NORDICCO NORTHERN AIR AMPLIFY User manual

Vers. 1.0

INSTALLATION MANUAL

NORTHERN AIR®AMPLIFY

ENGLISH

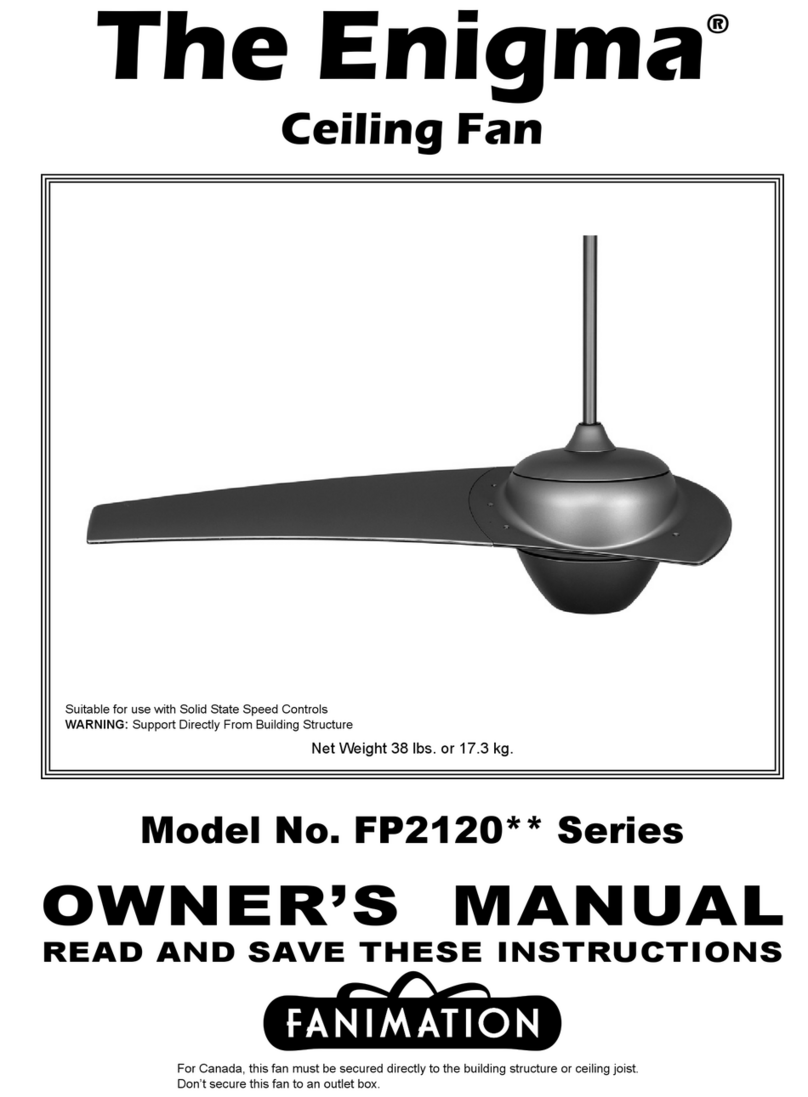

AMPLIFY Models are the ideal choice for providing year-round comfort in air circulation and destratification

applications. Featuring an aerodynamic, extruded aluminum airfoil design and a high efficiency direct drive motor,

Amplify delivers maximum airflow at a fraction of the operating cost of other HVLS fans. And, with its universal

ceiling mount, the Amplify fan is the easiest 6 m and 7,3 m HVLS fan to install in the market!

IMPORTANT: AMPLIFY fans must be installed with the supplied CAT communication cable or thru Northern

Sky. Cable must be twisted pair, shielded. CAT 5/6. Cable must use shielded RJ45 connectors with a soldered

drain. Individual CAT 5/6 cable lengths must not exceed 60 m in order to prevent network communication

issues.

Required Tools

The following tools will be required to complete the

installation of every Amplify fan. Additional tools may be

required depending on the application and installation

location of the fan.

• Socket Wrench and 17mm Sockets

• 11 m, 13 mm, 14 mm and 19 mm Wrenches

• Adjustable Wrench

• Torque Wrench (up to 70 Nm)

• Torque Wrench (up to 160 Nm)

• Drill and 19 mm Drill Bit

• Phillips Screwdriver

• Level

• Impact Driver

• #2 Phillips Bit and Driver

• 10 mm Magnetic Nut Driver

• Magnetic Nut Driver Extension

NOTE: Amplify fans components can weigh 41 kg or

greater depending upon the fan size and accessories

that are provided. A suitable means for lifting the weight

of the fan to the mounting point, such as a scissor lift,

should be used for all Amplify fan installations.

Quick Start Guide

Step 1 - Step 12 . . . . . . . . . . . . . . . . . . . . .

General Information

Required Tools

General Safety Information . . . . . . . . . . . . . . .

Receiving. . . . . . . . . . . . . . . . . . . . . . . . .

Unpacking . . . . . . . . . . . . . . . . . . . . . . . .

Storage. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Maintenance During Storage . . . . . .

Removing from Storage . . . . . . . . . . . . . . . . .

Fan Components. . . . . . . . . . . . . . . . . . . . .

Pre-Installation

Pre-Installation Checks. . . . . . . . . . . . . . . . . .

Minimum Spacing Requirements . . . . . . . . . . . .

Mechanical Installation

Mounting Installation . . . . . . . . . . . . . . . . . .

I-Beam Mounting . . . . . . . . . . . . . . . . . . .

Steel Truss Mounting . . . . . . . . . . . . . . . . .

Wood Beam Mounting . . . . . . . . . . . . . . . .

Motor/Hub to Downtube Installation . . . . . . . . . .

Safety Retention Cable Installation . . . . . . . . . . .

Standard Steel Cable Clamp . . . . . . . . . . . . .

Gripple® Hardware (Optional) . . . . . . . . . . . .

Guy Wire Installation. . . . . . . . . . . . . . . . . . .

Standard Steel Cable Clamp . . . . . . . . . . . . .

Gripple® Hardware (Optional) . . . . . . . . . . . .

Airfoil Blade and Winglet Installation . . . . . . . . . .

Hub Plate Installation . . . . . . . . . . . . . . . . . .

Fire System Integration

Fire System Integration (Optional) . . . . . . . . . . .

Electrical Installation

Motor Cable Connection . . . . . . . . . . . . . . . .

Power Wiring. . . . . . . . . . . . . . . . . . . . . . .

With Optional Electrical Plug . . . . . . . . . . . . .

Without Optional Electrical Plug . . . . . . . . . . .

Disconnect and Fuse Installation . . . . . . . . . . . .

Communication Wiring . . . . . . . . . . . . . . . . .

With Pre-Built CAT-5/6 Cable . . . . . . . . . . . . .

Fan Networking

First Fan . . . . . . . . . . . . . . . . . . . . . . . . .

All Remaining Fans. . . . . . . . . . . . . . . . . . . .

Operation And Maintenance

Pre-Start-Up Checks . . . . . . . . . . . . . . . . . . .

Fan Operation . . . . . . . . . . . . . . . . . . . . . .

Fan Inspection . . . . . . . . . . . . . . . . . . . . . .

Fan Maintenance. . . . . . . . . . . . . . . . . . . . .

Table of Contents

Quick Start

Guide

General

Information Pre-Installation Mechanical

Installation

Fire System

Integration

Electrical

Installation

Fan

Networking

Operation And

Maintenance

3

22

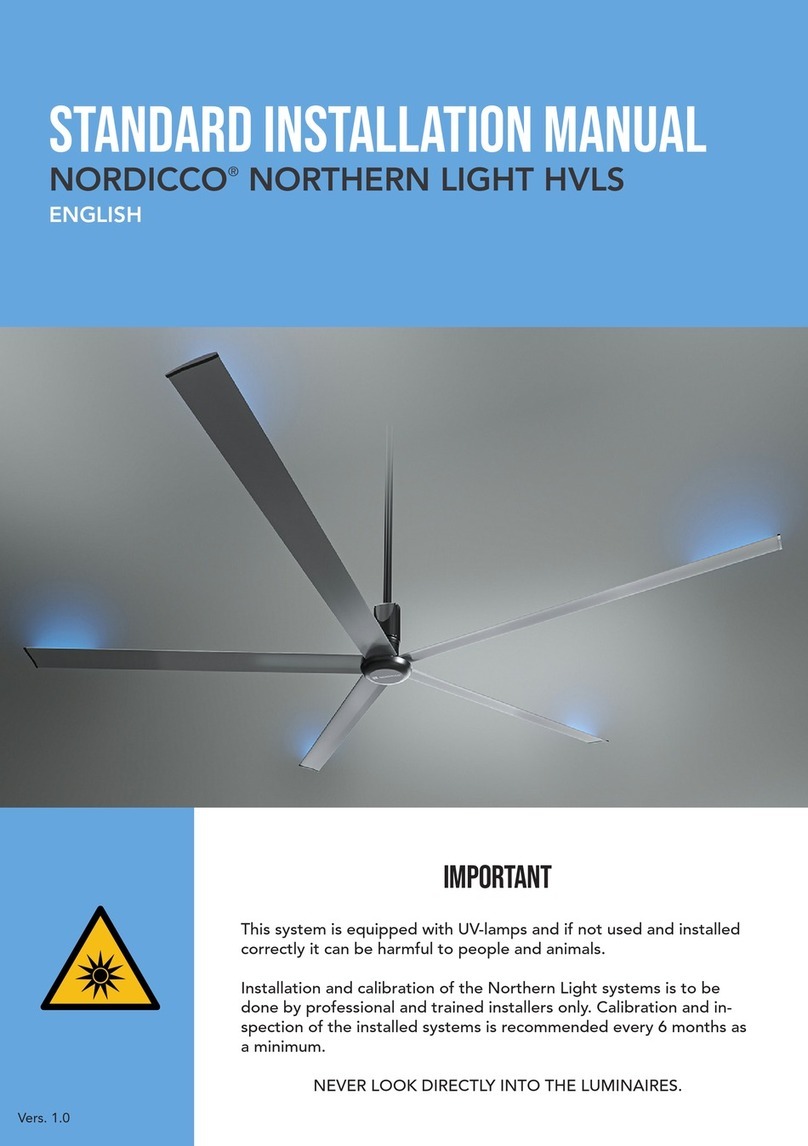

NORTHERN AIR®AMPLIFY

Overhead Ceiling Fans

Installation, Operation and Maintenance Manual

Please read and save these instructions for future reference. Read carefully before attempting to assemble, install,

operate or maintain the product described. Protect yourself and others by observing all safety information. Failure

to comply with these instructions will result in voiding of the product warranty and may result in personal injury

and/or property damage.

Overhead Ceiling Fans

Quick Start Guide

REFER TO INSTALLATION MANUAL FOR COMPLETE INSTALLATION INSTRUCTIONS.

QUICK START GUIDE DOES NOT REPLACE INSTALLATION MANUAL INSTRUCTIONS.

STEEL BEAM

DOWNTUBE AND MOUNT ASSEMBLY

GRADE 8 NYLON LOCKNUT

WASHER

I-BEAM CLAMPING PLATE SHIM

I-BEAM CLAMPING PLATE

PROVIDED GRADE 8 BOLTS

UNIVERSAL MOUNTING PLATE

STEEL I-BEAM INSTALLATION

• GO TO SECTION MECHANICAL INSTALLATION

• FASTENER KIT

IMPORTANT: I-BEAM MUST HAVE MINIMUM 127 MM.

FLANGE WIDTH AND 13 MM. FLANGE THICKNESS

IMPORTANT: DO NOT INSTALL ON FABRICATED

I-BEAMS

STEP #1 - MOUNT INSTALLATION

DOWNTUBE AND MOUNT ASSEMBLY

13 MM GRADE 8 BOLT

WASHER

GRADE 8 NYLON LOCKNUT

13 MM GRADE 8 BOLT

(BY OTHERS)

13 MM GRADE 8

NYLON LOCKNUT

WASHER

SQUARE WASHER PLATE

STEEL TRUSS - BAR JOIST

STEEL TRUSS - BAR JOIST

STRUCTURAL STEEL ANGLES

(BY OTHERS)

STEEL TRUSS INSTALLATION

• GO TO SECTION MECHANICAL

INSTALLATION

• FASTENER KIT

IMPORTANT: TRUSSES MUST HAVE

MINIMUM 127 MM CHORD WIDTH

IMPORTANT: STEEL ANGLES MUST BE

MINIMUM OF 100 x 100 x 6,5 MM THICK

IMPORTANT: SPAN LENGTH MUST NOT

EXCEED 2,4 M.

GRADE 8 NYLON LOCKNUT

WASHER

DOWNTUBE AND MOUNT ASSEMBLY

13 MM GRADE 8 BOLT

WOOD BEAM

(BY OTHERS)

UNIVERSAL MOUNTING PLATE

WOOD BEAM BRACKET

13 MM GRADE 8 BOLT

(BY OTHERS)

WASHER

WOOD BEAM INSTALLATION

• GO TO SECTION MECHANICAL INSTALLATION

• FASTENER KIT

IMPORTANT: WOOD BEAM MUST BE 115 TO

225 MM WIDE

IMPORTANT: TORQUE ALL BOLTS TO 80 FT-LBF (108.5 N-m)

IMPORTANT: TORQUE ALL BOLTS TO 80 FT-LBF (108.5 N-m)

IMPORTANT: TORQUE ALL BOLTS TO 45 FT-LBF (61.0 N-m)

Quick Start

Guide

General

Information Pre-Installation Mechanical

Installation

Fire System

Integration

Electrical

Installation

Fan

Networking

Operation And

Maintenance Troubleshooting Reference

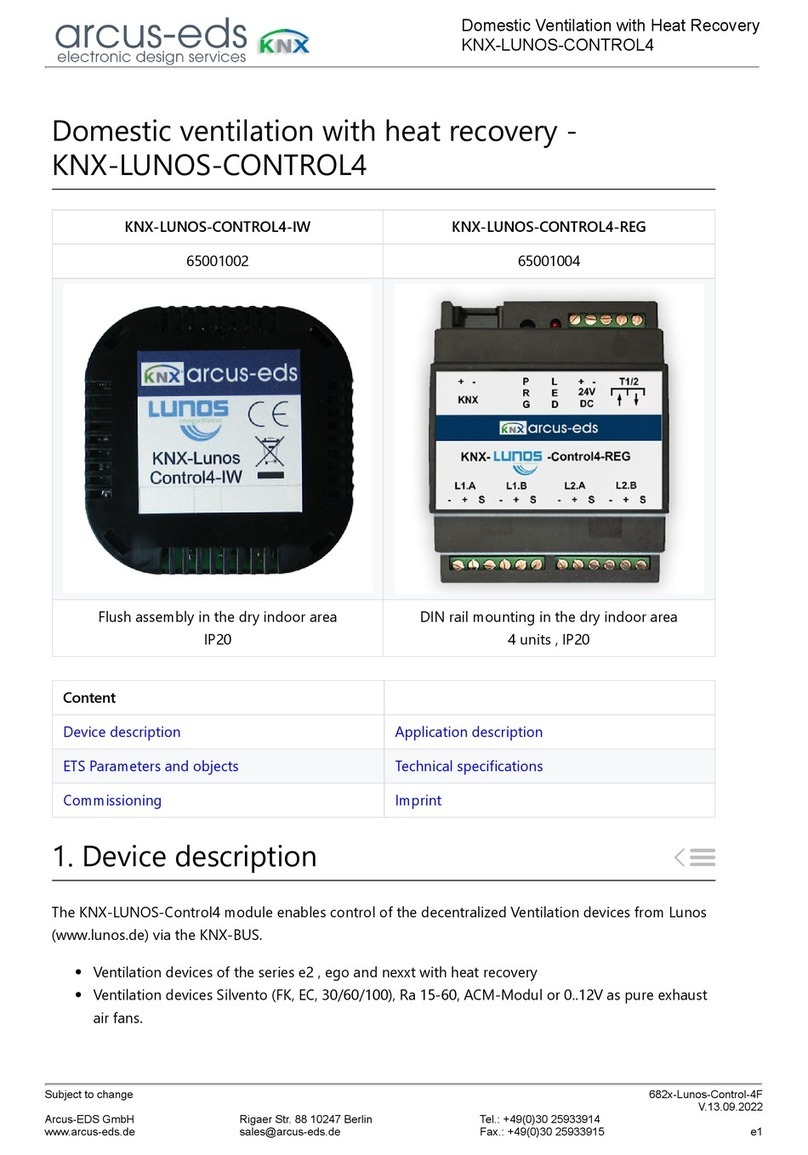

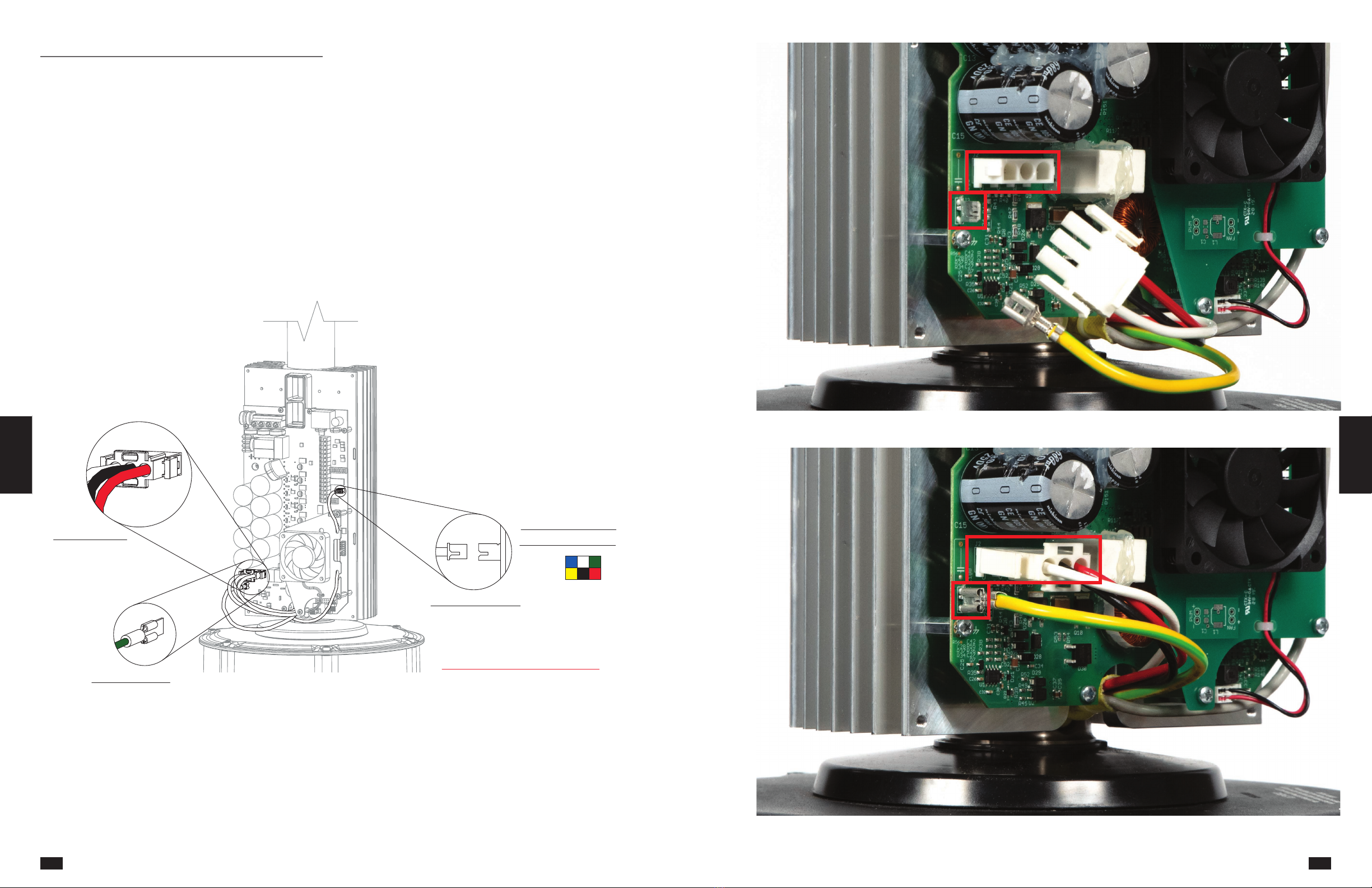

STEP #2 - MOTOR INSTALLATION

STEP #3 - SAFETY CABLE AND GUY WIRE INSTALLATION

10 MM GRADE 8 BOLT

1

2

1

POWER

GROUND

POWER

2

GROUND

M4 - 0.7 x 10 MACHINE SCREW

FRONT VFD COVER

DOWNTUBE AND MOUNT ASSEMBLY

3

HALL CONNECTION

NOTE:

HALL CABLE PLUG HAS

BUILT-IN ALIGNMENT TAB

DO NOT FORCE THIS PLUG

3HALL

CONNECTION

MOTOR INSTALLATION

• GO TO SECTION MECHANICAL

INSTALLATION

• FASTENER KIT

IMPORTANT: ELECTRICAL CABLES

FROM MOTOR MUST BE ON SAME

SIDE AS BLACK PLASTIC VFD COVER.

CABLES ARE NOT LONG ENOUGH

TO REACH CIRCUIT BOARD FROM

OPPOSITE SIDE. MOTOR MUST BE

REMOVED AND ROTATED 180° IF

INSTALLED INCORRECTLY.

TURNBUCKLE

CABLE CLAMP

GUY WIRE

QUICK LINK

EYEBOLT

BEAM CLAMP

ASSEMBLY

SAFETY CABLE

CABLE CLAMP

DOWNTUBE AND

MOUNT ASSEMBLY

DEAD END

LIVE END

CABLE CLAMP

U- BOLT

CABLE CLAMP

SADDLE

45° TO 60°

140 MM

MIN.

SAFETY CABLE AND GUY WIRE

INSTALLATION

• GO TO SECTION

MECHANICAL INSTALLATION

• FASTENER KIT

• OPTIONAL GRIPPLE

HARDWARE

IMPORTANT: PLACE A LEVEL AGAINST

DOWNTUBE AND TIGHTEN ALL (4)

TURNBUCKLES BY HAND UNTIL GUY WIRES

ARE TIGHT AND FAN IS PLUMB. MOVE LEVEL

AROUND DOWNTUBE TO ENSURE THAT FAN

IS PLUMB.

IMPORTANT: TORQUE BOLTS TO 33 FT-LBF (44.75 N-m)

Reference Troubleshooting Operation And

Maintenance

Fan

Networking

Electrical

Installation

Fire System

Integration

Mechanical

Installation Pre-Installation General

Information

Quick Start

Guide

5

4

Quick Start

Guide

General

Information Pre-Installation Mechanical

Installation

Fire System

Integration

Electrical

Installation

Fan

Networking

Operation And

Maintenance Troubleshooting Reference

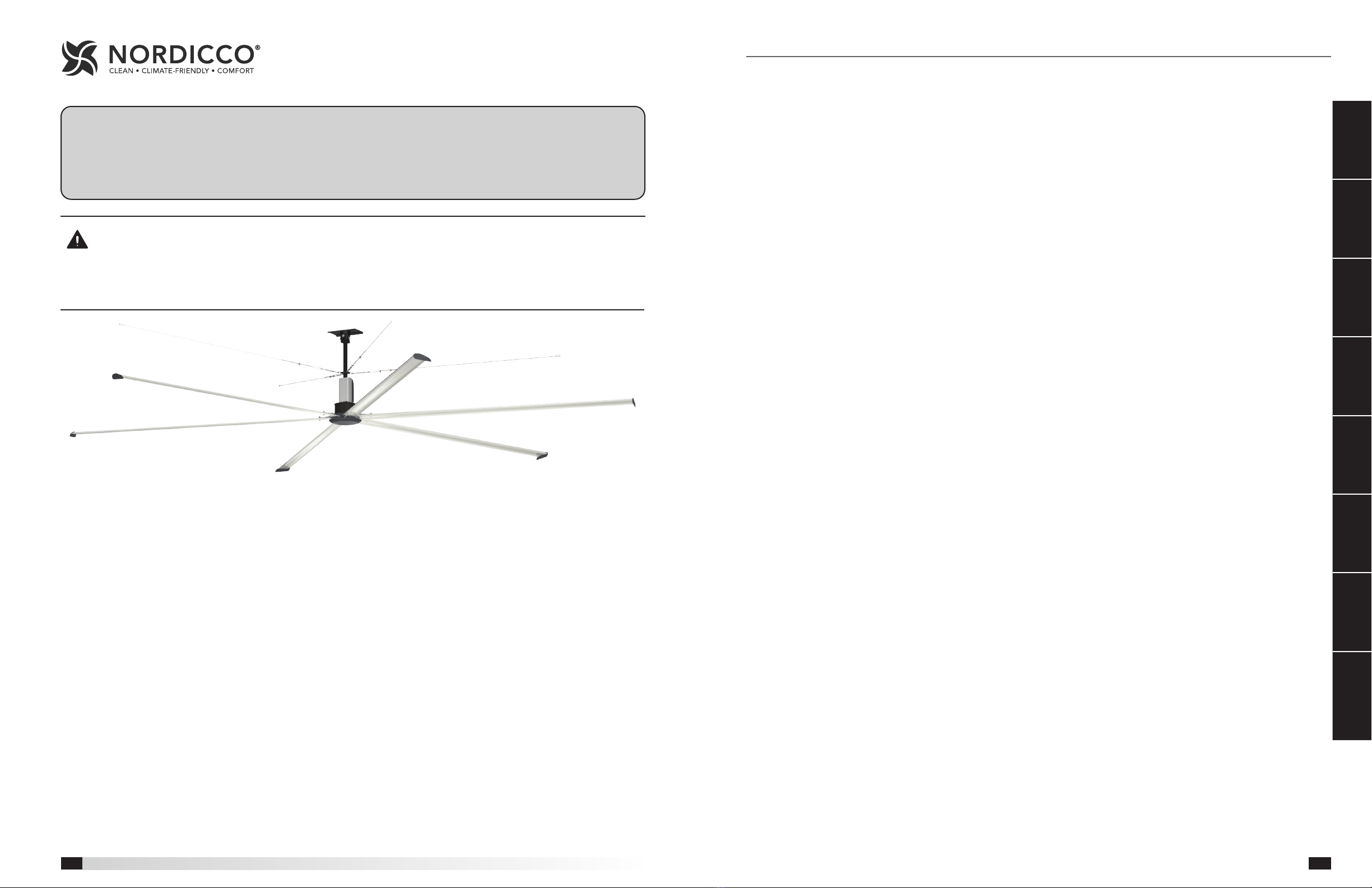

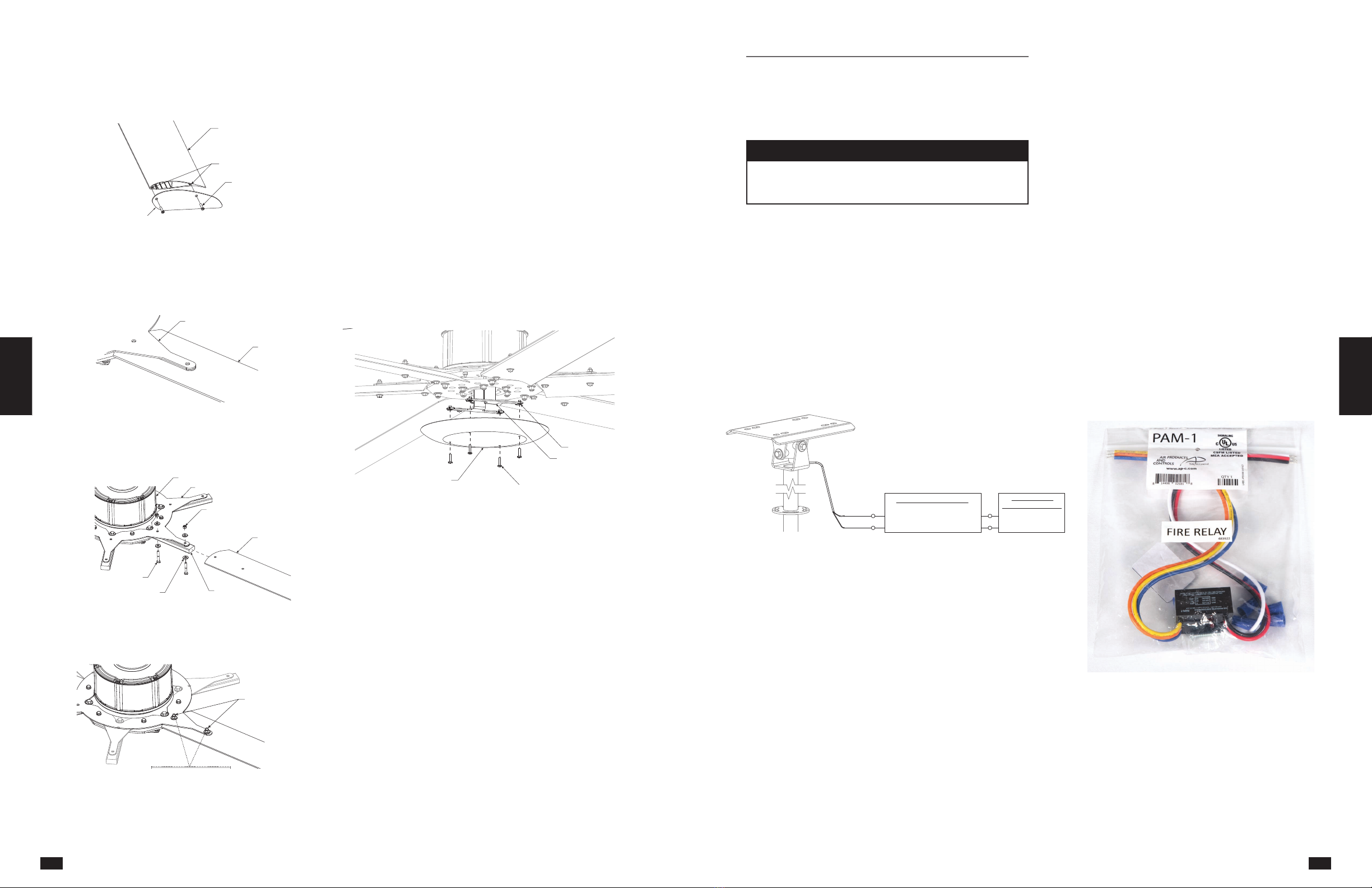

STEP #6 - FIRE ALARM RELAY INSTALLATION

HALL CABLE COLOR

PINOUT REFERENCE

HALL CONNECTION

NOTE: HALL CABLE PLUG

HAS BUILT-IN ALIGNMENT TAB

DO NOT FORCE THIS PLUG

MOTOR GROUND

MOTOR POWER

MOTOR CABLE CONNECTION TO VFD

• GO TO SECTION MECHANICAL INSTALLATION

IMPORTANT: PLUGS MUST BE FULLY SEATED AND

IN PROPER ORIENTATION FOR FAN OPERATION

STEP #7 - MOTOR CABLE CONNECTION TO VFD

RED

BLACK

WHITE

GREEN

POWER SOURCE

L3

L2

L1

GROUND

BLACK

WHITE

GREEN

POWER SOURCE

L2

L1

GROUND

1-PHASE INPUT POWER

OR

3-PHASE INPUT POWER

POWER WIRING

• GO TO SECTION MECHANICAL INSTALLATION

IMPORTANT: SOURCE POWER MUST COMPLY

WITH REQUIRED SPECS

STEP #8 - POWER WIRING

TO NEXT FAN

(IF APPLICABLE)

TO CONTROL

SHIELDED CAT 5/6 CONNECTION

FAN 1

CONTROL

FAN 2

COMMUNICATION WIRING

• GO TO SECTION MECHANICAL INSTALLATION

IMPORTANT: MUST USE PROVIDED CAT 5/6 CABLE

OR SHIELDED CABLE THAT COMPLIES WITH

REQUIRED SPECS FOR CABLED INSTALLATION.

STEP #9 - COMMUNICATION WIRING - IF WIRED INSTALLATION

TORQUE TO 96 IN∙LBF

(10.8 N∙m)

HUB PLATE INSTALLATION

• GO TO SECTION MECHANICAL INSTALLATION

• HARDWARE KIT

IMPORTANT: ROTATE FAN BY HAND TO ENSURE

THAT IT MOVES FREELY AND DOES NOT RUB OR

CONTACT ANY OBSTRUCTIONS.

STEP #5 - HUB PLATE INSTALLATION

STEP #4 - AIRFOIL INSTALLATION

TORQUE SCREWS TO 96 IN-LBF

TORQUE TO 25 FT∙LBF

(34 N∙m)

TORQUE TO 60 IN∙LBF

(6.8 N∙m)

FIRE RELAY

RED (+)

WHITE (-)

YELLOW (NC)

BLUE (COMMON)

BLACK

RED

FIRE ALARM

CONTROL PANEL

RED

WHITE

FIRE ALARM RELAY INSTALLATION

• GO TO SECTION MECHANICAL INSTALLATION

IMPORTANT: MUST USE PROVIDED PAM-1 RELAY OR OTHER

APPROVED ELECTROMECHANICAL RELAY

Reference Troubleshooting Operation And

Maintenance

Fan

Networking

Electrical

Installation

Fire System

Integration

Mechanical

Installation Pre-Installation General

Information

Quick Start

Guide

AIRFOIL INSTALLATION

• GO TO SECTION MECHANICAL INSTALLATION

• FASTENER KIT

7

6

Quick Start

Guide

General

Information Pre-Installation Mechanical

Installation

Fire System

Integration

Electrical

Installation

Fan

Networking

Operation And

Maintenance Troubleshooting Reference

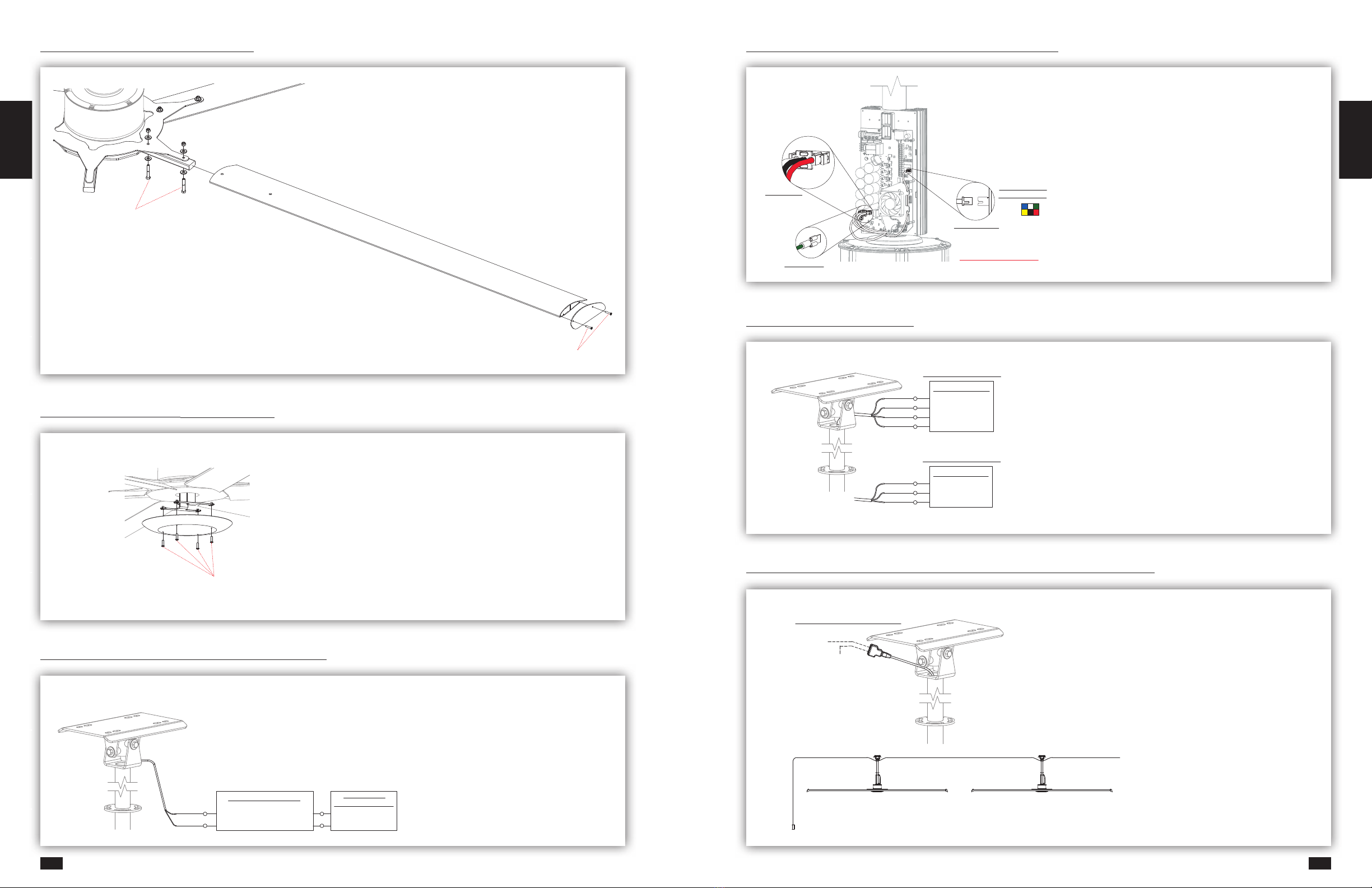

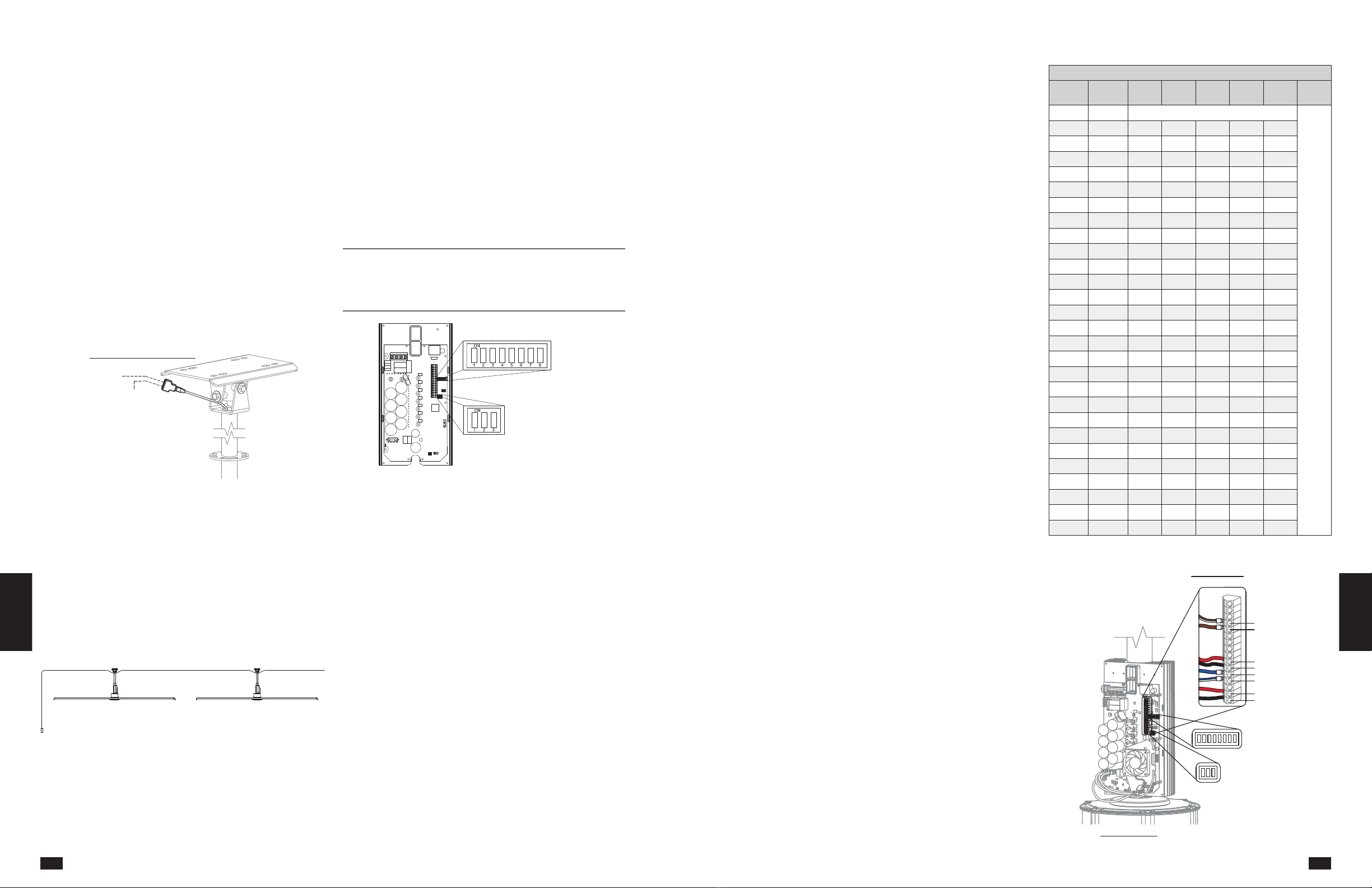

GND

FIRE +

FIRE -

DATA +

DATA -

0-10V

GND (OPTIONAL)

ALL OTHER FANS IN SERIES

GND

FIRE +

FIRE -

DATA +

DATA -

0-10V

GND (OPTIONAL)

LOW VOLTAGE WIRING

24v

FIRST FAN IN SERIES

LOW VOLTAGE WIRING

DIP SWITCH BANK 2

1 2 345 6 78

ON

1 2 3

ON

DIP SWITCH BANK 3

DIP SWITCH BANK 2

1 2 345 6 78

ON

1 2 3

ON

DIP SWITCH BANK 3

EF

FIRST FAN IN DAISY-CHAIN

• GO TO SECTION FAN NETWORKING

• NO VFD WIRING MODIFICATIONS REQUIRED

• VERIFY VFD WIRING MATCHES

• MODIFY DIP SWITCH BANKS 2 AND 3

AS SHOWN

STEP #10 - FAN NETWORKING - IF WIRED INSTALLATION

ALL REMAINING FANS IN DAISY-CHAIN

• GO TO SECTION FAN NETWORKING

• REMOVE WHITE/BROWN 24V WIRE AND CAP

• VERIFY VFD WIRING MATCHES

• MODIFY DIP SWITCH BANKS 2 AND 3

AS SHOWN

IMPORTANT: DO NOT REMOVE BROWN GND WIRE

GND

FIRE +

FIRE -

DATA +

DATA -

0-10V

GND (OPTIONAL)

ALL OTHER FANS IN SERIES

GND

FIRE +

FIRE -

DATA +

DATA -

0-10V

GND (OPTIONAL)

LOW VOLTAGE WIRING

24v

FIRST FAN IN SERIES

LOW VOLTAGE WIRING

DIP SWITCH BANK 2

1 2 345 6 78

ON

1 2 3

ON

DIP SWITCH BANK 3

DIP SWITCH BANK 2

1 2 345 6 78

ON

1 2 3

ON

DIP SWITCH BANK 3

EF

DIPSWITCH BANK 2 SETTINGS DIPSWITCH BANK 3 SETTINGS

POST INSTALLATION CHECKLIST

□ALL BOLTS TIGHTENED PROPERLY

□ONLY USED SHIELDED NETWORKING COMPONENTS PROVIDED

□MODBUS ADDRESSES SET

□SAFETY CABLE INSTALLED PROPERLY

□VERIFY POWER AND NETWORKING CABLES CONNECTED

STEP #1 STEEL BEAM INSTALLATION

STEP #3 SAFETY CABLE

INSTALLATION

HARDWARE KIT 854832 OR 915066

TORQUE SCREWS TO 60 IN-LBF

(MANUAL PAGE 15-16)

HARDWARE KIT 915065

TORQUE BOLTS TO 33 FT-LBF

(MANUAL PAGES 10-11)

HARDWARE KIT 915428

TORQUE BOLTS TO 45 FT-LBF

(MANUAL PAGE 7)

HARDWARE KIT 916290

TORQUE U-BOLTS TO 54 IN-LBF

(MANUAL PAGE 12-13)

HARDWARE KIT 916290

TORQUE U-BOLTS TO 54 IN-LBF

(MANUAL PAGE 14-15)

QUICK START GUIDE FOR INDUSTRIAL FAN INSTALLATION

STEP #5 WINGLET

INSTALLATION

TOOL LIST:

- IMPACT DRIVER

- 7/16 IN., 1/2 IN., 9/16 IN. AND 3/4 IN. SOCKETS

- 1/2 IN. AND 3/4 IN. WRENCHES

- #2 PHILLIPS SCREWDRIVER

- #2 PHILLIPS IMPACT BIT

- MAGNETIC TORPEDO LEVEL

- TORQUE WRENCH (UP TO 50 FT-LBF)

- TORQUE WRENCH (UP TO 120 IN-LBF)

- REFER TO INSTALLATION MANUAL FOR COMPLETE INSTALLATION INFORMATION

- THIS QUICK START GUIDE DOES NOT REPLACE INSTALLATION MANUAL INSTRUCTIONS

HARDWARE KIT 854832 OR 915066

TORQUE TO 25 FT-LBF

(MANUAL PAGE 15-16)

STEP #6 AIRFOIL

INSTALLATION

STEP #2 MOTOR TO DOWNTUBE

STEP #7 HUB PLATE INSTALLATION

HARDWARE KIT 854832 OR 915066

TORQUE SCREWS TO 96 IN-LBF

(MANUAL PAGE 17)

STEP #4 GUY WIRE

INSTALLATION

ALTERNATE MOUNTING - MANUAL PAGES 7-9

FIRE

RELAY

FIRE SUPPRESSION SYSTEM

LANDING POINT AT FAN

FIRE ALARM LANDING POINT

FIRE RELAY INSTALLATION AND WIRING

TO FAN WIRING

BLUE - COMMON

YELLOW - NORMALLY CLOSED

ORANGE - NORMALLY OPEN

(FAN DISABLED WHEN RELAY OPEN)

20 TO 32 VDC

RED (+)

WHITE (-)

OPTIONAL LED LIGHT INSTALLATION - MANUAL PAGE 15

5-1/2 IN.

MIN.

FIRST FAN IN SERIES

ALL OTHER FANS IN SERIES

- REMOVE BROWN/WHITE 24V WIRE AND CAP

- DO NOT REMOVE BROWN GROUND WIRE

- REMOVE SILVER SHIELD AND SECURE IN A WAY

THAT PREVENTS CONTACT WITH VFD BOARD

NOTE

DO NOT CUT CABLE OR REMOVE CRIMP CAP IF NOT USING FIRE RELAY.

1 2 3

ON

1 2 3

ON

FAN 1 ALL OTHER FANS

IN SERIES

DIP SWITCH BANK 2 SETTINGS

HELPFUL HINT

ALL NETWORKING MODIFICATIONS CAN BE COMPLETED PRIOR TO BLADE INSTALLATION.

FAN NETWORKING

FOR ALL WIRING AND NETWORKING - SEE MANUAL PAGES 11-12 AND 18-20

1 2 345678

ON

1 2 3

ON

MOTOR-TO-VFD WIRING AND DIP SWITCH BANK LOCATIONS

3

3

DIP SWITCH BANK 3

DIP SWITCH BANK 2

NOTE

HALL CABLE PLUG HAS BUILT-IN

ALIGNMENT TAB. DO NOT FORCE

THIS PLUG.

2

1

1

2

DIP SWITCH BANK 3 SETTINGS (MODBUS ADDRESSES)

MODBUS

ADDRESS

2

3

4

5

6

7

8

9

10

11

SWITCH

1

SWITCH

2

SWITCH

3

SWITCH

4

SWITCH

5

ON OFF OFF OFF OFF

ON

ON ON

ON

ON ON

ON ON

ON ON ON

ON

ON ON

ON ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

DO

NOT

MODIFY

SWITCH

6, 7, 8

Fan

Number

Modbus

Address

Position

1

Position

2

Position

3

Position

4

Position

5

Position

6, 7, 8

N/A 1 Reserved for HVLS Fan Control

Do Not

Modify

1 2 On Off Off Off Off

2 3 Off On Off Off Off

3 4 On On Off Off Off

4 5 Off Off On Off Off

5 6 On Off On Off Off

6 7 Off On On Off Off

7 8 On On On Off Off

8 9 Off Off Off On Off

9 10 On Off Off On Off

10 11 Off On Off On Off

IMPORTANT: DO NOT MODIFY POSITIONS 6, 7, AND 8 ON

DIPSWITCH BANK 3. DEFAULT SETTINGS ARE ON, OFF, OFF

(UP, DOWN, DOWN)

Position

1

Position

2

Position

3

OFF ON ON

POST INSTALLATION CHECKLIST

□ALL BOLTS TIGHTENED PROPERLY

□ONLY USED SHIELDED NETWORKING COMPONENTS PROVIDED

□MODBUS ADDRESSES SET

□SAFETY CABLE INSTALLED PROPERLY

□VERIFY POWER AND NETWORKING CABLES CONNECTED

STEP #1 STEEL BEAM INSTALLATION

STEP #3 SAFETY CABLE

INSTALLATION

HARDWARE KIT 854832 OR 915066

TORQUE SCREWS TO 60 IN-LBF

(MANUAL PAGE 15-16)

HARDWARE KIT 915065

TORQUE BOLTS TO 33 FT-LBF

(MANUAL PAGES 10-11)

HARDWARE KIT 915428

TORQUE BOLTS TO 45 FT-LBF

(MANUAL PAGE 7)

HARDWARE KIT 916290

TORQUE U-BOLTS TO 54 IN-LBF

(MANUAL PAGE 12-13)

HARDWARE KIT 916290

TORQUE U-BOLTS TO 54 IN-LBF

(MANUAL PAGE 14-15)

QUICK START GUIDE FOR INDUSTRIAL FAN INSTALLATION

STEP #5 WINGLET

INSTALLATION

TOOL LIST:

- IMPACT DRIVER

- 7/16 IN., 1/2 IN., 9/16 IN. AND 3/4 IN. SOCKETS

- 1/2 IN. AND 3/4 IN. WRENCHES

- #2 PHILLIPS SCREWDRIVER

- #2 PHILLIPS IMPACT BIT

- MAGNETIC TORPEDO LEVEL

- TORQUE WRENCH (UP TO 50 FT-LBF)

- TORQUE WRENCH (UP TO 120 IN-LBF)

- REFER TO INSTALLATION MANUAL FOR COMPLETE INSTALLATION INFORMATION

- THIS QUICK START GUIDE DOES NOT REPLACE INSTALLATION MANUAL INSTRUCTIONS

HARDWARE KIT 854832 OR 915066

TORQUE TO 25 FT-LBF

(MANUAL PAGE 15-16)

STEP #6 AIRFOIL

INSTALLATION

STEP #2 MOTOR TO DOWNTUBE

STEP #7 HUB PLATE INSTALLATION

HARDWARE KIT 854832 OR 915066

TORQUE SCREWS TO 96 IN-LBF

(MANUAL PAGE 17)

STEP #4 GUY WIRE

INSTALLATION

ALTERNATE MOUNTING - MANUAL PAGES 7-9

FIRE

RELAY

FIRE SUPPRESSION SYSTEM

LANDING POINT AT FAN

FIRE ALARM LANDING POINT

FIRE RELAY INSTALLATION AND WIRING

TO FAN WIRING

BLUE - COMMON

YELLOW - NORMALLY CLOSED

ORANGE - NORMALLY OPEN

(FAN DISABLED WHEN RELAY OPEN)

20 TO 32 VDC

RED (+)

WHITE (-)

OPTIONAL LED LIGHT INSTALLATION - MANUAL PAGE 15

5-1/2 IN.

MIN.

FIRST FAN IN SERIES

ALL OTHER FANS IN SERIES

- REMOVE BROWN/WHITE 24V WIRE AND CAP

- DO NOT REMOVE BROWN GROUND WIRE

- REMOVE SILVER SHIELD AND SECURE IN A WAY

THAT PREVENTS CONTACT WITH VFD BOARD

NOTE

DO NOT CUT CABLE OR REMOVE CRIMP CAP IF NOT USING FIRE RELAY.

1 2 3

ON

1 2 3

ON

FAN 1 ALL OTHER FANS

IN SERIES

DIP SWITCH BANK 2 SETTINGS

HELPFUL HINT

ALL NETWORKING MODIFICATIONS CAN BE COMPLETED PRIOR TO BLADE INSTALLATION.

FAN NETWORKING

FOR ALL WIRING AND NETWORKING - SEE MANUAL PAGES 11-12 AND 18-20

1 2 345678

ON

1 2 3

ON

MOTOR-TO-VFD WIRING AND DIP SWITCH BANK LOCATIONS

3

3

DIP SWITCH BANK 3

DIP SWITCH BANK 2

NOTE

HALL CABLE PLUG HAS BUILT-IN

ALIGNMENT TAB. DO NOT FORCE

THIS PLUG.

2

1

1

2

DIP SWITCH BANK 3 SETTINGS (MODBUS ADDRESSES)

MODBUS

ADDRESS

2

3

4

5

6

7

8

9

10

11

SWITCH

1

SWITCH

2

SWITCH

3

SWITCH

4

SWITCH

5

ON OFF OFF OFF OFF

ON

ON ON

ON

ON ON

ON ON

ON ON ON

ON

ON ON

ON ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

DO

NOT

MODIFY

SWITCH

6, 7, 8

Position

1

Position

2

Position

3

OFF OFF OFF

SURFACE MOUNT KEYPAD CONTROL (HMI)

• REFER TO CONTROL MANUAL

KEYPAD CONTROL (HMI)

CAT-5/6 CABLE TO FAN(S)

STEP #11 - CONTROLS INSTALLATION - IF WIRED INSTALLATION

POST INSTALLATION CHECKLIST

□ALL BOLTS TIGHTENED PROPERLY

□ONLY USED SHIELDED NETWORKING COMPONENTS PROVIDED

□MODBUS ADDRESSES SET

□SAFETY CABLE INSTALLED PROPERLY

□VERIFY POWER AND NETWORKING CABLES CONNECTED

STEP #1 STEEL BEAM INSTALLATION

STEP #3 SAFETY CABLE

INSTALLATION

HARDWARE KIT 854832 OR 915066

TORQUE SCREWS TO 60 IN-LBF

(MANUAL PAGE 15-16)

HARDWARE KIT 915065

TORQUE BOLTS TO 33 FT-LBF

(MANUAL PAGES 10-11)

HARDWARE KIT 915428

TORQUE BOLTS TO 45 FT-LBF

(MANUAL PAGE 7)

HARDWARE KIT 916290

TORQUE U-BOLTS TO 54 IN-LBF

(MANUAL PAGE 12-13)

HARDWARE KIT 916290

TORQUE U-BOLTS TO 54 IN-LBF

(MANUAL PAGE 14-15)

QUICK START GUIDE FOR INDUSTRIAL FAN INSTALLATION

STEP #5 WINGLET

INSTALLATION

TOOL LIST:

- IMPACT DRIVER

- 7/16 IN., 1/2 IN., 9/16 IN. AND 3/4 IN. SOCKETS

- 1/2 IN. AND 3/4 IN. WRENCHES

- #2 PHILLIPS SCREWDRIVER

- #2 PHILLIPS IMPACT BIT

- MAGNETIC TORPEDO LEVEL

- TORQUE WRENCH (UP TO 50 FT-LBF)

- TORQUE WRENCH (UP TO 120 IN-LBF)

- REFER TO INSTALLATION MANUAL FOR COMPLETE INSTALLATION INFORMATION

- THIS QUICK START GUIDE DOES NOT REPLACE INSTALLATION MANUAL INSTRUCTIONS

HARDWARE KIT 854832 OR 915066

TORQUE TO 25 FT-LBF

(MANUAL PAGE 15-16)

STEP #6 AIRFOIL

INSTALLATION

STEP #2 MOTOR TO DOWNTUBE

STEP #7 HUB PLATE INSTALLATION

HARDWARE KIT 854832 OR 915066

TORQUE SCREWS TO 96 IN-LBF

(MANUAL PAGE 17)

STEP #4 GUY WIRE

INSTALLATION

ALTERNATE MOUNTING - MANUAL PAGES 7-9

FIRE

RELAY

FIRE SUPPRESSION SYSTEM

LANDING POINT AT FAN

FIRE ALARM LANDING POINT

FIRE RELAY INSTALLATION AND WIRING

TO FAN WIRING

BLUE - COMMON

YELLOW - NORMALLY CLOSED

ORANGE - NORMALLY OPEN

(FAN DISABLED WHEN RELAY OPEN)

20 TO 32 VDC

RED (+)

WHITE (-)

OPTIONAL LED LIGHT INSTALLATION - MANUAL PAGE 15

5-1/2 IN.

MIN.

FIRST FAN IN SERIES

ALL OTHER FANS IN SERIES

- REMOVE BROWN/WHITE 24V WIRE AND CAP

- DO NOT REMOVE BROWN GROUND WIRE

- REMOVE SILVER SHIELD AND SECURE IN A WAY

THAT PREVENTS CONTACT WITH VFD BOARD

NOTE

DO NOT CUT CABLE OR REMOVE CRIMP CAP IF NOT USING FIRE RELAY.

1 2 3

ON

1 2 3

ON

FAN 1

ALL OTHER FANS

IN SERIES

DIP SWITCH BANK 2 SETTINGS

HELPFUL HINT

ALL NETWORKING MODIFICATIONS CAN BE COMPLETED PRIOR TO BLADE INSTALLATION.

FAN NETWORKING

FOR ALL WIRING AND NETWORKING - SEE MANUAL PAGES 11-12 AND 18-20

1 2 345678

ON

1 2 3

ON

MOTOR-TO-VFD WIRING AND DIP SWITCH BANK LOCATIONS

3

3

DIP SWITCH BANK 3

DIP SWITCH BANK 2

NOTE

HALL CABLE PLUG HAS BUILT-IN

ALIGNMENT TAB. DO NOT FORCE

THIS PLUG.

2

1

1

2

DIP SWITCH BANK 3 SETTINGS (MODBUS ADDRESSES)

MODBUS

ADDRESS

2

3

4

5

6

7

8

9

10

11

SWITCH

1

SWITCH

2

SWITCH

3

SWITCH

4

SWITCH

5

ON OFF OFF OFF OFF

ON

ON ON

ON

ON ON

ON ON

ON ON ON

ON

ON ON

ON ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

DO

NOT

MODIFY

SWITCH

6, 7, 8

POST INSTALLATION CHECKLIST

□ALL BOLTS TIGHTENED PROPERLY

□ONLY USED SHIELDED NETWORKING COMPONENTS PROVIDED

□MODBUS ADDRESSES SET

□SAFETY CABLE INSTALLED PROPERLY

□VERIFY POWER AND NETWORKING CABLES CONNECTED

STEP #1 STEEL BEAM INSTALLATION

STEP #3 SAFETY CABLE

INSTALLATION

HARDWARE KIT 854832 OR 915066

TORQUE SCREWS TO 60 IN-LBF

(MANUAL PAGE 15-16)

HARDWARE KIT 915065

TORQUE BOLTS TO 33 FT-LBF

(MANUAL PAGES 10-11)

HARDWARE KIT 915428

TORQUE BOLTS TO 45 FT-LBF

(MANUAL PAGE 7)

HARDWARE KIT 916290

TORQUE U-BOLTS TO 54 IN-LBF

(MANUAL PAGE 12-13)

HARDWARE KIT 916290

TORQUE U-BOLTS TO 54 IN-LBF

(MANUAL PAGE 14-15)

QUICK START GUIDE FOR INDUSTRIAL FAN INSTALLATION

STEP #5 WINGLET

INSTALLATION

TOOL LIST:

- IMPACT DRIVER

- 7/16 IN., 1/2 IN., 9/16 IN. AND 3/4 IN. SOCKETS

- 1/2 IN. AND 3/4 IN. WRENCHES

- #2 PHILLIPS SCREWDRIVER

- #2 PHILLIPS IMPACT BIT

- MAGNETIC TORPEDO LEVEL

- TORQUE WRENCH (UP TO 50 FT-LBF)

- TORQUE WRENCH (UP TO 120 IN-LBF)

- REFER TO INSTALLATION MANUAL FOR COMPLETE INSTALLATION INFORMATION

- THIS QUICK START GUIDE DOES NOT REPLACE INSTALLATION MANUAL INSTRUCTIONS

HARDWARE KIT 854832 OR 915066

TORQUE TO 25 FT-LBF

(MANUAL PAGE 15-16)

STEP #6 AIRFOIL

INSTALLATION

STEP #2 MOTOR TO DOWNTUBE

STEP #7 HUB PLATE INSTALLATION

HARDWARE KIT 854832 OR 915066

TORQUE SCREWS TO 96 IN-LBF

(MANUAL PAGE 17)

STEP #4 GUY WIRE

INSTALLATION

ALTERNATE MOUNTING - MANUAL PAGES 7-9

FIRE

RELAY

FIRE SUPPRESSION SYSTEM

LANDING POINT AT FAN

FIRE ALARM LANDING POINT

FIRE RELAY INSTALLATION AND WIRING

TO FAN WIRING

BLUE - COMMON

YELLOW - NORMALLY CLOSED

ORANGE - NORMALLY OPEN

(FAN DISABLED WHEN RELAY OPEN)

20 TO 32 VDC

RED (+)

WHITE (-)

OPTIONAL LED LIGHT INSTALLATION - MANUAL PAGE 15

5-1/2 IN.

MIN.

FIRST FAN IN SERIES

ALL OTHER FANS IN SERIES

- REMOVE BROWN/WHITE 24V WIRE AND CAP

- DO NOT REMOVE BROWN GROUND WIRE

- REMOVE SILVER SHIELD AND SECURE IN A WAY

THAT PREVENTS CONTACT WITH VFD BOARD

NOTE

DO NOT CUT CABLE OR REMOVE CRIMP CAP IF NOT USING FIRE RELAY.

1 2 3

ON

1 2 3

ON

FAN 1 ALL OTHER FANS

IN SERIES

DIP SWITCH BANK 2 SETTINGS

HELPFUL HINT

ALL NETWORKING MODIFICATIONS CAN BE COMPLETED PRIOR TO BLADE INSTALLATION.

FAN NETWORKING

FOR ALL WIRING AND NETWORKING - SEE MANUAL PAGES 11-12 AND 18-20

1 2 345678

ON

1 2 3

ON

MOTOR-TO-VFD WIRING AND DIP SWITCH BANK LOCATIONS

3

3

DIP SWITCH BANK 3

DIP SWITCH BANK 2

NOTE

HALL CABLE PLUG HAS BUILT-IN

ALIGNMENT TAB. DO NOT FORCE

THIS PLUG.

2

1

1

2

DIP SWITCH BANK 3 SETTINGS (MODBUS ADDRESSES)

MODBUS

ADDRESS

2

3

4

5

6

7

8

9

10

11

SWITCH

1

SWITCH

2

SWITCH

3

SWITCH

4

SWITCH

5

ON OFF OFF OFF OFF

ON

ON ON

ON

ON ON

ON ON

ON ON ON

ON

ON ON

ON ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

DO

NOT

MODIFY

SWITCH

6, 7, 8

Reference Troubleshooting Operation And

Maintenance

Fan

Networking

Electrical

Installation

Fire System

Integration

Mechanical

Installation Pre-Installation General

Information

Quick Start

Guide

FAN START-UP

• HMI - REFER TO CONTROL MANUAL

IMPORTANT: BLADE COUNT AND FAN SIZE

MUST BE SET APPROPRIATELY IN CONTROL

MENUS FOR PROPER FAN OPERATION.

STEP #12 - FAN START-UP

9

8

General Safety Information

IMPORTANT: To reduce the risk of fire, electric shock, or

injury to persons, AMPLIFY fans must be installed with

a mount assembly, motor assembly and airfoils that are

marked (on their cartons) to indicate suitability with this

model. Other mounts, motors, and airfoils cannot be

substituted.

Only qualified personnel should install this fan.

Personnel should have a clear understanding of these

instructions and should be aware of general safety

precautions. Improper installation can result in electric

shock, possible injury due to coming in contact with

moving parts, as well as other potential hazards. Other

considerations may be required if high winds or seismic

activity are present. If more information is needed,

contact a licensed professional engineer before moving

forward.

1. Follow all local electrical and safety codes, as well

as the National Electrical Codes and any National

Fire Protection Agencys, where applicable.

2. The rotation of the impeller is critical. It must be

free to rotate without striking or rubbing any

stationary objects.

3. Motor must be securely and adequately grounded.

4. Do not allow the power cable to kink or come in

contact with oil, grease, hot surfaces or chemicals.

Replace cord immediately if damaged.

5. Verify that the power source is compatible with the

equipment.

WARNING

To reduce the risk of fire, electric shock, or injury to

persons, observe the following:

1. Use this unit only in the manner intended by the

manufacturer. If you have questions, contact the

manufacturer.

2. Before servicing or cleaning unit, switch

power off at service panel and lock the service

disconnecting means to prevent power from

being switched on accidentally. When the service

disconnecting means cannot be locked, securely

fasten a prominent warning device, such as a tag,

to the service panel.

WARNING

To reduce the risk of fire, electric shock, or injury to

persons, observe the following:

1. Installation work and electrical wiring must be

done by qualified person(s) in accordance with all

applicable codes and standards, including fire-

rated construction.

2. When cutting or drilling into wall or ceiling, do not

damage electrical wiring and other hidden utilities.

WARNING

This appliance can be used by children aged from 8

years and above and persons with reduced physical,

sensory or mental capabilities or lack of experience

and knowledge if they have been given supervision or

instruction concerning use of the appliance in a safe

way and understand the hazards involved. Children

shall not play with the appliance. Cleaning and user

maintenance shall not be made by children.

Receiving

Upon receiving the product, check to ensure all items

are accounted for by referencing the delivery receipt or

packing list. Inspect each crate or carton for shipping

damage before accepting delivery. Alert the carrier of

any damage detected. The customer will note damage

(or shortage of items) on the delivery receipt and all

copies of the bill of lading which is countersigned by

the delivering carrier. If damaged, contact your local

representative immediately. Any physical damage to

the unit after acceptance is not the responsibility of the

manufacturer.

Unpacking

Verify that all required parts and the correct quantity

of each item have been received using the component

list within this manual. If any items are missing, report

shortages to your local representative to arrange for

obtaining missing parts. Sometimes it is not possible

that all items for the unit be shipped together due

to availability of transportation and truck space.

Confirmation of shipment(s) must be limited to only

items on the bill of lading.

Storage

Fans are protected against damage during shipment.

If the unit cannot be installed and operated

immediately, precautions need to be taken to prevent

deterioration of the unit during storage. The user

General Information

DANGER

Always disconnect, lock, and tag power source before

installing or servicing. Failure to disconnect power

source can result in fire, shock or serious injury.

CAUTION

When servicing the fan, motor may be hot enough

to cause pain or injury. Allow motor to cool before

servicing.

CAUTION

Precaution should be taken in explosive atmospheres.

assumes responsibility of the fan and accessories while

in storage. The manufacturer will not be responsible

for damage during storage. These suggestions are

provided solely as a convenience to the user.

Indoor - The ideal environment for the storage of

fans and accessories is indoors, above grade, in a low

humidity atmosphere that is sealed to prevent the entry

of blowing dust, rain or snow. Temperatures should be

evenly maintained between -1° to 43°C (30° to 110°F).

Wide temperature swings may cause condensation

and “sweating” of metal parts. All accessories must be

stored indoors in a clean, dry atmosphere.

Remove any accumulations of dirt, water, ice or snow

and wipe dry before moving to indoor storage. To avoid

“sweating” of metal parts, allow cold parts to reach

room temperature. To dry parts and packages, use a

portable electric heater to get rid of any moisture build

up. Leave coverings loose to permit air circulation and

to allow for periodic inspection.

The unit should be stored at least 90 mm (3-1/2 in.)

off the floor on wooden blocks covered with moisture

proof paper or polyethylene sheathing. Aisles between

parts and along all walls should be provided to permit

air circulation and space for inspection.

Inspection and Maintenance During Storage

While in storage, inspect fans once per month. Keep a

record of inspection and maintenance performed.

If moisture or dirt accumulations are found on parts,

the source should be located and eliminated. If paint

deterioration begins, consideration should be given to

touch-up or repainting. Fans with special coatings may

require special techniques for touch-up or repair.

Machined parts coated with rust preventive should be

restored to good condition promptly if signs of rust

occur. Immediately remove the original rust preventive

coating with petroleum solvent and clean with lint

free cloths. Polish any remaining rust from surface

with crocus cloth or fine emery paper and oil. Do not

destroy the continuity of the surfaces. Thoroughly wipe

clean with Tectyl®506 or the equivalent. For hard to

reach internal surfaces or for occasional use, consider

using Tectyl®511M Rust Preventive, WD-40®or the

equivalent.

Removing from Storage

As fans are removed from storage to be installed in

their final location, they should be protected and

maintained in a similar fashion until the fan equipment

goes into operation.

Reference Troubleshooting Operation And

Maintenance

Fan

Networking

Electrical

Installation

Fire System

Integration

Mechanical

Installation Pre-Installation General

Information

Quick Start

Guide

Quick Start

Guide

General

Information Pre-Installation Mechanical

Installation

Fire System

Integration

Electrical

Installation

Fan

Networking

Operation And

Maintenance Troubleshooting Reference

11

10

Fan Components

Verify that all of the following parts and hardware

have been received prior to beginning installation.

Contact your local representative or the manufacturer if

replacement parts are required.

NOTE: Additional parts (provided by others) may be

required to complete the fan installation, including

additional wiring, steel angle or Unistrut®channel, and

hardware for connecting the fan mount to the building

structure.

NOTE: Hardware quantities listed below indicate what

is required to complete installation. Hardware kits may

include extra fasteners as a convenience.

POWER CABLE

FACTORY INSTALLED VFD

FIRE ALARM LANDING POINT

COMMUNICATION CABLE

WITH RJ45 SPLITTER

Downtube and Mount Assembly (1)

Airfoil Blade (6)

Winglet (6)

AIRFOIL BLADE

SCREW BOSSES

WINGLET

SCREW

(2 PER BLADE)

Motor/Hub Assembly (1)

Guy Wire Fastener Kit Bag # 916290

DOWNTUBE & MOUNT ASSEMBLY

UG2 GRIPPLE®TURNBUCKLE

GUY WIRE

GUY WIRE

GUY WIRE

GUY WIRE CLAMP ASSEMBLY

GUY WIRE CLAMP BOLT

45º to 60º

TURNBUCKLE

GUY WIRE ATTACHMENT RING

QUICK LINK

CABLE CLAMP

QUICK LINK

U-Bolt Steel Cable

Clamps (10) Turnbuckle (4)

DOWNTUBE & MOUNT ASSEMBLY

UG2 GRIPPLE®TURNBUCKLE

GUY WIRE

GUY WIRE

GUY WIRE

GUY WIRE CLAMP ASSEMBLY

GUY WIRE CLAMP BOLT

45º to 60º

TURNBUCKLE

GUY WIRE ATTACHMENT RING

QUICK LINK

CABLE CLAMP

QUICK LINK

Guy Wire

Clamps (4)

DOWNTUBE & MOUNT ASSEMBLY

UG2 GRIPPLE®TURNBUCKLE

GUY WIRE

GUY WIRE

GUY WIRE

GUY WIRE CLAMP ASSEMBLY

GUY WIRE CLAMP BOLT

45º to 60º

UG2 GRIPPLE®TURNBUCKLE

GUY WIRE ATTACHMENT RING

QUICK LINK

Quick Link (8)

DOWNTUBE & MOUNT ASSEMBLY

GUY WIRE

GUY WIRE

GUY WIRE CLAMP ASSEMBLY

GUY WIRE CLAMP BOLT

45º to 60º

No. 4 GRIPPLE®CONNECTOR

GUY WIRE ATTACHMENT RING

QUICK LINK

TURNBUCKLE

Motor/Hub Fastener Kit Bag

Grade 8, Hex Bolt (2)

Machine Screw (4)

Airfoil Blade and Hub Plate Fastener Kit

Washers (24)

Grade 8, Nylon Locknut (12)

Grade 8, Hex Bolt (12)

Screws (12)

Machine Screws (4)

20 Ft.

Guy Wire (4)

DOWNTUBE & MOUNT ASSEMBLY

GUY WIRE

GUY WIRE

GUY WIRE CLAMP ASSEMBLY

GUY WIRE CLAMP BOLT

45º to 60º

No. 4 GRIPPLE®CONNECTOR

GUY WIRE ATTACHMENT RING

QUICK LINK

TURNBUCKLE

Rear VFD Cover (1)

DOWNTUBE & MOUNT ASSEMBLY

MOTOR & HUB ASSEMBLY

FRONT VFD COVER

REAR VFD COVER

M4 - 0.7 x 10 MACHINE SCREW

Hub Plate (1)

HUB PLATE

U-NUT

HUB RETENTION BRACKET

MACHINE SCREW

Reference Troubleshooting Operation And

Maintenance

Fan

Networking

Electrical

Installation

Fire System

Integration

Mechanical

Installation Pre-Installation General

Information

Quick Start

Guide

Optional Fan Components

I-Beam Mounting Kit (Optional)

I-BEAM CLAMPING PLATE

I-BEAM CLAMPING PLATE SHIM

UNIVERSAL MOUNTING PLATE

1/2 in. WASHER

1/2 in. - 13 GRADE 8 NYLON LOCKNUT

DOWNTUBE & MOUNT ASSEMBLY

1/2 in. - 13 X 2-1/2 GRADE 8 HEX BOLT

STEEL BEAM

I-Beam Clamping

Plate (2)

I-Beam Clamping

Plate Shim (2)

I-BEAM CLAMPING PLATE

I-BEAM CLAMPING PLATE SHIM

UNIVERSAL MOUNTING PLATE

1/2 in. WASHER

1/2 in. - 13 GRADE 8 NYLON LOCKNUT

DOWNTUBE & MOUNT ASSEMBLY

1/2 in. - 13 X 2-1/2 GRADE 8 HEX BOLT

STEEL BEAM

I-Beam Fastener Kit (Optional)

Washers (8)

Nylon Locknut (4)

Hex Bolt (4)

Steel Truss Mounting Kit (Optional)

STEEL TRUSS / BAR JOIST

STRUCTURAL STEEL ANGLES

(BY OTHERS)

1/2 in. - 13 GRADE 8 HEX BOLT

(BY OTHERS)

1/2 in. - 13 GRADE 8 NYLON LOCKNUT

SQUARE WASHER PLATE

1/2 in. WASHER

STRUCTURAL STEEL ANGLES

(BY OTHERS)

STEEL TRUSS / BAR JOIST

GRADE 8 HEX BOLT

(BY OTHERS)

STEEL TRUSS / BAR JOIST

SQUARE WASHER PLATE

WASHER

GRADE 8 NYLON LOCKNUT

Square Washer Plate (4)

Steel Truss Fastener Kit (Optional)

Washer (16)

Grade 8, Nylon Locknut (8)

Grade 8, Hex Bolt (4)

Gripple®Installation Kit (Optional)

20 Ft. Guy Wire (4)

DOWNTUBE & MOUNT ASSEMBLY

GUY WIRE

GUY WIRE

GUY WIRE CLAMP ASSEMBLY

GUY WIRE CLAMP BOLT

45º to 60º

No. 4 GRIPPLE®CONNECTOR

GUY WIRE ATTACHMENT RING

QUICK LINK

TURNBUCKLE

Gripple®Fastener Kit (Optional)

No. 4 Gripple®(5)

DOWNTUBE & MOUNT ASSEMBLY

GUY WIRE

GUY WIRE

GUY WIRE CLAMP ASSEMBLY

GUY WIRE CLAMP BOLT

45º to 60º

No. 4 GRIPPLE®CONNECTOR

GUY WIRE ATTACHMENT RING

QUICK LINK

TURNBUCKLE

Quick Link (8)

DOWNTUBE & MOUNT ASSEMBLY

GUY WIRE

GUY WIRE

GUY WIRE CLAMP ASSEMBLY

GUY WIRE CLAMP BOLT

45º to 60º

No. 4 GRIPPLE®CONNECTOR

GUY WIRE ATTACHMENT RING

QUICK LINK

TURNBUCKLE

Turnbuckle (4)

DOWNTUBE & MOUNT ASSEMBLY

UG2 GRIPPLE®TURNBUCKLE

GUY WIRE

GUY WIRE

GUY WIRE

GUY WIRE CLAMP ASSEMBLY

GUY WIRE CLAMP BOLT

45º to 60º

TURNBUCKLE

GUY WIRE ATTACHMENT RING

QUICK LINK

CABLE CLAMP

QUICK LINK

Wood Beam Mounting Kit (Optional)

1/2 in. WASHER

1/2 in. - 13 GRADE 8

NYLON LOCKNUT

WOOD BEAM

WOOD BEAM

BRACKET

1/2 in. - 13 GRADE 8 HEX BOLT

(BY OTHERS)

Wood Beam Bracket (2)

Wood Beam Fastener Kit (Optional)

Hex Bolt (4)

Nylon Locknut (8)

Washers (16)

Quick Start

Guide

General

Information Pre-Installation Mechanical

Installation

Fire System

Integration

Electrical

Installation

Fan

Networking

Operation And

Maintenance Troubleshooting Reference

13

12

Pre-Installation Checks

IMPORTANT: Consult all applicable national and local

codes to ensure that all necessary code requirements

are met. It is the sole responsibility of the installer to

ensure compliance with applicable codes.

Prior to installing the fan, perform each of the following

checks:

1. Verify that fan components are undamaged.

Do not install or operate any damaged fan

components, fans, or fan accessories. Failure to

comply with this instruction may result in property

damage, personal injury and/or death.

2. Verify that the fan is to be installed in a location

where the airfoils will be a minimum of 3 m.

above the finished floor with a minimum of 1

m. of horizontal and vertical clearance to any

obstructions.

3. Verify that the fan is to be installed in a location

where the center of the fan is a minimum of 1.5 fan

diameters away from building walls and corners.

4. For best performance, the fan must be installed

with a two fan diameter minimum clearance to

radiant heaters and HVAC system discharges or

intakes.

5. Check that the fan will not be mounted in a

location near overhead doors or other building

openings where gusts of wind may occur. Fan

should not be installed or operated in locations

where wind is present.

6. If the building is equipped with a fire sprinkler

system, verify that the placement of the fan will

not interfere with correct sprinkler operation and

that the fan installation complies with all national,

state and local codes. Fan must also be interlocked

to shut down upon receiving a waterflow signal

from the building’s alarm system.

7. Check to see if the intended placement of the fan

is directly below any building lights or skylights. If

possible, avoid installing fan directly below a light

source to prevent a strobing effect that can be

caused by fan rotation.

8. If the building has a mezzanine or other elevated

spaces that may be occupied by people, verify that

no component of the fan can be reached from the

highest level or deck. The fan must be positioned

so that the tips of the airfoils are a minimum of 1

m away from the furthest point that a person could

reach or otherwise come in contact, to prevent

injury.

9. If the fan is to be mounted in an area where

materials or equipment may be elevated into its

path, ensure that the floor is marked or painted

to alert personnel of the overhead location of the

fan(s).

10. Before installation, it is important to verify that the

mounting surface will bear the operating weight

and maximum torque (twisting force) of the unit. It

is the sole responsibility of the installer to ensure

that the mounting structure and fan installation

method are adequate for safe operation of the

fan.

Fan Size

m

AMPLIFY

*Max. Fan

Weight (kg)

Max. Torque

(Nm)

6 123 165

7,3 130 170

*Maximum weight is shown in

pounds and includes all available

options, actual fan weight may be

less.

Pre-Installation

Reference Troubleshooting Operation And

Maintenance

Fan

Networking

Electrical

Installation

Fire System

Integration

Mechanical

Installation Pre-Installation General

Information

Quick Start

Guide

B

A

1 M CLEARANCE AROUND BLADES

2X FAN DIAMETER

FROM HVAC

MINIMUM 3 M ABOVE

FINISHED FLOOR

HVAC

DIFFUSER

WHEN FULL DIFFUSER OUTLET

IS BELOW HVLS FAN,

HVLS FAN MUST BE 1X FAN DIAMETER AWAY

1 M CLEARANCE AROUND BLADES

Minimum Spacing From Center of Fan (m)

Fan Size (m) A B

6 9,2 18,3

7,3 11 22

Minimum Spacing Requirements

Quick Start

Guide

General

Information Pre-Installation Mechanical

Installation

Fire System

Integration

Electrical

Installation

Fan

Networking

Operation And

Maintenance Troubleshooting Reference

15

14

Mounting Installation

DANGER

Always disconnect, lock and tag power source before

installing or servicing. Failure to disconnect power

source can result in fire, shock or serious injury.

The following mounting installations are covered in this

manual. Identify the supplied mounting kit, locate the

appropriate installation within this manual.

• I-Beam Mounting Kit

• Steel Truss Mounting Kit

• Wood Beam Mounting Kit

I-Beam Mounting Kit

(For Flanges up to 250 mm Wide)

IMPORTANT: A Structural Engineer must perform

thorough evaluation of mounting structure and

determine final mounting requirements before fan is

installed. Manufacturer is not liable for any problems

that arise as the result of insufficient structure, including

(but not limited to) vibration, noise, or safety hazards.

Product warranty will be voided at manufacturer’s

discretion if structure is deemed insufficient.

Installations must comply with the following

requirements at a minimum, but The Structural

Engineer may require more stringent specifications at

their discretion:

• Do not install HVLS fans on fabricated I-beams.

• HVLS fans should only be installed on I-beams that

are part of the existing building structure.

• I-beam must have a minimum flange width of 130

mm and a minimum flange thickness of 13 mm.

• Do not weld HVLS fans to I-beams.

• Do not use I-beam mounting kit on any other type

of structure (steel trusses, steel angles, etc.).

Required Loose Components (Included):

• I-Beam Clamping Plate (2)

• I-Beam Clamping Plate Shim (2)

Required Components:

• Grade 8 Hex Bolt (4)

• Grade 8 Nylon Locknut (4)

• Washer (8)

Hardware/Tools Needed (Not Included):

• Torque Wrench

• Socket and Ratchet Kit

• Wrench

1. Using appropriate lifting equipment, raise the

downtube and mount assembly until the universal

mounting plate is positioned on the bottom of the

I-beam.

2. Using the universal mounting plate as a guide,

identify the appropriate set of mounting slots to

use for installation. The universal mounting plate

can accommodate I-beams with a flange width up

to 250 mm, a flange thickness up to 25 mm, and a

vertical web thickness up to 69 mm.

3. Attach (1) I-beam clamping plate shim and (1)

I-beam clamping plate to the universal mounting

plate using (2) grade 8 hex bolts, (4) washers,

and (2) grade 8 nylon locknuts. Hook the I-beam

clamping plate onto one side of the I-beam and

tighten hardware until the universal mounting

plate is snug against the beam but can still be

moved (approximately 6 mm of the bolt threads

exposed below the nylon locknut).

IMPORTANT: I-beam clamping plate shims and I-beam

clamping plates must be installed so that the laser-cut

arrows are pointing towards the I-beam. Ensure that

the narrowest possible set of mounting holes is used

on the universal mounting plate to ensure maximum

engagement with the I-beam.

I-BEAM CLAMPING PLATE

I-BEAM CLAMPING PLATE SHIM

UNIVERSAL MOUNTING PLATE

1/2 in. WASHER

1/2 in. - 13 GRADE 8 NYLON LOCKNUT

DOWNTUBE & MOUNT ASSEMBLY

GRADE 8 HEX BOLT

STEEL BEAM

TORQUE TO 45 FT∙LBF

(61.0 N∙m)

4. Attach the opposing I-beam clamp plate shim and

I-beam clamp plate on to the universal mounting

plate and I-beam. Hand tighten hardware.

5. Center the universal mounting plate under the

I-beam. Ensure the I-beam clamp plates have

maximum engagement on both sides and tighten

hardware evenly to 45 ftlbf (61.0 Nm).

6. Continue with Motor/Hub to Downtube

Installation.

Mechanical Installation Steel Truss Mounting Kit

IMPORTANT: A Structural Engineer must perform

thorough evaluation of mounting structure and

determine final mounting requirements before fan is

installed. Manufacturer is not liable for any problems

that arise as the result of insufficient structure, including

(but not limited to) vibration, noise, or safety hazards.

Product warranty will be voided at manufacturer’s

discretion if structure is deemed insufficient.

Installations must comply with the following

requirements at a minimum, but The Structural

Engineer may require more stringent specifications at

their discretion:

• Do not install HVLS fans on a single steel truss.

Structural steel angles must be used to span a

minimum of 2 trusses.

• Steel trusses must have a minimum chord width of

130 mm.

• Structural steel angle span lengths must not exceed

2,4 m. For span lengths up to 2,4 m, a minimum of

2 structural steel angles are required.

• Size of structural steel angles must be specified by

a structural engineer. Angles must be a minimum

of 100 x 100 x 6 mm thick. Larger angles may be

required for span lengths up to 2,4 m. Angles shall

be sufficiently stiff to avoid harmonic resonance

excitation during fan operation (120 RPM;

+/- 20%).

Required Loose Components (Included):

• Square Washer Plate (4)

Required Components:

• Grade 8 Hex Bolt (4)

• Grade 8 Nylon Locknut (8)

• Washer (16)

Hardware/Tools Needed (Not Included):

• Structural Steel Angles (2)

• Grade 8 Hex Bolt (4), length determined by truss

and steel angle material thickness

• Torque Wrench

• Socket and Wrench Kit

• Wrench

• Drill and 15 mm Drill Bit

1. Size structural steel angles (by others) to fit within

steel trusses/bar joists. Size of steel angle to be

determined by structural engineer.

2. Mount structural steel angles to steel trusses/bar

joists using (4) grade 8, M14 bolts (by others to

accommodate varying material thickness), and

supplied (8) washers, (4) square washer plates, and

(4) 14M nylon locknuts. Note that the hardware

should be installed through the gap in the bottom

chord of the steel trusses/bar joists (reference

drawing on to the right). Torque hardware to 80

ftlbf (108.5 Nm).

STEEL TRUSS / BAR JOIST

STRUCTURAL STEEL ANGLES

(BY OTHERS)

M14 GRADE 8 HEX BOLT

(BY OTHERS)

GRADE 8 NYLON LOCKNUT

SQUARE WASHER PLATE

WASHER

STRUCTURAL STEEL ANGLES

(BY OTHERS)

STEEL TRUSS / BAR JOIST

GRADE 8 HEX BOLT

(BY OTHERS)

STEEL TRUSS / BAR JOIST

SQUARE WASHER PLATE

WASHER

GRADE 8 NYLON LOCKNUT

TORQUE TO 80 FT∙LBF

(108.5 N∙m)

Lorem ipsum

STEEL TRUSS / BAR JOIST

STRUCTURAL STEEL ANGLES

(BY OTHERS)

1/2 in. - 13 GRADE 8 HEX BOLT

(BY OTHERS)

1/2 in. - 13 GRADE 8 NYLON LOCKNUT

SQUARE WASHER PLATE

1/2 in. WASHER

STRUCTURAL STEEL ANGLES

(BY OTHERS)

STEEL TRUSS / BAR JOIST

GRADE 8 HEX BOLT

(BY OTHERS)

STEEL TRUSS / BAR JOIST

SQUARE WASHER PLATE

WASHER

GRADE 8 NYLON LOCKNUT

3. Locate desired fan hanging location. Using the

universal mounting plate as a template, mark and

drill (4) 15 mm holes in structural steel angles.

4. Bolt universal mounting plate into place using

supplied (4) grade 8 hex bolts, (8) washers and (4)

grade 8 nylon locknuts. Torque to 80 ftlbf

(108.5 Nm).

STRUCTURAL STEEL ANGLES

(BY OTHERS)

GRADE 8 HEX BOLT

UNIVERSAL MOUNTING PLATE

DOWNTUBE & MOUNT ASSEMBLY

WASHER

GRADE 8 NYLON LOCKNUT

TORQUE TO 80 FT∙LBF

(108.5 N∙m)

5. Continue with Motor/Hub to Downtube

Installation.

Reference Troubleshooting Operation And

Maintenance

Fan

Networking

Electrical

Installation

Fire System

Integration

Mechanical

Installation Pre-Installation General

Information

Quick Start

Guide

Quick Start

Guide

General

Information Pre-Installation Mechanical

Installation

Fire System

Integration

Electrical

Installation

Fan

Networking

Operation And

Maintenance Troubleshooting Reference

17

16

Wood Beam Mounting Kit

(For Beams 115-225 mm Wide)

IMPORTANT: A Structural Engineer must perform

thorough evaluation of mounting structure and

determine final mounting requirements before fan is

installed. Manufacturer is not liable for any problems

that arise as the result of insufficient structure, including

(but not limited to) vibration, noise, or safety hazards.

Product warranty will be voided at manufacturer’s

discretion if structure is deemed insufficient.

Installations must comply with the following

requirements at a minimum, but The Structural

Engineer may require more stringent specifications at

their discretion:

• Do not use the wood beam mounting kit on wood

beams that are less than 115 mm wide. For thinner

wood beams, span two or more beams using

structural steel angles or unistrut. Refer to steel

truss or unistrut mounting kit instructions.

Required Loose Components (Included):

• Wood Beam Bracket (2)

Required Components:

• Grade 8 Hex Bolt (4)

• Grade 8 Nylon Locknut (8)

• Washer (16)

Hardware/Tools Needed (Not Included):

• M14 Grade 8 Hex Bolt (4), length determined by

wood beam thickness

• Torque Wrench

• Socket and Wrench Kit

• Wrench

• Drill and 15 mm Drill Bit

1. Locate desired fan hanging location. Using the

supplied wood beam brackets as a template, mark

and drill (4) 15 mm holes in the wood beam. Be

sure bottom of brackets are flush or slightly below

bottom of wood beam to effectively connect to

the universal mounting plate.

2. Bolt wood beam brackets into place using (4)

grade 8, M14 bolts (by others to accommodate

varying material thickness), and supplied (4) M14

nylon locknuts, and (8) washers. Torque hardware

to 80 ftlbf (108.5 Nm).

WASHER

M14 NYLON LOCKNUT

(BY OTHERS)

WOOD BEAM

WOOD BEAM

BRACKET

M14 GRADE 8 HEX BOLT

(BY OTHERS)

TORQUE TO 80 FT∙LBF

(108.5 N∙m)

3. With wood beam brackets installed, line up

universal mounting plate and bolt into wood beam

brackets using supplied (4) hex bolts, (8) 1/2 in.

washers, and (4) nylon locknuts.

WASHER

GRADE 8 NYLON LOCKNUT

WOOD BEAM

DOWNTUBE & MOUNT ASSEMBLY

GRADE 8 HEX BOLT

UNIVERSAL MOUNTING PLATE

TORQUE TO 80 FT∙LBF

(108.5 N∙m)

4. Torque hardware to 80 ftlbf (108.5 Nm).

5. Continue with Motor/Hub to Downtube

Installation.

Reference Troubleshooting Operation And

Maintenance

Fan

Networking

Electrical

Installation

Fire System

Integration

Mechanical

Installation Pre-Installation General

Information

Quick Start

Guide

Motor/Hub to Downtube Installation

Required Loose Components (Included):

• Motor/Hub Assembly (1)

• Rear VFD Cover (1)

Required Components:

• Grade 8 Hex Bolt (2)

• M4 – 0.7 x 10 Machine Screw (4)

Hardware/Tools Needed (Not Included):

• 14 mm Socket Kit

• Socket Wrench

• Torque Wrench

• Phillips Screwdriver

• Lifting Equipment

• Cribbing (optional)

• Awl (optional)

DANGER

Always disconnect, lock and tag power source before

installing or servicing. Failure to disconnect power

source can result in fire, shock or serious injury.

1. Using a scissor lift or other suitable lifting device, lift

the motor/hub assembly by resting the struts on the

lift structure or cribbing.

FRONT VFD COVER DOWNTUBE AND MOUNT ASSEMBLY

MOTOR AND HUB ASSEMBLY

2. Feed the safety retention cable that is attached to

the motor/hub assembly up through the bottom

of the downtube until the loose end of the safety

cable is accessible at the top of the downtube. Pull

the loose end of the safety retention cable from the

top of the downtube until all of the slack is pulled

through.

DOWNTUBE AND MOUNT ASSEMBLY

MOTOR AND HUB ASSEMBLY

SAFETY RETENTION CABLE

MOTOR POWER, GROUND AND

COMMUNICATION CABLES

4. Carefully align the motor axle with the downtube

opening, making sure that the electrical cables

protruding from the motor axle are on the same

side as the black plastic VFD cover.

IMPORTANT: Electrical cables from motor must be on

same side as black plastic VFD cover. Cables are not

long enough to reach circuit board from opposite side.

Motor must be removed and rotated 180° if installed

incorrectly.

5. Slowly lift the motor/hub assembly until the motor

axle is nested inside the downtube. Take care to

align the motor axle holes with the downtube holes.

IMPORTANT: Do not crush safety cable or wiring while

lifting the motor/hub assembly into the downtube.

If the safety cable or the wiring are damaged during

installation, contact your local rep or the manufacturer.

MOTOR AND HUB ASSEMBLY

DOWNTUBE AND MOUNT ASSEMBLY

Quick Start

Guide

General

Information Pre-Installation Mechanical

Installation

Fire System

Integration

Electrical

Installation

Fan

Networking

Operation And

Maintenance Troubleshooting Reference

19

18

6. Install the supplied (2) grade 8hex bolts into the

locknuts attached to the downtube. Torque the

bolts to a value of 33 ftlbf (44.75 Nm).

NOTE: The attached locknuts are not visible while the

VFD is installed on the downtube of the fan.

MOTOR AND HUB ASSEMBLY

DOWNTUBE AND MOUNT ASSEMBLY

3/8 in. - 16 x 2-3/4 in. GRADE 8 HEX BOLT

7. Install rear VFD cover to the back of the VFD using

(4) M4-0.7 x 10mm machine screws.

DOWNTUBE & MOUNT ASSEMBLY

MOTOR & HUB ASSEMBLY

FRONT VFD COVER

REAR VFD COVER

M4 - 0.7 x 10 MACHINE SCREW

Safety Retention Cable Installation

IMPORTANT: Do not put excessive tension on the

safety retention cable during installation. Safety

retention cable should be taut with only a small amount

of slack in the cable to ensure proper functioning. Do

not allow safety retention cable to contact any sharp

edges.

IMPORTANT: Failure to install the safety retention cable

will result in voiding of the fan warranty.

Standard Steel Cable Clamp

The following instructions apply to

standard fan installations. For fans that

were supplied with optional Gripple®

hardware, refer to the instructions.

Required Components

• U-Bolt Steel Cable Clamp (2)

Hardware/Tools Needed (Not

Included):

• Torque Wrench

• Socket and Wrench

• Cable Cutters (optional)

1. From the top of the downtube, pull the safety

retention cable until it is taut inside the downtube.

2. Wrap the loose end of the safety cable around

the mounting structure. Cable may be wrapped

around structure multiple times if length allows.

Do not allow the cable to come in contact with any

sharp edges.

3. Align the loose end of the safety cable (referred to

as the dead-end) with the length of cable that is

wrapped around the mounting structure (referred

to as the live-end).

4. Attach the dead-end of the safety cable to the live-

end using the supplied u-bolt steel cable.

IMPORTANT: The first steel cable clamp must be

installed a minimum of 140 mm away from the dead-

end of the safety cable to ensure proper functioning.

IMPORTANT: Steel cable clamps are composed of two

parts: the u-bolt and the saddle. Steel cable clamps

must be installed with the u-bolt over the dead-end

of the safety retention cable and the saddle over the

live-end of the safety cable. Failure to install steel cable

clamps in this manner may result in unsafe operating

conditions. Refer to drawing below for correct

orientation.

5. Pull the dead-end of the safety cable through the

steel cable clamps to tighten the cable. The cable

should be pulled taut, leaving only a small amount

of slack in the cable to ensure proper functioning.

6. Tighten the nuts on the steel cable clamps using

a socket and torque to 54 inlbf (6.10 Nm),

alternating between nuts until reaching proper

torque.

7. Cut or organize excess safety cable to ensure it

does not interfere with fan performance. Make

sure to leave at least 140 mm of cable between

the dead-end of the cable and the first steel cable

clamp to ensure proper functioning.

DOWNTUBE SAFETY CABLE

DOWNTUBE & MOUNT ASSEMBLY

CABLE CLAMP CABLE CLAMP

SADDLE

CABLE CLAMP U-BOLT

DEAD END

LIVE END

TORQUE TO 54 IN∙LBF

(6.10 N∙m)

140 MM.

Gripple®Hardware (Optional)

Components required:

• No. 4 Gripple®Connector (1)

Hardware/Tools (Not Included):

• 1/16 in. Allen Wrench (optional)

• Cable Cutters (optional)

1. From the top of the downtube, pull the safety

retention cable until the cable is taut inside the

downtube.

2. Insert the loose end of the safety cable into the

No. 4 Gripple connector. Note that the cable will

only feed through the Gripple connector in one

direction (marked on the Gripple connector with

an arrow).

3. Slide the No. 4 Gripple connector down the safety

cable until it is located near the opening at the top

of the downtube.

4. Wrap the loose end of the safety cable around

the mounting structure. Do not allow the cable to

come in contact with any sharp edges.

5. Insert the loose end of the safety cable into the

open hole of the No. 4 Gripple connector. Note

that the cable will only feed through the Gripple

connector in one direction (marked on the Gripple

connector with an arrow).

6. Pull the loose end of the safety cable through the

Gripple connector to tighten the cable. The cable

should be pulled taut, leaving only a small amount

of slack in the cable to ensure proper functioning.

7. Cut or organize excess safety cable to ensure it

does not interfere with fan rotation.

NOTE: If necessary, the safety cable can be loosened

by inserting the long end of a 1/16 in. allen wrench into

either of the pin holes on the No. 4 Gripple connector

and pulling the cable in the opposite direction of the

arrow marked on the Gripple connector.

DOWNTUBE SAFETY CABLE

DOWNTUBE SAFETY CABLE

DOWNTUBE & MOUNT ASSEMBLY

NO. 4 GRIPPLE

Quick Start

Guide

General

Information Pre-Installation Mechanical

Installation

Fire System

Integration

Electrical

Installation

Fan

Networking

Operation And

Maintenance Troubleshooting Reference

Reference Troubleshooting Operation And

Maintenance

Fan

Networking

Electrical

Installation

Fire System

Integration

Mechanical

Installation Pre-Installation General

Information

Quick Start

Guide

21

20

Guy Wire Installation

IMPORTANT: Guy wires must be installed 45º to 60º

from vertical to ensure proper functioning.

Standard Steel Cable Clamp

Required Loose Components (Included):

• 6 m Guy Wire (4)

Required Components:

• Guy Wire Clamp Assembly (4)

• Guy Wire Clamp Bolt (4)

• Quick Link (8)

• U-Bolt Steel Cable Clamp (8)

• Turnbuckle (4)

Hardware/Tools Needed (Not Included):

• Level

• Torque Wrench

• Socket and Wrench

• Socket and Wrench

• Adjustable Wrench

• Cable Cutters (optional)

1. Secure guy wire clamps to the building structure

using the guy wire clamp bolts and an adjustable

wrench. Attach guy wires to the eyelets on the guy

wire clamp assemblies using (4) supplied quick

links.

DOWNTUBE & MOUNT ASSEMBLY

UG2 GRIPPLE®TURNBUCKLE

GUY WIRE

GUY WIRE

GUY WIRE

GUY WIRE CLAMP ASSEMBLY

GUY WIRE CLAMP BOLT

45º to 60º

UG2 GRIPPLE®TURNBUCKLE

GUY WIRE ATTACHMENT RING

QUICK LINK

2. Insert the loose end of each guy wire through the

eyebolt on a turnbuckle. Turn the guy wire back

onto itself and align the loose end of the guy wire

(referred to as the dead-end) with the length of

guy wire that is attached to the building structure

(referred to as the live-end).

3. Attach the dead-end of each guy wire to the live-

end using (2) of the supplied u-bolt steel cable

clamps. Loosely tighten the nuts on the steel cable

clamps, leaving enough room for the guy wire to

slide through the steel cable clamps.

IMPORTANT: The first steel cable clamp must be

installed a minimum of 140 mm away from the dead-

end of the guy wire to ensure proper functioning.

IMPORTANT: Steel cable clamps consist of two parts:

the u-bolt and the saddle. Steel cable clamps must be

installed with the u-bolt over the dead-end of the guy

wire and the saddle over the live-end of the guy wire.

Failure to install steel cable clamps in this manner may

result in unsafe operating conditions. Refer to drawing

below for correct orientation.

TURNBUCKLE

45° TO 60°

DOWNTUBE AND

MOUNT ASSEMBLY

GUY WIRE

CABLE CLAMP

QUICK LINK

EYEBOLT

BEAM CLAMP ASSEMBLY

140 MM MIN.

CABLE CLAMP U- BOLT

DEAD END

LIVE END

CABLE CLAMP SADDLE

O

4. Attach all (4) turnbuckles to the guy wire

attachment ring located on the downtube using

(4)supplied quick links.

5. Pull the dead-end of each guy wire through the

steel cable clamps until taut.

6. Tighten the nuts on the steel cable clamps using

a socket and torque to 54 inlbf (6.10 Nm),

alternating between nuts until reaching proper

torque.

7. Place a level against the downtube and tighten all

(4) turnbuckles by hand in a crisscross pattern until

the guy wires are tight and the fan is level.

NOTE: When leveling the fan, place the level against

the downtube in-between two neighboring guy wires

to simplify the leveling process. The level should also

be moved around the circumference of the downtube

periodically to ensure that the fan is level in all

directions.

8. Cut or organize excess guy wires to ensure that

they do not interfere with fan performance. Make

sure to leave at least 140 mm of wire between the

dead-end of the guy wire and the first wire rope

clip to ensure proper functioning.

Gripple®Hardware (Optional)

IMPORTANT: Guy wires must be installed 45º to 60º

from vertical to ensure proper functioning.

Required Loose Components (Included):

• 6 m Guy Wire (4)

• No. 4 Gripple®Connector (4)

Components required:

• Guy Wire Clamp Assembly (4)

• Guy Wire Clamp Bolt (4)

• Quick Link (8)

• Turnbuckle (4)

Hardware/Tools Needed (Not Included):

• Adjustable Wrench

• Level

• Allen Wrench (optional)

1. Secure guy wire clamps to the building structure

using the guy wire clamp bolts. Attach guy wires

to the eyelets on the guy wire clamp assemblies

using (4) supplied quick links.

DOWNTUBE & MOUNT ASSEMBLY

UG2 GRIPPLE®TURNBUCKLE

GUY WIRE

GUY WIRE

GUY WIRE

GUY WIRE CLAMP ASSEMBLY

GUY WIRE CLAMP BOLT

45º to 60º

UG2 GRIPPLE®TURNBUCKLE

GUY WIRE ATTACHMENT RING

QUICK LINK

2. Insert the loose end of each guy wire into a No. 4

Gripple connector until a length of wire is pushed

through the connector. Insert the loose end of the

guy wire through the end of the turnbuckle and

push back through the No. 4 Gripple connector to

close the loop.

3. Attach all (4) turnbuckles to the guy wire

attachment ring located on the downtube using

(4) supplied quick links. Pull the loose end of each

guy wire through the No. 4 Gripple connector until

each guy wire is taut.

TURNBUCKLE

45° TO 60°

DOWNTUBE AND MOUNT ASSEMBLY

GUY WIRE

No. 4 GRIPPLE CONNECTOR

QUICK LINK

EYEBOLT

BEAM CLAMP ASSEMBLY

4. Place a level against the downtube and tighten

all (4) turnbuckles by hand in a crisscross pattern

until the guy wires are tight and the fan is level.

NOTE: When leveling the fan, place the level against

the downtube in-between two neighboring guy wires

to simplify the leveling process. The level should also

be moved around the circumference of the downtube

periodically to ensure that the fan is level in all

directions.

5. Cut or organize excess guy wires to ensure that

they do not interfere with fan rotation.

NOTE: If necessary, the guy wires can be loosened by

inserting the long end of a 1/16 in. allen wrench into

either of the pin holes on the No. 4 Gripple connector

and pulling the cable in the opposite direction of the

arrow marked on the Gripple connector.

Airfoil Blade and Winglet Installation

IMPORTANT: Do not operate fans without the airfoil

blades. Failure to comply with this warning will result

in voiding of the product warranty and may result in

permanent damage to the VFD and motor.

WARNING

To reduce the risk of personal injury, do not bend

motor struts, airfoil blades, or airfoil retaining links

when installing the airfoil blades, balancing the blades,

or cleaning the fan. Damage to these components may

result in unsafe operation of the fan, which can lead

to property damage, personal injury or death. Contact

your local representative or the factory if replacement

parts are needed.

WARNING

To reduce the risk of personal injury, do not insert

foreign objects in between rotating fan blades.

Required Loose Components (Included):

• Airfoil Blade (6)

• Winglet (6)

Required Components:

• #10 – 12 x 3/4 in. Screw (12)

• Washers (24)

• Grade 8 Nylon Locknut (12)

• Grade 8 Hex Bolt (12)

Hardware/Tools Needed (Not Included):

• Socket and Socket Wrench

• Wrench

• Torque Wrench

• #2 Phillips Bit and Driver

Reference Troubleshooting Operation And

Maintenance

Fan

Networking

Electrical

Installation

Fire System

Integration

Mechanical

Installation Pre-Installation General

Information

Quick Start

Guide

Quick Start

Guide

General

Information Pre-Installation Mechanical

Installation

Fire System

Integration

Electrical

Installation

Fan

Networking

Operation And

Maintenance Troubleshooting Reference

23

22

1. Install one winglet per airfoil blade using the screw

bosses located in each blade on the opposite end

from the mounting holes. Use a #2 phillips bit to

install (2) screws per winglet. Torque screws to 60

inlbf (6.8 Nm).

AIRFOIL BLADE

SCREW BOSSES

WINGLET

SCREW

(2 PER BLADE)

NOTE: Improperly fastened winglets may result in

unwanted noise.

2. Lift the first blade into place, and slide over the

motor strut allowing the airfoil retaining ring

to rest on top of the airfoil blade. It might be

necessary to use two people for this step.

5/16 in. WASHER

(2 PER BLADE)

5/16 in. - 18 GRADE 8 NYLON LOCKNUT

(2 PER BLADE)

MOTOR & HUB ASSEMBLY

5/16 in. - 18 x 2 GRADE 8 HEX BOLT

(2 PER BLADE)

MOTOR STRUT

AIRFOIL BLADE

AIRFOIL RETAINING RING SHIM

AIRFOIL BLADE

AIRFOIL RETAINING RING

AIRFOIL RETAINING RING

3. With the blade in position on the motor strut,

install (2) hex bolts, (4) washers, and (2) 18 nylon