2

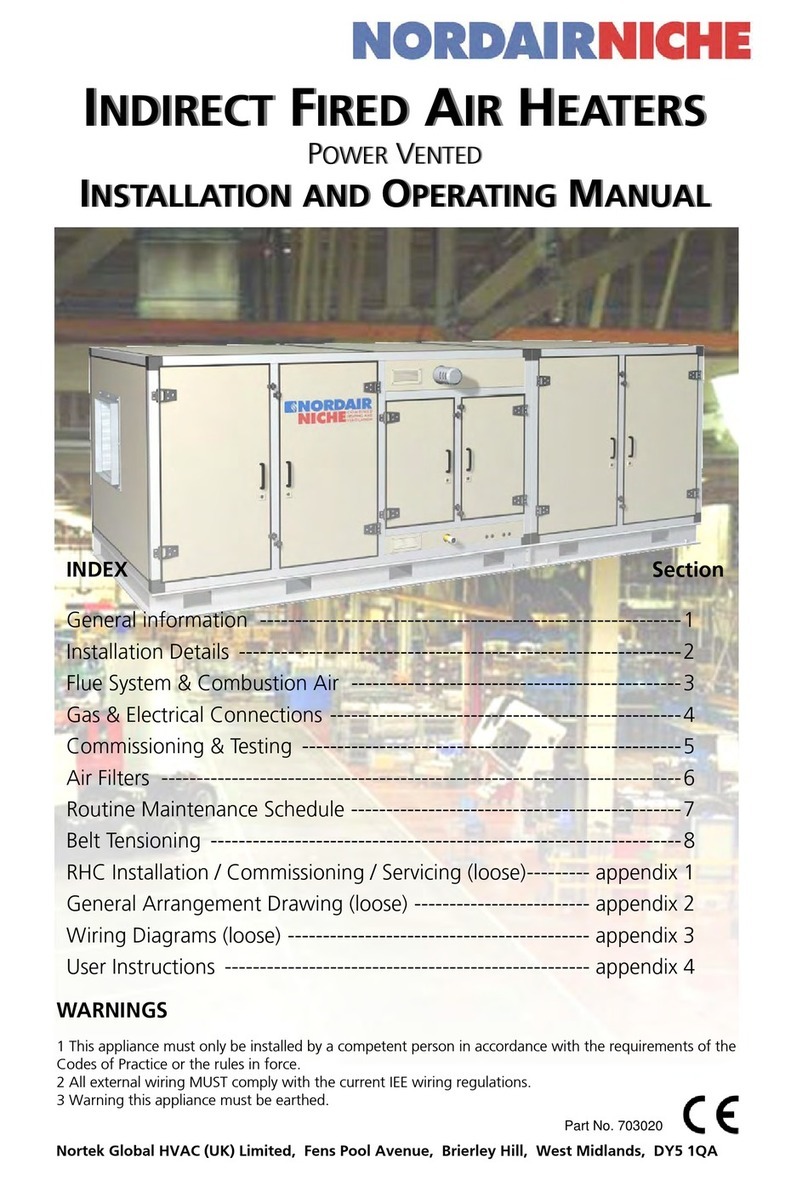

1. General Information

Before installation, check that the appliance as

described on the packaging label is in

accordance with the correct type and model as

specified on the data plate and complies with the

site requirements.

Please read this document before commencing

installation.

Check that the local distribution conditions of

electricity supply, type of gas and pressure of the

appliance are compatible.

The installation must comply with the

requirements and recommendations of British

Standards BS 6230 1991. “Installation of Gas

Fired Forced Convection Air Heaters for

Commercial and Industrial Space Heating”.

The installation must also be in accordance with

relevant requirements of The Gas

safety (Installation and use Regulations) and

(Amendment regulation 1990) and the Building

and Electrical Regulation (in GB and IEE

Regulations). The requirements of the Local

Building Standards Office, the premises

Insurance undertaking and the Fire Authority

must also be observed.

Unauthorised modification of this appliance or

departure from use in the manner for which it

was intended by the manufacturer or installed in

a manner contrary to these instructions, may

constitute a hazard or jeopardise all warranties.

Deviations should only be carried out after formal

consent has been obtained from the

manufacturer.

Ensure the environment in which the air heater

will be installed will not create a hazard, i.e,

where excessive (volatile) dust, flammable or

corrosive substances and/or vapours and

combustible materials may be present. When

installing outdoor heaters care must be taken to

ensure that unauthorised access to the building

cannot be gained via the appliance or its

ductwork system.

This appliance has been tested and set

according to the data plate before leaving the

factory.

After installation the appliance must be fully

commissioned and the settings re-checked.

This appliance incorporates indirect gas fired

heat exchange modules. The modules are

purpose designed to be incorporated into air

heating appliances and the modules comply with

CE directives.

This appliance is suitable for operation within a

-10°C to +40°C temperature range.

Invalidation of guarantee

The following misuses or maltreatment of Nordair

Niche equipment will render all guarantees, as

set out on the Conditions of Sales, void.

• Failure to install, set up or put to work any part

of the equipment as specified in Nordair Niche

installation, operation and maintenance

instructions.

• Attempting to operate motors and other

electrical equipment with an electrical supply

other than that designated on the motor name

plate, or failing to connect and protect such

equipment in accordance with I.E.E

Regulations and local by-laws.

• Failure to notify Nordair Niche of equipment

damaged on receipt in writing within five days.

• Failure to run equipment within the design

specifications as notified at the time of order.

• Modifications to designed arrangement or

performances without the prior written approval

of Nordair Niche.

• Damage caused to equipment on site through

lack of adequate protection from the elements

or misuse by other trades.

• Failure to observe all normally accepted

engineering practices during installation,

commissioning and subsequent operation of

equipment.

IMPORTANT NOTE

DO NOT USE IMPACT DRIVERS ON PANELS

OR DOOR CLAMPS!

USE M5 ALLEN KEY ONLY!