5

All models are shipped from the factory with the

following:

1. Zero clearance to combustibles

2. Multi-speed direct-drive blower.

3. Blower Speed Relay.

4. Horizontal or Down flow duct connections.

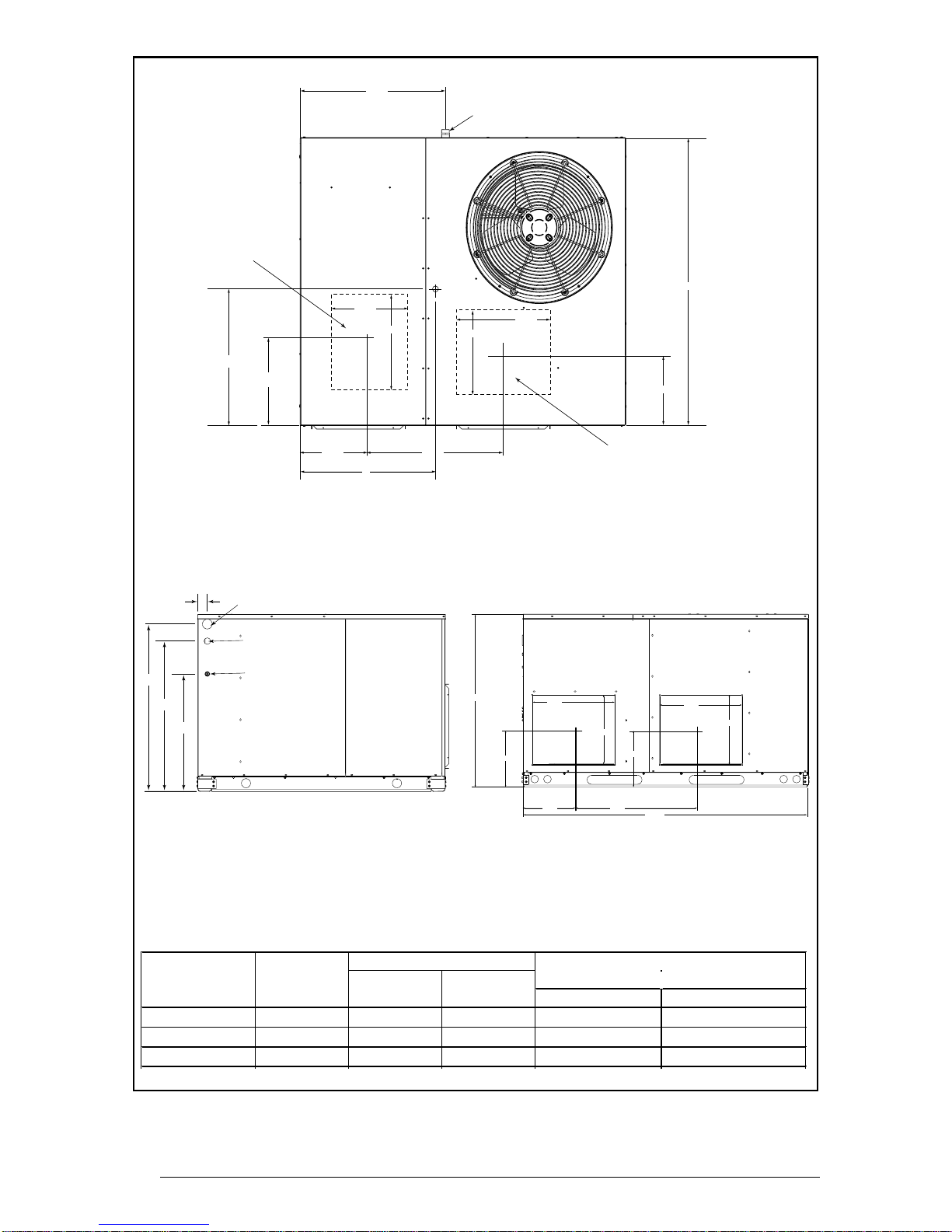

The unit dimensions are shown in Figure 3.

Optional field-installed electric heater kits are

available in 9 kw and 15 kw heating capacities.

A separate installation instruction document for

the electric heaters and their application

accompaniesthisone. Atwostageheat24VAC

thermostat should be used with electric heater

kits installed.

SAFETY CONSIDERATIONS

It is the responsibility of the installer to ensure

that the installation is made in accordance with

all applicable local and national codes.

!WARNING:

Improper installation, service,

adjustment,ormaintenancemaycause

explosion,fire,electricalshockorother

hazardousconditionswhichmayresult

in personal injury or property damage.

Unless otherwise noted in these

instructions, only factory authorized

kits or accessories may be used with

thisproduct. Noncompliancemayvoid

the unit’s warranty.

Labels, Tags —When working with this

equipment, follow all precautions in the

literature, on tags, and on labels provided with

the unit and/or approved field installed kits.

The type of hazard and severity are described

on each label or tag.

Pressures Within The System —This

equipment contains liquid and gaseous

refrigerant under high pressure. Installation or

servicing should only be performed by qualified

trained personnel thoroughly familiar with this

type equipment.

INSTALLATION REQUIREMENTS

Equipment Check —Before beginning the

installation, verify that the unit model is correct

for the job. The unit model number is printed on

the data label. All units have been securely

packaged at the point of shipment. After

unpacking the unit, carefully inspect it for

apparent and concealed damage. Claims for

damage should be filed with the carrier by the

consignee.

RequirementsandCodes—Theinstallermust

comply with all local codes and regulations

which govern this type equipment. Local codes

and regulations take precedence over any

recommendations contained in these

instructions. All electrical wiring must be made

in accordance with local codes and regulations

andwiththeNationalElectricCode(ANSI/NFPA

70) or in Canada the Canadian Electric Code

Part 1 CSA C.22.1. Air Ducts must be installed

inaccordancewiththestandardsoftheNational

Fire Protection Association “Standards for

Installation of Air Conditioning and Ventilation

Systems”(NFPA90A),“StandardforInstallation

of Residence Type Warm Air Heating and Air

Conditioning Systems” (NFPA 90B), these

instructions and all applicable local codes.

NFPA publications are available by writing:

National Fire Protection Association

Batterymarch Park

Quincy, Maine 02269

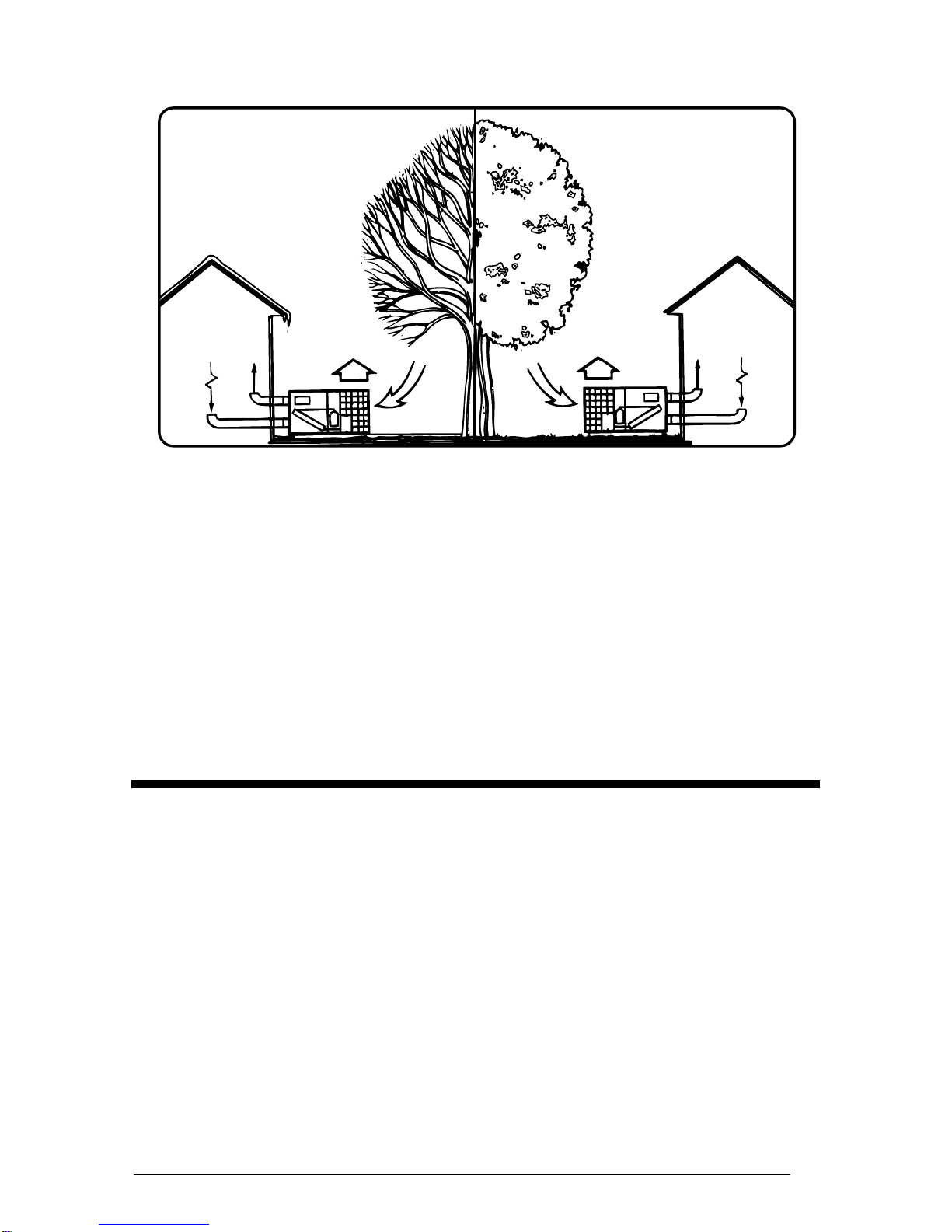

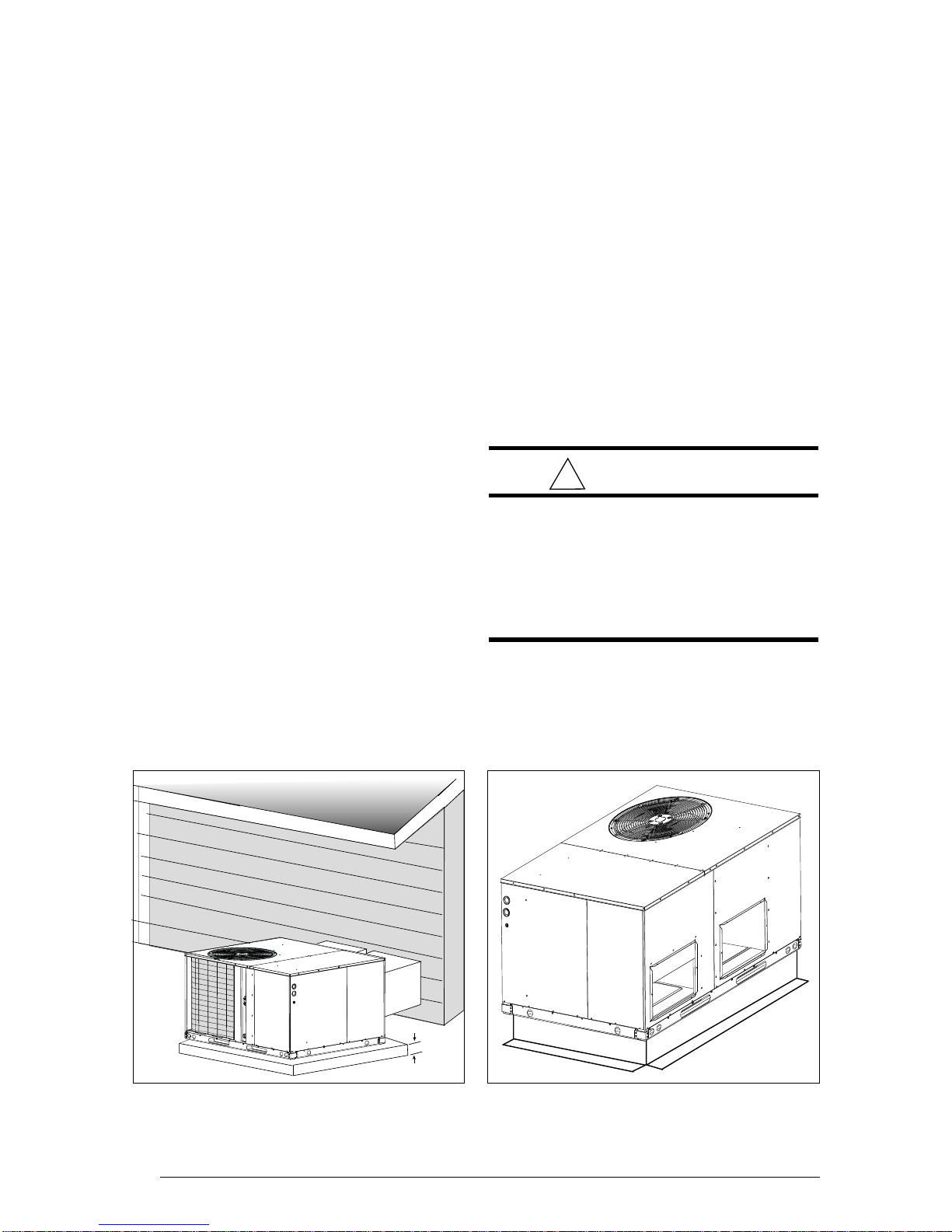

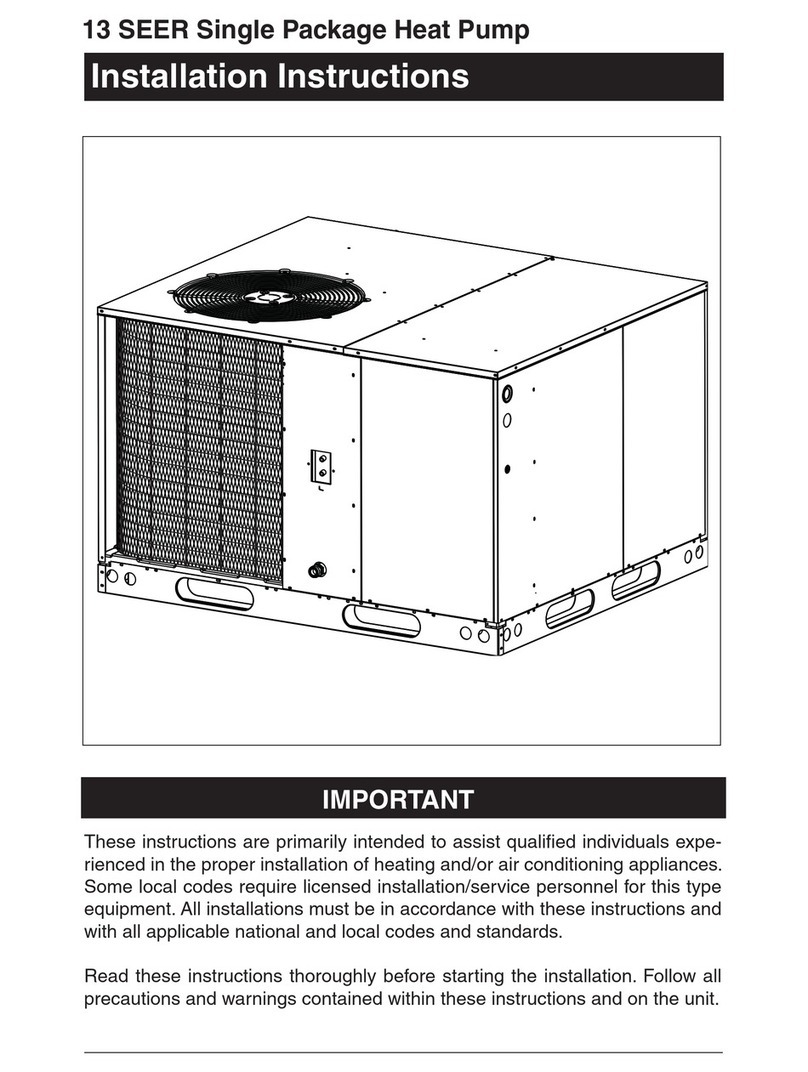

Unit Location —The Q4 series heat pump is

designedonlyforoutdoorinstallations.Choosing

the location of the unit should be based on

minimizing the length of the supply and return

ducts. Consideration should also be given to

availability of electric power, service access,

noise, and shade. Sufficient clearance for

unobstructed airflow through the outdoor coil

must be maintained in order to achieve rated

performance See Figure 4 for minimum

clearances to obstructions.

AirFilters—Asuitableairfiltermustbeinstalled

in the return air system. Air filter pressure drop

must not exceed 0.08 inches w.c. at 300 fpm.

Condensate Drain —Condensate is removed

from the unit through the 3/4" female pipe fitting

locatedonthefrontsideoftheunit. (SeeFigure

5.) Install a 2 inch condensate trap in the drain

line of the same size and prime with water.

Whenconnectingrigiddrainline,holdthefemale

fitting with a wrench to prevent twisting. Do not

over tighten! Refer to local codes and

restrictions for proper condensate disposal

requirements.