NORDICCO HVLS Guide

1

I

I

N

N

S

S

T

T

A

A

L

L

L

L

A

A

T

T

I

I

O

O

N

N

M

M

A

A

N

N

U

U

A

A

L

L

&

&

U

U

S

S

E

E

R

R

G

G

U

U

I

I

D

D

E

E

N

N

O

O

R

R

D

D

I

I

C

C

C

C

O

O

N

N

O

O

R

R

T

T

H

H

E

E

R

R

N

N

L

L

I

I

G

G

H

H

T

T

®

®

H

H

V

V

L

L

S

S

F

F

A

A

N

N

E

E

n

n

g

g

l

l

i

i

s

s

h

h

IIMMPPOORRTTAANNTTSSAAFFEETTYYWWAARRNNIINNGG

T

T

H

H

I

I

S

S

S

S

Y

Y

S

S

T

T

E

E

M

M

U

U

S

S

E

E

S

S

I

I

N

N

T

T

E

E

G

G

R

R

A

A

T

T

E

E

D

D

U

U

V

V

C

C

L

L

I

I

G

G

H

H

T

T

S

S

O

O

U

U

R

R

C

C

E

E

S

S

.

.

I

I

N

N

C

C

O

O

R

R

R

R

E

E

C

C

T

T

I

I

N

N

S

S

T

T

A

A

L

L

L

L

A

A

T

T

I

I

O

O

N

N

A

A

N

N

D

D

/

/

O

O

R

R

U

U

S

S

A

A

G

G

E

E

C

C

A

A

N

N

C

C

A

A

U

U

S

S

E

E

I

I

N

N

J

J

U

U

R

R

Y

Y

.

.

W

W

A

A

R

R

N

N

I

I

N

N

G

G

:

:

N

N

E

E

V

V

E

E

R

R

L

L

O

O

O

O

K

K

D

D

I

I

R

R

E

E

C

C

T

T

L

L

Y

Y

I

I

N

N

T

T

O

O

U

U

V

V

C

C

L

L

I

I

G

G

H

H

T

T

S

S

O

O

U

U

R

R

C

C

E

E

S

S

.

.

P

P

L

L

E

E

A

A

S

S

E

E

N

N

O

O

T

T

E

E

T

T

H

H

A

A

T

T

S

S

P

P

E

E

C

C

I

I

F

F

I

I

C

C

L

L

O

O

C

C

A

A

L

L

O

O

R

R

N

N

A

A

T

T

I

I

O

O

N

N

A

A

L

L

R

R

E

E

Q

Q

U

U

I

I

R

R

E

E

M

M

E

E

N

N

T

T

S

S

M

M

A

A

Y

Y

A

A

P

P

P

P

L

L

Y

Y

T

T

O

O

T

T

H

H

E

E

I

I

N

N

S

S

T

T

A

A

L

L

L

L

A

A

T

T

I

I

O

O

N

N

A

A

N

N

D

D

U

U

S

S

A

A

G

G

E

E

O

O

F

F

U

U

V

V

C

C

E

E

Q

Q

U

U

I

I

P

P

M

M

E

E

N

N

T

T

.

.

I

I

T

T

I

I

S

S

T

T

H

H

E

E

S

S

O

O

L

L

E

E

R

R

E

E

S

S

P

P

O

O

N

N

S

S

I

I

B

B

I

I

L

L

I

I

T

T

Y

Y

O

O

F

F

T

T

H

H

E

E

I

I

N

N

S

S

T

T

A

A

L

L

L

L

E

E

R

R

T

T

O

O

E

E

N

N

S

S

U

U

R

R

E

E

F

F

U

U

L

L

L

L

C

C

O

O

M

M

P

P

L

L

I

I

A

A

N

N

C

C

E

E

W

W

I

I

T

T

H

H

A

A

N

N

Y

Y

L

L

O

O

C

C

A

A

L

L

A

A

N

N

D

D

/

/

O

O

R

R

N

N

A

A

T

T

I

I

O

O

N

N

A

A

L

L

R

R

E

E

Q

Q

U

U

I

I

R

R

E

E

M

M

E

E

N

N

T

T

S

S

,

,

I

I

N

N

C

C

L

L

U

U

D

D

I

I

N

N

G

G

A

A

N

N

Y

Y

R

R

E

E

Q

Q

U

U

I

I

R

R

E

E

D

D

A

A

U

U

T

T

H

H

O

O

R

R

I

I

Z

Z

A

A

T

T

I

I

O

O

N

N

S

S

.

.

W

W

E

E

R

R

E

E

C

C

O

O

M

M

M

M

E

E

N

N

D

D

T

T

H

H

A

A

T

T

I

I

N

N

S

S

T

T

A

A

L

L

L

L

E

E

D

D

S

S

Y

Y

S

S

T

T

E

E

M

M

S

S

A

A

R

R

E

E

I

I

N

N

S

S

P

P

E

E

C

C

T

T

E

E

D

D

(

(

B

B

Y

Y

AAPPRROOFFEESSSSIIOONNAALLUUVVCCTTEECCHHNNIICCIIAANN))EEVVEERRYYSSIIXXMMOONNTTHHSS..

w

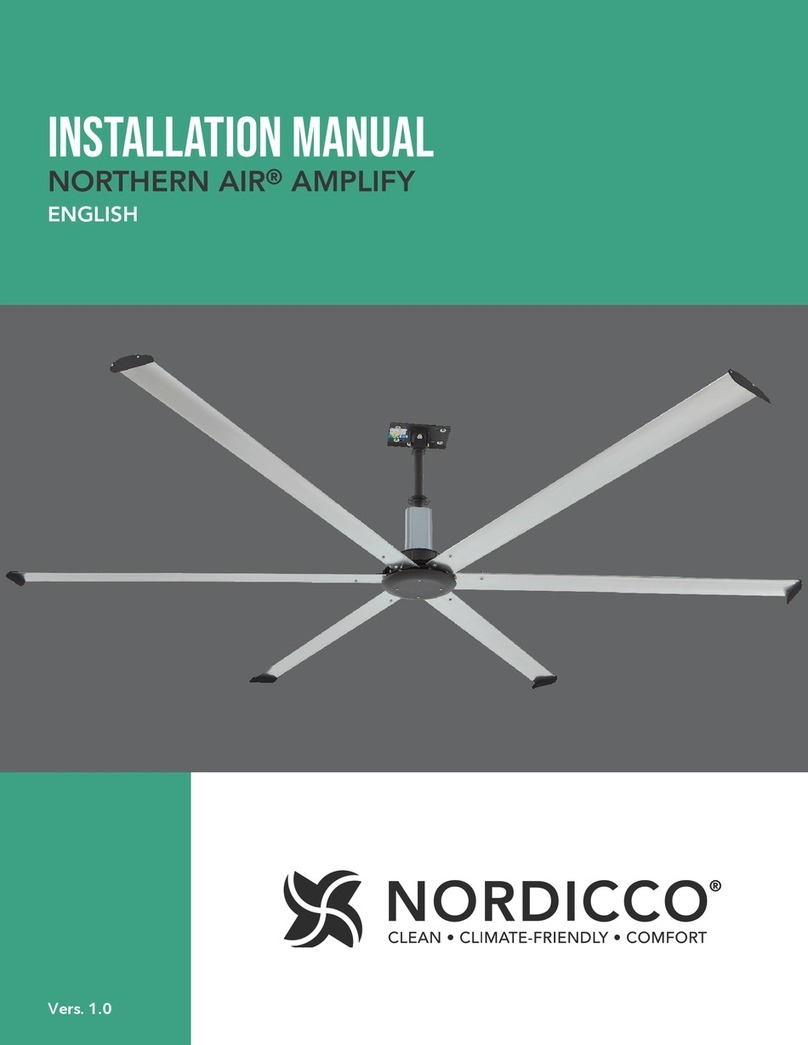

INSTALLATION MANUAL & USER GUIDE

NORDICCO NORTHERN LIGHT®HVLS FAN

ENGLISH

Vers. 3.0

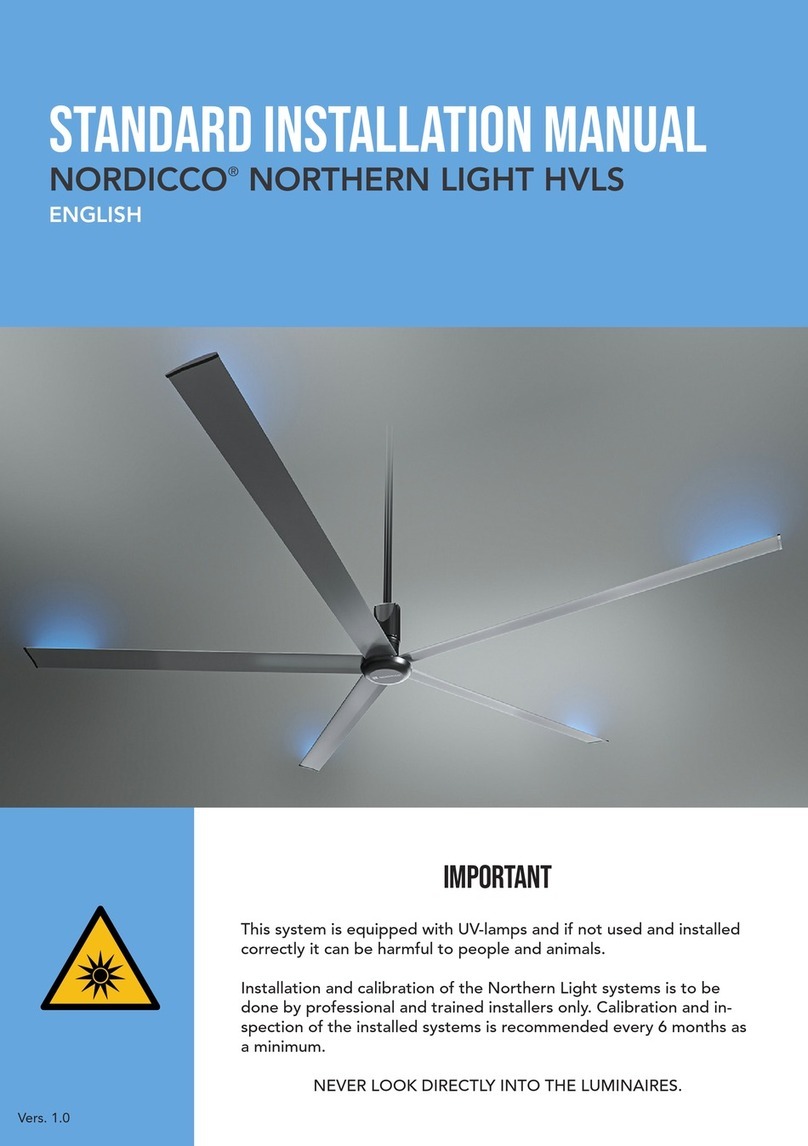

IMPORTANT SAFETY WARNING

THIS SYSTEM USES INTEGRATED UVC LIGHT SOURCES. INCORRECT INSTALLA-

TION AND/OR USAGE CAN CAUSE INJURY. WARNING: NEVER LOOK DIRECTLY

INTO UVC LIGHT SOURCES.

PLEASE NOTE THAT SPECIFIC LOCAL OR NATIONAL REQUIREMENTS MAY AP-

PLY TO THE INSTALLATION AND USAGE OF UVC EQUIPMENT. IT IS THE SOLE

RESPONSIBILITY OF THE INSTALLER TO ENSURE FULL COMPLIANCE WITH

ANY LOCAL AND/OR NATIONAL REQUIREMENTS, INCLUDING ANY REQUIRED

AUTHORIZATIONS.

WE RECOMMEND THAT INSTALLED SYSTEMS ARE INSPECTED (BY A

PROFESSIONAL UVC TECHNICIAN) EVERY SIX MONTHS.

Please note: this manual is not applicable for installations performed in Denmark. In this case, please see Danish manual.

2

BEFORE YOU BEGIN

TRANSPORT DAMAGE: THIS SYSTEM USES LIGHT SOURCES THAT CONTAIN

MERCURY. IT IS VERY UNLIKELY THAT A BROKEN LIGHT SOURCE WILL AFFECT

YOUR HEALTH. IF A LIGHT SOURCE BREAKS, THE ROOM MUST BE VENTILATED

FOR A MINIMUM OF 30 MINUTES AND THE BROKEN COMPONENTS REMOVED

(WE RECOMMEND THAT YOU WEAR GLOVES). PLACE THE BROKEN PARTS IN A

CLOSED PLASTIC BAG AND DEPOSIT AT YOUR LOCAL RECYCLING STATION. DO

NOT USE A VACUUM CLEANER.

IT IS EXTREMELY IMPORTANT THAT YOU READ CAREFULLY AND UNDERSTAND

THIS INSTALLATION MANUAL IN ITS ENTIRETY BEFORE USING THE NORDICCO

NORTHERN LIGHT®HVLS FAN. INCORRECT USE MAY CAUSE SEVERE PHYSICAL

INJURY AS WELL AS DAMAGE TO INVENTORY, ETC. BEFORE INSTALLATION, IT IS

IMPORTANT TO ENSURE THAT YOU UNDERSTAND AND COMPLY WITH ALL LOCAL

REGULATIONS AND RESTRICTIONS RELATED TO THE FAN’S INSTALLATION.

THE PURPOSE OF THIS INSTALLATION AND COMMISSIONING MANUAL IS TO

ENSURE THAT THE NORDICCO NORTHERN LIGHT®HVLS FAN IS CORRECTLY

INSTALLED AND THAT THE UVC IRRADIATION LEVELS ARE CORRECTLY

CALIBRATED AND BELOW THE LIMITS REQUIRED BY APPLICABLE NORMS AND

REGULATIONS. THE PROFESSIONAL INSTALLER IS RESPONSIBLE FOR THE

ACTIVATION, CALIBRATION AND COMMISSIONING OF THE UVC SYSTEM.

ONLY A PROFESSIONAL UVC INSTALLER MAY ACTIVATE THE UVC SYSTEM IN THE

FAN (REQUIRES A SPECIAL ACCESS CODE FOUND IN THIS MANUAL). IT IS

THEREFORE THE LATTER’S RESPONSIBILITY TO ENSURE THAT PEOPLE ARE NOT

EXPOSED TO EXCESSIVE UVC IRRADIATION LEVELS WHEN USING THE INSTALLED

SYSTEM. ONLY QUALIFIED/PROFESSIONAL UVC INSTALLERS WITH THE CORRECT

EQUIPMENT AND UNDERSTANDING OF UVC IRRADIATION ARE PERMITTED TO

PERFORM THE ASSESSMENT AND CONFIGURATION OF THE UVC COMPONENTS

IN THIS PRODUCT.

USE OF THE UVC SYSTEM OVER TIME CAN RESULT IN DISCOLORATION AND

DECOMPOSITION OF NON-UV-RESISTANT MATERIALS.

IT IS THE RESPONSIBILITY OF THE OWNER AND OPERATOR TO ENSURE THAT THE

IRRADIATION LEVEL OF THE INSTALLED NORDICCO NORTHERN LIGHT®HVLS FAN

IS REVIEWED AND RECALIBRATED BY A PROFESSIONAL UVC INSTALLER IF

CHANGES ARE MADE TO THE CEILING, INCL. NEW CEILING-MOUNTED

FITTINGS/INSTALLATIONS ETC. AND/OR IF A NORDICCO NORTHERN LIGHT®HVLS

FAN IS MOVED TO ANOTHER LOCATION.

THIS MANUAL MUST BE STORED IN A PLACE WHERE IT IS EASILY AVAILABLE TO

USERS, INSTALLERS AND OTHERS WHO MAY NEED TO FIND INFORMATION

ABOUT THE USE OF NORDICCO NORTHERN LIGHT®HVLS FANS.

IF A MANUAL IS MISPLACED IT CAN BE DOWNLOADED FROM

WWW.NORDICCO.EU

3

GENERAL SAFETY INFORMATION

WARNING

To reduce the risk of fire, electric shock or personal injury, the following must be observed:

1.

Use this system only as instructed by Nordicco A/S. If you have any questions, please

contact Nordicco A/S or its representatives.

2.

Before servicing or cleaning the system, turn off the power to the control unit and disconnect

it from the main supply to prevent the power from being turned on accidentally.

3.

Installation and electrical wiring must be performed by qualified professionals in

accordance with all applicable standards and regulations.

4.

DO NOT ALLOW WATER OR SOLVENTS TO ENTER THE MOTOR OR DRIVE. UNDER NO

CIRCUMSTANCES MAY THE MOTOR OR DRIVE BE SPRAYED WITH STEAM, WATER OR

SOLVENTS.

5.

It is recommended that a repair/safety breakers switch is installed between each NORDICCO

Northern Light®HVLS fan and the electrical power supply network. Make sure that such a

switch is NOT placed directly above the blades so that it is always accessible – even when the

fan is running.

IMPORTANT: CHECK ALL APPLICABLE STANDARDS AND REGULATIONS TO

ENSURE COMPLIANCE WITH ALL NECESSARY REQUIREMENTS. IT IS THE SOLE

RESPONSIBILITY OF THE INSTALLER TO ENSURE COMPLIANCE WITH APPLICABLE

REGULATIONS WHEN INSTALLING THE FAN.

IT IS THE RESPONSIBILITY OF THE PROFESSIONAL UVC INSTALLER TO ENSURE

THAT THE IRRADIATION LEVELS FROM THE INSTALLED NORDICCO NORTHERN

LIGHT®HVLS FAN(S) IS/ARE MEASURED CORRECTLY BEFORE COMMISSIONING

THE UVC LIGHT COMPONENT (Part 2). IT IS THE OWNER'S SOLE RESPONSIBILITY

TO ENSURE THAT THE IRRADIATION LEVEL IS REVIEWED AND RECALIBRATED IF

ALTERATIONS ARE MADE TO THE CEILING, INCL. NEW CEILING-MOUNTED

FITTINGS/INSTALLATIONS ETC. AND/OR IF A NORDICCO NORTHERN LIGHT®

HVLS FAN IS MOVED TO ANOTHER LOCATION.

TO AVOID THE RISK OF EXCESSIVE UVC IRRADIATION LEVELS, ALWAYS ENSURE

THAT THE SYSTEM IS DISCONNECTED FROM THE POWER SUPPLY AND IS

SECURED WHEN WORKING IN PROXIMITY TO OR ABOVE THE FAN AND ITS

BLADES.

4

CONTENTS

BEFORE YOU BEGIN...............................................................................................................2

GENERAL SAFETY INFORMATION..........................................................................................3

CONTENTS .............................................................................................................................4

INSTALLATION AND COMMISSIONING.................................................................................5

PART 1 MOUNTING & CONNECTION OF FAN (EXCLUDING UVC SYSTEM) .................................................................................... 6

PRE-INSTALLATION CHECK .............................................................................................................................................................. 7

FIRE PRECAUTIONS .......................................................................................................................................................................... 8

BEST PRACTICE IN RELATION TO FIRE AND FIRE HAZARDS ......................................................................................................... 8

INSIDE THE BOX ............................................................................................................................................................................. 10

REQUIRED TOOLS & ACCESSORIES ................................................................................................................................................ 12

STANDARD INSTALLATION ............................................................................................................................................................. 12

SADDLE DIMENSIONS ................................................................................................................................................................ 12

STANDARD INSTALLATION PROCESS ............................................................................................................................................. 13

INSTALLING & SECURING THE SAFETY WIRE ................................................................................................................................. 14

AIR BLADE INSTALLATION .............................................................................................................................................................. 15

CORRECT SCREW ALIGNMENT .................................................................................................................................................. 15

FIRE ALARM INSTALLATION ........................................................................................................................................................... 16

OPTIONAL FIRE ALARM INSTALLATION ..................................................................................................................................... 16

CONNECTION OF POWER AND TABLET ........................................................................................................................................ 17

CLEANING AND MAINTENANCE .................................................................................................................................................... 18

CLEANING: ................................................................................................................................................................................. 18

MAINTENANCE: ......................................................................................................................................................................... 18

REPAIRS AND SPARE PARTS: ..................................................................................................................................................... 18

PART 2 ACTIVATION AND COMMISSIONING OF THE NORTHERN LIGHT UVC SYSTEM According to EN 14255-1 ........................ 19

GENERAL INSTRUCTIONS ............................................................................................................................................................... 20

REQUIRED EQUIPMENT AND PROTECTIVE GEAR ...................................................................................................................... 20

ACTIVITIES PRIOR TO PERFORMING THE ASSESSMENT ................................................................................................................. 22

ASSESSMENT AND MEASUREMENT INSTRUCTIONS ..................................................................................................................... 23

PICTURE EXAMPLES OF THE ASSESSMENT PROCEDURE ........................................................................................................... 25

SENSOR ORIENTATION .............................................................................................................................................................. 26

MECHANICAL DAMPING OF UVC SYSTEM ..................................................................................................................................... 27

DOCUMENTATION AND DELIVERIES .............................................................................................................................................. 28

THE ASSESSMENT FORM ............................................................................................................................................................... 29

USER INSTRUCTIONS – QUICK GUIDE.................................................................................. 30

BRIEF ABOUT CONTROLLER ....................................................................................................................................................... 30

APPENDIX OVERVIEW........................................................................................................... 31

APPENDIX A – LIMIT VALUES FOR ARTIFICIAL OPTICAL IRRADIATION ....................................................................................... 32

APPENDIX B – CALCULATION EXAMPLE .................................................................................................................................... 33

APPENDIX C – REFLECTIVITY FACTORS ..................................................................................................................................... 36

APPENDIX D – ELECTRICAL DIAGRAM ...................................................................................................................................... 39

APPENDIX E – DECLARATION OF CONFORMITY ........................................................................................................................ 40

APPENDIX F – ASSESSMENT FORM .......................................................................................................................................... 41

5

INSTALLATION AND COMMISSIONING

Installation of the NORDICCO Northern Light®system is divided into three parts/sections, which

are each described below and illustrated in Figure 1.

PART 1: Installation of the HVLS fan

This part of the installation can be performed by an installer with a technically relevant

qualification, such as a Service Engineer or electrical fitter. The installer is responsible

for the processes and procedures presented in Part 1 of this installation manual.

PART 2: Activation, assessment and commissioning of the UVC system (Northern Light)

May only be performed by professional installation specialists experienced in

measuring and assessing UVC light systems. Activating the UVC component of the fan

requires a special password, which can be found in Part 2 of this manual.

The professional installer is responsible for the processes and procedures presented in

Part 2 of this installation manual as well as being responsible for ensuring that the

Administrator receives correct instruction and guidance in use of the system.

PART 3: Instruction, guidance and information

The professional installer will instruct and guide the Administrator in the correct use of

the system. The professional installer will also deliver the Assessment report as well as

inform the Administrator of the results found and measures taken during the

assessment and commissioning of the system.

Figure 1: Installation procedure

6

PART 1

MOUNTING & CONNECTION OF FAN

(EXCLUDING UVC SYSTEM)

7

PRE-INSTALLATION CHECK

1.

MAKE SURE THAT THE CEILING FAN IS INSTALLED IN A LOCATION WHERE THE BLADES ARE AT

LEAST 3.0 METERS ABOVE HIGHEST FLOOR LEVEL TO AVOID DIRECT EXPOSURE TO THE UVC

LIGHT. FURTHERMORE ENSURE A SAFE DISTANCE FROM ANY OBSTACLES ALLOWING THE FAN

TO OPERATE FREELY.

2. If the building has a mezzanine, staircase or other elevated area where people may be present this

must be taken into account when measuring distances in accordance with point 1.

3. Make sure the ceiling fan is not installed near overhead doors or other building openings where gusts of

wind may occur. The fan should not be installed or operated in places where wind is present.

4. If the building is equipped with a fire sprinkler system, verify that the placement of the fan will not

interfere with correct sprinkler operation and that the installation of the fan complies with all

applicable building codes, rules and regulations.

5. Check whether the intended placement of the fan is directly under lamps or skylights. If possible, avoid

installing fans below a light source to prevent a stroboscopic effect that can be caused by the fan’s

rotation.

6. To achieve the best possible performance, the fan must be installed with a minimum clearance

distance of two fan diameters to the nearest radiant heaters and HVAC system discharges (outlets)

or intakes (inlets).

7. BEFORE INSTALLATION, IT IS IMPORTANT TO VERIFY THAT THE MOUNTING SURFACE CAN BEAR

THE OPERATING WEIGHT AND MAXIMUM TORQUE (ROTATING FORCE) OF THE NORDICCO®FANS

THAT WILL BE INSTALLED. IT IS THE SOLE RESPONSIBILITY OF THE INSTALLER TO ENSURE THAT

THE MOUNTING STRUCTURE AND FAN INSTALLATION METHOD ARE ADEQUATE FOR SAFE

OPERATION OF THE NORDICCO®FAN.

MAX TORQUE PER NORDICCO®FAN SIZE

Fan size (meters)

2.0

3.0

4.0

5.0

Max. torque (Nm)

9

28

45

64

8. THE FITTINGS/FIXING MEANS FOR ATTACHMENT TO THE CEILING MUST HAVE SUFFICIENT

STRENGTH TO WITHSTAND FOUR (4) TIMES THE WEIGHT OF THE SPECIFIC NORDICCO®CEILING

FAN (SEE ALSO TABLE BELOW).

Northern Light®System

2.0M

3.0M

4.0M

5.0M

Suspended weight

33kg

39kg

45kg

51kg

4 x suspended weight

132kg

156kg

180kg

204kg

9. To reduce the risk of strong reflective irradiation, make sure that there are no highly reflective surfaces

above or near the top of the blades. These include, for example, aluminum, reflective lamps, polished

steel surfaces, etc. A complete irradiation assessment is required before commissioning the system.

10. Inspect the blade’s packaging before handling the blades to ensure that all UVC light sources are

intact. If there is a risk or suspicion that a light source is broken or otherwise damaged, the light

source should be checked by putting on gloves and ensuring that there is adequate ventilation until

you have confirmed that they are undamaged. If in doubt, contact Nordicco A/S for the processing of

a damage report and the replacement of spare parts if necessary.

11.

INSTALLATION AND MAINTENANCE SHOULD ONLY BE PERFORMED BY QUALIFIED

PROFESSIONAL PERSONNEL WHO ARE FAMILIAR WITH LOCAL REGULATIONS AND ARE

EXPERIENCED WITH THIS TYPE OF EQUIPMENT.

8

FIRE PRECAUTIONS

IMPORTANT: It is the installers responsibility to ensure full compliance with all national and

local requirements in relation to fire and fire hazards. Nordicco A/S always recommends that

a competent advisor is consulted prior to the installation.

The following 3 scenario examples have been developed by DBI (The Danish Institute of Fire and

Security Technology) as suggestions for a fire hazard assessment.

These scenarios are for

informational purposes only and do not replace any national or local requirements.

According to DBI it should be noted that the smaller the rotor diameter of an HVLS fan, the

lower the risk of a fire spreading. The risk of fire spreading also depends on the location of the

individual HVLS fan. Three (3) scenarios are described below, where it is relevant to assess the

early detection of an incipient fire.

Scenario 1:

HVLS fans installed in a room without any fire protection systems:

1. The HVLS fans should be installed so that they can be easily disconnected – for example

via a control panel, emergency stop button or safety switch mounted visibly at exits or

located at strategic/easily accessible locations in the room.

2. A vertical respecting distance of at least 0.5 meters from combustible / flammable storage

should be kept, to ensure that any fire spread is reduced.

3. HVLS fans should be installed as far away from storage (e.g. storage shelves) as possible.

When installing in shelved storage sections, fans should be installed above walking aisles,

and not above actual storage racks.

Scenario 2:

HVLS fans installed in a room, where an Automatic Fire Alarm system is installed.

1. The HVLS fans must stop when the Automatic Fire Alarm system detects a fire and

preferably do so even before a fire is detected. This can be achieved via the built-in "fire

alarm cable", or by using manual stop options, as indicated in scenario 1.

2. For systems with flame detectors, the location of the HVLS fans should be assessed in

relation to the flame detectors’ location. There are examples of ceiling fans causing

reflections that are mistaken for light from a flame, thereby giving an unintended alarm.

Flame detectors are typically used in rooms with high ceilings and in atriums.

3. The HVLS fans should not be installed in the line of sight of a linear smoke detector, as this

may cause false alarms to trigger on the Automatic Fire Alarm system. A linear smoke

detector uses invisible beams of ultraviolet and infra-red light. The light is either received

or reflected on an opposing wall. The Automatic Fire Alarm system goes into fault mode if

the light beam is interrupted.

4. Where point smoke detectors are installed, a number of considerations must be taken into

account:

a) The velocity of the airflow from the HVLS fan should not exceed 0.5 m/sec.

b) A respecting distance of at least 0.5 meters should be maintained from point smoke detectors

to the HVLS fan blades.

9

Scenario 3:

HVLS fans installed in a room where sprinkler systems are installed. The actions listed in

scenario 1 should be followed, in addition to the following points, which are recommended by the

NFPA (National Fire Protection Association):

1. The largest HVLS fan diameter should not exceed 8 meters.

2. The HVLS fans should be centered between four sprinkler heads.

3. The distance between the HVLS fans and the sprinkler heads should be at least 0.9

meters, so as not to disrupt sprinkler system activation.

4. HVLS fans should be connected to the Automatic Fire Alarm system (if installed in the

room) and the sprinkler system control and indication equipment, so that the HVLS fans

shut down when a fire is detected.

10

INSIDE THE BOX

SCREWS FOR CONCRETE

MOUNTING

HUS3-H 6X60MM (4 pcs)

SCREWS FOR WOOD

MOUNTING

8X70MM (4 pcs).

BOLTS FOR STEEL

MOUNTING

8X25MM (4 pcs).

4 washers, 4 locknuts

DROP TUBE & EXTENSION

TUBE BOLTS

10x70mm (10 pcs), 10 locknuts

20 plastic caps (secure at both ends)

BOX 1

1

2

3

4

5

6

78

9

10

10

11

12

13

14

16

1

1

1

1

2

1

3

4

1

5

6

1

7

8

1

9

10

1

11

12

1

1

1

13

14

1

15

16

Saddle

Drop Tube

Drive and Onboard Electronics

Motor

Controller (if ordered)

Starfish Blade Hub

Patch cable (optional)

230V power cable (3 x 1.0 mm2)

Fire alarm cable

Mount Cover (if ordered)

Safety wire

Safety wire lock (Gripple)

2 x Extension Tubes

2 x Alu Extension Connectors

Required screws and bolts

Bottom cover

1

1

17 UVC-irradiation aperture shields

11

17 UVC aperture

shields /

emission

dampers

95% 90% 80% 60% 40%

Percentage reduction of irradiation using various aperture shields

BOX 1

BOX 2

NO DRILL BIT NEEDED

SCREWS FOR MOUNTING

AIR BLADES

6 x 16mm (10 pcs)

lock spring washers (10 pcs)

1Anodised

aluminium air

blades with UVC

system

2Required screws

12

12

REQUIRED TOOLS & ACCESSORIES

STANDARD INSTALLATION

Using the saddle allows the Northern Light®system to be

mounted directly on standard I and H steel beams, as well as

wooden and concrete beams. This is done using the

supplied screws and bolts, as shown in item 15 of the section

‘Inside the Box'.

SADDLE DIMENSIONS

Before carrying out a standard installation, make sure that

the mounting beam is of sufficient width to accommodate

the saddle. If this is not the case, additional mounting

brackets can be used. Contact your Nordicco supplier.

For installations that use optional mounting brackets or

additional stabilizing wires, refer to the manuals for these,

which can be found in the relevant product boxes or can

be downloaded from: www.nordicco.eu/downloads

LIFT OR

SCAFFOLDING

PATCH CABLE

(OPTIONAL)

PHILLIPS

SCREWDRIVER

ELECTRIC DRILLLEVEL

10, 13 & 17 MM

WRENCH

4 MM

ALLEN KEY

10, 13 & 17 MM

WRENCH SOCKET

SOCKET

WRENCH

SLOTTED

SCREWDRIVER

REMEMBER to tighten screws /

bolts after suspending and

levelling the fan.

13

STANDARD INSTALLATION PROCESS

Use the saddle as a template to drill

the required holes in the mounting

beam using the drill bit specified.

If needed, attach one or two

Extension Tubes to the Drop Tube

using the Alu Extension connectors.

Pull the cables through the Drop

Tube.

Line up holes and tighten bolts

thoroughly.

Fasten the saddle to the mounting

surface using screws (wood and

concrete) or bolts (steel). Tighten

thoroughly.

Attach the fan assembly to the

swivel mount via the drop tube

using specified bolts and secure

tightly.

Attach the safety wire around the

mounting beam.

IMPORTANT

: follow

the steps on page 14.

IF ORDERED: Push up the mount

cover and twist to lock in place using

the two small screws as shown

above.

PLEASE NOTE: IF YOU ARE

UNABLE TO INSTALL DIRECTLY

ON THE MOUNTING SURFACE,

YOU CAN USE EXTRA

MOUNTING BRACKETS.

SEE SEPARATE MANUAL OR

CONTACT YOUR NORDICCO

SUPPLIER:

WWW.NORDICCO.EU/DOWNLOADS

14

INSTALLING & SECURING THE SAFETY WIRE

Insert the wire by inserting it into

A

and turning it

clockwise.

Pull the wire through

B

.

Pull the wire around the mounting beam and insert the

wire into

C

. Follow the direction of the arrows.

Tighten the wire. Cut or adjust excess wire to ensure that it does not affect the fan when in operation.

WARNING: THE SAFETY WIRE

MUST

BE

INSTALLED.

THE SAFETY WIRE WILL PREVENT THE FAN FROM FALLING DOWN IF THE INSTALLATION

SYSTEM FAILS. THE FAN SHOULD NEVER BE OPERATED WITHOUT A PROPERLY INSTALLED

SAFETY WIRE, AS THIS MAY RESULT IN SERIOUS INJURY, DEATH OR DAMAGE TO

INVENTORY.

15

AIR BLADE INSTALLATION

CORRECT SCREW ALIGNMENT

Blades viewed from

above

Blades viewed from

below

Base cover viewed from

the side

IMPORTANT: Systems must NOT

be connected to a power supply

when the following steps are

performed.

Position the blade onto the starfish

(make sure that the wires are not

damaged during installation)

Secure the blade with specified

screws and tools.

Connect power from the fan’s

power distributor plate to the

blades

Move the base cover to the correct

position and secure with the screws

AFTER AIR BLADE

INSTALLATION: ROTATE

THE FAN BY HAND TO

ENSURE THAT IT CAN

ROTATE FREELY

WITHOUT INTERFERING

WITH ANY OBSTACLES.

PLEASE NOTE: Make sure that the fan is vertically and horizontally levelled before mounting the blades.

IMPORTANT: Do not use the fan without mounting the blades, as this may damage the motor and drive.

16

FIRE ALARM INSTALLATION

OPTIONAL FIRE ALARM INSTALLATION

Note: This section is only relevant in buildings equipped with fire extinguishing systems. For

buildings with no fire suppression system, simply leave the fire cable untouched inside the

drop tube.

Important: The fire alarm relay must only be installed by qualified persons who understand

how to deal with fire suppression systems. It is the sole responsibility of the installer to ensure

correct handling of the fire alarm relay in the event of a fire in the building.

Remove the excess length of wire and attach to a normally-closed (N.C.) potential-free relay

on the fire alarm emergency stop and the building's fire suppression system following the wire

diagram above.

17

CONNECTION OF POWER & CONTROL

Connect the power plug to the power cable.

Then connect a 230 VAC single-phase power supply with earth.

CONTROL OPTIONS

When ordering the fan, you have chosen one of the control options

mentioned below which will determine the further installation process.

•

Northern Sky:

Log in via app.northernsky.io with the user information you have received by e-mail.

Please note

: It can take up to 20 minutes until the system is online after connecting to 230V.

•

Nordicco HMI Controller:

Insert the patch cable in the controller and see the manual for HMI-

Controller for further steps.

•

BMS:

If the Nordicco fan is to be monitored and controlled with a Building Management System

(BMS) please use the CAT6 cable to connect it to the BMS system.

Contact your local BMS operator for further implementation. Furthermore, see the manual

’ADVANCED OPERATIONS – INTEGRATING TO A BUILDING MANAGEMENT SYSTEM’ which can

be found at https://nordicco.eu/downloads/

SECURITY CHECK

Before use, please perform an initial security check of the fan on a secure distance by slowly

increasing speed one level at a time. If any shaking, vibrations, or similar appears, decrease

speed immediately and make the fan come to a complete stop. Go back and make sure all

installation steps were performed correctly and make any necessary adjustments. Perform a

second check, and if any abnormalities persist, please turn off fan and contact your local

support office.

2

1Tilslut strømstikket til strømkablet. Forbind derefter en

230 VAC enkel fase strømforsyning med jord.

18

CLEANING AND MAINTENANCE

CLEANING

- The fan must be powered off using the repair/safety switch before commencing any

cleaning tasks.

- The fan's exterior surfaces, including blades, motor, drive and drop tube, can be wiped

down with a damp cloth. Use only clean water for cleaning.

MAINTENANCE

- The fan must be powered off using the repair/safety switch before commencing any

maintenance tasks.

- Mounting screws should be inspected and retightened at least once a year. This includes

blade mounting screws, drop tube assembly screws and screws in fixed construction.

- The system's safety wire should be inspected annually to ensure that it shows no signs of

visible damage, beginning wear or other signs of damage. Likewise, the point where the

safety wire is attached to the fixed structure should be inspected to ensure full

attachment.

- The safety wire and/or the attachment point should be replaced if in any doubt.

Contact NORDICCO for information about replacing the safety wire.

- The motor and other moving parts are lifetime lubricated and require no maintenance.

- We recommend that installed systems are inspected by a UVC-professional every six

months.

REPAIRS AND SPARE PARTS

- Contact Nordicco for access to spare parts and guidance on how to perform repairs and

replacement of spare parts.

- When repairs are required, contact Nordicco.

Telephone +45 73 70 90 83

www.nordicco.eu

19

PART 2

ACTIVATION AND COMMISSIONING OF THE NORTHERN LIGHT UVC

SYSTEM

ACCORDING TO EN 14255-1

ACTIVATION OF THE UVC SYSTEM IS PROTECTED WITH AN ACTIVATION CODE.

ONLY PROFFESSIONAL UVC INSTALLERS MAY ACTIVATE AND ADJUST THE UVC

SYSTEM BEFORE COMMISSIONING.

UVC ACTIVATION CODE: 7000#Karet

20

GENERAL INSTRUCTIONS

UVC irradiation measurements are required in several cases, including:

o At first installation

o When installing new UVC light sources

o When moving the fan to a new position in the room

o When making changes or adjustments in the room (e.g. height, position, change in

placement of walls or ceiling and wall materials, change in room dimensions etc.)

o When any kind of reports or complaints about possible overexposure have been made

After the measurement assessment, the system will be in compliance with the limit values

specified in EN 62471, c.f. the formula below (4.1).

!!"#$

%%

!"

&

'(#

)

"*#$

&

'

)

"+#"+',-./,,,,,,,,,,,,,,,,,0"1%&

'

())

&))

REQUIRED EQUIPMENT AND PROTECTIVE GEAR

Please note: Required measuring equipment, materials and protective equipment are sold separately.

MATERIALS & MEASURING EQUIPMENT

Safester UVC

o The sensor must have a valid certification of

the calibration.

o The sensor must be calibrated to measure

254nm low pressure lamps.

o Documentation material (Assessment form)

o Tripod stand to mount the Safester sensor

o Ruler / measuring tape to measure the height of the

Safester sensor head before starting the assessment

process

Figure 2: Safester UVC

measuring equipment

Table of contents

Other NORDICCO Fan manuals

NORDICCO

NORDICCO NORTHERN AIR AMPLIFY User manual

NORDICCO

NORDICCO NORTHERN LIGHT User manual

NORDICCO

NORDICCO NORTHERN LIGHT HVLS User manual

NORDICCO

NORDICCO HVLS Series User manual

NORDICCO

NORDICCO NORTHERN AIR MINI User manual

NORDICCO

NORDICCO NORTHERN AIR 200 Guide

NORDICCO

NORDICCO NORTHERN LIGHT Guide

NORDICCO

NORDICCO NORTHERN AIR MINI User manual

NORDICCO

NORDICCO AIR MINI User manual