NOREMAT Optima 51 User manual

Optima

ARTICULATED SIDE-ARM

Operator’s MANUAL

Eco-friendly printing on 100% recycled paper.

This book contains pictures that are not contractual.

Translation of the operator’s manual original version

Book ref : 120076 Index : B

Operator’s manual

Optima 51 / M51 / M56 / M57T / 60T 2

Dynapôle Ludres/Fléville, 166 rue Ampère/BP 60093 - 54714 LUDRES - FRANCE - Tél.+33 (0)3 83 25 69 60 - Fax. +33 (0)3 83 26 12 85

Index

INTRODUCTION 4

RECOMMENDATIONS 5

RESPONSIBILITIES OF THE USER 6

GENERAL SAFETY RULES 7

1. Contact with oil 7

2. Noise/dust 7

3. Vibrations 8

4. Heat 8

5. Delivery 8

6. Before tting to the tractor/cv 9

7. Before starting the rotor

9

8. Before leaving the tractor/cv 9

9. Transport of the machine by lorry 10

9 1Unloading 12

9 2Externaldimensionsofthemachines 13

CHAPTER 1 : TECHNICAL CHARACTERISTICS 15

1. Description of the machine 15

2. Technical specications

16

2 1Performance 16

2 2Weights 17

2 3Rotorhydrauliccircuit 18

2 4Movementhydrauliccircuit 18

2 5FIltrationandcooling 18

2 6Hydrauliccylinderpressures 19

2 7Dual-Pressure‘breakback’systempressures 20

2 8Hydraulicpumppressures 21

3. Types of mounting frame 22

3 1Quickmountingframe 22

3 2‘C’mountinginterfaceformultipurposeframealreadyinplace 22

3 3Automaticchassisattachment 23

3 4Adjustmentofpalonnier/toplinkassembly 24

4. Transport position between worksites

25

Operator’s manual

Optima 51 / M51 / M56 / M57T / 60T 3

Dynapôle Ludres/Fléville, 166 rue Ampère/BP 60093 - 54714 LUDRES - FRANCE - Tél.+33 (0)3 83 25 69 60 - Fax. +33 (0)3 83 26 12 85

CHAPTER 2 : OPERATION AND MAINTENANCE 27

1. Safe use of the machine 27

2. Identication of movements 29

3. Identication of controls 30

4. Preperation and attachment 31

4 1Recommendationsbeforeattaching 31

4 2Attachmentofthemachinetothetractor/cv 32

4 3Counterbalancingthetractor/cv 35

5. First-time operation 36

5 1Beforestartingwork 36

5 2Startingtherotor 36

5 3Stoppingtherotor 37

6. Working position 38

7. Removal 39

8. Storage 39

9. Maintenance 40

9 1Bolttoghteningtorques 40

9 2Dailymaintenance 40

9 3Replacementoftherotor 41

9 4Maintenanceofthecuttingtool 41

9 5Maintenanceoftheaccumulator 41

9 6Maintenanceoftheradiator 41

9 7Armshock-absorberandit’sreplacement 42

10. Greasing 43

10 1Recommendationsaboutgreasing 43

10 2Greasingplanandintervals 43

10 3PTOdriveshaftgreasing 44

11. Oil changes 45

11 1Recommendationsaboutoilchanges 45

11 2Rotorandmovementhydrauliccircuitoilchanges 46

11 3Oilltercartridgereplacement 46

11 4Gearboxoilchange 46

12. Warranty 47

12 1Warrantyapplication 47

12 2Importantnumbers 48

Notes 49

Operator’s manual

Optima 51 / M51 / M56 / M57T / 60T 4

Dynapôle Ludres/Fléville, 166 rue Ampère/BP 60093 - 54714 LUDRES - FRANCE - Tél.+33 (0)3 83 25 69 60 - Fax. +33 (0)3 83 26 12 85

INTRODUCTION

Congratulations on acquiring your new side-arm mower/ail-cutter*

Model

OPTIMA 51

OPTIMA M51

OPTIMA M56

OPTIMA Visiobra M57T - OPTIMA 60T

From it’s introduction, OPTIMA has given the user, greater benets of ease of operation and operating

comfort not found in a rear mounted arm machine.

We hope that it will give you the satisfaction that you justiably expect and that motivated your choice.

SAFETY ALERT SYMBOL

This symbol identies the important safety messages in the manual. When you

see it, take note about the risks, read the accompanying message carefully and

inform other users.

This specication and operation manual contains the information that will enable you to:

1.Familiarise yourself with your machine and take full advantage of it’s technical renements

in the best usage conditions.

2.Obtain optimum performance by simple, but strict observance of

the maintenance recommendations.

3.Deal with incidents that do not require the help of a specialist, without wasting time.

For the safety of any persons nearby, it is very important to follow

the advice given in this manual.

ATTENTION

Your side arm mower must NEVER be used as a lifting device.

*To help with the reading of this manual, the terms, ail mower and articulated side-arm mower are

covered by the word ‘machine’. Terms for ‘cutting head’, reciprocating knife etc will be referred to as

the ‘tool’. Carrying vehicles other than conventional agricultural tractors eg Fastrac, Unimog etc will be

referred to as cv’s.

Operator’s manual

Optima 51 / M51 / M56 / M57T / 60T 5

Dynapôle Ludres/Fléville, 166 rue Ampère/BP 60093 - 54714 LUDRES - FRANCE - Tél.+33 (0)3 83 25 69 60 - Fax. +33 (0)3 83 26 12 85

RECOMMENDATIONS

Your machine is likely to be tted to an agricultural tractor.

NOREMAT would like to draw your attention to the following points :

- Please refer to the relevant authority in your country or state for;

-required certicates of competence to drive and use a tractor/mower combination on

the public highway or other;

-related Health and Safety regulations and requirements.

The job in hand and the use of your machine, just like the whole tractor will necessitate a period of

acclimatization.

NOREMAT will assist you with information and advice.

It is recommended that you make contact with a NOREMAT technician to establish your informational

and instructional needs in relation to the machine and it’s use.

Furthermore, it is desirable that each user can benet from the experience and expertise of NOREMAT,

your Direct-Constructor.

Operator’s manual

Optima 51 / M51 / M56 / M57T / 60T 6

Dynapôle Ludres/Fléville, 166 rue Ampère/BP 60093 - 54714 LUDRES - FRANCE - Tél.+33 (0)3 83 25 69 60 - Fax. +33 (0)3 83 26 12 85

RESPONSIBILITIES OF THE USER

The user is responsible to adhere strictly to the safe-use regulations

and safety points which are dened in this manual.

As with the driving of all machines, the user must match his speed

of travel in the transport position or during work, to the condition of

the roadway or terrain.

Before carrying out any operation with your machine, you are advised to read this section carefully.

All modications carried out on the machine are the sole responsibility of the person instigating them.

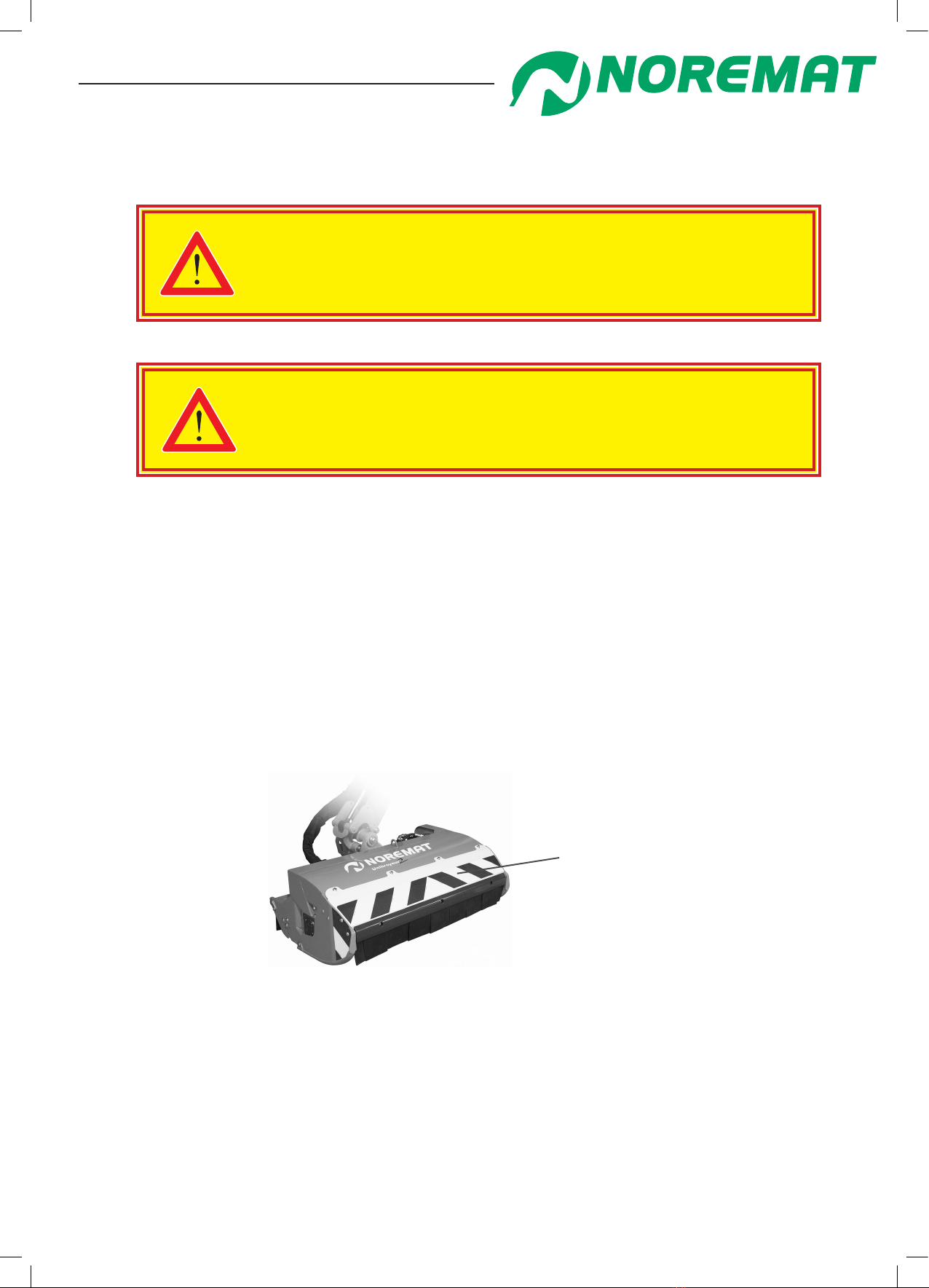

To use the machine for mowing (rotor turning in the opposite direction to the tractor wheels), it is

imperative that the front hood and aps are tted to avoid the risk of debris being thrown from the rotor.

gure 1.01

example of

hood and aps

If these regulations are not respected, responsibility lies with the user alone.

Operator’s manual

Optima 51 / M51 / M56 / M57T / 60T 7

Dynapôle Ludres/Fléville, 166 rue Ampère/BP 60093 - 54714 LUDRES - FRANCE - Tél.+33 (0)3 83 25 69 60 - Fax. +33 (0)3 83 26 12 85

GENERAL SAFETY RULES

It is essential to follow the instructions in this manual to ensure the

safety of persons operating or in the vicinity of the machine.

1. Contact with oil

At the time of oil changes or when working on any components which

may retain hydraulic pressure, ALWAYS wear adequate safety equipment

Body

Protection

Gloves Face

Visor

-In the event of contact with the skin:

If a high pressure jet of oil is applied to the skin there is a danger of the oil penetrating

the surface. The injured person should be taken to hospital even if no wound is apparent.

Remove all contaminated clothing. Wash the suspected area immediately with plenty of soap

and water.

-In the event of contact with the eyes:

Wash immediately with plenty of water. Hold the eyelids apart for at least 15 minutes.

-Ingestion:

Risk of vomiting and diarrhoea. Do not make the person drink to avoid the risk of inhalation by

the respiratory tracts. Do not drink water.

-Aspiration:

If there is a suspicion that the person may have inhaled oil into the lungs (when vomiting for

instance), take them to hospital immediately.

In all cases seek immediate medical attention

2. Noise / dust

Take necessary precautions against the risk

of exposure to noise and dust during working

and travelling periods.

Wear Ear

Defenders

Operator’s manual

Optima 51 / M51 / M56 / M57T / 60T 8

Dynapôle Ludres/Fléville, 166 rue Ampère/BP 60093 - 54714 LUDRES - FRANCE - Tél.+33 (0)3 83 25 69 60 - Fax. +33 (0)3 83 26 12 85

3. Vibrations

To improve safety and health conditions of workers, the decree 2005-746 from July 4th, 2005 forces

the employer to evaluate the levels of exposure of its employees to the vibrations transmitted to the

whole body, and to start protection of the driver beyond exposure limit values.

These daily exposure limit values are precised in the article R 231-119 of the Labour regulation.

Noremat carried out trial runs to evaluate the level of vibrations emitted by a tractor /machine unit and

transmitted to the operator’s seat. As an indication, the median value recorded is 0.45m/s2 per eight

hours base period in normal work conditions as recommended by the manufacturer.

4. Heat

Take necessary precautions against the risks

due to the heat released by the hydraulic

components (hoses, pump, motor, gearbox,

valve block, rotor shaft).

Wear heat

protection

5. Delivery

Observe safety and handling rules, in particular:

-only use designated slinging points for all slings.

-never lift the machine with slings that are in poor condition or are too weak in lifting capacity.

-check that the means of lifting is satisfactory and suitable to lift the load.

-never stand or walk under the load.

-never attempt to remove the delivery supports (blue pieces) before tting

of the machine has been completed.

Operator’s manual

Optima 51 / M51 / M56 / M57T / 60T 9

Dynapôle Ludres/Fléville, 166 rue Ampère/BP 60093 - 54714 LUDRES - FRANCE - Tél.+33 (0)3 83 25 69 60 - Fax. +33 (0)3 83 26 12 85

6. Before tting to the tractor/cv

-It is necessary that the tractor is equipped with a cab or means of protecting the driver from possible

debris thrown from the tool.

-Check the condition of the PTO shaft guard on the tractor.

-Carefully read the tting instructions supplied with the drive shaft.

-Check all tyre pressures.

7. Before starting the rotor

-Read chapter 2, section 3, ‘Identication of controls’.

-Read the operator’s manual for the tool to be used.

-Do not start the machine in an explosive atmosphere or near inammable items.

-It is recommended that the rst trial be carried out on ground which is rm, at and without obstacles.

-Ensure that the operator is familiar with the tractor/machine combination.

-Check that the control unit is mounted securely in the cab/on the tractor.

-Never start the rotor if anyone is standing within the trajectory of possible debris thrown from the rotor.

-Ensure that all persons remain outside of the working area of the tractor and machine.

-Never remove the front hood of the cutting tool during work when mowing (direction of rotor opposite

to the forward motion of the carrying vehicle, see chapter ‘User responsibilities’).

8. Before leaving the tractor/cv

Before leaving that tractor/cv or allowing anyone to approach, it is imperative to:

- lower the tool to the ground.

- stop the rotor.

- stop the PTO.

- switch the machine off.

- apply the parking brake.

- stop the tractor engine.

General Safety Rules

Operator’s manual

Optima 51 / M51 / M56 / M57T / 60T 10

Dynapôle Ludres/Fléville, 166 rue Ampère/BP 60093 - 54714 LUDRES - FRANCE - Tél.+33 (0)3 83 25 69 60 - Fax. +33 (0)3 83 26 12 85

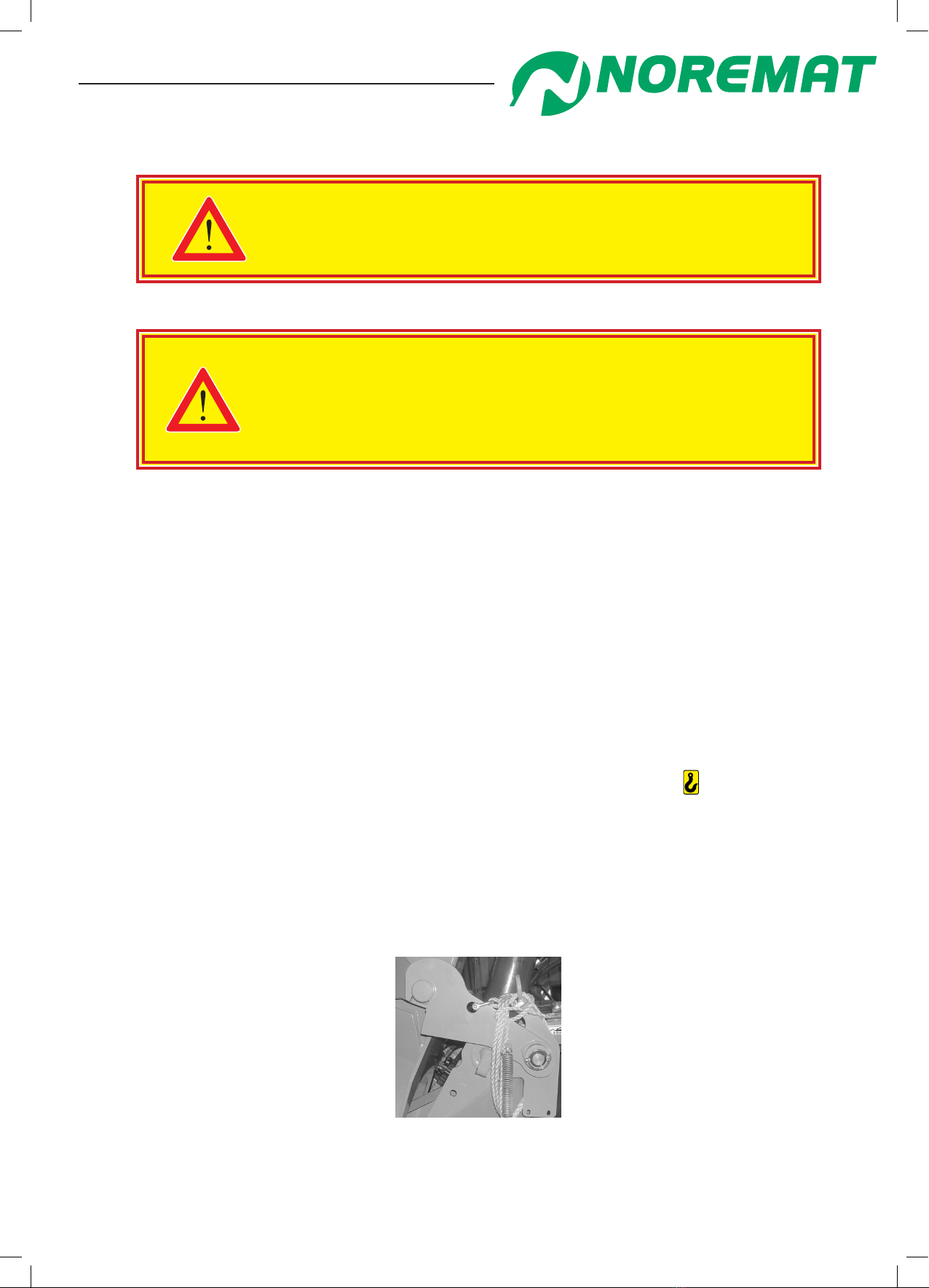

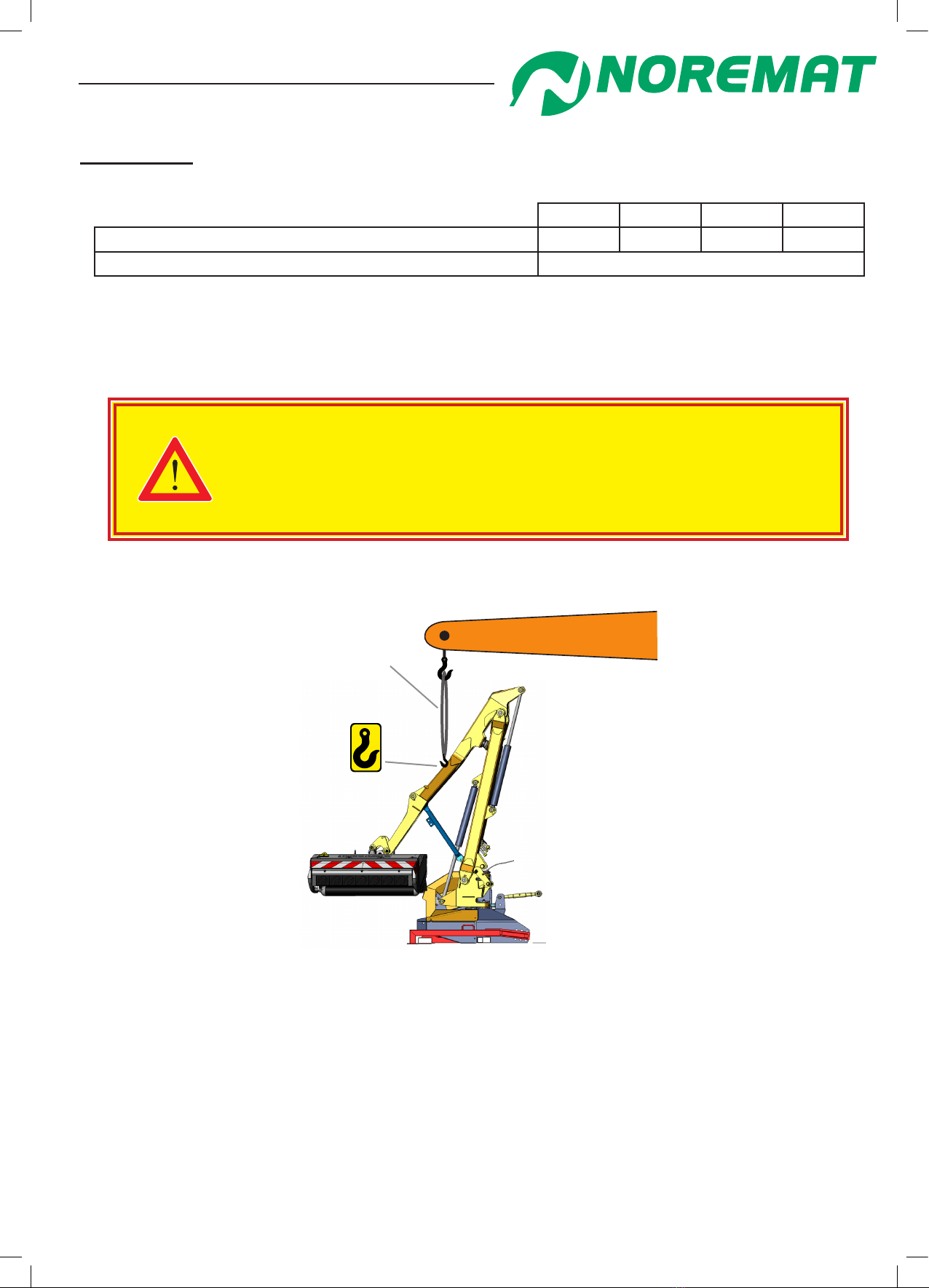

9. Transport of the machine by lorry

The machine should be secured to the lorry in such a way as to

guarantee absolute safety for nearby persons and equipment.

See Safety Rules on Page 7.

Precautions for carriage when not tted to a tractor or carrying vehicle:

It is essential to lock the arm with the locking kit (blue supports)

supplied with the machine (Figures 1.02, 1.03, 1.04, 1.05, 1.06).

Contact NOREMAT who can supply you with the correct locking kit.

For safety reasons, the equipment is delivered in the ‘delivery’ position. In this position, machine

movements are locked by supports that serve both for lifting the machine and for anchoring it

to the lorry.

These supports are identied by their unusual blue colour.

When it is delivered, the machine is unloaded and placed on the ground on it’s stands at the correct

height to be tted to a standard tractor.

The supports should not be moved until the machine is tted to the tractor and started.

Observe lifting safety rules. In particular:

-use only designated points to attach slings and lift only at these points shown

in the following diagrams.

-never lift the machine with slings that are in poor condition or incapable of lifting

the required weight.

-never walk or stand under the machine.

gure 1.02

General Safety Rules

Operator’s manual

Optima 51 / M51 / M56 / M57T / 60T 11

Dynapôle Ludres/Fléville, 166 rue Ampère/BP 60093 - 54714 LUDRES - FRANCE - Tél.+33 (0)3 83 25 69 60 - Fax. +33 (0)3 83 26 12 85

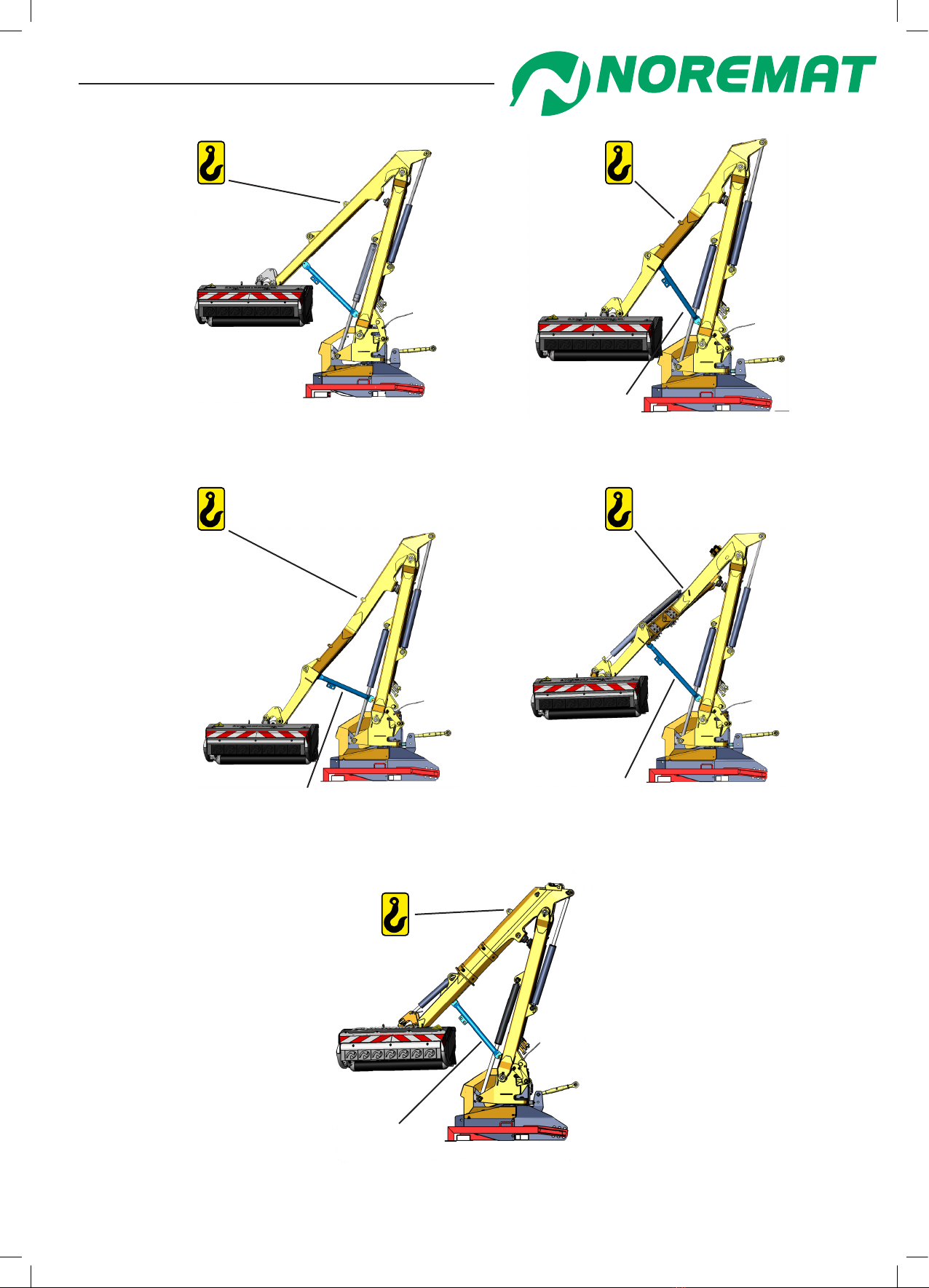

General Safety Rules

Locking kit

119324

gure 1.03 :Optima51

Locking kit

118875

gure 1.04 :Optima:M51

Locking kit

118877

gure 1.05 :Optima:M56

Locking kit

118867

gure 1.06 :Optima:M57T

Locking kit

123969

gure :Optima:60T

Operator’s manual

Optima 51 / M51 / M56 / M57T / 60T 12

Dynapôle Ludres/Fléville, 166 rue Ampère/BP 60093 - 54714 LUDRES - FRANCE - Tél.+33 (0)3 83 25 69 60 - Fax. +33 (0)3 83 26 12 85

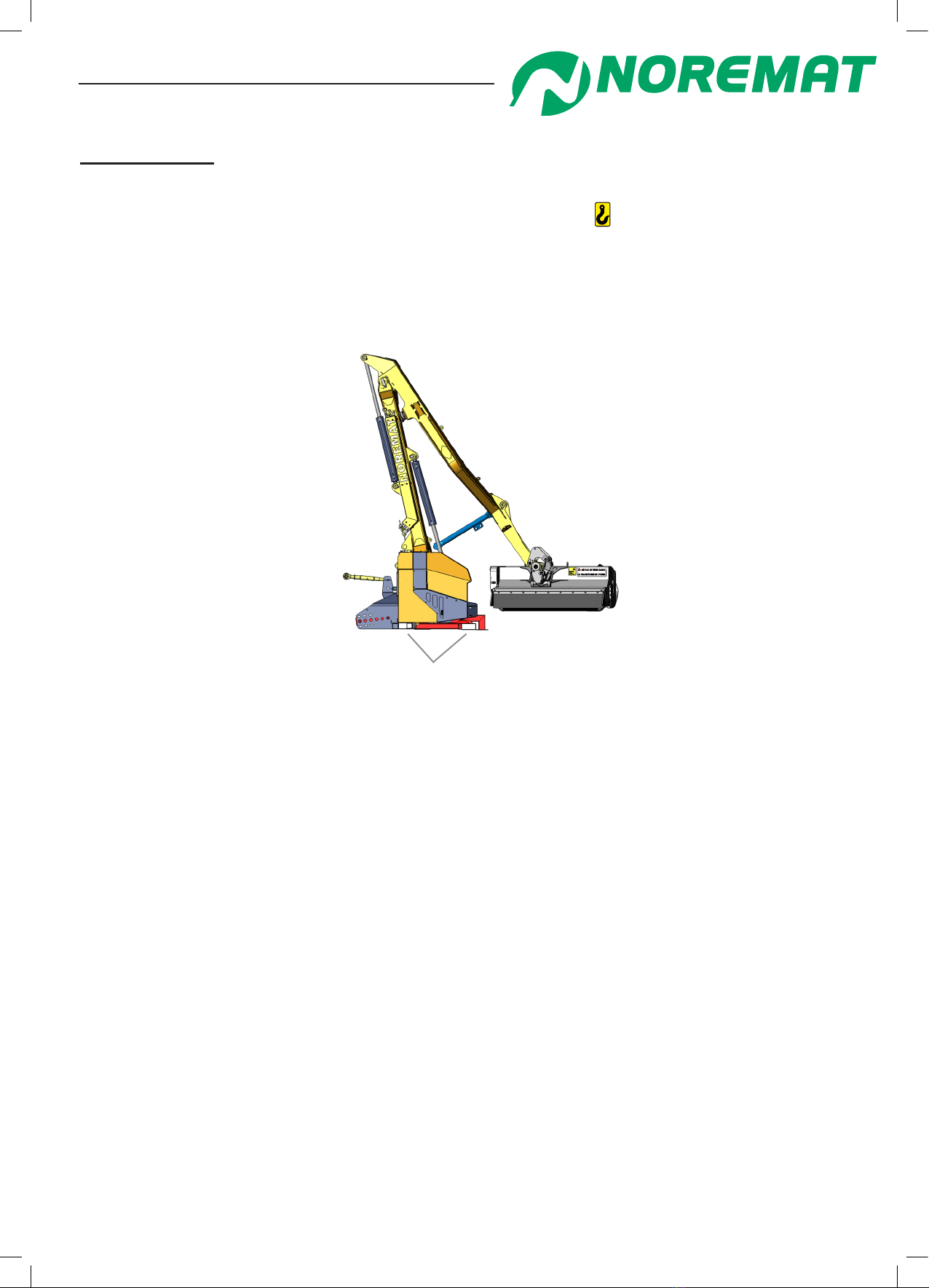

9 1Unloading

- Lift the machine with the help of a suitable gantry crane :

- travelling crane : use the lifting point shown by the symbol in the diagrams

on the previous pages.

- fork truck : use only if the necessary kit (red pieces) is tted to the machine ( gure 1.07)

Kit for fork truck lift:

(red pieces) tted

for the entry of the forks.

gure 1.07

Move clear of the lorry and t the adjustable stands to the machine

- Lower the machine slowly. Before it touches the ground, adjust the stands so that

it will remain level.

- Place the machine on the ground.

- Remove the parts tted for adapting it to the fork truck lifting means.

You now only need to hitch the machine to the tractor/carrying vehicle. See paragraph ‘Fittings and

mountings’.

General Safety Rules

Operator’s manual

Optima 51 / M51 / M56 / M57T / 60T 13

Dynapôle Ludres/Fléville, 166 rue Ampère/BP 60093 - 54714 LUDRES - FRANCE - Tél.+33 (0)3 83 25 69 60 - Fax. +33 (0)3 83 26 12 85

9 2Externaldimensionsofthemachines

2948 mm

3393 mm

2320 mm

gure 1.09 :

Optima M51

gure 1.08 :

Optima 51

3170 mm

3314 mm

1777 mm

General Safety Rules

Operator’s manual

Optima 51 / M51 / M56 / M57T / 60T 14

Dynapôle Ludres/Fléville, 166 rue Ampère/BP 60093 - 54714 LUDRES - FRANCE - Tél.+33 (0)3 83 25 69 60 - Fax. +33 (0)3 83 26 12 85

General Safety Rules

gure 1.10 :

Optima M56

gure 1.11 :

Optima Visiobra M57T

gure :

Optima 60T

3238 mm 2269 mm

3391 mm

3188 mm 2273 mm

3353 mm

3064 mm 1775 mm

3490 mm

3400 mm

90 mm

Operator’s manual

Optima 51 / M51 / M56 / M57T / 60T 15

Dynapôle Ludres/Fléville, 166 rue Ampère/BP 60093 - 54714 LUDRES - FRANCE - Tél.+33 (0)3 83 25 69 60 - Fax. +33 (0)3 83 26 12 85

CHAPTER 1 : TECHNICAL CHARACTERISTICS

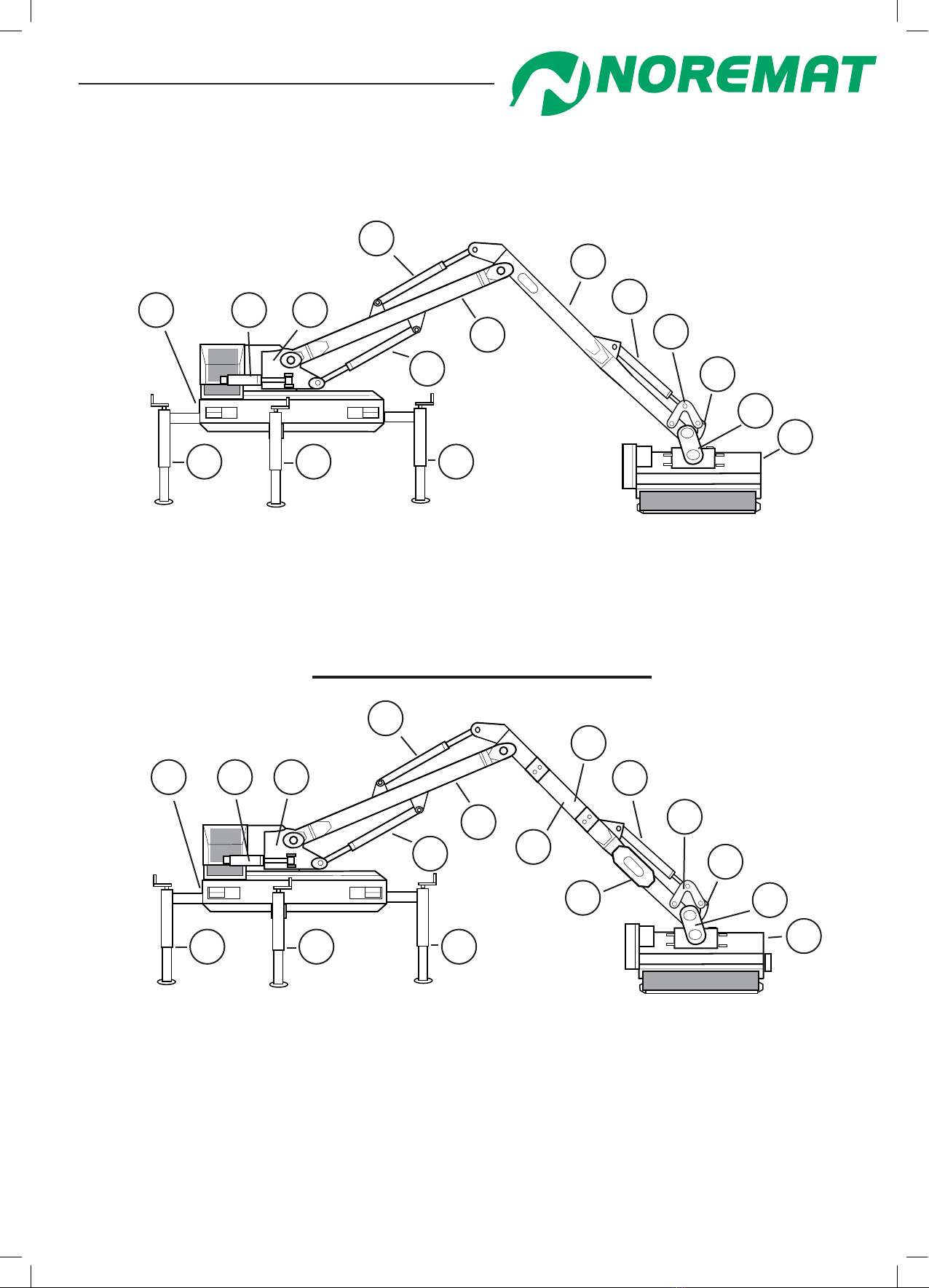

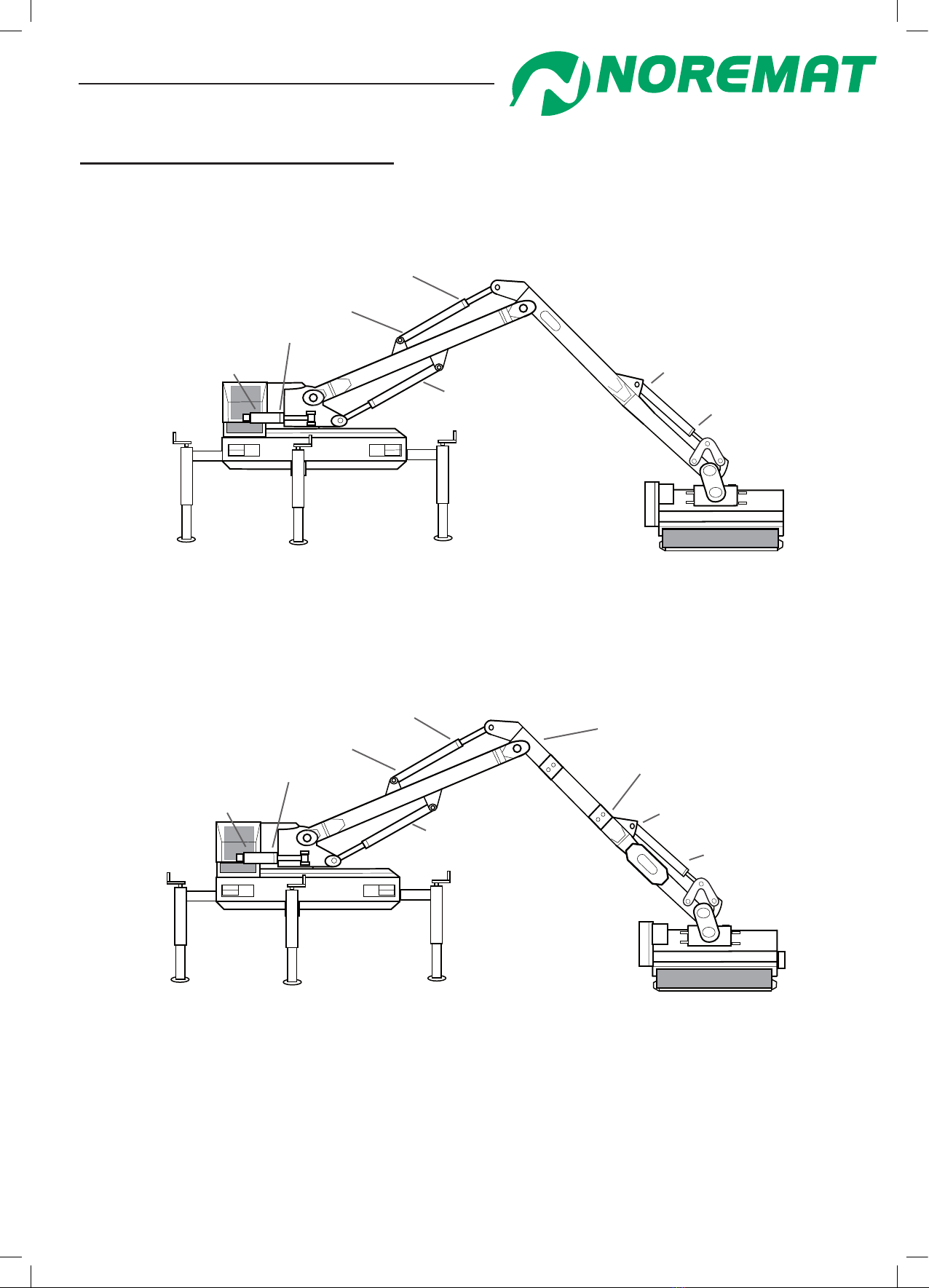

1. Description of the machine

1 - Frame

2 - Machine orientation cylinder

3 - Arm pivot assembly

4 - Second-arm cylinder

5 - Second-arm

6 - Tool orientation cylinder

7 - Transfer link bracket

8 - Angle transfer bracket

9 - Tool pivot bracket

10 - Tool

11 - First-arm

12 - First-arm cylinder

13 - Parking stands

51 / M51 / M56

gure 1.12

11

9

8

7

6

2

5

3

12

4

13 13

13

10

1

1 - Frame

2 - Machine orientation cylinder

3 - Arm pivot assembly

4 - Second-arm cylinder

5 - Integral telescopic arm inside

second arm

6 - Tool orientation cylinder

7 - Transfer link bracket

8 - Angle transfer bracket

9 - Tool pivot bracket

10 - Tool

11 - Telescopic arm

12 - Telescopic support arm

13 - First-arm

14 - First-arm cylinder

15 - Parking stands

gure 1.13

1

5

8

2

7

9

13

3

14

4

6

15 15 15

12

11

10

M57T

Operator’s manual

Optima 51 / M51 / M56 / M57T / 60T 16

Dynapôle Ludres/Fléville, 166 rue Ampère/BP 60093 - 54714 LUDRES - FRANCE - Tél.+33 (0)3 83 25 69 60 - Fax. +33 (0)3 83 26 12 85

2. Technical specications

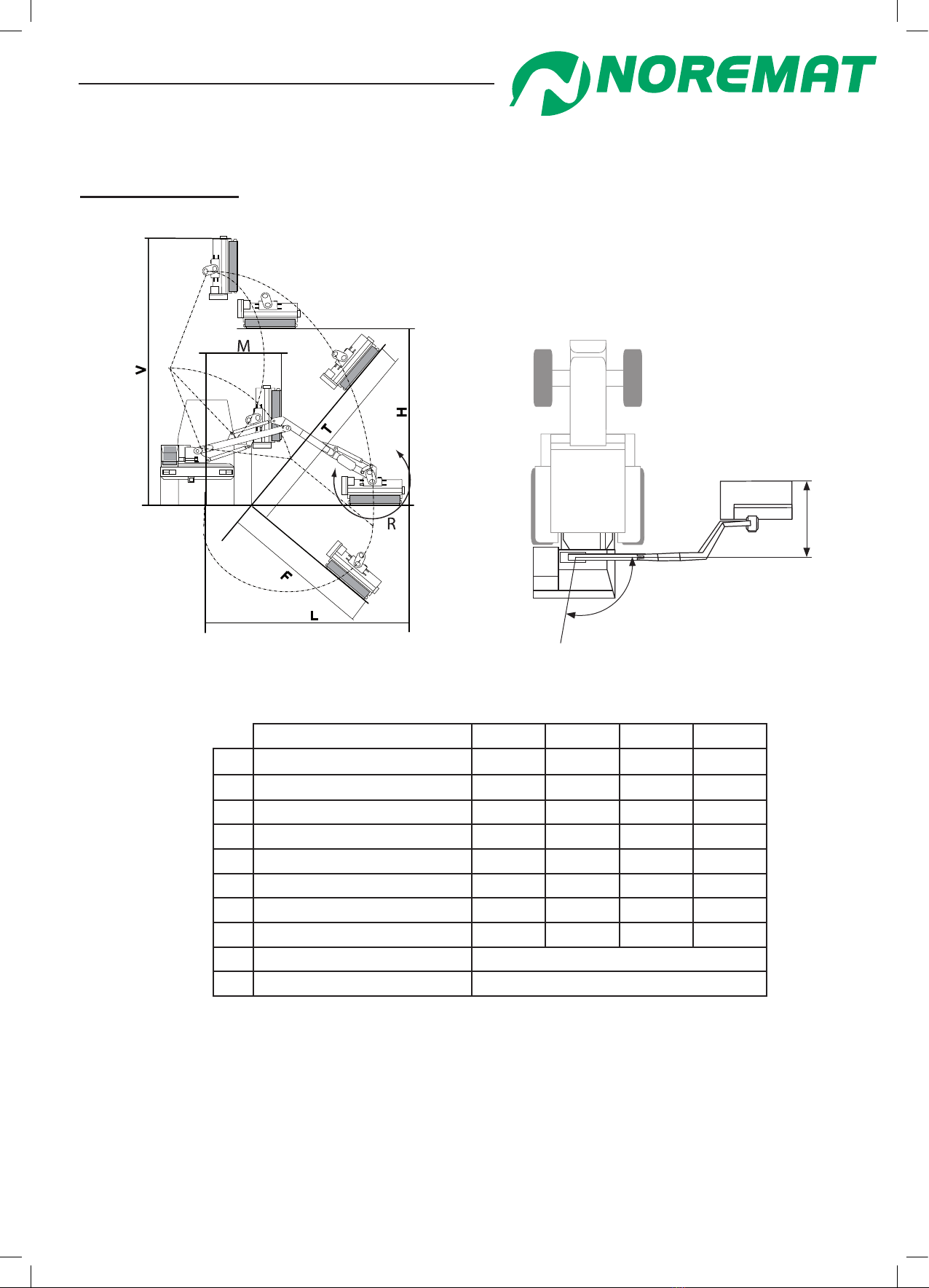

2 1Performance

Model 51 M51 M56 M57T

LMaximum lateral reach*5.10 m 5.10 m 5.60 m 5.70 m

V Vertical reach 6.55 m 6.55 m 7.00 m 7.10 m

T Bank reach 5.25 m 5.25 m 5.70 m 5.80 m

H Over-hedge reach 4.40 m 4.40 m 4.65 m 4.70 m

F Ditch reach 3 m 3 m 3.50 m 3.60 m

M Minimum lateral reach 1.75 m 1.75 m 1.85 m 1.75 m

N Forward reach 0.98 m 1.63 m 1.63 m 2.33 m

Telescopic NO NO NO YES

P Orientation angle 100°

R Tool orientation 230°

P

N

gure 1.14

*Measured from the centreline of the tractor.

Average dimensions, variable according to the type of tractor.

Technical characteristics

Operator’s manual

Optima 51 / M51 / M56 / M57T / 60T 17

Dynapôle Ludres/Fléville, 166 rue Ampère/BP 60093 - 54714 LUDRES - FRANCE - Tél.+33 (0)3 83 25 69 60 - Fax. +33 (0)3 83 26 12 85

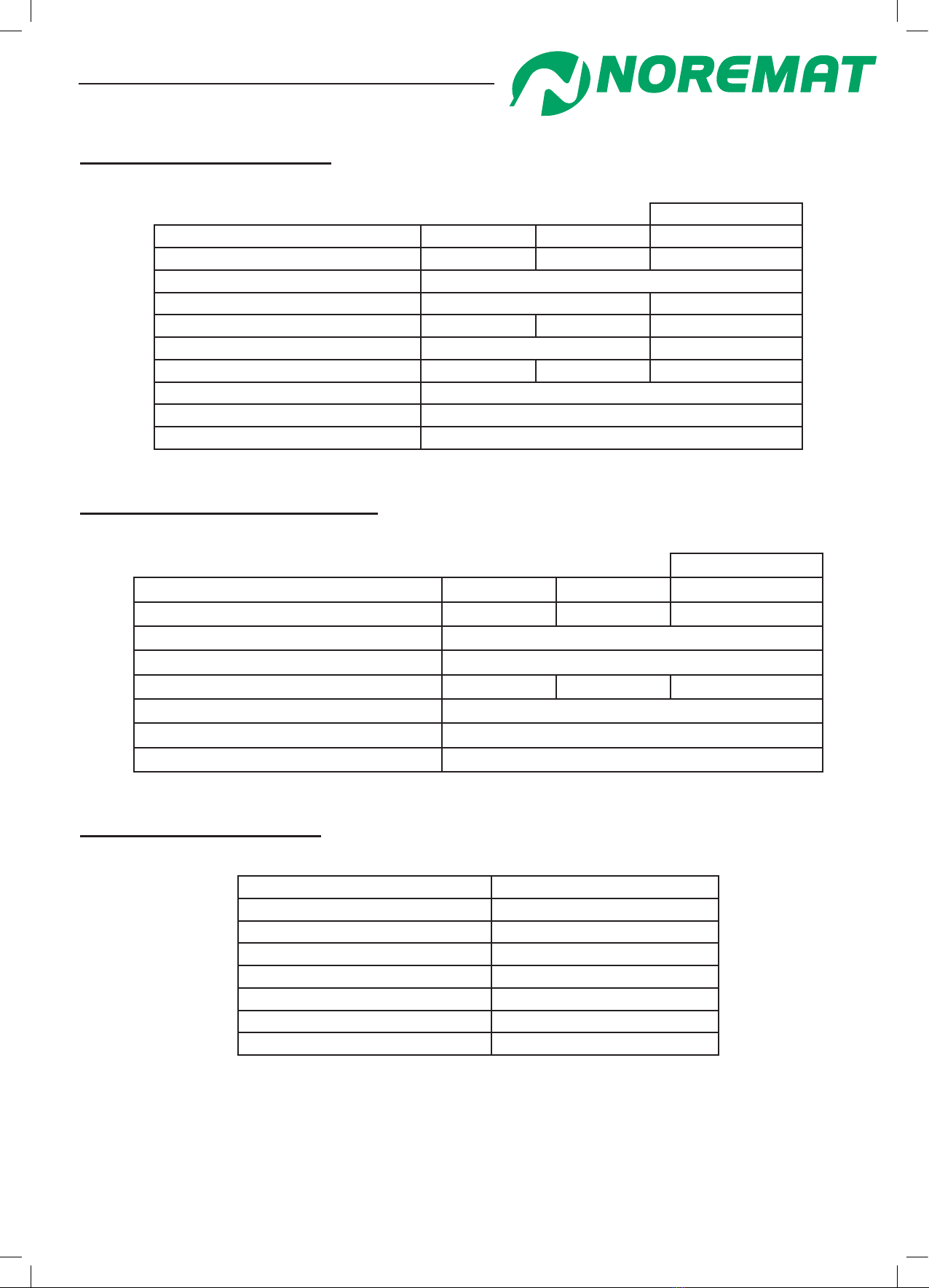

2 2Weights

51 M51 M56 M57T

Weight in working set-up (without fool tted) 1220 kg 1250 kg 1300 kg 1400 kg

Maximum tool weight at end of arm*390 kg

* Except with written permission from NOREMAT

To nd out the weight of the tool, refer to the appropriate User Manual.

A sling may be used to lift the machine.

For safety reasons we recommend using a sling of 2 tonnes minimum

capacity for Optima models.

See the chapter <Transport of the machine by lorry> for advice on safety

and handling

Means of Lifting

sling

gure 1.15 : Lifting of a machine using a sling.

Technical characteristics

Operator’s manual

Optima 51 / M51 / M56 / M57T / 60T 18

Dynapôle Ludres/Fléville, 166 rue Ampère/BP 60093 - 54714 LUDRES - FRANCE - Tél.+33 (0)3 83 25 69 60 - Fax. +33 (0)3 83 26 12 85

2 3Rotorhydrauliccircuit

Hydroshift

Power Take Off speed 540 rpm 1000 rpm /

Gearbox ratio 1 : 4 1 : 2,5 /

Hydraulic pump piston

Capacity 46 cc 41 cc

Flow 100 lpm 115 lpm 86 lpm

Maximum pressure 300 bar 280 bar

Power 68 CV 78 CV 57 CV

Controls electric

Hydraulic motor piston

Capacity 35 cc

2 4Movementhydrauliccircuit

Hydroshift

Power Take Off speed 540 rpm 1000 rpm /

Gearbox ratio 1 : 4 1 : 2,5 /

Hydraulic pump gear

Capacity 17 cc

Flow 36 lpm 42 lpm 36 lpm

Maximum service pressure at pump outlet 220 bar

Hydraulic cylinder double acting

Electrical equipment parachute valves on 1st and 2nd arms

2 5Filtrationandcooling

Reservoir capacity 70 liters

Reservoir pressurisation not pressurised

Reservoir oil specication HV 46

Filtration type submerged suction return

Filtration 10 microns absolute

Radiator construction aluminium

Cooling fan electric, Ø 305mm

Heat exchange capacity 14.5 kW

Technical characteristics

Operator’s manual

Optima 51 / M51 / M56 / M57T / 60T 19

Dynapôle Ludres/Fléville, 166 rue Ampère/BP 60093 - 54714 LUDRES - FRANCE - Tél.+33 (0)3 83 25 69 60 - Fax. +33 (0)3 83 26 12 85

2 6Hydrauliccylinderpressures

51 / M51 / M56

gure 1.16

125 bar

190 bar

160 bar for 51 and M51

210 bar for M56

210 bar

210 bar

140 bar

160 bar

M57T

gure 1.17

210 bar*

125 bar*

125 bar

190 bar

210 bar

140 bar

160 bar 210 bar

210 bar

*Telescopic cylinder pressure is checked on cylinder inside the second-arm.

Technical characteristics

Operator’s manual

Optima 51 / M51 / M56 / M57T / 60T 20

Dynapôle Ludres/Fléville, 166 rue Ampère/BP 60093 - 54714 LUDRES - FRANCE - Tél.+33 (0)3 83 25 69 60 - Fax. +33 (0)3 83 26 12 85

Technical characteristics

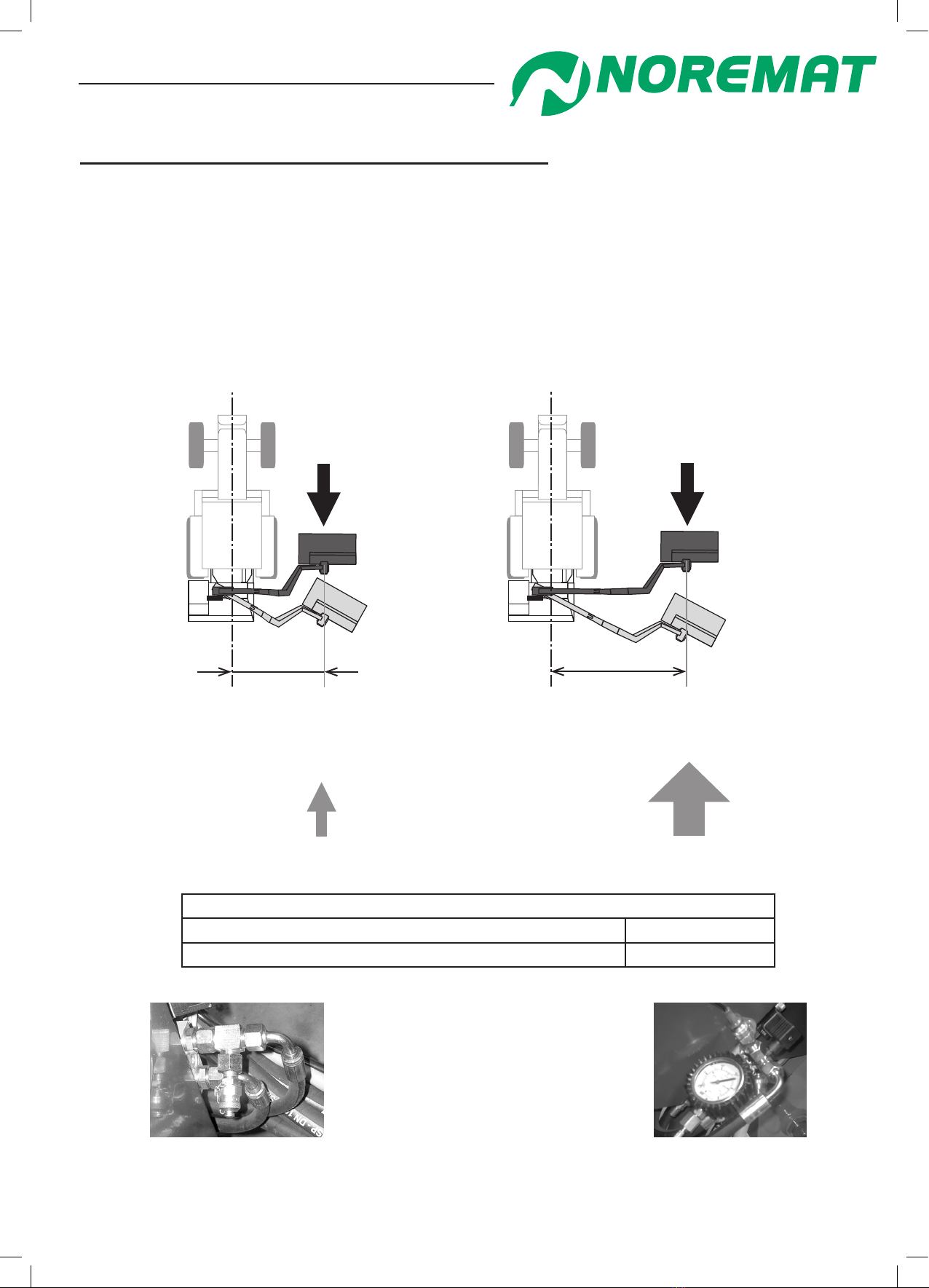

2 7Dual-Pressure‘breakback’systempressures

Your machine is equipped as standard with an arm ‘breakback’ system called Dual-Pressure

(gure 1.18) French patent applied for 15th Sept 2004.

Normally, in the event of meeting an obstacle or when the forward speed is too high for the vegetation

being cut, the pressure rises in the orientation cylinder of the machine. When a designated pressure is

exceeded, a regulating valve opens and allows the arm to ‘breakback’ towards the rear.

In the Dual-Pressure system, the opening pressure of the regulating valve depends on the position of

the arm. If the distance from the centre-line of the tractor to the tool is more than the halfway reach

point, the pressure necessary for ‘breakback’ will be increased, or reduced if nearer.

gure 1.18

breakback pressure

110 bar

distance between centreline of

tractor and tool is less than half of

the maximum arm reach

obstacle

breakback pressure

160 bar

distance between centreline of

tractor and tool is more half of

the maximum arm reach.

obstacle

Dual-Pressure system

Pressure at DP valve test point (g 1.19 & 1.20) 110 bar

Pressure (high setting) at valve block 160 bar

gure 1.20

gure 1.19

This manual suits for next models

4

Table of contents

Popular Farm Equipment manuals by other brands

Horizont

Horizont trapper AB15 instruction manual

Tatu Marchesan

Tatu Marchesan GNFH Operator's manual

Krone

Krone X-Disc 620 Original operating instructions

Spearhead

Spearhead Trident 4000 Handbook

AG SHIELD

AG SHIELD LandRoller OPERATOR’S HANDBOOK AND PARTS MANUAL

Econo-Wrap

Econo-Wrap EW-450A Operator's manual

AgLand

AgLand POWERMERGER6618 Operator's manual

Landoll

Landoll 2512 Series Operator's manual

New Holland

New Holland H9870 Service manual

M K Martin Enterprise

M K Martin Enterprise PULSAR 120 Operator and parts manual

Ovlac

Ovlac MINIVID OPERATING INSTRUCIONS AND SPARE PARTS

Sulky

Sulky Isobus X Series Original instructions