Nordco CGS User manual

APPENDIX A

CGS HAMMER

RAIL GAGER

Operation and

Maintenance

Manual

Applies to S/N 480025 and Above

Last Revision: Rev. -

JUNE 2007

This manual is a guide for the operation and routine maintenance of a NORDCO Railroad Maintenance

Machine. It covers product technical information, basic operating and maintenance procedures, and

safety information and is provided for use by the qualified personnel who will supervise, operate or service

the equipment described herein.

Measurements in this manual are given in both metric and customary U.S. unit equivalents.

Personnel responsible for the operation and maintenance of this equipment should thoroughly study the

manual before commencing operation or maintenance procedures.

This manual should be considered a permanent part of your machine and should

remain with the machine at all times.

Additional copies of this manual are available either as a part (Operation Manual

only) or a whole (operation and parts manual), at a nominal cost, through our Part

Sales Department. Additional service information, parts, and application information

is available through these Nordco product support resources:

NORDCO Sales: Milwaukee, Wisconsin

(414) 766-2180

NORDCO Parts: Milwaukee, Wisconsin

1-800-647-1724

Oshawa, Ontario, Canada

(905) 579-4058, Ext. 224

NORDCO Service: 1-800-445-9258

We ask that if you have any comments or suggestions about this manual, let us hear from you. We are

here to be of service to you, our customers. Direct your comments and inquiries to:

Technical Documentation Department

NORDCO Inc.

245 W. Forest Hill Avenue

Oak Creek, WI 53154

HAZARDOUS MATERIAL DATA

In an effort to provide information necessary for your employee safety training program and to meet the

requirements of OSHA Hazard Communication Standard 1910.1200, we have OSHA Form 20 Safety Data

Sheets available that cover the material contained in this machine.

If you are interested in receiving this information, please refer to the Name, model, and Serial Number of

your machine when calling or writing, and direct your inquiries to:

Vice-President of Operations

NORDCO Inc.

245 W. Forest Hill Avenue

Oak Creek, WI 53154

Fax: (414) 766-2299

Phone: (414) 766-2288

Curve Gang Hammer Model A APPENDIX A

JUNE/2007 (4945-4800) Safety, Page 1

SAFETY

GENERAL

These safety instructions are in addition to those

listed in the SAFETY section of CGS Machine

manuals. These instructions only apply to the use of

the Rail Gager. It is important that you understand

ALL of the safety instructions before you operate this

piece of optional equipment. Learn how to operate

the Rail Gager and how to use controls properly.

DO NOT use this option for work operations other

than for which it was intended.

NORDCO is not responsible for any modifications

made without authorization or written approval.

Replace all NORDCO and OEM parts with genuine

NORDCO or OEM parts. Use of non-OEM parts

could compromise the safety of your machine.

FRA regulations require that a copy of this Operation

Manual be kept on the machine at all times.

Additional copies of the Operation Manual only can be

ordered from Nordco Parts Sales at 1-800-647-1724.

FOLLOW SAFETY INSTRUCTIONS

Carefully read all safety messages in this manual.

Learn how to operate the machine and how to use

controls properly. Do not let anyone operate this

machine without instruction. Failure to understand the

contents of this manual could result in serious

personal injury or death.

SAFETY ALERT SYMBOLS!

These are the safety-alert symbols. These

symbols means pay attention! Your safety is

at risk!

DANGER is used to indicate a definite hazardous

situation which, if not avoided, WILL result in severe

bodily harm or even death.

WARNING indicates a potentially hazardous situation

which, if not avoided, COULD result in severe bodily

harm or even death.

CAUTION indicates a potentially hazardous situation

which, if not avoided, MAY result in minor or

moderate injury.

CAUTION without the safety “!” means that failure to

follow the alert may result in machine damage.

SAFETY means that the following points are

instructions for safely operating the machine or the

specific component of the machine.

Please read and comply with all of the safety

precautions in both the CGS Machine Manual and

this optional equipment manual.

APPENDIX A Curve Gang Hammer Model A

Safety, Page 2 JUNE/2007 (4945-4800)

GENERAL SAFETY TIPS

Only trained and authorized personnel familiar with

the function of a gaging machine should be allowed to

operate this machine. In addition, all personnel at the

worksite (gang) should be aware of the safety

concerns and their individual responsibilities prior to

working this machine.

•Review the operating instructions if you are

unsure of anything.

•Use the “Pre-operational Checklist” to check the

machine for obvious faults. Repair or replace as

necessary PRIOR to operating the machine.

•Before climbing onto the machine, make certain

the area around and under the machine is clear of

obstructions and personnel.

•Never climb on to, or off of, the machine while it is

in motion.

•There are lockups on this machine that are used

for both work and travel. These should be kept

clear and free of debris, grease, etc. See

Lockup section for instructions on their use.

•Inspect safety decals and replace when they

become unreadable or are damaged. (See

“Safety Decals”at the end of this Safety section).

•Use the “STARTUP Checklist” to check the

machine controls and gauges to make certain all

systems are operating correctly.

•Press the EMERGENCY STOP pushbutton on

the center control console in emergencies and

potentially dangerous situations.

•If personnel or bystanders are near the machine

during operation, give a warning signal using the

air horn. If they fail to respond to this warning,

stop operation immediately.

•When leaving a machine engine running, make

certain that the parking brake is applied and the

electrical interlock button has been activated.

SAFETY DURING MAINTENANCE

The following guidelines are suggested when

performing maintenance:

1. Always chock the wheels

2. Alert others in the area that service or

maintenance is being performed on this

machine.

3. Become familiar with, and use, your

company’s lockout/tagout procedures when

performing maintenance on this machine.

See LOCKOUT/TAGOUT REQUIREMENTS

later in this Safety Section for a chart on

energy sources located on this machine.

4. Do not start the engine if repairs or work is

being performed alone. You should always

have at least two people working together if

the engine must be run during service. One

person needs to remain in the command

position (at the controls), ready to stop the

machine and shut off engine if the need

arises.

5. Collect oils and fuels and dispose of them

properly. There is a danger of scalding when

working with engine oils.

6. Use only Nordco supplied repair parts for this

machine. Use of non-OEM designed parts

could comprise the integrity of this machine.

7. There are welding cautions on this machine.

Pay attention to them PRIOR to welding.

8. Kits supplied by Nordco have welding

instructions included. Welding of any

components NOT of Nordco’s manufacture or

failure to follow these instructions may affect

the stability of this machine.

Curve Gang Hammer Model A APPENDIX A

JUNE/2007 (4945-4800) Safety, Page 3

CGS RAIL GAGER

SAFETY ALERTS

Failure to engage all lockup devices before propelling at travel speed can result in injury to

personnel and/or extensive damage to the machine.

Always turn off machine when performing maintenance, making adjustments, or whenever

unintended movement of machine could occur; unless directed otherwise. Failure to

comply could result in personal injury and/or damage to the machine.

Do not attempt to operate or adjust the Rail Gager without first learning how to operate the

spiking machine.

APPENDIX A Curve Gang Hammer Model A

Before Operation, Page 4 JUNE/2007 (4945-4800)

BEFORE OPERATION

Do not attempt to operate or adjust the Rail Gager

without first learning how to operate the spiking

machine.

It is always a good practice to become familiar with the components of

the machine you are using.

GENERAL

To better understand the function of the CGS Gager, you have to

understand the concept of bringing a rail “to gage”.

Track gage is the distance between rail heads. See Figure 1. Standard

track gage is 56-1/2" but gage may vary at crossings, switches and

curves.

The process of adjusting the distance between rail ball heads is called

gaging. The rail gager on the CGS Machine accomplishes this in two

basic steps:

1. An LVDT inside the Gager Buggy measures the actual distance

between rail heads and relays this information electronically to

the Programmable Logic Controller (PLC) inside the Operator

Control Box and to a meter located in front of the Spike Driver

Operator.

2. After the gage distance signal is received at the PLC, signals are

sent to the solenoid valves that control the rail gage assembly.

See Figure 3. The rail clamp, positioned over the fixed rail,

closes. Next, the pregager cylinder/lever pushes the rail and the

tie plates slightly under gage. The gager cylinder then pushes

the free rail and tie plates out until the rail reaches the gage

position selected at the gager meter by the operator, after which

spikes can be driven.

The CGS Rail Gager consists of two assemblies, both of which MUST be

locked up for travel (See Lockups later in this manual):

Curve Gang Hammer Model A APPENDIX A

JUNE/2007 (4945-4800) Before Operation, Page 5

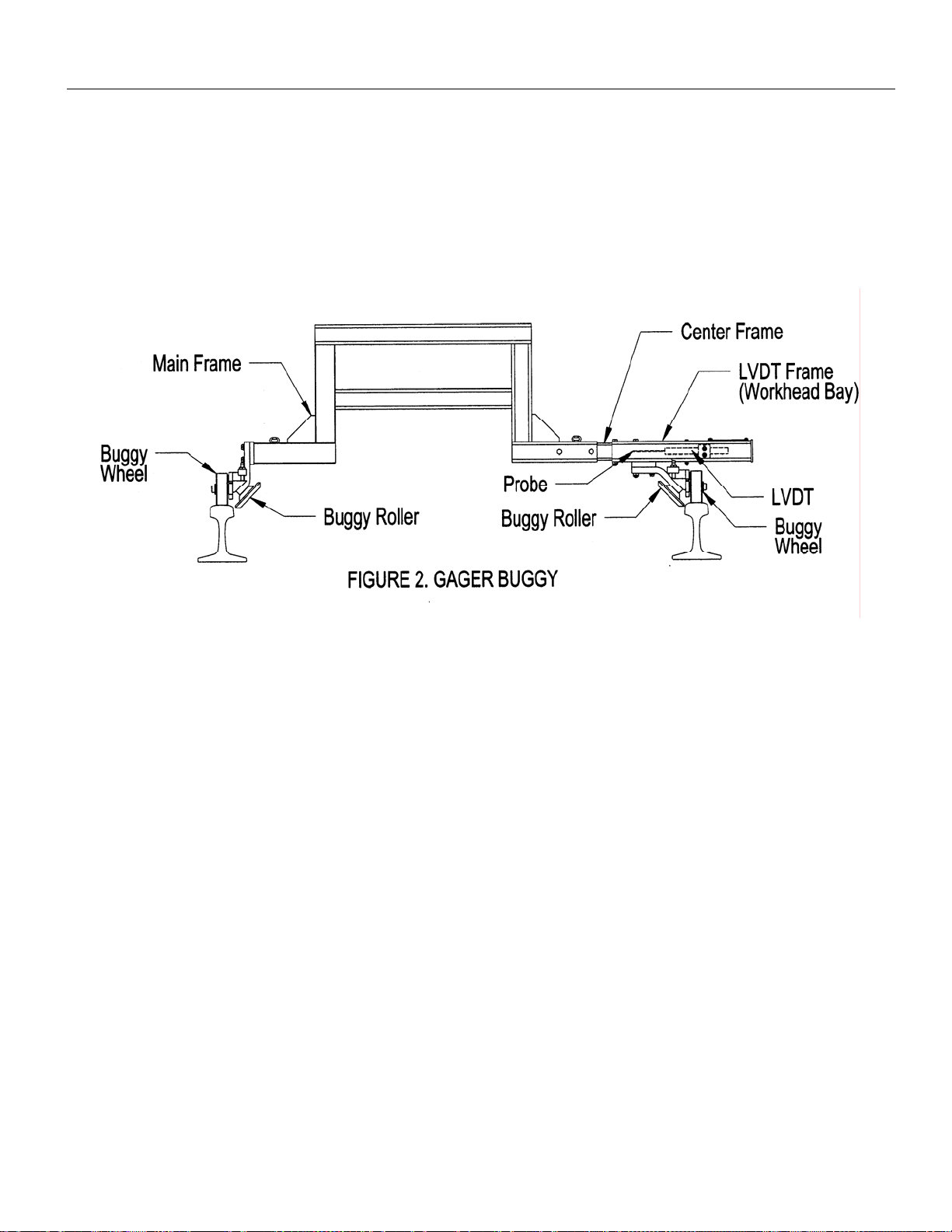

GAGER BUGGY

The gager buggy consists of a three piece tubular frame with a roller

assembly mounted to each end. These roller assemblies allow the buggy

to ride the rail continuously during gaging operations. The LVDT frame

houses the LVDT position sensor.

The Gager Buggy LVDT monitors the position of the free rail, and sends a

signal back to the PLC and electronic meter.

APPENDIX A Curve Gang Hammer Model A

Before Operation, Page 6 JUNE/2007 (4945-4800)

GAGER ASSEMBLY

The gager assembly consists of a free floating frame, a rail clamp

assembly, a pregaging lever and cylinder, a gaging cylinder, and two

roller assemblies. The gager frame is supported by a cylinder which not

only raises and lowers the assembly, but includes the lockup feature of

the gager. A pair of rollers is attached to the gager frame to allow the

gager to ride on top of the rail. The position of these rollers is adjustable

to accommodate various rail sizes.

The gager assembly is designed to apply the necessary force to the free

rail to position it at the proper gage distance from the fixed rail prior to

spiking operations.

Curve Gang Hammer Model A APPENDIX A

JUNE/2007 (4945-4800) Before Operation, Page 7

INSTRUMENTS AND CONTROLS

The gager meter box and portions of the Main Control Panel control the gager assembly in its entirety. An “At-Gage”

light in front of the Spike Driver Operator will illuminate when the rail has reached gage, and is the signal for the

operator to begin spiking.

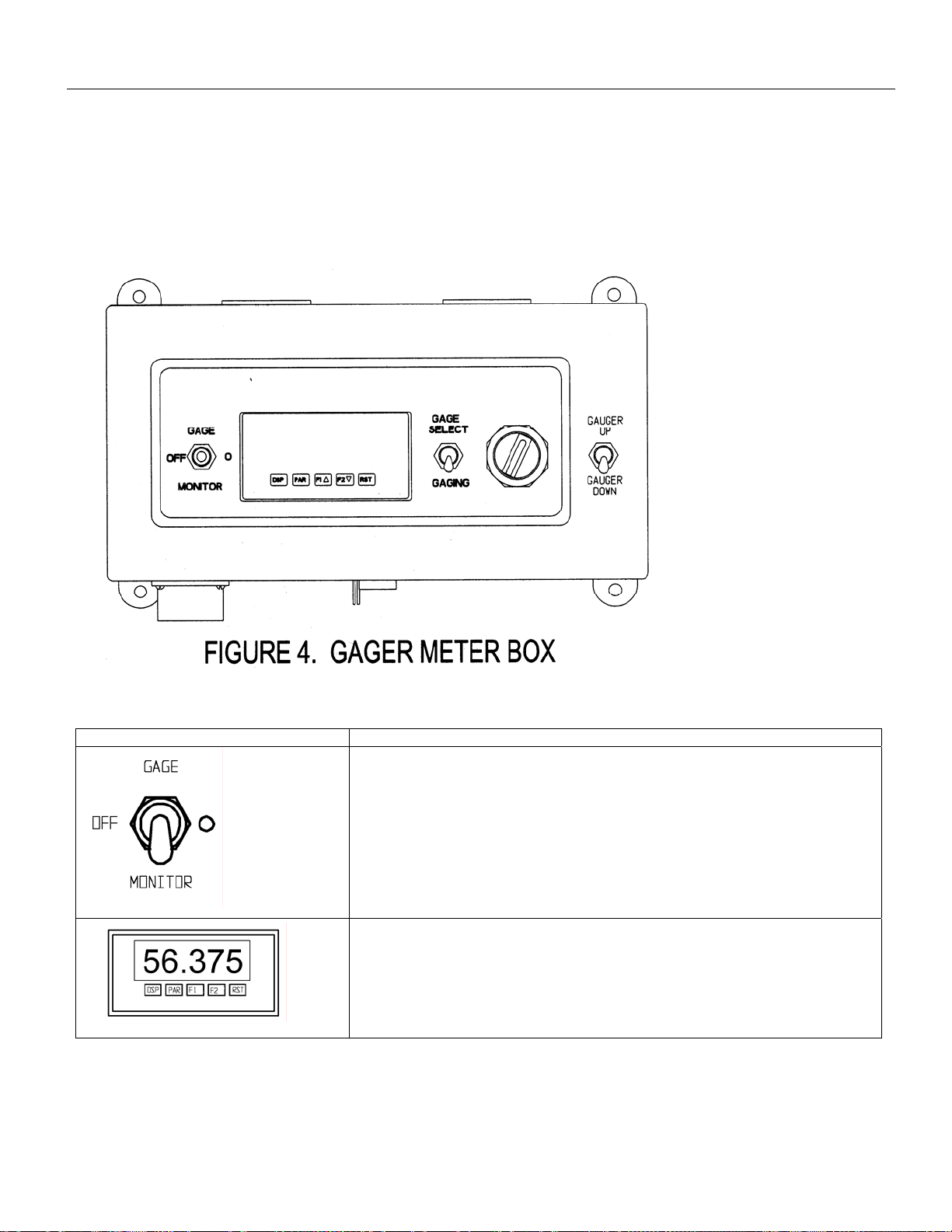

GAGER METER BOX

CONTROL OR INSTRUMENT FUNCTION

This is a 3-position switch that controls the electrical components of the

gager. The switch positions and their functions are as follows:

Gage: Turns the gager electronic system ON. Readout meter will light up

and remain on until this switch is turned to the OFF position.

OFF: Turns the gager electronic system OFF.

MONITOR: Used to monitor the rail gage WITHOUT the use of the gager.

Readout meter will remain on until switch is manually returned to center.

READOUT METER: Indicates rail gage. Meter scale is digital and reads to

the thousandths of an inch. This meter has been pre-programmed prior to

sale. Instructions for reprogramming in the event of catastrophic failure are

included in the maintenance section of this appendix.

The buttons at the bottom of the readout meter are used for reprogramming

the meter.

APPENDIX A Curve Gang Hammer Model A

Before Operation, Page 8 JUNE/2007 (4945-4800)

CONTROL OR INSTRUMENT FUNCTION

This is a two position switch that controls the work operations of the gager

itself.

SELECT: Activates the potentiometer allowing you to set the gage. The

digital meter will read the potentiometer position.

GAGING: The digital meter will read the actual rail gage (LVDT position).

Gager SELECT Potentiometer:

The gage select switch must be in the SELECT mode before the

potentiometer functions. This is used by the operator to change the

desired gage for varying track conditions such as crossings, switches,

steep curves, etc.

Gager UP/DOWN Control Switch:

This is a two position switch that activates and deactivates the rail gaging

process. Immediate action of the gager assembly is dependent on the rail

type mode selected (JOINTED or WELDED) on the Main Control Panel.

GAGER UP: Deactivates the gaging process, and raises the rail gager

assembly to the stored/lockup position.

GAGER DOWN: Activates the gaging process based on the position of

JOINTED or WELDED switch:

If the rail type mode is WELDED, the rail gager assembly is immediately

lowered to the rail.

If the rail type mode is JOINTED, the gager assembly will not lower onto

the rails until the SET button on either hand controller has been pressed.

Curve Gang Hammer Model A APPENDIX A

JUNE/2007 (4945-4800) Before Operation, Page 9

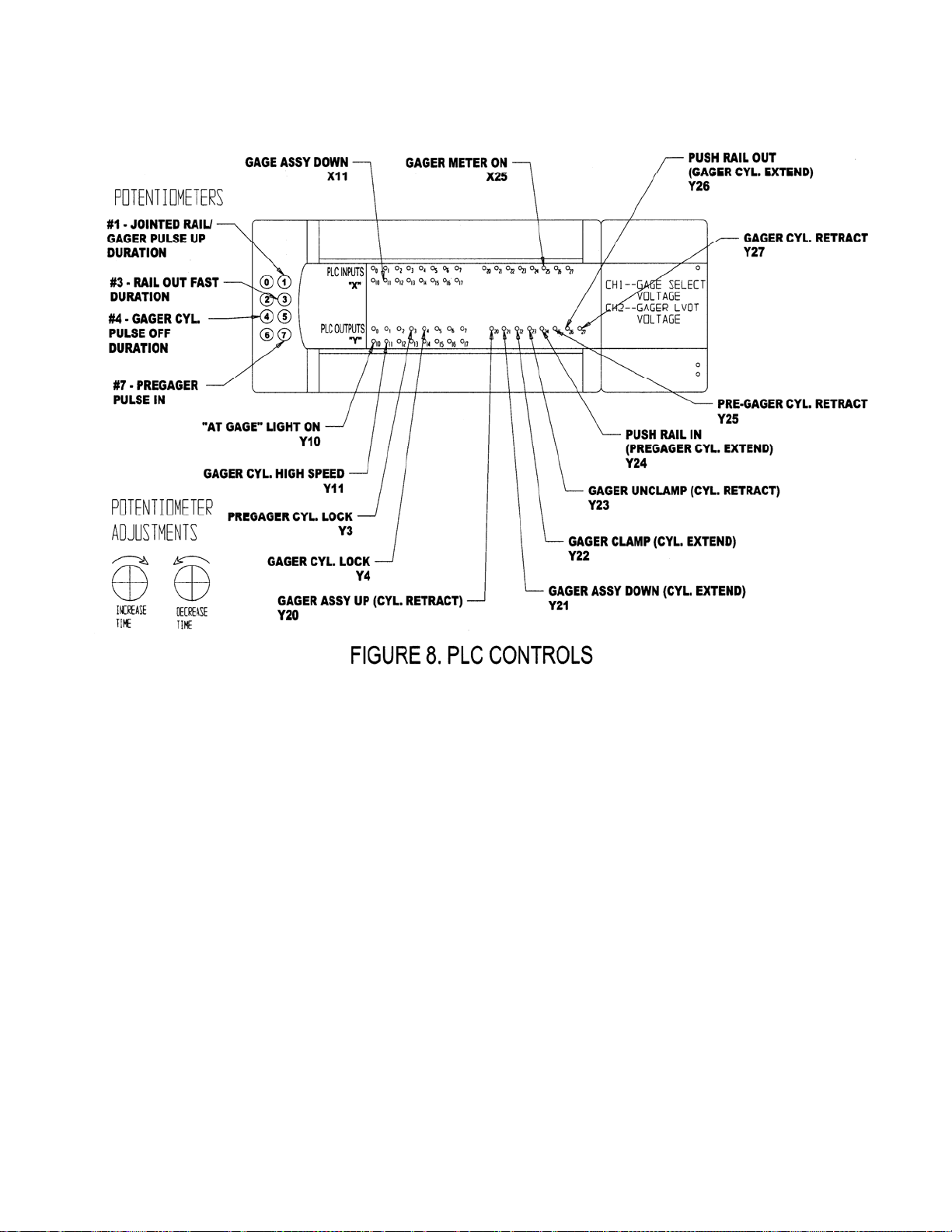

GAGER-RELATED ITEMS IN THE OPERATOR CONTROL BOX

The following figures represent gager controls that are housed in the operator control box. These are for reference

only. Refer to the Electrical Section of the CGS manual for details and most current drawings of these controls.

APPENDIX A Curve Gang Hammer Model A

Before Operation, Page 10 JUNE/2007 (4945-4800)

Curve Gang Hammer Model A APPENDIX A

JUNE/2007 (4945-4800) Before Operation, Page 11

APPENDIX A Curve Gang Hammer Model A

Before Operation, Page 12 JUNE/2007 (4945-4800)

Curve Gang Hammer Model A APPENDIX A

JUNE/2007 (4945-4800) Before Operation, Page 13

LOCKUPS

Certain machine components have lock-up features for use during high-

speed travel, towing, or during machine storage.

Failure to engage all lockup devices before propelling at

travel speed can result in injury to personnel and/or

extensive damage to the machine.

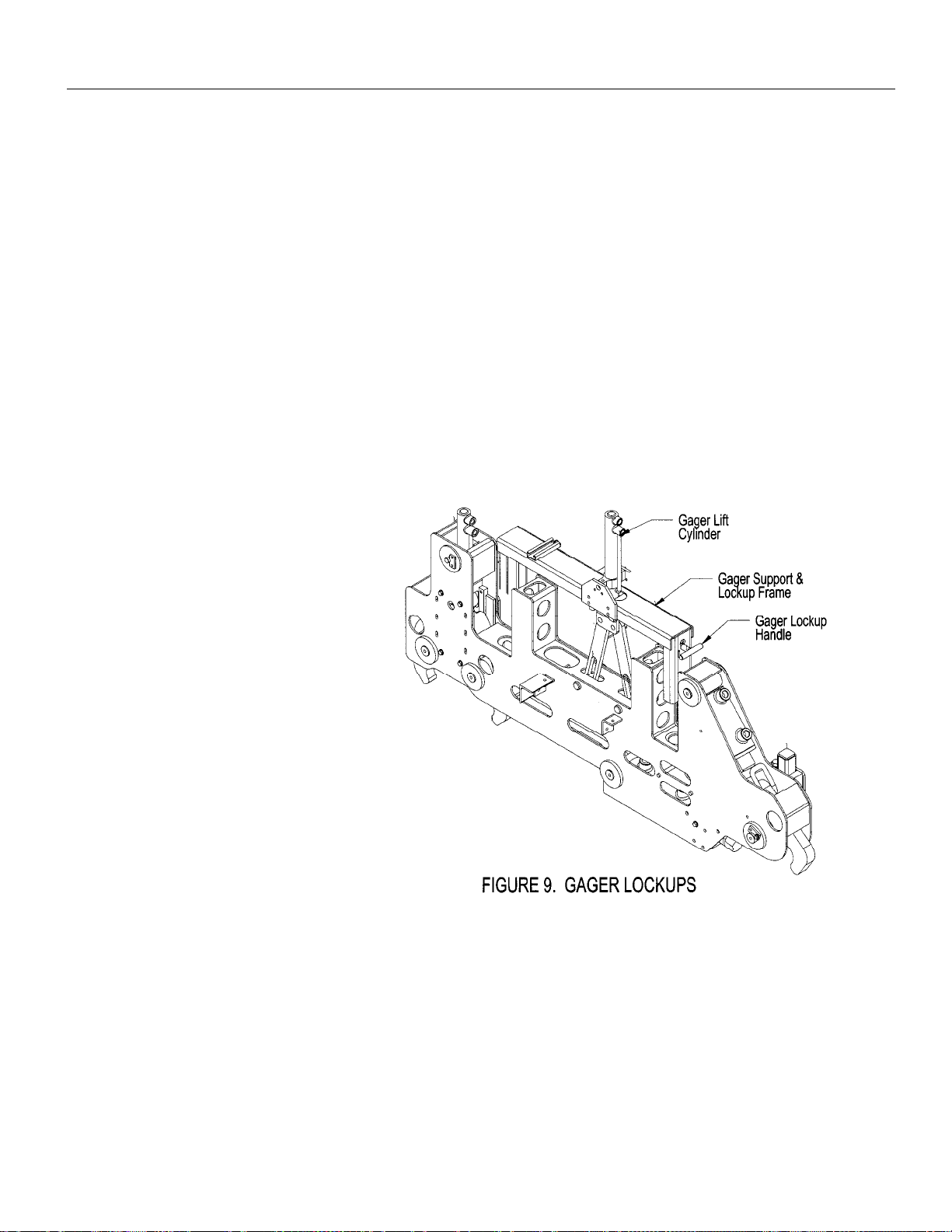

RAIL GAGER

The rail gager assembly is equipped with a single lockup pin. See

Figure 9. The rail gager must be in the fully raised and stored position

before the lockup pin can be inserted. This can be accomplished by

either switching the Gager UP/DOWN toggle switch to the UP position

or switching the WORK/TRAVEL toggle switch to the TRAVEL mode.

APPENDIX A Curve Gang Hammer Model A

Before Operation, Page 14 JUNE/2007 (4945-4800)

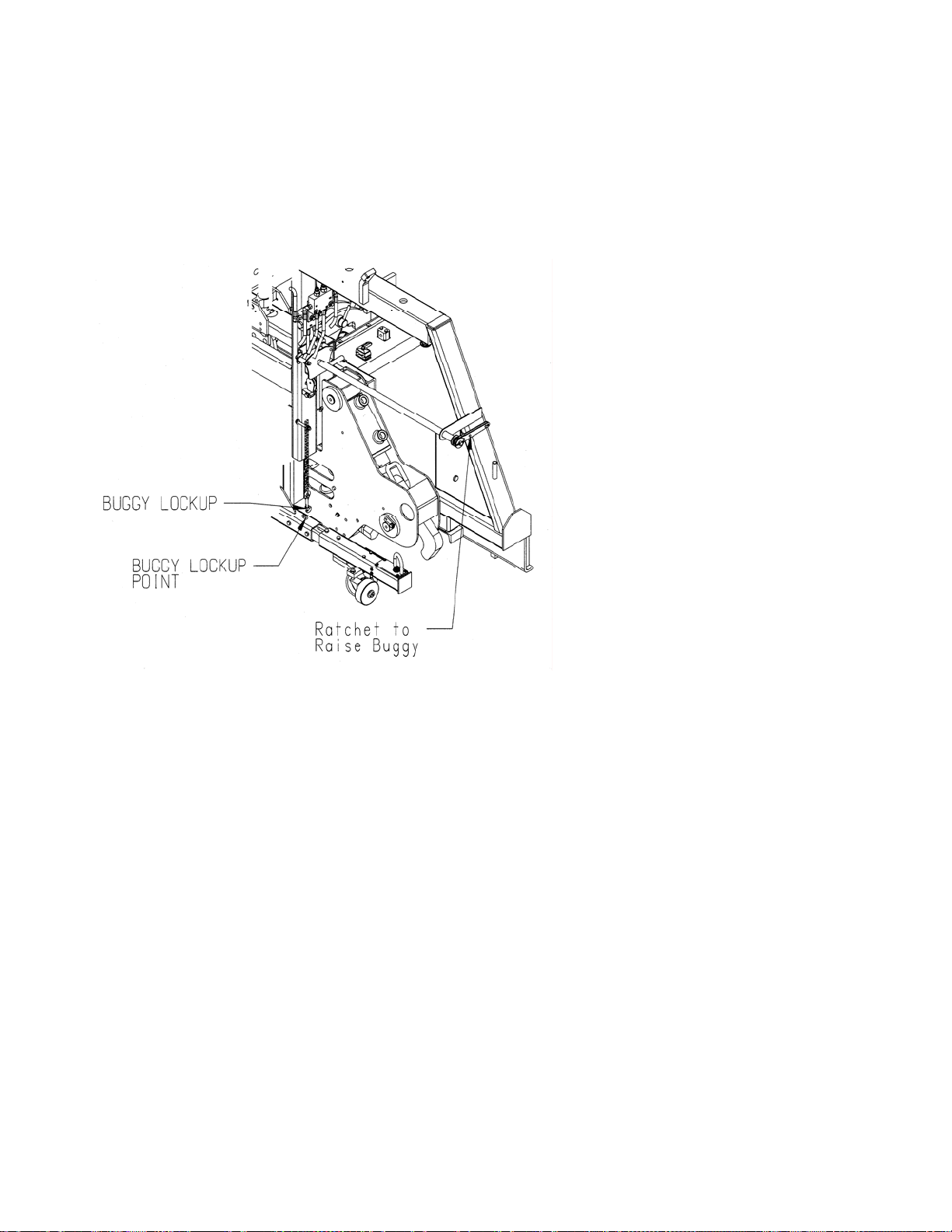

ROLLER BUGGY

The Roller Buggy is locked up on both the left frame and right frame by a

chain/hook assembly. The buggy must be raised off the rail to a point

the chain/hook will easily attach to the eyes on the frame.

To lower the buggy, turn the crank handle counter clockwise, to raise the

buggy turn the crank handle clockwise.

FIGURE 10. GAGER BUGGY LOCKUPS

Curve Gang Hammer Model A APPENDIX A

JUNE/2007 (49454800) Setup, Page 15

GAGER SETUP/ADJUSTMENTS

Prior to using the gager on any track conditions, the adjustment and

alibration procedures given in this section must be performed.c

Always turn off machine when performing maintenance,

making adjustments, or whenever unintended movement of

machine could occur; unless directed otherwise. Failure to

comply could result in personal injury and/or damage to the

machine.

ROLLER BUGGY WHEEL HEIGHT ADJUSTMENT

The Roller Buggy must ride on the rails so that each buggy guide

roller rides against the inside of the both rails at the correct height.

To adjust the Roller Buggy height proceed as follows:

1. Lower Roller Buggy to track with enough slack in cable to

allow the weight of the buggy to rest on rail.

2. Make certain that the buggy guide roller on the main frame

is on the inside of the rail.

3. Push on end of LVDT frame until buggy guide roller snaps onto

the inside of rail.

4. Locate locknut and adjustment screw as shown in Figure 12.

Loosen nut. Note: LVDT Frame side is shown, main frame side

is opposite.

APPENDIX A Curve Gang Hammer Model A

Before Operation, Page 16 JUNE/2007 (49454800)

5. Turn adjustment screw until buggy guide roller is lowered to

a position 5/8" down from the top of the rail, or as shown in

Figure 13.

6. Tighten locknut.

7. Repeat steps 4 through 6 for the Main Frame (Left) Roller

Buggy guide roller.

Table of contents

Other Nordco Industrial Equipment manuals