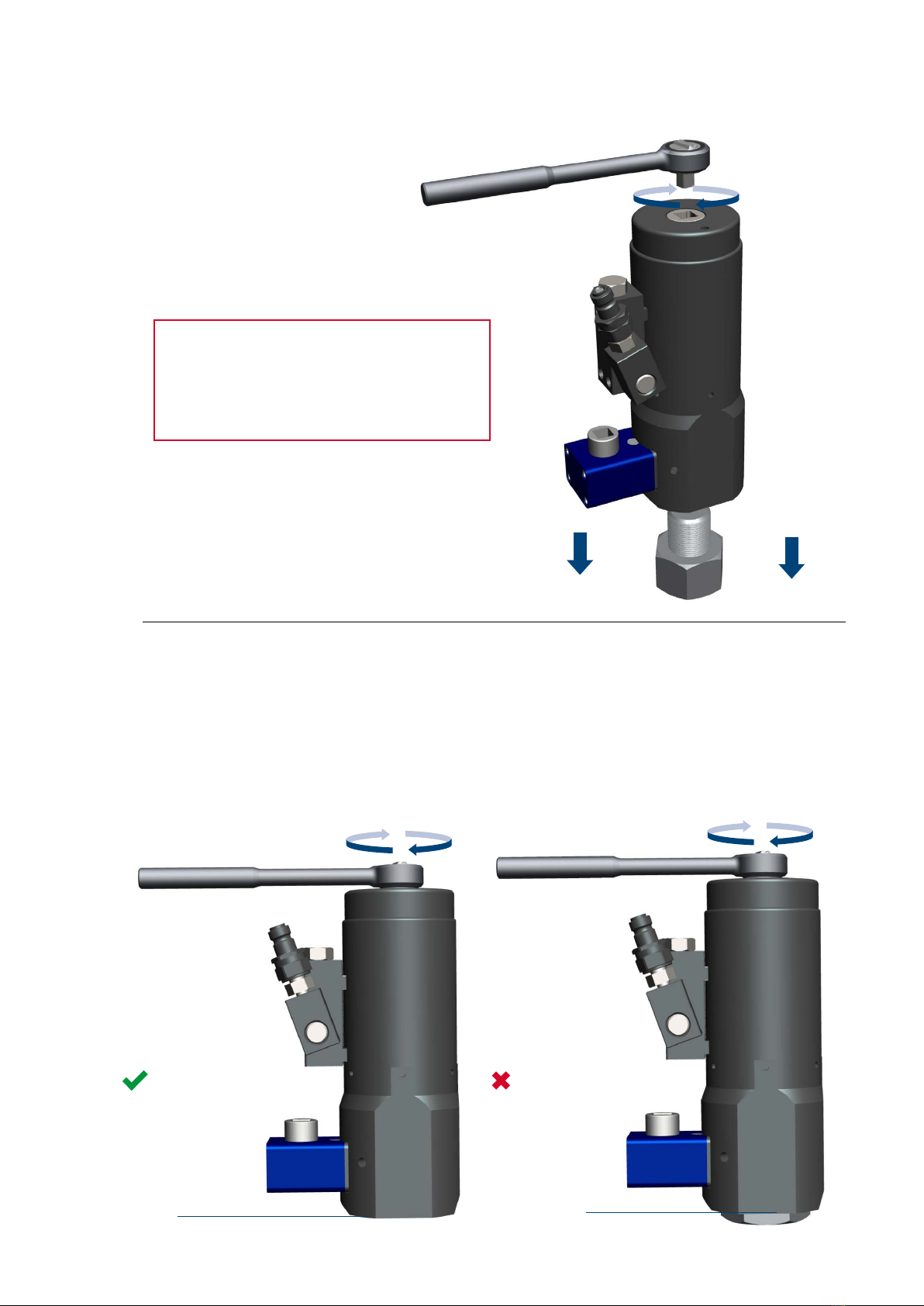

Step 1

Please follow all safety instructions set out in Section 1. Ensure the

joint has been assembled using the correct nuts and bolts required

for tensioning.

To ensure the safe and effective use of the hydraulic bolt tensioner

ensure that a minimum of 2 x bolt diameters of bolt length is

protruding from the surface of the joint face. Bolt protrusion

should not exceed maximum stated on general arrangement

drawing.

It is imperative that the correct bolt length is available prior to the

hydraulic tensioner activation as failure to do so may result in the

threads stripping off the bolt and the bolt tensioner puller bar.

2.3 TENSIONING A BOLT

HEALTH & SAFETY WARNING

If only a few threads protrude and an attempt is made to apply

tension the bolt threads will strip and components of the tensioner

could be propelled with the possibility of serious injury and may

cause damage to the bolt and tensioner.

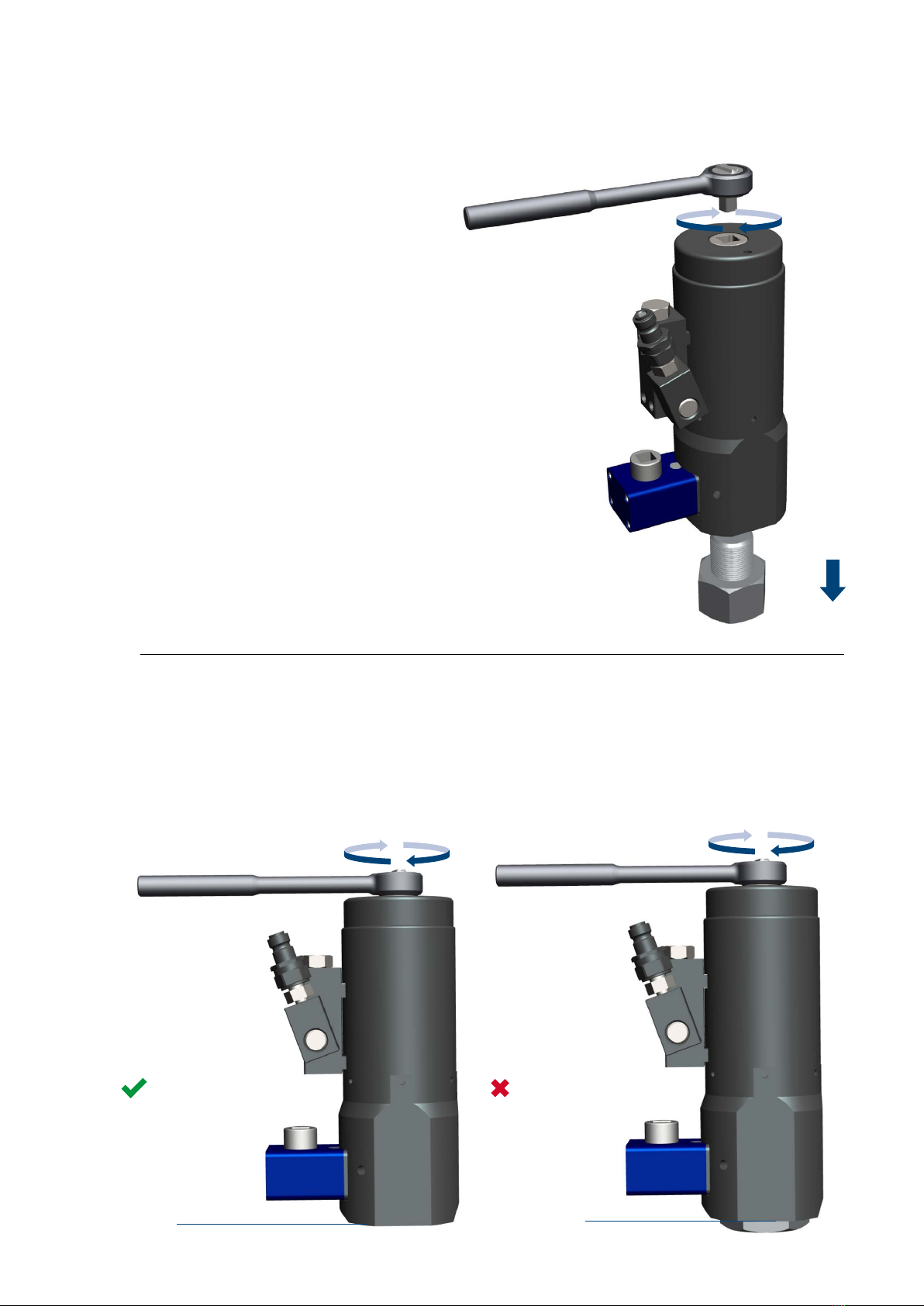

Step 2

Position the Tensioner over the bolt to be tightened.

Position the tensioner so that manifold is accessible,

and such that the bridge allows access to the gear box.

CORRECT AND SAFE

WRONG AND DANGEROUS

D

≥ D

< D

D

10 TENSIONING A BOLT IBOLTIGHT – TYPHOON+ USER MANUAL

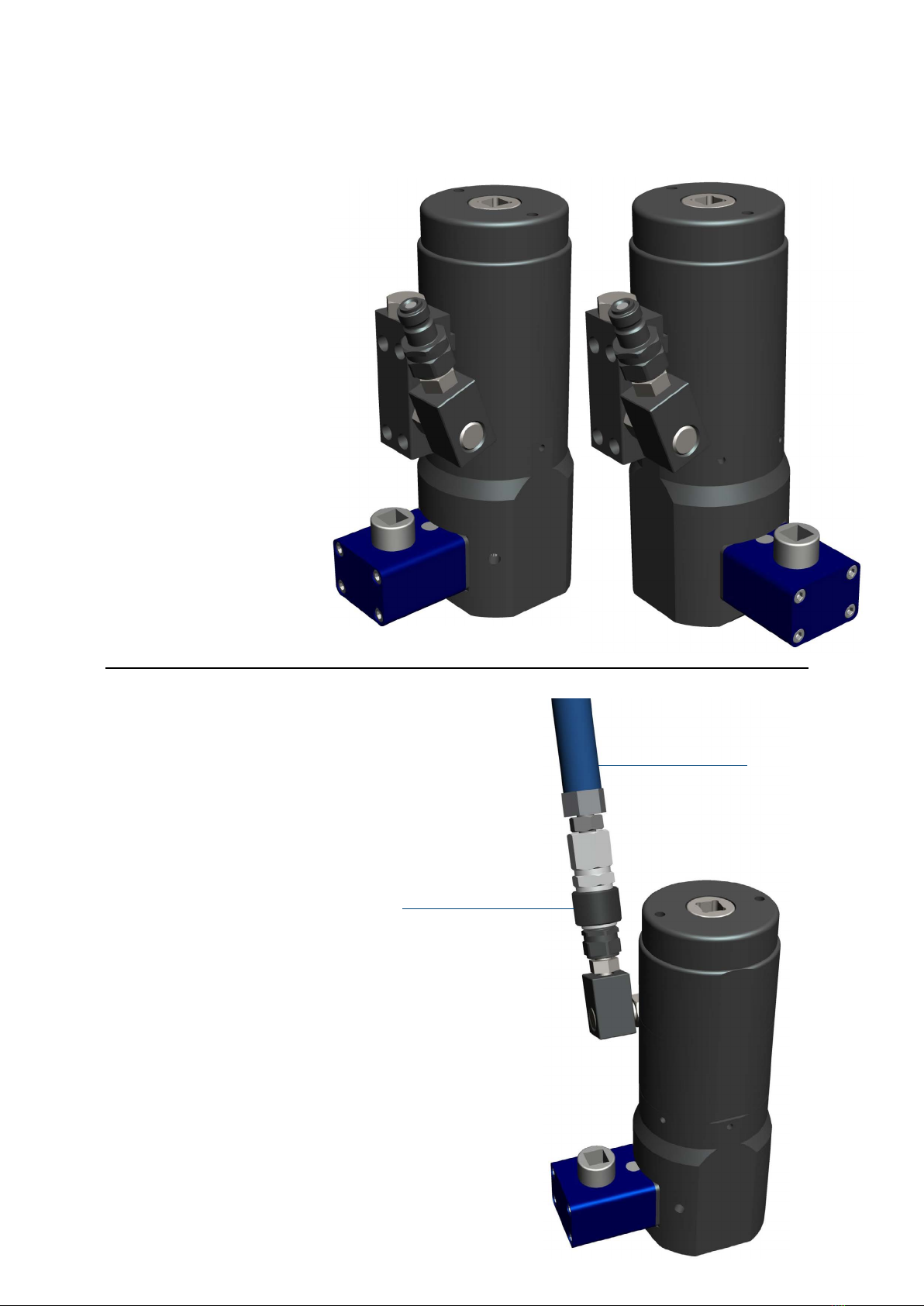

Step 4

Continue rotating the puller bar, increasing its engagement with the bolt until the bridge is flush

with the application surface. To ensure the tool is fully flush, it may be necessary to rotate the

gearbox slightly whilst lowering to fully engage the gear driven socket with the nut. Make sure

that the bridge is seated on a flat and level surface and avoids any adjacent nuts or application

obstructions.

Step 3

Engage the puller bar with the bolt. A ½”

square drive socket is provided - insert

into the top of the puller bar so that the

tensioner orientation can be maintained

whilst the puller bar engages the bolt.

FLUSH

CORRECT AND SAFE

NOT FLUSH

WRONG AND DANGEROUS

11BOLTIGHT – TYPHOON+ USER MANUAL ITENSIONING A BOLT

Step 5

Once the tensioner is in situ, it should still be

possible to rotate the bridge to a suitable

angle to access the bolt if required.

Step 6

Connect the tensioner to corresponding hydraulic

hose and pump unit.

Make sure the quick connect coupling is fully

engaged. See Section 1.3.

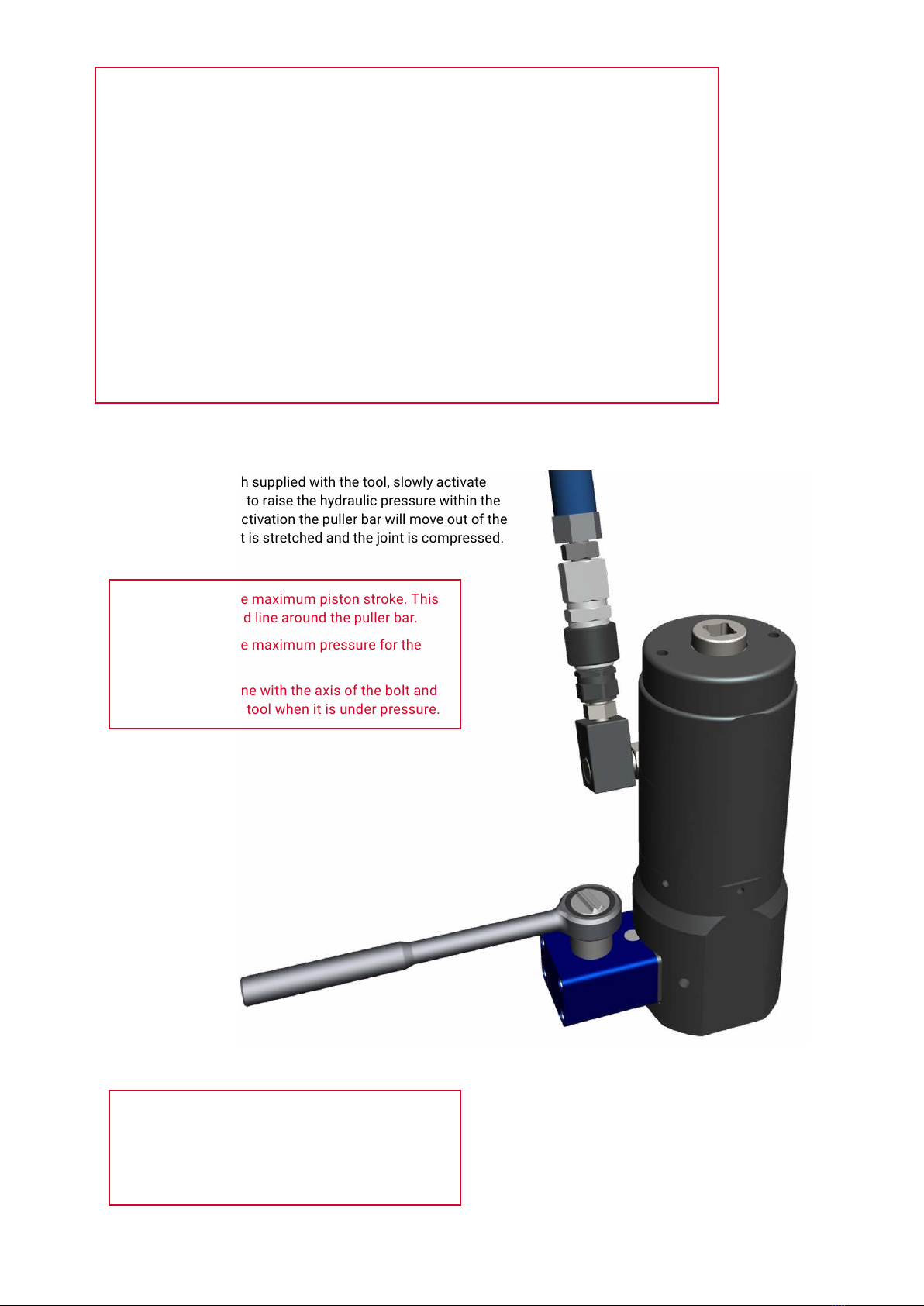

HYDRAULIC HOSE

QUICK CONNECT COUPLING

12 TENSIONING A BOLT IBOLTIGHT – TYPHOON+ USER MANUAL

TENSIONING A BOLT – HEALTH & SAFETY

The bolt tensioning tool is now ready to be pressurised. Before proceeding read the Health

& Safety Instructions given in Section 1 of this manual then proceed as follows:

— Ensure suitable PPE has been utilised prior to pressurisation.

— Clear all personnel from the area where the bolt tensioning operation is to be

performed. Position the pump a safe distance away from the bolt tensioning tools. Set

up barriers and warning signs, or make other adequate arrangements to prevent

unauthorised personnel from accidentally straying into the bolt tensioning area.

— Release the oil pressure immediately if any unauthorised person moves into the bolt

tensioning area and especially is anyone stands in front of a bolt tensioning tool under

pressure or stands in line with the long axis of a bolt being tensioned.

— Determine the correct working pressure for the bolts to be tightened. Proceed with the

following operations keeping the bolt tensioning tools under pressure for the minimum

time necessary to complete the bolt tightening operation.

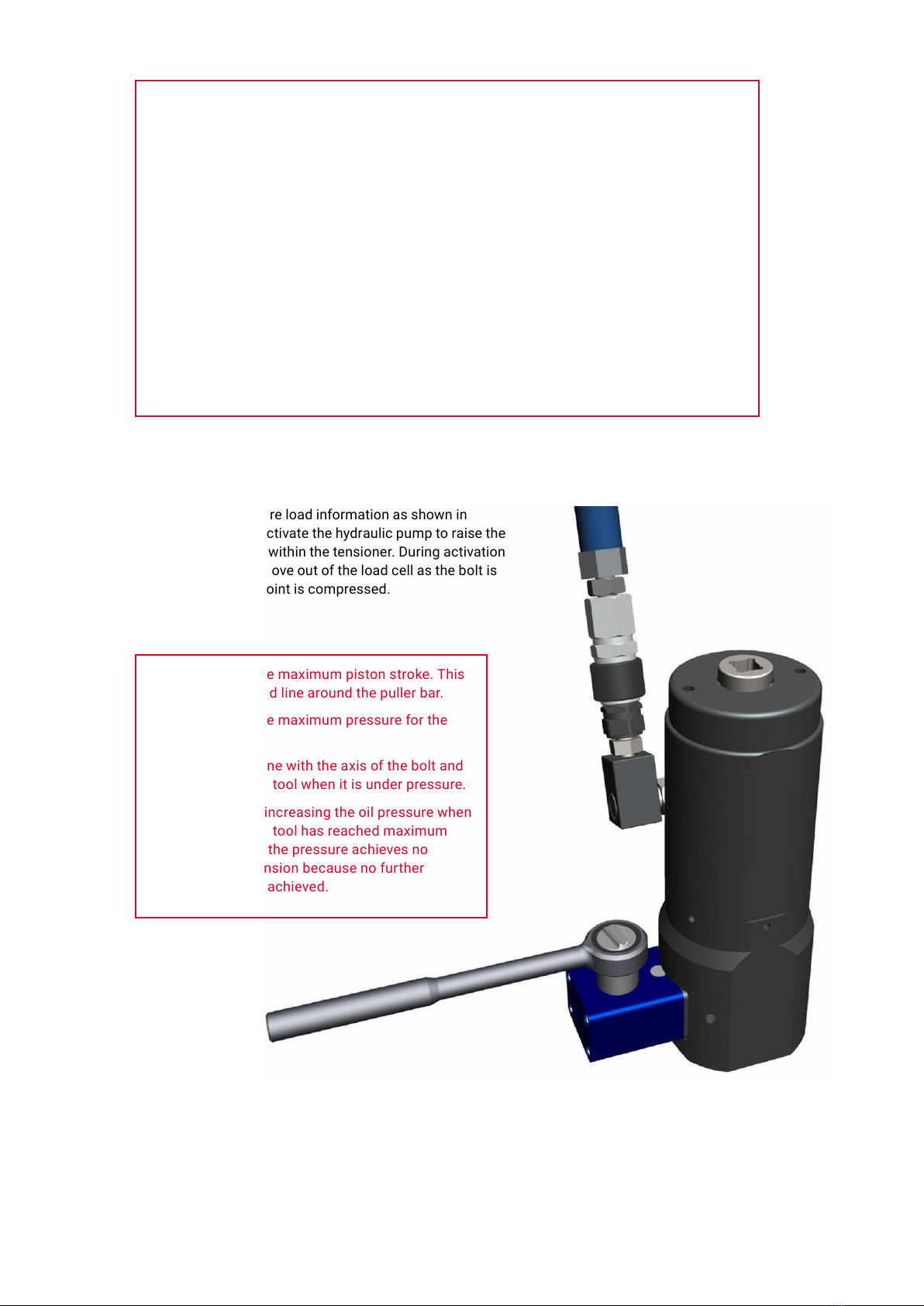

Step 7

Utilising the pressure load information as shown on the

pressure load graph supplied with the tool, slowly activate

the hydraulic pump to raise the hydraulic pressure within the

tensioner. During activation the puller bar will move out of the

load cell as the bolt is stretched and the joint is compressed.

DO NOT exceed the maximum piston stroke. This

is indicated by a red line around the puller bar.

DO NOT exceed the maximum pressure for the

tool.

DO NOT stand in line with the axis of the bolt and

the bolt tensioning tool when it is under pressure.

If the indicator shows the tensioner has reached

maximum stroke before the correct hydraulic pressure

has been achieved, stop the pump and proceed as

follows :-

Tighten the Nut

Release the Pressure

Allow the tensioner to retract fully

Reengage the tool

Apply the correct Pressure

If necessary repeat this sequence until the bolt

tensioning tool reaches the correct oil pressure

without reaching the maximum piston stroke.

DO NOT continue increasing the oil pressure when

the bolt tensioning tool has reached maximum

stroke. Increasing the pressure achieves no

increase in bolt tension because no further

elongation can be achieved.

13BOLTIGHT – TYPHOON+ USER MANUAL ITENSIONING A BOLT

Step 8

Using a ½” square drive socket insert into drive hole

situated on the top of the gearbox. Rotate the until

the nut is firmly seated on the application.

Step 9

Slowly release the hydraulic pressure by opening the

pressure release valve on the hydraulic pump.

The spring return system will now fully retract the

tensioning tool. The top of the puller bar will be flush with

the spring cap at zero stroke.

DO NOT disconnect the hose from the tensioner as this

will prevent the tool from retracting.

14 TENSIONING A BOLT IBOLTIGHT – TYPHOON+ USER MANUAL

Step 10

The Tensioner will have retracted upwards as the bolt will have

elongated. The tool will need reengaging onto the flange. Using

the ½” square drive socket, reengage the puller onto the stud

until the tool is flush with the flange.

FLUSH

THEN ONE ADDITIONAL

HALF TURN

NOT FLUSH

Step 11

Apply the correct hydraulic pressure and

wind the nut clockwise again once this

is achieved.

Do not exceed the maximum working

pressure for the tool.

The operator is alerted that maximum stroke

has been achieved by the indicator ring which

is mounted in the shaft of the puller bar.

15BOLTIGHT – TYPHOON+ USER MANUAL ITENSIONING A BOLT

Step 12

Slowly release the hydraulic pressure by opening the

pressure release valve on the hydraulic pump’

The spring return system will now fully retract the

tensioning tool. The top of the puller bar will be flush with

the spring cap at zero stroke.

DO NOT disconnect the hose from the tensioner as this

will prevent the tool from retracting.

Remove the hose once the stroke has returned to zero.

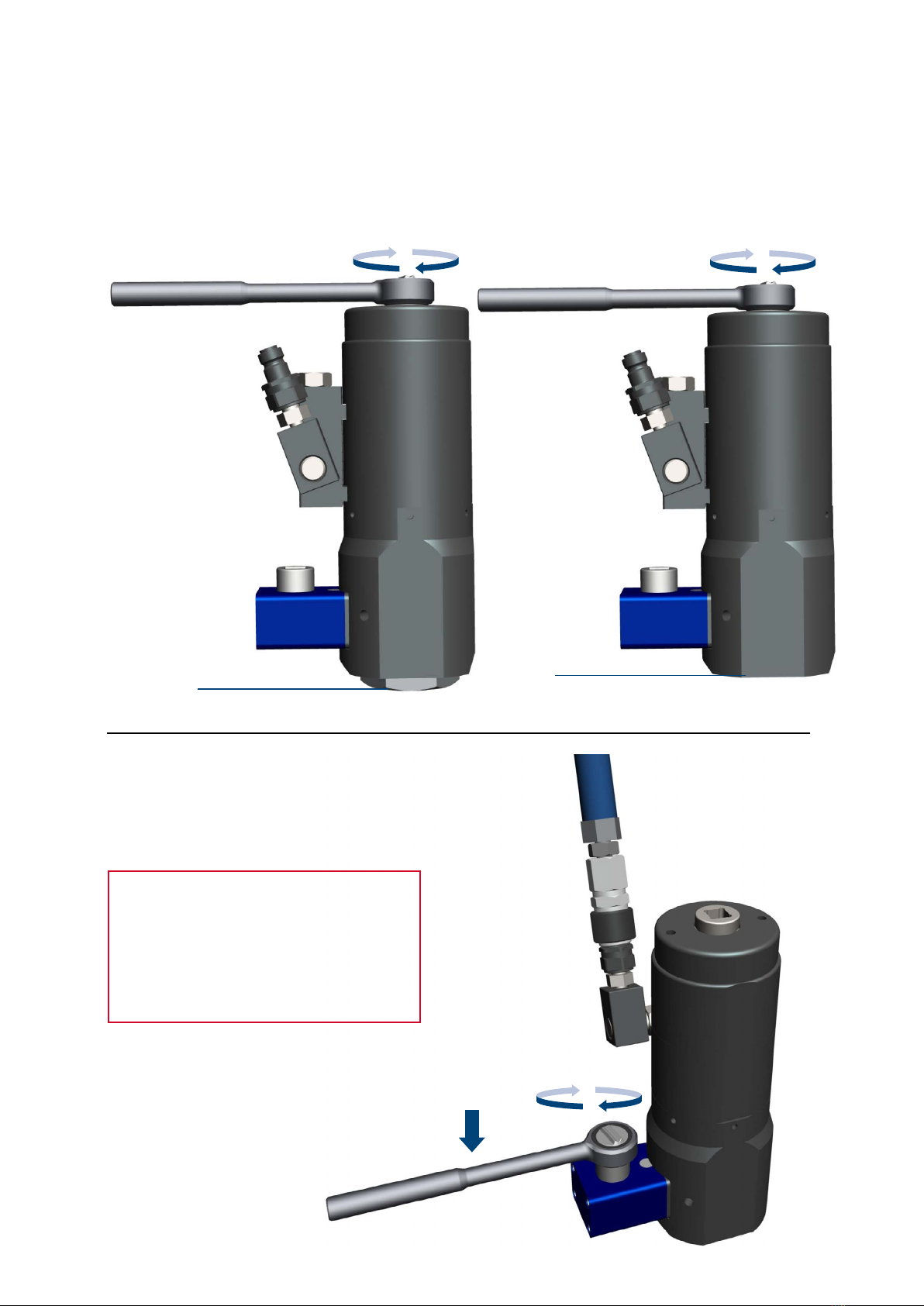

Step 13

Turning anti-clockwise remove the tensioner

using the ½” square drive socket in the top of

the puller.

16 TENSIONING A BOLT IBOLTIGHT – TYPHOON+ USER MANUAL

Step 1

De-tensioning of a bolt follows many of the steps as shown in the

previous section. There are however a few key differences in the

process which are explained within the following section.

Follow all safety instructions set out in Section 1 then visually

inspect the bolts to be de-tensioned. To ensure the safe and

effective use of the hydraulic bolt tensioner ensure that a minimum

of 2 x bolt diameter of bolt length is protruding from the surface of

the joint face. Bolt protrusion should not exceed maximum stated

on general arrangement drawing.

It is imperative that the correct bolt length is available prior to the

hydraulic tensioner activation as failure to do so may result in the

threads stripping off the bolt and the bolt tensioner puller bar.

Next ensure that the threads are clean and have not been

damaged. Any damage to the threads should be rectified with a

thread file or die nut before attempting to assemble the hydraulic

bolt tensioning tool onto the bolt.

2.4 DE-TENSIONING A BOLT

HEALTH & SAFETY WARNING

If only a few threads protrude and an attempt is made to apply

tension the bolt threads will strip and components of the tensioner

could be propelled with the possibility of serious injury and may

cause damage to the bolt and tensioner.

CORRECT AND SAFE

WRONG AND DANGEROUS

D

≥ D

< D

D

Step 2

Position the tensioner over the bolt to be loosened.

Position the tensioner so that manifold is accessible,

and that the bridge allows access to the gear box.

17BOLTIGHT – TYPHOON+ USER MANUAL IDE-TENSIONING A BOLT

Step 4

Continue rotating the puller, increasing its engagement with the bolt until the

bridge is flush with the application surface. To ensure the tool is fully flush, it

may be necessary to rotate the gearbox slightly whilst lowering to fully

engage the gear driven socket with the nut. Make sure that the bridge is

seated on a flat and level surface and avoids any adjacent nuts or application

obstructions. Ensure the bridge does not largely overhang or react off uneven

surfaces.

FLUSH

CORRECT AND SAFE

NOT FLUSH

WRONG AND DANGEROUS

Step 3

Engage the puller bar with the bolt. A ½”

square drive socket is provided - insert

into the top of the puller bar so that the

tensioner orientation can be maintained

whilst the puller bar engages the bolt.

During the rotation of the puller, ensure that

the bolt remains stationary as failure to do

so could result in a reduced thread

engagement in both the puller or application.

18 DE-TENSIONING A BOLT IBOLTIGHT – TYPHOON+ USER MANUAL

Step 5

Now rotate the Puller ANTI-CLOCKWISE BY

HALF A TURN

This is to prevent the Tensioner from locking

onto the stud. This will raise the tensioner

slightly so the bridge is no longer flush with

the application surface.

Once the Tensioner is in situ, it should still be

possible to rotate the bridge to a suitable angle to

access the bolt if required.

ANTI-CLOCKWISE

HALF A TURN

Step 6

Connect the tensioner to corresponding hydraulic

hose and pump unit.

Make sure the quick connect coupling is fully

engaged. See Section 1.3.

HYDRAULIC HOSE

QUICK CONNECT COUPLING

19BOLTIGHT – TYPHOON+ USER MANUAL IDE-TENSIONING A BOLT

Step 7

Utilising the pressure load information as shown in

Section 4, slowly activate the hydraulic pump to raise the

hydraulic pressure within the tensioner. During activation

the puller bar will move out of the load cell as the bolt is

stretched and the joint is compressed.

DO NOT exceed the maximum piston stroke. This

is indicated by a red line around the puller bar.

DO NOT exceed the maximum pressure for the

tool.

DO NOT stand in line with the axis of the bolt and

the bolt tensioning tool when it is under pressure.

DO NOT continue increasing the oil pressure when

the bolt tensioning tool has reached maximum

stroke. Increasing the pressure achieves no

increase in bolt tension because no further

elongation can be achieved.

TENSIONING A BOLT – HEALTH & SAFETY

The bolt tensioning tool is now ready to be pressurised. Before proceeding read the Health

& Safety Instructions given in Section 1 of this manual then proceed as follows:

— Ensure suitable PPE has been utilised prior to pressurisation.

— Clear all personnel from the area where the bolt tensioning operation is to be

performed. Position the pump a safe distance away from the bolt tensioning tools. Set

up barriers and warning signs, or make other adequate arrangements to prevent

unauthorised personnel from accidentally straying into the bolt tensioning area.

— Release the oil pressure immediately if any unauthorised person moves into the bolt

tensioning area and especially is anyone stands in front of a bolt tensioning tool under

pressure or stands in line with the long axis of a bolt being tensioned.

— Determine the correct working pressure for the bolts to be tightened. Proceed with the

following operations keeping the bolt tensioning tools under pressure for the minimum

time necessary to complete the bolt tightening operation.

20 DE-TENSIONING A BOLT IBOLTIGHT – TYPHOON+ USER MANUAL

Table of contents

Other NORD-LOCK Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

oventrop

oventrop Regudis W Installation passport

Tekelec

Tekelec EAGLE 5 Commands Error Recovery Manual

HEIDENHAIN

HEIDENHAIN M12 Mounting instructions

schmalenberger

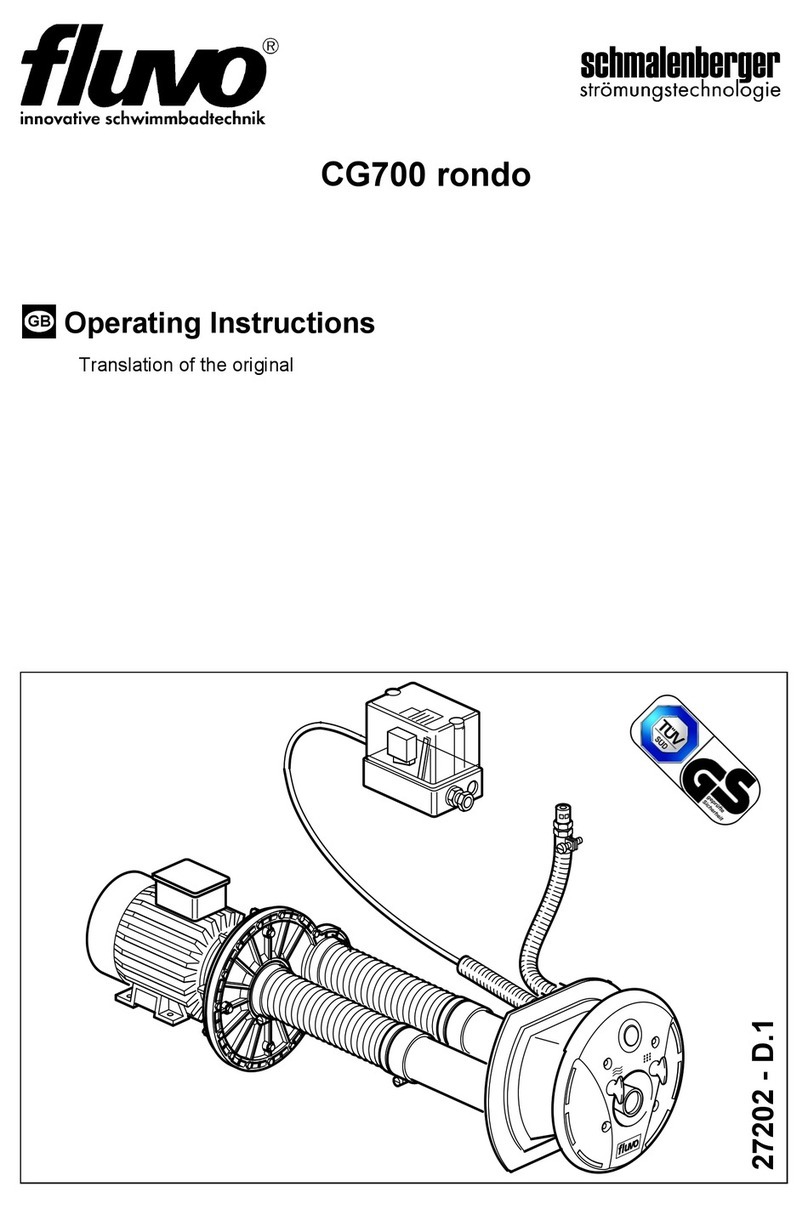

schmalenberger fluvo CG700 rondo operating instructions

ITW Dynatec

ITW Dynatec DYNAMINI 4-HOSE Technical documentation

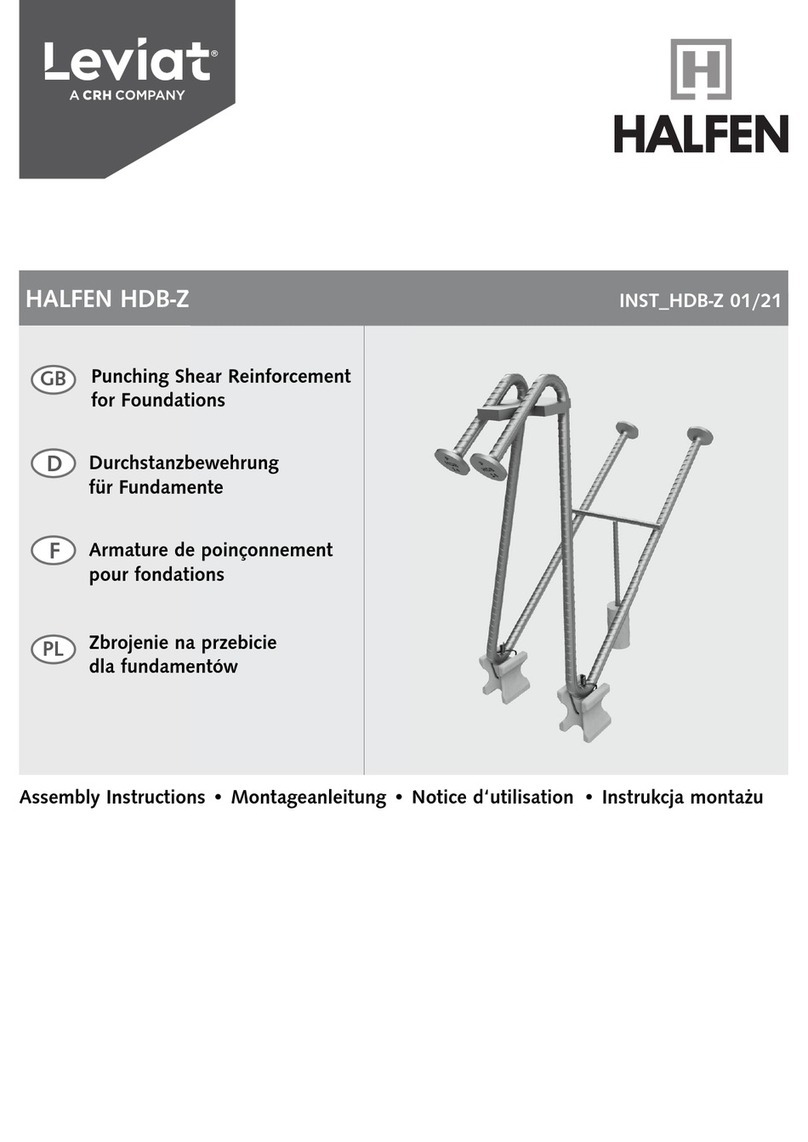

CRH

CRH Leviat HALFEN HDB-Z Assembly instructions