Nordyne CMF80-PG Operating instructions

Owners Manual/Installation Instructions

CMF80-PG Convertible (65, 75, and 90 KBTU/H Inputs),

CMF 100-PG (90 KBTU/H Input)

CMF80-PO Convertible (65, 75, and 90 KBTU/H Inputs),

CMF 100-PO (90 KBTU/H Input)

Counterflow Gas or Oil Heating Appliance

Read all instructions carefully before beginning the installation. Read all labels and tags

on the furnace carefully and follow all precautions outlined on those labels and tags.

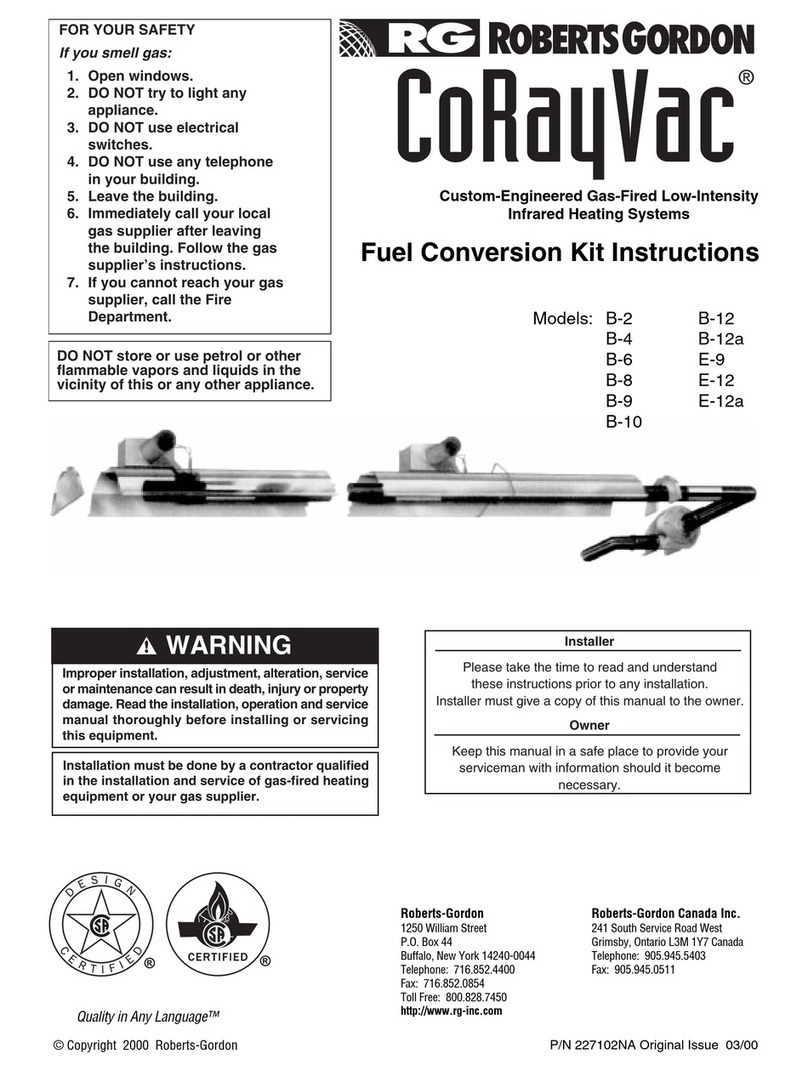

FOR YOUR SAFETY

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

!

WARNING:

Improper installation, alteration, ser-

vice or maintenance can cause injury

or property damage. Refer to this

manual for assistance or consult a

qualified installer, service agency, or

the gas supplier for additional infor-

mation.

FOR YOUR SAFETY

WHAT TO DO IF YOU

SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

neighbor’sphone.Followthegassupplier’s

instructions.

• If you cannot reach your gas supplier, call

the fire department.

Rated CMF-PG CMF-PO CMF-PG CMF-PO

BTUH 80 CONV. 80 CONV. 100 100

Input 75,000 75,000 90,000 90,000

Output 56,000 60,000 68,000 72,000

GENERAL

CMF furnaces are high quality, direct vent

furnaces used for manufactured housing, rec-

reational vehicle, and residential†applications.

These furnaces are offered in either power gas

(designated by PG) or power oil (designated by

PO) models. The power gas models are de-

signed for operation with either natural or pro-

pane (LP) gas.

The CMF series is convertible from power oil to

power gas, and vice versa. Furthermore, the

firing rate of the CMF80 Convertible Series can

be changed using a certified NORDYNE

conversionkitfield-installedbyaqualifiedservice

technician. Refertothe“FiringRateConversion”

section later in these instructions for more

information on the firing rate change.

These furnaces are certified to the UL307

standards (UL 307A for oil models; UL 307B for

gasmodels),andcanbeinstalledinavarietyof

applications,asshowninTable1. Thisfurnace

is not to be used for temporary heating of

buildings or structures under construction.

!WARNING:

This furnace must be installed by a quali-

fied installing agency and in accordance

with applicable local codes and ordi-

nances that govern this type of equip-

ment. Failure to properly install the fur-

nace, base assembly, and venting sys-

tem as described herein may damage the

equipment and/or the home, can create a

fire or asphyxiation hazard, violates U.S.

listing requirements, and will void the

warranty. This furnace is NOT approved

for installation with split system air con-

ditioning. Use a NORDYNE packaged air

conditioning system.

2

!WARNING:

Do not use this appliance if any part has

been submerged under water. Immedi-

ately call a qualified service technician to

inspect the appliance and to replace any

part of the control system and any gas

control that has been submerged under

water.

INSTALLATIONREQUIREMENTS

Equipment Check

All units are securely packaged at the time of

shipment and should be carefully inspected

upon arrival for damage. Claims for damages

(apparent or concealed), shortage in shipment,

ornondeliveryshouldbefiledimmediatelyagainst

the carrier by the consignee. The carrier is

responsible for making prompt inspection of

damage and for a thorough investigation of

each claim. The manufacturer will not accept

claims for transportation damage.

Requirements and Codes:

Installershallbefamiliarwithandcomplywithall

codes and regulations and applicable to the

installation of these heating appliances and

related equipment.

All manufactured housing installations must

conform with these instructions, all applicable

local codes, ANSI Z223.1/NFPA 54 (National

Fuel Gas Code), ANSI/NFPA 31 (Installation of

Oil Burning Equipment), ANSI/NFPA 70

(National Electrical Code), the Manufactured

Home Construction and Safety Standard, Title

24 CFR, part 3280, or when this standard is not

applicable,thestandardforManufacturedHome

Installations (Manufactured Home Sites,

Communities, and Set-ups), ANSI 225.1.

All residential installations (Refer to Table 1)

must conform with these instructions, all

applicable local building codes, ANSI Z223.1/

NFPA 54 (National Fuel Gas Code), ANSI/

NFPA31(InstallationofOil-BurningEquipment),

ANSI/NFPA70 (National Electrical Code), and

NFPA 211 (Chimneys, Fireplaces, Vents, and

Solid Fuel-Burning Appliances).

The National Fuel Gas Code is available by

writing:

American National Standards

Institute, Inc.

1430 Broadway

New York, NY 10018

NFPA publications are available by writing:

National Fire Protection Association

Batterymarch Park

Quincy, ME 02269

Combustion Air and Ventilation

Requirements

Provisions for adequate combustion air and

ventilation air must be in accordance with the

ANSI Z223.1/NFPA 54, (National Fuel Gas

Code),ANSI/NFPA31(InstallationofOilBurning

Equipment), and all applicable local codes.

Depending upon the type of installation (See

Table 1), the CMF furnace can draw the

combustion air either from outside the home

(directvent)orfromthespacebeingconditioned.

A direct vent system is one in which the flue

products are exhausted to and the combustion

air is drawn from outside the house. A direct

vent system can also be referred to as a sealed

combustion system.

Type of Ducted Direct Vent Furnace Flue Products

Installation Application System Required Base Used Exhausted By

Manufactured

Housing or Yes Yes

Recreational Vehicle MA-100 or MA-200 NORDYNE SRJ Roofjack or

Universal Base an Existing Chimney*

CB-200A Cottage NORDYNE SRJ Roofjack or

Base an Existing Chimney*

CB-200A Cottage NORDYNE SRJ Roofjack or

Base an Existing Chimney*

†Residential is only defined as a single-story non-manufactured housing installation.

*Refer to the "Venting Requirements" section later in these instructions for more details on properly venting this appliance

throu

g

h an existin

g

chimney.

MA-100 or MA-200

Universal Base NORDYNE SRJ

Roofjack Only

Yes

No

Yes

Yes

Residential

†

Residential

†

Residential

†

Yes

No

Table 1

3

Fordirectventapplicationseitherthecombustion

air duct provided with the MA Series base kit or

the direct vent kit can be used. The direct vent

kit must be ordered separately. Only for a

special CB-200A cottage base installation can

the CMF draw the combustion air from the

conditionedspace. TheCB-200Acottage base

kit must be ordered separately. Refer to the

replacement parts listing provided with the

furnacetoorderthedirectvent kitorthe cottage

base kit. Follow the instructions provided with

the kits for proper installation.

When unsure about combustion air supply

availability, a direct vent system should be

used. For small rooms, confined spaces, tight

construction or similar situations in which the

combustion air requirements of the furnace

might not be met, a direct vent system must be

used. Theairopeningsinthedooroftheunitand

the warm air registers from the ductwork or

base must not be restricted.

Combustion air must not be drawn from a

contaminated atmosphere. Excessive

exposure to contaminated combustion air will

result in safety and performance related

problems. Some examples of chemical

contaminants are chlorine, fluorine, and sulfur,

which can be found in a wide variety of some

common commercial and household products.

The installation of the furnace must allow for an

adequate supply of combustion air. The

combustion air opening of the furnace must be

designed and located to prevent blockage by

snow.

When drawing the combustion air from

underneaththehome,ensurethataventorduct

of at least 18 square inches of free area is

providedfromoutside. Checktoensurethatthe

combustion air opening is unobstructed. When

using the combustion air duct, ensure that it

extends through the floor. When using the

direct vent kit, the combustion air opening must

belocatedinthesamepressurezoneastheflue

exit of the roof jack or chimney. Refer to the

instructions provided with the direct vent kit for

more information.

Venting Requirements — Manufactured

Housing Installations

For all manufactured housing applications, the

CMF furnace must be vented using the SRJ

series roofjack. The instructions for selecting

the proper roofjack for your installation are

detailed later in these instructions.

Venting Requirements — Residential

Installations

!WARNING:

This furnace is not to be connected to a

chimney flue serving a separate appli-

ance designed to burn solid fuel.

For residential applications (Refer to Table 1),

the CMF furnace may be vented through the

SRJ series roofjack or through an existing

chimney. Ifthe SRJ roofjack is to be used, then

theinstructionsfor selectingtheproper roofjack

for your installation are detailed later in these

instructions. If venting through an existing

chimney,thentheventingsystemusedmustbe

in accordance with these instructions, all

applicable local building codes, ANSI Z223.1/

NFPA 54 (National Fuel Gas Code), ANSI/

NFPA31(InstallationofOil-BurningEquipment),

and NFPA 211 (Chimneys, Fireplaces, Vents,

and Solid Fuel-Burning Appliances).

!WARNING:

When venting through a chimney, check

the chimney for soot, leaks, obstruc-

tions, and proper installation.

The materials used to construct the venting

system must be capable of withstanding

exposuretotemperaturesofatleast700degrees

F. The existing chimney servicing this furnace

must be vertical. Horizontal distances to an

existing chimney must be as short as possible,

and the connecting pipe must slope upward to

the chimney at not less than a 45 degree angle.

The total length of the sloping pipe must not

exceed 6 feet. The venting system must have

no obstructions or sharp bends where soot and

other foreign matter can accumulate.

If an inspection determines that the chimney is

obstructed, the chimney must be cleaned.

Furthermore, the connecting flue pipe must be

cleaned or replaced.

For ONLY a CMF power oil furnace installation

vented into an existing chimney, a barometric

damper can be installed at the vent connection

ofthefurnacetoregulatethedraft. Thebarometric

damper must be properly installed per the

manufacturer’s instructions. Refer to all

applicable codes to determine whether or not a

4

barometric damper can be used for your CMF

power oil furnace installation. The barometric

damper used must be installed such that air

from the conditioned space can only enter the

flue passageway. Do not use a double acting

barometricdamper. Allfluepipejointsshouldbe

fastened with sheet metal screws for rigidity.

Thechimneyheight,requireddraft,andnumber

of appliances served by the chimney must be

in accordance with all applicable codes. To

prevent down draft, the chimney should extend

at least two feet above the peak of the roof.

It is recommended that the furnace flue serve

nootherappliances. Whenthechimneyserves

only the furnace, the flue area must be sized

accordingtoallapplicablecodes. Theminimum

internalareaofthefluemustbeequaltoatleast

the area of the furnace flue exit.

Whentwoormoreappliancesmustventthrough

a common flue, the area of the common flue

shouldbesizedinaccordancewithallapplicable

codes.

Whenanexistingfurnaceisremovedorreplaced

in a venting system, then the venting system

may not be properly sized to vent the attached

appliances. The venting system must be

checked to ensure proper venting. Improperly

sizedventingsystemscanresultintheformation

of condensate, leakage, spillage, et cetera.

Refer to the ANSI Z223.1/NFPA 54, (National

FuelGasCode),andANSI/NFPA31(Installation

of Oil Burning Equipment) for correcting any

improperly operating venting system.

The following steps shall be followed with each

appliance connected to the venting system

placed in operation, while any other appliances

connected to the venting system are not in

operation:

(a) Seal any unused openings in the venting

system.

(b) Inspect the venting system for proper size

and horizontal pitch, as required in the

ANSIZ223.1/NFPA54,(NationalFuelGas

Code) and ANSI/NFPA 31 (Installation of

Oil

Burning Equipment), and these instruc-

tions. Determine

that there is no blockage or restriction,

leakage, corrosion

orotherdeficiencieswhichcouldcausean

unsafe condition.

(c) In so far as is practical, close all building

doors and windows and all doors between

the space in which the appliance(s) con-

nected to the venting system are located

and other spaces of the building. Turn on

clothes dryers and any appliance not con-

nectedtotheventing system. Turnon any

exhaust fans, such as range hoods and

bathroom exhausts, so they shall operate

at maximum speed. Do not operate a

summer exhaust fan. Close fireplace

dampers.

(d) Follow the lighting instructions. Place the

appliance being inspected in operation.

Adjustthermostat so applianceshall oper-

ate continuously.

(e) Test for draft hood equipped appliance

spillage at the draft hood relief opening

after 5 minutes of main burner operation.

Use the flame of a match or candle.

(f) After it has been determined that each

appliance connected to the venting sys-

tem properly vents when tested as out-

lined above, return doors, windows,

exhaust fans,fireplace dampers and any

other gas burning appliance to their previ-

ous conditions of use.

Flashing

Barrel

Ceiling Plate

Vent

Ventilation

Knock-Out

DUCT

CONNECTOR

Return Air

Grille and

Filter

Power Supply

Connection

Access

Door

Base Pan

Fuel Line

Feeder Duct

Combustion

Air Duct

FURNACE

ASSEMBLY

ROOF JACK

ASSEMBLY

Combustion Air

Adapter (Not Shown)

is to be Installed

Over Combustion

Air Duct

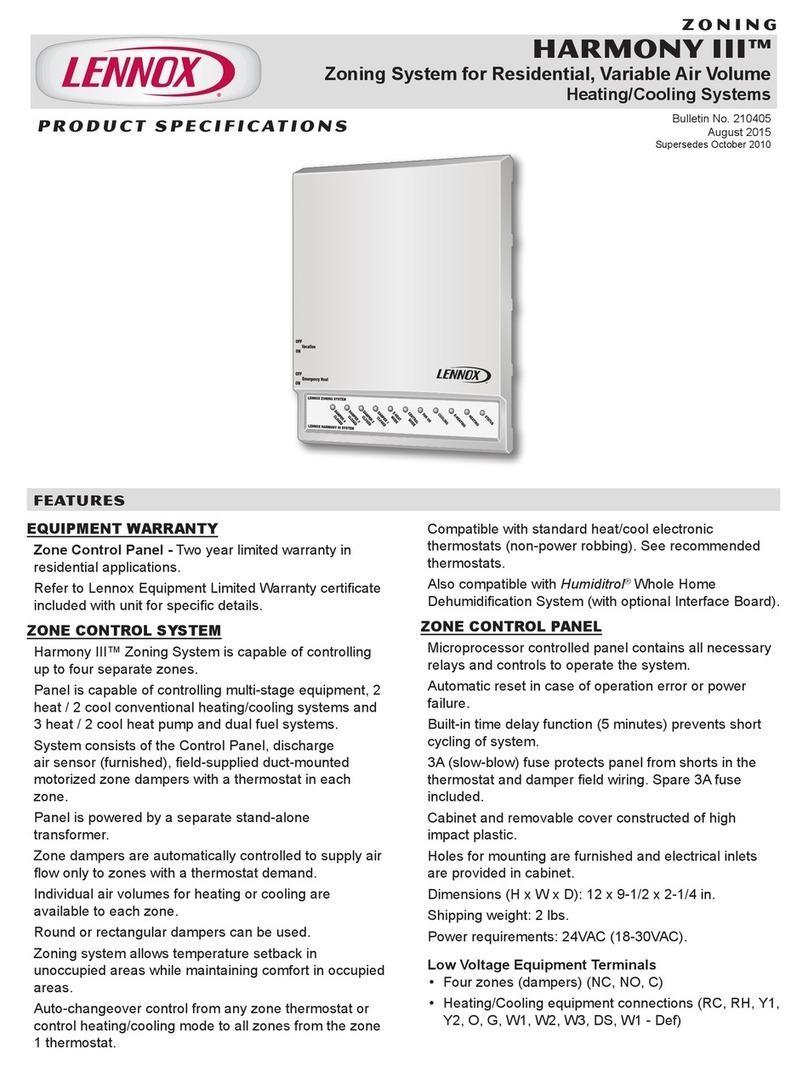

Figure 1. Typical Furnace Installation for

Manufactured Housing Applications

5

(g) If improper venting is observed during any

of the above tests, the venting system

must be corrected.

Unit Location and Clearance to Adjacent

Material Requirements

Theunitmustbeinstalledinalevelposition. The

furnace must be installed with the minimum

clearancesfrom adjacent materials as stated in

Table2. Additionalclearanceshouldbeprovided

to permit servicing of filters, blower, motors,

controls, combustion air connections, and vent

connections.

UNIT INSTALLATION

These instructions are intended for the use of

qualified individuals specially trained and

experiencedininstallationofthistypeequipment

and related system components. Installation

and service personnel are required by some

governing bodies to be licensed. Persons not

qualified should not attempt to install this

equipment or interpret these instructions.

MA-200 Base Installation

The MA-200 base is designed for O.E.M. and

replacement installation of the CMF series fur-

nace (see Figures 2 and 3). The warm air duct

system should be designed so the duct static

pressure external to the furnace does not

exceed the static pressure listed on the furnace

data label.

Use the base pan to mark the 12-1/8" x 12-1/

8"centeropeningforthefeederduct. Whenthe

4" offset feeder duct is used, the floor opening

will be offset 4 inches from the opening in the

main duct. If using the combustion air duct,

select and knock out the combustion air open-

ing to be used. Then mark the 2-1/4" x 7-1/4"

opening for the combustion air duct.

Cuttheopeningforthefeederduct14-1/8"x14-

1/8" in flooring (cutting opening 1" larger all the

waywillallowtheflangesontheundersideofthe

base pan to fit in the opening).

Ifusingthecombustionairduct,cuttheopening

for the duct about 1/8" larger than the marking

onthefloor. Besuretocutthroughallinsulation

andthebottomboardsothatthecombustionair

duct is unobstructed to outside air.

Drillanapproximate1"diameterholeforthefuel

line through the floor and bottom board to the

outside. Fuel lines are not supplied with the

furnace. They should be installed to comply

with all applicable codes.

Drop transition or offset feeder duct upside

down through the floor opening and center the

top of the feeder duct in 14-1/8" x 14-1/8" floor

opening. Usingthefeederductasaguide,mark

and cut a 12" x 12" opening in the distribution

duct. (See Figure 3)

Insert the feeder tabs into the main duct and

bend them over tightly so that the main duct

edges are trapped between flanges and tabs.

Metal tape may also be used to ensure an air

tight connection.

** See Item K in the "Closet Installation of

Furnace" section later in these instruc-

tions for clearance less than 6".

Table 2. Minimum Clearances

to Adjacent Materials

Closet Alcove

ALL MODELS Installation Installation

Sides 0" 0"

Back 0" 0"

Front 6"** 18"

Top 17" 17"

Vent 6" 6"

Ductwithin 3’from Furnace 1/4" 1/4"

Plenum 1" 1"

Roof Jack Barrel 0" 0"

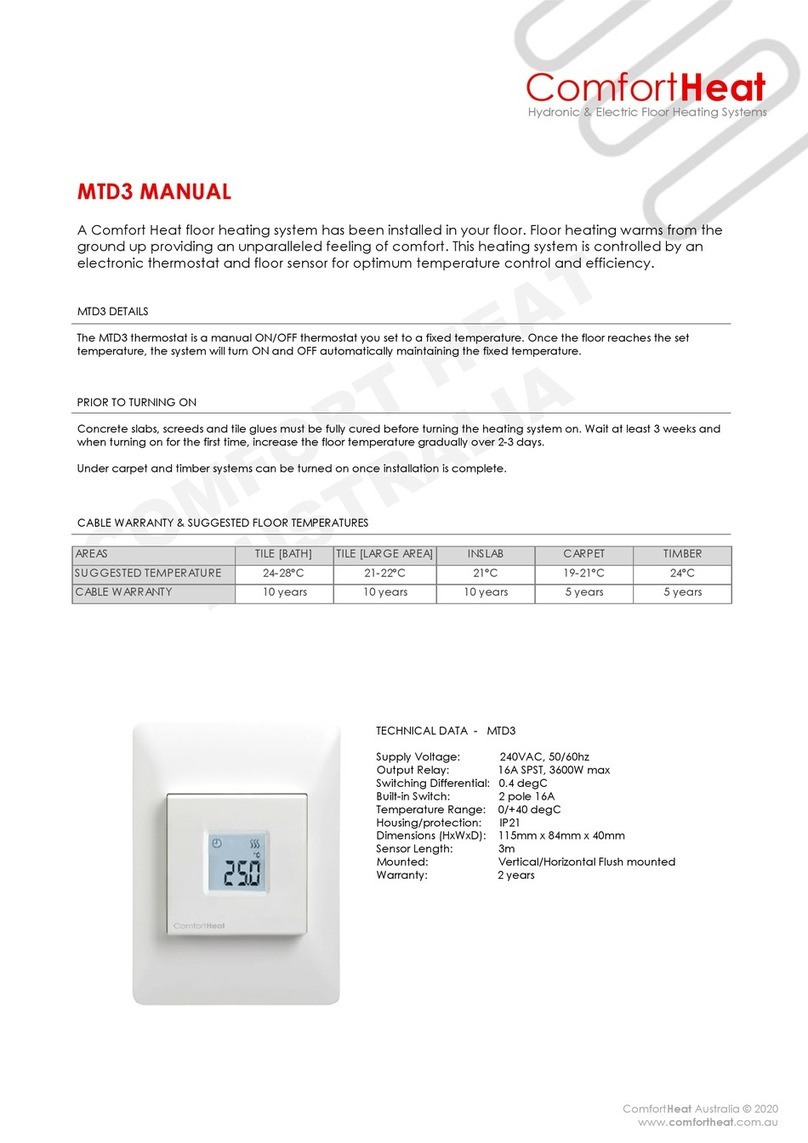

Figure 2. MA-200 Base Pan

FRONT

7-1/8 X 2-3/16 Knock-outs

Combustion Air

Feeder Duct

Opening

Flue

Location

24-1/8

8-3/8

12-1/8

12-1/8

9-1/8 18-1/4

6

Installthe base pan around the feeder duct with

the (2) screws through the holes towards the

rear of the base pan.

Slit the corners of the feeder duct down to the

top of the base pan. While the top of the

distributionductispulledupwithonehand,bend

down each side of the feeder duct tightly to the

basewiththeotherhand. Trimthemetaltoallow

a one inch flange over the top of the base pan

and seal that flange with the metal tape.

If a “V”or “U”-box crossover system is to be

used, see the instructions provided with the

crossover system.

Figure 4. MA-100 Universal Base,

Bottom Panel

12-1/8

12-1/8

Feeder Duct

Opening

7-1/8 X 2-3/16 Knock-outs

Combustion Air

18-1/4

24-1/2

Figure 5. Feeder Duct Installation

Heat Duct Below Joists

Base Feeder Duct

Floor

Joists

Cut This Line

Bend Over

Along This Line

1"

Figure 3. Transition and Offset Ducts

Heater Duct Below Joists

Flange

Bend Over Tabs

Base

Floor

Joists

Slit 4 Corners Bend Down 4 Sides

TRANSITION

DUCT

Floor

Joists

Heater Duct Below Joists

Bend Over Tabs

Flange

Slit 4 Corners

Base

Bend Down 4 Sides

MA-100 Universal Base Installation

The MA-100 base is designed primarily for

replacement installation of the CMF series fur-

nace where the manufactured home duct sys-

tem may be small and restrictive to proper air

flow. The MA-100 base provides approxi-

mately four (4) inches of additional plenum

spacebeforethedischargeairentersthemanu-

factured home duct system. (See Figures 4

and 5)

Use the bottom panel of the base assembly to

mark the 12-1/8" x 12-1/8" center opening for

thefeederduct. Ifusingthecombustionairduct,

select and knock out the combustion air open-

ing to be used. Then mark the 2-1/4" x 7-1/4"

opening for the combustion air duct.

Cuttheopeningforthefeederduct14-1/8"x14-

1/8" in flooring (cutting opening 1" larger all the

way around 12-1/8" x 12-1/8" template mark-

ing). This will allow the four flanges on the

underside of the panel to fit into the opening.

Ifusingthecombustionairduct,cuttheopening

for the duct about 1/8" larger than the marking

onthefloor. Besuretocutthroughallinsulation

andthebottomboardsothatthecombustionair

duct is unobstructed to the outside air.

Drilla1"holeforthefuellinethroughthefloorand

bottom board to the outside. Fuel lines are not

supplied with the furnace. They should be

installed to comply with local codes.

Put the bottom base panel in place (See Figure

5). Dropthe transition feeder duct upside down

through the opening and mark a 12" x 12"

opening to be cut into the distribution duct.

Remove the bottom panel and transition feeder

duct; then cut the opening into the distribution

duct.

7

Damper Installation

An automatic shut-off damper is available (see

replacement parts list). An automated shut off

damper is required when the home is air con-

ditioned by a self-contained unit. This damper

is designed to fit in the feeder duct cavity,

directlyunderthefurnace. Adamperisrequired

to prevent chilled air from flowing over the

furnace heat exchanger. For proper installa-

tion, refer to the instructions provided with the

damper.

Installation of Furnace onto the MA-200

Base

Lift the furnace over the base so that the flange

at the back comes to rest on the inside rails of

the base.

Raisethefrontofthefurnacetoclearthegasket

on the bottom of the furnace and slide the back

untiltherearflangedropsintothechannelatthe

rear of the base. Be careful not to damage the

combustion air adapter, if present, while posi-

tioning the unit.

Be sure that the furnace is all the way back so

as to engage the tabs on the rear flange on the

base.

Open the access door. Fasten the front of the

furnace and the base to the floor with #8 x 1/2"

long sheet metal screws.

Using the provided hose clamp, secure the

flexiblecombustionairtubingfromtheburnerto

the combustion air adapter.

Installation of Furnace onto the MA-100

Base

Tilt the furnace forward and carefully work the

furnace back over the MA-100 Universal base.

Lift the furnace as necessary when positioning

the unit over the base assembly to prevent any

damage to the feeder duct assembly and com-

bustion air adapter, if present.

Be sure the furnace is positioned all the way to

the back of the base assembly.

Open the furnace door and fasten the furnace

to the base using #8 x 1/2" long sheet metal

screws.

Installthefeederductbybendingthetabsinside

theheatductand using the metal tape to insure

an airtight connection.

Setthe bottom basepanel over thefeederduct.

Slit the corners of the feeder duct down to the

topof the base. While the top of the distribution

ductispulledupwithonehand,benddowneach

sideofthefeederducttightlytothebasewiththe

other hand. Trim the metal to allow one inch

flange over the top of the base and seal that

flange with the metal tape.

Secure the top panel to the floor with two (2)

screws through the front flange.

If a “V”or “U”-box crossover system is to be

used, see the instructions provided with the

crossover system.

Combustion Air Duct/Pipe Installation

TheCMFfurnacemustdrawthecombustionair

from outside, except for special installations

(SeeTable1). Thiscanbeaccomplishedeither

by using the 2”X7”rectangular combustion air

ductprovidedintheMAseriesbasekitsorusing

the direct vent kit.

When the rectangular combustion air duct is to

be used, install the combustion air duct through

the selected knockout in the base. For direct

vent applications, the rear knock-out in the

furnace base cannot be used. After the

combustionairducthasbeenpositioned,install

the combustion air adapter. This adapter will

transition the 2”X7”opening of the combustion

air duct to the 2”diameter of the burner flexible

tubing. ThisadapterisincludedintheMAseries

base kits. For retrofit applications in which the

MA series base is already installed, the

combustion air adapter can be ordered as a kit.

Refer to the Replacement Parts List for more

details on ordering this kit.

Secure the adapter with either wood or metal

fasteners (field provided), depending upon the

particular installation. Ensure that the gasket

for the adapter is positioned properly before

installing the adapter. Attach the flexible hose

from the burner to the combustion air adapter

using the provided metal hose clamp.

When the direct vent kit is used, follow the

instructions provided with the kit. Note: The

direct vent kit should be installed before

positioning the furnace on the base.

8

Using the provided hose clamp, secure the

flexiblecombustionairtubingfromtheburnerto

the combustion air adapter.

CB-200A Cottage Base Installation

TheCMFcanbeinstalledonaCB-200Acottage

baseincertainapplications,asdescribedearlier

intheseinstructions (SeeTable1).Refertothe

Replacement Parts List for information on

ordering this base. For installation, refer to the

instructionsthatare provided with the CB-200A

base kit.

Closet Installation of the Furnace

Returnairsystemsforaclosetinstallationofthe

furnace may consist of a grille or grilles in a

closet door or side wall that

communicates with the living area of the home.

(See Figure 6) Return air openings should not

be located to draw air directly from a bathroom.

Grilles placed in a side wall require a 6" clear-

ance from the wall to the furnace so that the air

may enter the front grille of the furnace. In

addition, all return air systems, including the

floorand ceiling systems, must meet thefollow-

ing conditions:

A. The return-air opening into the closet,

regardless of its location, is to be a mini-

mum of 200 square inches.

B. If the return-air opening is located in the

floor of the closet (versus the vertical front

or side wall), the opening is to be provided

with means to prevent its inadvertent clo-

sure by a flat object placed over the open-

ing.

C. The cross-sectional area of the return

duct system (when located in the floor or

ceilingof the manufacturedhome) leading

into the closet is to be not less than 200

square inches.

D. The total free area of the openings in the

floor or the ceiling registers serving the

returnairductsystemistobenotlessthan

300 square inches. At least one such

register is to be located where the likeli-

hood of its being covered by carpeting,

boxes, and other objects is minimized.

E. Materialslocatedinthereturnductsystem

shall have a flame spread classification of

200 or less.

F. Noncombustible pans having one inch

upturned flanges are located beneath

openings in a floor return duct system.

G. Hollow spaces used as ducts or plenums

forenvironmentalairmay containmineral-

insulatedmetalsheathedcable,aluminum

sheathed cable, electrical metallic tubing,

rigid metal conduit, flexible metal conduit

not to exceed four (4) feet, or metal-clad

cables. Wiring materials, fixtures, are to

be suitable for the expected ambient

temperatures to which they will be sub-

jected.

H. Gas piping cannot be located in the return

duct system.

I. The negative pressure in the closet must

not be less than minus 0.05 inches water

columnwiththeclosetdoorclosedandthe

fan operating at high speed. A reading

below minus 0.05" indicates a dirty filter or

a restricted return air system.

Figure 6. Closet Installation

9

J. For floor return systems, the manufac-

tured housing manufacturer or installer

shall affix a prominent marking on or near

the appliance where it is easily read when

theclosetdoor is open. The marking shall

read: “CAUTION, HAZARD OF AS-

PHYXIATION. DO NOT COVER OR

RESTRICTFLOORRETURNAIR OPEN-

ING.”orequivalent. (Thislabelis supplied

with the instruction manual in each fur-

nace.)

K. For closet installation with less than 6"

front clearance, but not less than 1", a

louvered door must be used having a

minimum 200 square inch free area open-

ing directly in line with openings in the

furnacedoor. A fullylouvered door having

the minimum free area is also permitted if

the front tolerance is not less than 4".

Adjust duct registers to obtain a tempera-

ture rise within the range specified on the

furnace nameplate.

!

WARNING:

Failure to comply with the above proce-

dure and the following instructions may

result in fire, asphyxiation or carbon

monoxide poisoning.

SRJ Roof Jack Installation

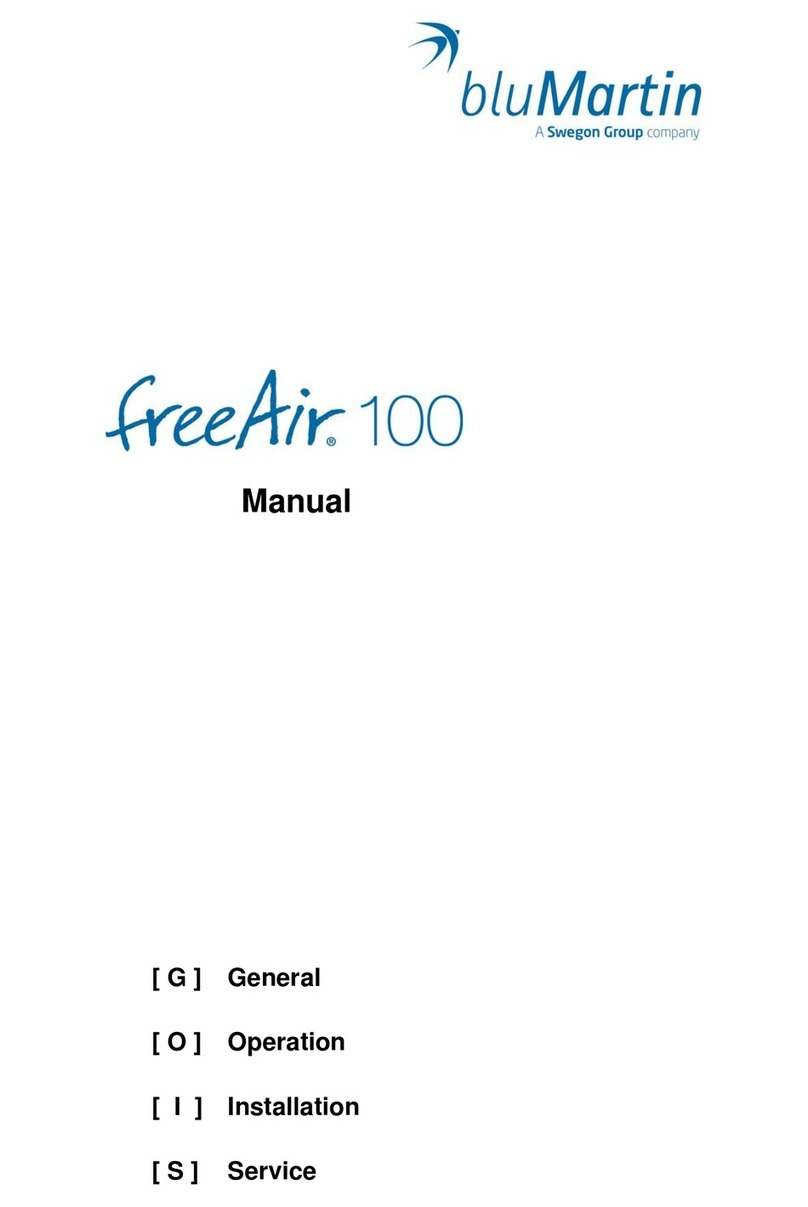

Refer to Figure 7 to determine SRJ roof jack

and appropriate accessories required for

your installation.

Furnace Base Package for O.E.M. and replacement installations .Model No. MA-200

See Replacement Parts List for types of Base Packages offered.

Furnace Base Package for replacement installations.....................Model No. MA-100

See Replacement Parts List for types of Base Packages offered.

RA-S4

RA-S3

RA-S2.5

4/12

3/12

2-1/2/12

None Flat

SRJ1 & SRJ2 Models are one piece construction

SRJ3, SRJ4, & SRJ5 Models are two piece construction

-C Models are two piece construction

OPTIONAL:

Raised Inlet Models (-C)

RoofJack Adaptor (Use to mount roofjack on pitched roof)

Protective Cap (Use when top of roofjack is removed)

Use Adaptor

Model No.

When roof pitch is: 1/2 Minimum

Furnace

CMF Series

57"

Add -C for Raised Inlet Models

Example: SRJ3-34-C

And Ceiling Height is:

Add Suffix

For Vent Pipe

7'

-28 7'6"

-34 8'

-40

Ceiling Trim Plates

When Ceiling Cavity is:

Use Roof Jack Model No.

49" to 59"

37" to 48"

SRJ5

25" to 36"

13" to 24"

12" or Less

SRJ4

SRJ3

SRJ2

SRJ1

Adaptor

14" Removable SRJ3, SRJ4, & SRJ5

25" Removable All -C Models

Figure 7. Selection of Roof Jack and Accessories Chart

10

!WARNING:

1. The roof jack and vent pipe as deter-

mined from the chart on in Figure 7

must be applied.

2. The indicating line near the bottom of

the roof jack must extend below the

finished ceiling.

3. The vent pipe must be attached to the

furnace flue collar with the sheet metal

screw provided.

4. DO NOT install any elbows (adjust-

able or non-adjustable) or a stack

damper in the venting system.

NOTICE: Accuracy in locating the base pan

and the roof jack openings with respect to the

flue outlet is required to avoid hazardous mis-

alignment of the air and vent systems. (See

Figure 1)

Use only the SRJ series roof jack as specified

on the furnace label.

Cut an approximate 8-1/4" diameter opening

through the roof and ceiling directly in line with

the flue connection on the top of the furnace.

A roof jack adaptor is required for use on a

sloping roof. Center the adaptor opening over

the roof opening, use sealant or caulking under

the adaptor. Use roofing nails or screws on

wood construction or sheet metal screws on

metal roofs (caulking, nails or screws not pro-

vided).

Insert the vent pipe into the bottom of the roof

jack; locking slot, downward, toward the fur-

nace. Slidethepipeintotheroofjacktoalength

thatwillallowaconvenientreachtotheconnec-

tion at the top of the furnace.

Ease the roof jack assembly through the open-

ings. The lower portion of the outer barrel must

extend through the finished ceiling as indicated

on the barrel. Use sealant or caulking on the

roof or adaptor to seal under the flashing of the

roof jack assembly.

Extendtheventpipedowntoengagethelocking

slot with the screw in the top of the furnace flue

pipe. Turn to lock and tighten the screw. All

joints and connections should be inspected

before start up of the furnace. (See Figures 8

& 9)

Fasten the ceiling trim/fire stop plates around

the upper barrel with four nails or wood screws

(not provided).

NOTE: Model SRJ-3, 4, and 5 roof jacks

permit the top section to be removed for transit

ofthedwelling. Ifthe topis removed,remaining

openingsmust besealed fromrain, debris,etc.,

until the top is replaced. A plastic accessory

cap is to be fastened to the lower roof jack

sectionwiththesamescrewsusedtomountthe

roof jack cap assembly. (See Figure 8)

Figure 8. Roof Jack Figure 9. Vent Pipe Installation

VENTPIPE

SLIDEDOWNTO

ENGAGESCREW

FLUEPIPE

OFFURNACE

TURNTOLOCK-

TIGHTENSCREW

;;;

;;;

;;;

;;;

;;;;

;;;;

;;;;

Insert Sliding Pipe

Fasten Ceiling

Trim Plates

Ceiling

Roof

Roof Jack Adaptor

Install With Line

Below Ceiling

Remove three screws

to separate two piece

models; replace with

protective cap for

transit only

Fasten roof flashing to adaptor

or flat roof; apply sealant or

caulking underneath

Fasten adaptor to

sloped roof; apply

sealant or caulking

underneath

;;;

;;;

11

IMPORTANT: When the top section of the

roof jack is removed for transit, a special warn-

ing label must be attached adjacent to the fuel

line connection of the gas or oil burner. The

special warning label is suppled with two piece

roof jack assemblies.

Chimney Installation

When venting the CMF through an existing

chimney, the materials, sizing, and installation

of the chimney must be in accordance with the

ANSI Z223.1/NFPA 54, (National Fuel Gas

Code), ANSI/NFPA 31(Installation of Oil Burn-

ing Equipment), NFPA 211 (Chimneys, Fire-

places, Vents, and Solid Fuel-Burning Appli-

ances) and all applicable local codes. The

materialsusedmustbecapableofwithstanding

exposure to temperatures of at least 700°F .

The CMF power gas units are fan-assisted.

Installation of Ventilaire III or IV Air

Quality Package (Accessory)

TheVentilaireairqualitypackagesareavailable

tomeettheventilationrequirementsasoutlined

VENT PIPE

3 FEET MIN.

ROOF JACK ASSY.

ROOF CAP ASSY.

FLEX DUCT

CEILING TRIM COLLAR

CONNECTOR

DRAW BAND

DRAW BAND

FURNACE

Figure 10. Typical Installation

FURNACE

CAUTION

MAINTAIN 2 1/2" MINIMUM CLEARANCE

BETWEEN FLUE PIPE AND FLEX DUCT.

FAILURE TO COMPLY WITH THIS

RESTRICTION COULD CAUSE

EQUIPMENTDAMAGE.VENTILAIRE III

ILLUSTRATED OTHER LISTED

VARIATIONS AVAILABLE. CHECK WITH

MANUFACTURER.

VentilAire III

VentilAireIV

Figure 11. VentilAire III and IV

12

Table 3. Pipe Length Selection Chart

Type of

Pipe

Black Iron

Pipe for 20’_ 60’100’

Natural Gas

Aluminum or

Copper Tubing* 10’_ 30’_

for Natural Gas

Aluminum or

Copper Tubing _ 40’100’_

for LP Gas

*Copper tubing should be internally tin coated.

1/2" 5/8" 3/4" 1"

Maximum Possible Pipe

Length Required for Different

Pipe Diameters

inH.U.D.StandardPart3280.103(b)(2). These

packages introduce outdoor air into the living

space during furnace blower operation. The

VentilAire IV also serves to exhaust moist and/

or hot air from the attic space. See Figures 10

and 11 for typical installation. Complete

installation instructions are supplied with each

air quality package.

FUEL CONNECTIONS

Gas Piping Requirements - PG Series Only

Gas piping should be sized and installed in

accordance with local codes ANSI Z223.1/

NFPA 54 (National Fuel Gas Code) and utility

regulations. To install the gas supply piping,

connect a separate gas line from the gas meter

to the burner with a manual shut-off valve

installed in the line at the furnace. This valve

should be readily accessible to shut-off the gas

supply to the furnace in case of an emergency

shutdown. When installing the gas supply line,

always use new clean piping and route the line

in such a manner as to be easily accessible.

The piping and threading must be free from

cutting burrs and defects. The line must be

durable, substantial, and gas tight. Installing a

tee fitting with a sediment trap at the bottom of

the riser to catch any foreign debris in the gas

supplylineisrecommended. Anadditionalmain

manual shut-off valve may be installed in the

gas supply line to shut-off the main fuel supply,

ifdesiredbythehomeownerorrequiredbylocal

codes.

The proper gas supply line size can be

determined using the gas piping chart, shown

in Table 3. Black pipe is the most practical for

naturalgas,becauseofthelargersizesrequired.

Copper tubing with an internal coating of tin is

recommended for use with propane (LP) gas

installations.Compoundsused onthe threaded

jointsmustberesistanttotheactionsofpropane

(LP) gases.

Carefully check for gas leaks with a soap

solution or a commercial leak detector fluid.

NEVER USE A MATCH OR OPEN FLAME TO

DETECT A GAS LEAK!

!CAUTION:

The furnace and its appliance main gas

valve must be disconnected from the gas

supply piping system during any pres-

sure testing of that system at test pres-

sures in excess of ½psi (3.5 kPa). The

furnace must be isolated from the gas

supplypipingsystembyclosingtheequip-

ment shut-off valve during any pressure

testing of the gas supply piping system at

test pressures equal to or less than ½psi

(3.5 kPa).

Oil Piping Installation —PO Series Only

The following procedures are recommended

as good practice. However, requirements of

local codes and ordinances, H.U.D. Manufac-

tured Home and Safety Standards or National

Fire Protection Association must be satisfied,

where they apply, for an approved installation.

Use a tank capacity suitable for the application

with a weatherproof, capped fill opening and a

shieldedventtoletinairasfuelisused. Thetank

must be clean inside before filling. All water,

rust, sediment, and other foreign matter must

be flushed out.

Ifatwo pipesystem isusedorifoilistaken from

the bottom of the tank, a filter is recommended.

Furthermore, a manual shut-off valve may be

usedonasinglepipeortwopipesystem.Please

note that local codes will dictate the specific

installation requirements.

13

A fuel or tank gauge is recommended for easy

checking of the fuel level. Check the gauge

reading with a dip stick.

Locate the storage tank conveniently near the

home. Forabovegroundfueltankinstallations,

the tank may rest three to four inches off the

ground. Fuel tanks may also be buried if

properly coated to resist corrosion. For below

ground fuel tank installations, the vertical di-

mension from the bottom of the tank to the fuel

pump must not exceed ten feet. Keep the tank

filled especially in the summer to reduce the

accumulation of condensation.

Fuel Line Hook-Up: One Line System

The one line system is highly recommended

where vertical lift, from bottom of tank to pump,

isnotmore thaneightfeet. A singlelinehookup

has the advantage of costing less and giving

quieter operation.

Fuel Line Hook-Up: Two Line System

Use a two line system only if the vertical lift

exceeds 8 feet.

1. Install the oil feed line as outlined in steps

1-6 below.

2. Install the oil pump bypass plug in the

bottom return port.

3. Run the return line up through the furnace

base to the return port of the pump. Run

the other end of the line to the tank, using

3/8" O.D. copper tubing or 1/4" pipe with

the ends capped, and routing the line so it

stays clean.

Figure 12. Recommended Tank Hook-Up

200 to 300 Gallon Tank

Drain

End of Oil Supply Line

3" to 5" Above

Bottom Drain

Guide pipe

Gauge Vent with

Cap 2" Duplex

Bushing 2" Fill

3/8" Oil Supply Line

Note: Additional venting may

be required if tank is filled rapidly.

4. Insert the return line through the second

opening in the duplex bushing. If the

bottom of the tank is lower than the pump

intake,thetubeshouldbeinsertedthreeor

four inches from the tank bottom. If the

bottom of the tank is higher than the pump

intake, the return line should extend not

more than 8" inside the tank.

Hook-Up Procedure (See Figure 12)

1. Use 3/8" O.D. copper tubing for the fuel

line. Capthe end withtape to keepoutdirt

while the line is being routed.

2. Install duplex bushing for two 3/8" lines in

the top fitting of the tank.

3. Insert one end of the tubing through the

duplexbushinguntilitisthreetofiveinches

from the bottom drain. Tighten the bush-

ing.

4. Run the line where it will not be subject to

damage. Also make bends gradually and

avoid kinks which might restrict oil flow.

5. Open the burner access door. Connect

the oil line to the intake port on the pump.

Tighten other port plugs on the pump.

6. Besuretheoillineisairtight! Air leakscan

cause the pump to lose prime and will

create other problems such as nozzle

failure, odors, rumbling noise, and false

safety shut down.

7. Insert the short length of the copper tube

levelwiththebottomoftheduplexbushing.

Tightenthebushing. Formthetubeintoan

inverted “U”to serve as a vent.

How to Eliminate Air Leaks

To eliminate problems caused by air in the oil

line, all connections in the oil supply line and all

plugs, nuts, and fittings on the pump must be

airtight. This includes the nut that covers the

pressure adjustment. It is important that the

hook-up be done carefully and with a good

flaring tool.

Fuel Oil Type

Do not use fuel oil heavier than Grade No. 2.

Grade No. 1 may be used where the oil supply

is subject to low temperatures.

14

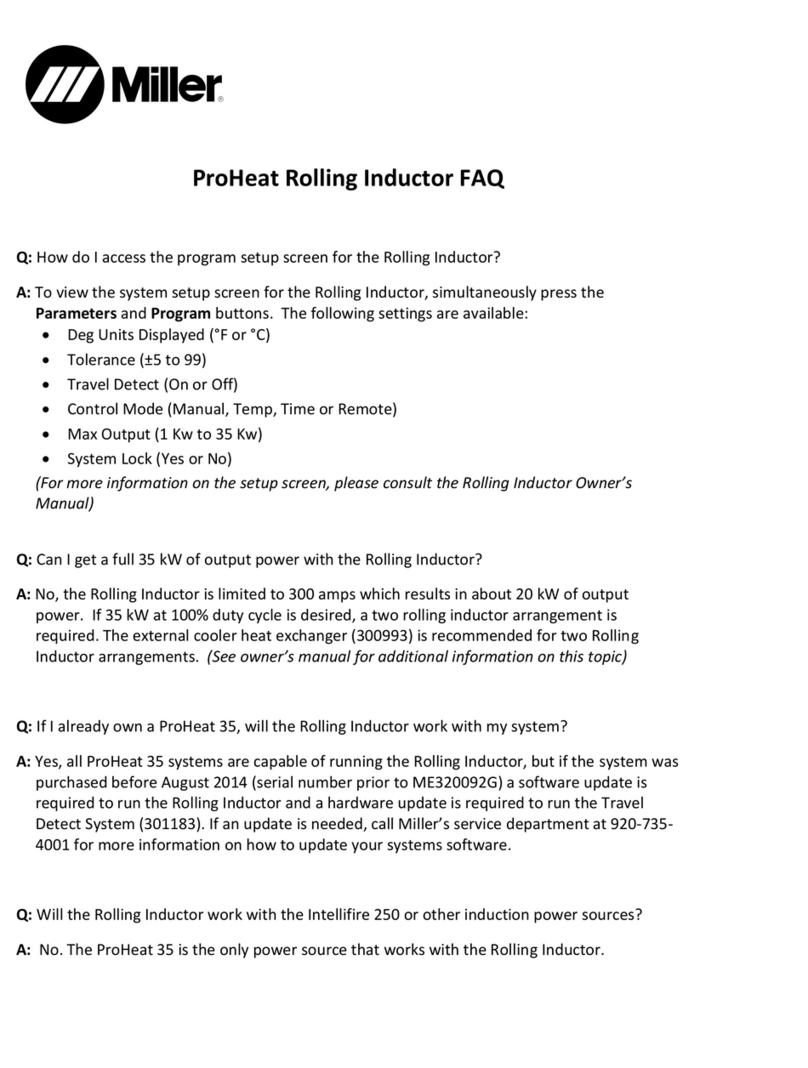

Burner Plug

Receptacle

Blower Speed Setting Shown

is the Medium Speed

(see table)

Fan & Limit

Control

Manual Sw.

Fan Sw.

If any of the original wire supplied

with the appliance is replaced, use

105 C wire or equivalent.

Limit

Sw.Aux.

Sw.Door

Sw.Recpt.

Motor

Door

Switch

120V N

L1

G

Aux. Limit

Blk

Blk L1 120V

G

N

1

2

3

4

5

6

1

2

3

4

5

6

1

1

1

1

Blue

Red

Blower

Motor

Wht

Wht

Blk

Red

Blue

Blk

Wht

Wht

Blk

Red

Blower

Wire

Color Blower

Speed

Blue

Black

Low

Med.

High

Represents Control Box

Blk

Brn Brn

Blower

Motor

Capacitor

Burner

Plug

L1 NIgnition

Transformer

Burner

Motor

BLACK

WHITE

ORANGE

Cad Cell

Primary

Control

T2

T1

F

F

TERMINAL HOUSING

IGNITOR

CONTROL

MODULE

GAS

VALVE

IND

L1

HSI

HSIG

L2

W

PSI

FSI

GV

PSO

FSG

C

WHITE

RED

RED

GREEN

BLUE BLUE

BLACK

BLACK

BLACK

BLACK

RED

TERMINAL

BOARD

BUSHING

LINE CORD

BUSHING

TO COMBUSTION MOTOR

BURNER ELECTRICAL BOX

BUSHING

BUSHING

OPTIONAL 24V COMMON

(FOR OPTIONAL ACCESSORY KITS)

C

N

L1

GROUND

SCREW

YELLOW

CLOSED

END

CONNECTOR

BLUE

BLACK

BLACK

RED

RED

TT

(C & W)

Figure 13. Wiring Diagram

Model PGB-DI Power Gas Burner “Direct Ignition”

Model AF-15 Oil Burner

7037900

Model CMF Series Furnace

Typical wiring diagram

for 24 Vac thermostat

and R7184 for an

oil-fired forced

air system

LIMIT

BURNER

MOTOR

IGNITOR IGNITOR

L2

L1

L2

T

T

R7184

BURNER

MOTOR

CAD

CELL

JUNCTION

BOX

CAD

CELL

ORANGE

BLUE

BLACK

WHITE

L2

L1

(HOT)

FAN RELAY COOLING

CONTROL

T8600

RC

G

Y

R

W

1

1

L1

(HOT)

1POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

LEGEND: SCREWTERMINAL

1/4 IN. QUICK CONNECTTERMINAL

15

DONOT USE GASOLINE,CRANKCASE OIL,

OR ANY OIL CONTAINING GASOLINE.

!WARNING:

Failure to keep supply oil clean by various

procedures described above may cause

failure of certain components such as the

fuel pump gears, check valve, shaft seal,

or burner nozzle which may result in a

burner fire.

ELECTRICAL WIRING

General

Allelectricalwiringmustbemadeinaccordance

with these instructions, all local codes, and

ANSI/NFPA 70 (National Electric Code). This

furnace shall be installed so the electrical

components are protected from water.

If any of the original wiring supplied with the

appliancemustbereplaced,itmustbereplaced

with wiring of the same material, gauge, and

temperature rating.

Line Voltage Requirements

Before proceeding with the electrical connec-

tions, make certain that the voltage, frequency,

and phase of the supply source are the same

as those specified on the unit rating plate. This

unit must be electrically grounded in accor-

dance with local codes, or in the absence of

localcodes,withANSI/NFPA70(NationalElec-

trical Code).

Use14-2TypeNMcablewithgroundorconduit

with single wires. Secure the cable at the

appliance using a code approved connector.

Line Voltage Connections

Before connecting the power supply wiring,

becomefamiliarwiththewiringofthisappliance

by reviewing the wiring diagram, shown in

Figure 13 , or the wiring label located on the

inside of the appliance.

1. Open the appliance door to gain access to

the control box.

2. Remove the control box cover.

3. Connecttheblackwireofthepowersupply

cable to the black wire of the appliance.

4. Connectthewhitewireofthepowersupply

cable to the white wire of the appliance.

5. Connect the ground wire of the power

supply cable to the green screw located in

the control box of the appliance.

6. Check all electrical connections, which

should be secure and tight.

CAUTION

Do Not Rotate —Hold

Dial When Setting Pointers

Scaleplate

Limit Stop*

Fan OFF

Indicator

Fan ON

Indicator

Limit Indicator

(Factory-Set at 160 F)

5

0

1

0

0

1

5

0

2

0

0

2

5

0

F

A

N

L

I

M

I

T

O

F

F

O

N

O

F

F

Figure 14. Fan and Limit Settings

16

7. Replace the control box cover.

8. Install a disconnect switch (fused or un-

fused) between the appliance and the

electrical supply at a convenient location

near the appliance. This switch should be

easily accessible.

Room Thermostat Requirements

When selecting thermostat location, consider-

ation must be given to the following:

1. Locate the thermostat approximately five

feetabovethefloorinalocationaccessible

for wiring and setting, preferably in a living

or adjoining room.

2. Locate on an inside wall.

3. Do not locate where influenced by abnor-

mal heat, such as from sunlight, radio,

T.V., or lamps.

4. Do not locate where influenced by abnor-

mal cold, such as on an outside wall, on a

wall separating an unheated room,

near drafts from stairwells or doors, or

close to windows.

5. Do not locate where air circulation is poor,

such as behind open doors, in corners or

alcoves, or close to furniture.

Theheatanticipatorofthethermostatshouldbe

adjusted to .4 amps for power oil models, and

.9 for power gas direct ignition models.

Room Thermostat Connections

1. Run R and W from the thermostat to the

burner compartment.

2. Connect R to one of the low voltage

terminals on the burner.

3. ConnectWtotheotherlowvoltageterminal

on the burner.

FAN AND LIMIT CONTROLS

Constant Blower Operation

The button protruding through the cover of the

fan and limit control provides either automatic

operation of the blower through the thermostat

orconstantbloweroperation. Pullthebuttonout

for automatic operation. Push the button in for

constant blower operation.

Fan and Limit Settings

!

CAUTION:

When adjusting the fan setting levers,

hold the scaleplate dial to keep it from

turning and straining the sensing ele-

ment.

The fan and limit switch has three levers: FAN

ON, FAN OFF, and LIMIT OFF. These levers

control the blower operation of the appliance.

The FAN ON lever controls the temperature at

which the blower energizes. This lever can be

adjustedthrougharangeof15oFabovetheFAN

OFF setting to 30 o

F below the LIMIT OFF

setting. The recommended factory setting is

110oF.

The FAN OFF lever controls the temperature

at which the blower is to stop to prevent the

circulationofcoolair. Therecommendedfactory

setting is 90oF.

TheLIMITOFFleverisasafetystop. Thislever

shouldnot beadjustedor tamperedwithfor any

reason. The factory setting is 160oF.

Figure 15. Direct Ignition Gas Valve

17

Auxiliary Limit

Thisfurnaceisequippedwithanauxiliarymanual

reset limit. This limit is designed to function

("trip") in the event of a blower motor failure. If

the limit trips, reset the limit by firmly pressing

the red button in the center of the limit. The limit

is located on the left hand side of the blower

assembly. If the limit will not reset, continues to

trip, or the blower does not function, notify your

NORDYNE Distributor or Service PRO

immediately.

MAINTENANCE

Air Filters

Air filters should be inspected and cleaned

monthly.

Combustion Air and Venting System

Inspect the combustion air and venting system

at the beginning and end of the heating system

for deterioration, blockage, or damage. Clean

the system, if necessary.

LIGHTING AND OPERATING

INSTRUCTIONS FOR CMF PG DIRECT

IGNITION GAS BURNERS

For Your Safety Read Before Lighting or

Operating.

!WARNING:

If you do not follow these instructions

exactly, a fire or explosion may result

causing property damage, personal in-

jury or loss of life.

A. This appliance does not have a pilot. It is

equipped with an ignition device which

automaticallylightsthe burner. Donot try

to light the burner by hand.

B. BEFORE LIGHTING OR OPERATING

smellallaroundtheapplianceareaforgas.

Be sure to smell next to the floor because

somegasisheavierthanair and will settle

on the floor.

WHAT TO DO IF YOU SMELL GAS:

•Do not try to light any appliance.

•Do not touch any electric switch, do not

use the phone.

•Leave the building immediately, then

call your gas supplier.

•Ifyoucannotreachthegassupplier,call

the fire department.

C. Use only your hand to push in and move

the gas control lever. Never use tools. If

the lever will not push in by hand, don't try

to repair it, call a qualified service techni-

cian. Forceorattempted repairmayresult

in a fire or explosion.

D. Do not use this appliance if any part has

been under water. Immediately call a

qualified service technician to inspect the

appliance and to replace any part of the

control system and any gas control which

has been under water.

E. Should overheating occur, or the gas sup-

ply fail to shut off, turn off the manual gas

valve to the appliance.

Operating Instructions for PG Direct

Ignition Burner

1. STOP! Readthesafetyinformationabove.

2. Set the thermostat to OFF or to its lowest

setting.

3. Turn offall electric powerto the appliance.

4. Thisappliance isequippedwith anignition

device which automatically lights the

burner. DO NOT try to light the burner by

hand.

5. Turn the latch and open the furnace door.

6. Push in the gas control lever and move to

OFF. DO NOT FORCE.

7. Wait ten (10) minutesto clear out any gas.

If you then smell gas, STOP! Follow

Section B in the safety information above.

If you don’t smell gas, go to the next step.

18

8. Move the gas control lever to ON.

9. Close the furnace door and turn the latch.

10. Turn onallelectric powerto theappliance.

11. Turn the thermostat to ON and set to the

desired setting.

12. If the appliance will not operate after one

re-try, follow the instructions in the “To

TurnOffGas ToAppliance”Section below

and call your service technician or gas

supplier.

To Turn Off Gas to the Appliance

1. Set the thermostat to OFF or to its lowest

setting.

2. Turn off all electric power to the appliance

if service is to be performed.

3. Turn the latch and open the furnace door.

4. Push in the gas control lever and move to

OFF. DO NOT FORCE.

5. Close the furnace door and turn the latch.

Checking the Input of the Furnace

Refer to the rating plate on the furnace to

determine the firing rate for your application.

UsingTable4,determinetheappropriateorifice

sizeforthefiringrateandgasbeingusedinyour

application. Check the burner orifice to ensure

that it is the correct size.

The input of this furnace can be checked using

the following procedure, which is based on

using a one cubic foot gas meter:

FiringRate Natural Gas NaturalGas LP Gas LP Gas Time

Burner Input Orifice Time Per Rev.* Orifice Per Rev.**

Designation (BTUH) Number (sec) Number (sec)

Gas Gun-65-DI-S 65,000 24 55 43 138

Gas Gun-75-DI-S 75,000 20 48 40 120

Gas Gun-90-DI-S 90,000 16 40 36 100

* There times are based on natural gas at an average of 1,000 BTU per cubic foot, a burner

manifold pressure of 3.5 in WC, and a meter dial size of 1 cubic foot.

** There times are based on LP gas at an average of 2,500 BTU per cubic foot, a burner

manifold pressure of 3.5 in WC, and a meter dial size of 1 cubic foot.

Table 4. Natural and LP Gas Orifices

1. Shut off all other gas fired appliances,

except for any pilots.

2. Startthefurnaceinheatingmodeandallow

it to run for at least three minutes.

3. Measure the amount of time (in seconds)

requiredforthegasmetertocompleteone

revolution. Notethatonerevolution willbe

equal to one cubic foot of gas.

4. Compare the time measured with the

appropriatetimelistedinTable4. Ifthetime

varies by more that 5% from the times

shown in the table, then measure the inlet

and gas valve manifold pressures, using

the procedure outlined in the “Measuring

the Inlet Supply and Manifold Pressures”

section.

5. If both the inlet gas pressure and the

manifold pressure are properly set, then

check the burner orifice to ensure that it is

properly sized. Further gas problems

shouldbereferredtothelocalgassupplier.

Measuring the Inlet Gas and Manifold

Pressures

For natural gas installations, the inlet gas line

pressureatthe gasvalveinlet mustbebetween

5 in WC and 7 in WC. For LP gas installations,

the incoming gas line pressure at the gas valve

inlet must be between 11 in WC and 13 in WC.

This pressure can be checked at the port

located on the gas inlet end of the gas valve

using a pressure gauge or U-tube manometer,

which must be installed according to the

manufacturer’s supplied instructions.

For natural gas installations, the manifold

pressure must be set at 3.5 in WC. For LP gas

installations, the manifold pressure must be set

19

at 10.0 in WC. This pressure can be checked

at the port located on the gas outlet end of the

gas valve using a pressure gauge or U-tube

manometer, which must be installed according

to the manufacturer’s supplied instructions. If

the manifold pressure is not equal to the valves

above, then it must be adjusted. To adjust the

manifold pressure, remove the regulator

converter from the gas valve, as shown in

Figure 16. Then turn the adjusting screw

clockwise to increase the pressure or

counterclockwisetoreducethepressure. Once

the manifold pressure is correctly set, replace

the regulator converter in the same manner as

it was removed earlier.

ToinstallapressuregaugeorU-tubemanometer

in the gas valve:

1. Determinewhichpressure, theinlet gasor

manifold pressure, you want to measure.

2. With a 3/16”Allen wrench, remove the

appropriate tap plug located on the gas

valve. When measuring the inlet gas

pressure, remove the tap plug on the inlet

sideofthegasvalve. Whenmeasuringthe

manifoldpressure,removethe tapplug on

the outlet side of the gas valve.

3. Install a fitting, which has a 1/8”NPT pipe

threadthatiscompatiblewiththepressure

gauge or U-tube manometer.

4. Install the pressure gauge or U-tube ma-

nometer according to the manufacturer’s

supplied instructions.

5. After measuring the pressure, be sure to

remove the pressure gauge or U-tube

manometerfromthegasvalveandreplace

thetapplug. Ensurethatthetapplugistight

and not cross-threaded.

Gas Burner Controls

The gas valve lever can be set to ON or OFF,

asshowninFigure16. WhenintheONposition,

gas flow through the gas valve is allowed when

the valve is energized electrically. When in the

OFF position, gas flow is completely shut off.

Combustion Blower Centrifugal Switch

Figure 16. Natural Gas Configuration

Theelectricmotorfortheblowerwhichsupplies

combustion air to the burner is equipped with a

centrifugalswitchwiredinserieswiththeburner

controls. This switch is normally open until the

speed of the blower motor closes it thereby

powering the burner controls. The burner

controls will not function until the blower motor

is operating at full speed.

Natural Gas to LP Conversion

This gas fired heating appliance was shipped

from the factory for use with natural gas. How-

ever,theappliancecanbeconvertedtobeused

with LP gas. Use the following procedure for

gas conversion of the burner.

1. Follow instructions “To Turn Off Gas To

Appliance”earlier in these instructions.

2. Shut off gas supply at meter.

3. Disconnect gas burner electric cord, gas

piping to burner, and thermostat leads.

4. Remove three (3) hexagon nuts holding

burner in place.

5. Disconnect inlet pipe union at burner.

Table 5. Air Shutter Setting

for Different Fuels

Input Natural LP Gas Oil

(BTU/H) Gas Setting Setting Setting

65,000 3.0 3.0 3.0

75,000 3.5 3.5 4.0

90,000 4.0 4.0 3.5

Regulator

Converter

20

6. Disconnect the two wires leading to gas

control valve.

7. Remove three (3) bolts from U-shaped

manifold plate and orifice assembly.

8. Removethemainorificeandreplaceitwith

theappropriateLP fuelorifice.Refertothe

ratingplateonthefurnacetodeterminethe

firing rate for your application. If the firing

rate of your furnace has been converted,

ensure that the appropriate LP orifice for

the new firing rate is installed. Then, use

Table 4 to determine the proper LP orifice

for your firing rate.

9. Remove the regulator converter and its

blackcoverlocatedontopofthegasvalve

and invert. (See Figure 16 —For LP, the

redringwillbelocatedatthebottomandthe

“LP”stampingontheconverterwillappear

right side up.)

10. Screw converter back into the regulator,

hand tight plus

1/8 turn, and replace the black cover onto

the converter top to protect the threads.

11. Reinstall the burner assembly into the

furnace.

12. Reconnect the gas piping and electrical

wires to the gas valve.

Figure 17. Oil Pumps

AIR BLEED

VALVE

NOZZLE

PORT

NOZZLE

PORT WEBSTER

SUNTEC

INLET PORT

INLET PORT

INLET PORT

AIR BLEED

VALVE

13. Open the manual shut-off valve andfollow

the “Operating Instructions”as outlined

previouslyinthismanualtoputthefurnace

into operation.

Adjusting the Burner

The air shutter is factory pre-set for installation

in a given furnace, as shown in Table 5. You

should not need to adjust the air shutter setting

of the gas gun burner except when converting

thefiringrateofthefurnace.Foryourinstallation,

check to ensure that the air shutter setting is

correct. It is very important that the combustion

air supply be ample without decreasing the

efficiencyof the burner. An inadequate amount

of air can cause carbon monoxide (CO)

production. The carbon dioxide (CO2) content

of the flue products should be in the range of

8.0%to9.0%fornaturalgasand9.0%to10.0%

for LP gas. The burner should run quietly.

For high altitude operation (altitudes greater

than2,000feet),theinputshouldbede-ratedby

4% for each 1,000 feet above sea level by

reducing the orifice size or decreasing the

manifold pressure. When decreasing the

manifold pressure, the pressure must not be

set below 3.2 in WC. If the pressure needs to

besetbelow3.2inWCtoachievetheproperde-

rate, then change the orifice size and raise the

manifold pressure back to 3.5 in WC.

Figure 18. PO Oil Burner Electrode Settings

5/32" Gap Electrode

5/16" ABOVE CL Nozzle

1/16"

1-1/8" - 65,000 and 75,000

BTU/HR Inputs, FO Head

1-13/32" - 90,000 BTU/HR

Input, F3H Head

This manual suits for next models

3

Table of contents

Popular Heating System manuals by other brands

Haier

Haier HACI-RP Series Installation, use and maintenance manual

Salda

Salda RIRS 400VE EKO 3.0 Technical manual

Oxygen

Oxygen X-Air V500E Installation and operation manual

Airxcel

Airxcel Aqua-Hot 200 Series Service manual

Roberts Gorden

Roberts Gorden CoRayVac B-2 instructions

VOKERA

VOKERA Linea User instructions