L73M, L73C

Installation & Maintenance

Instructions

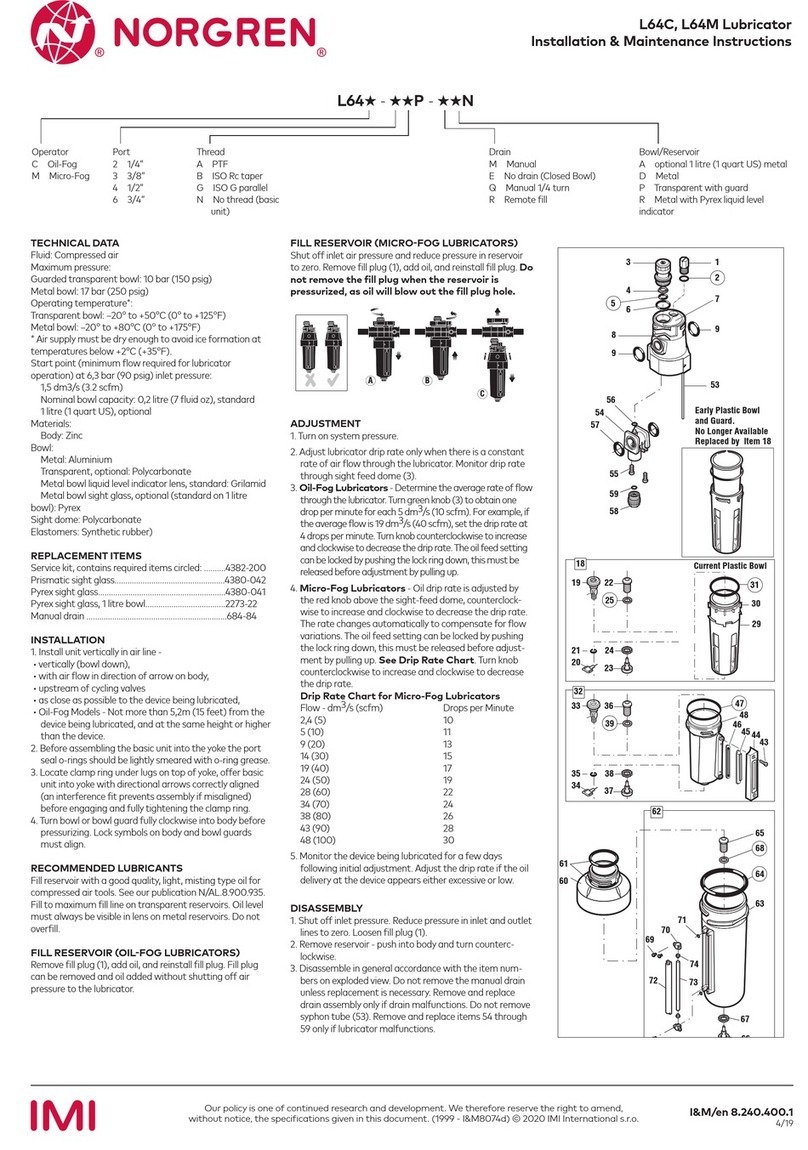

FILL RESERVOIR MICROFOG LUBRICATORS

Shut off inlet air pressure and reduce pressure in

reservoir to zero. Remove fill plug (2), add oil, and

reinstall fill plug. Do not remove the fill plug when the

reservoir is pressurized, as oil will blow out the fill plug

hole. Micro-fog lubricators can be filled under pressure

only if equipped with the optional quick fill cap (4),

which requires a quick fill connector and oil pump.

ADJUSTMENT

1. Turn on system pressure.

2. Adjust lubricator drip rate only when there is a

constant rate of air flow thru the lubricator. Monitor

drip rate thru sight feed dome (6).

3. Oil-Fog Lubricators - Determine the average rate of

flow thru the lubricator. Turn slotted green rotator in

sight feed dome (6) to obtain one drop per minute for

each 5 dm3/s (10 scfm). For example, if the average

flow is 19 dm3/s (40 scfm), set the drip rate at 4 drops

per minute. Turn rotator counterclockwise to increase

and clockwise to decrease the drip rate. Total travel of

rotator is 320°.

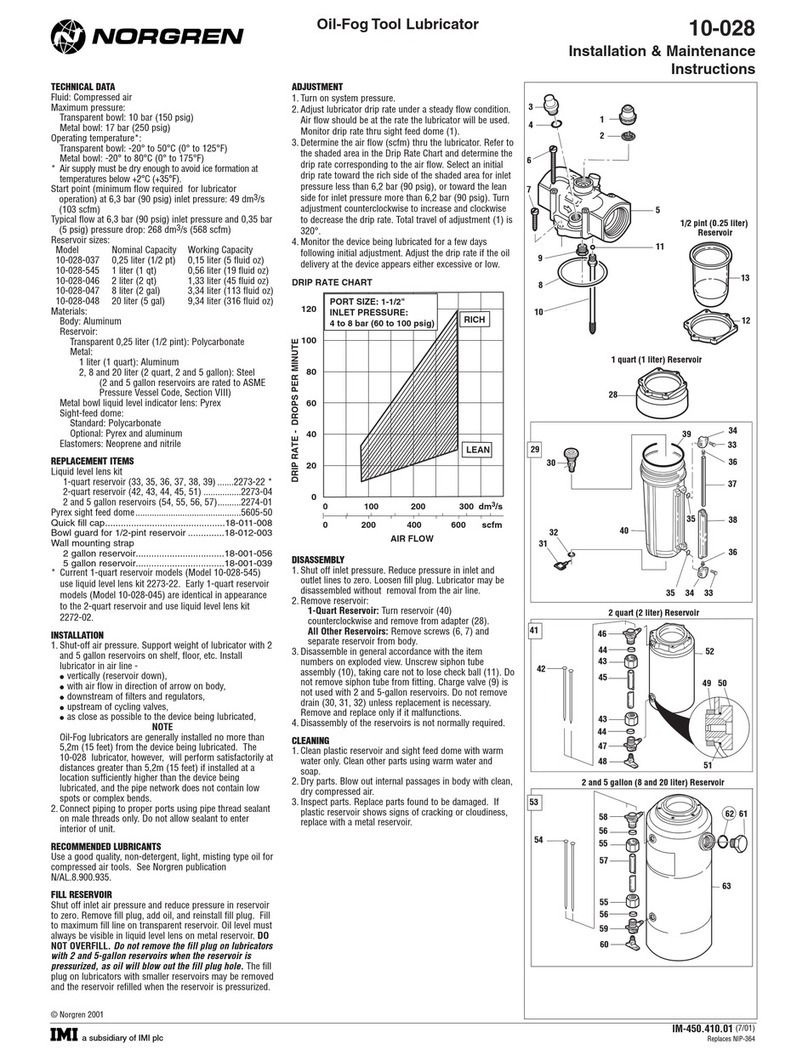

4. Micro-Fog Lubricators - Determine the average rate of

flow thru the lubricator. Turn slotted red rotator in

sight feed dome (6) to obtain the recommended

drops per minute. See Drip Rate Chart. Turn rotator

counterclockwise to increase and clockwise to

decrease the drip rate. Total travel of rotator is 320°.

Drip Rate Chart for Micro-Fog Lubricators

Flow - dm3/s (scfm) Drops per Minute

2 (5) 3

5 (10) 4

10 (20) 7

15 (30) 9

20 (40) 12

25 (50) 15

5. Monitor the device being lubricated for a few days

following initial adjustment. Adjust the drip rate if the

oil delivery at the device appears either excessive or

low.

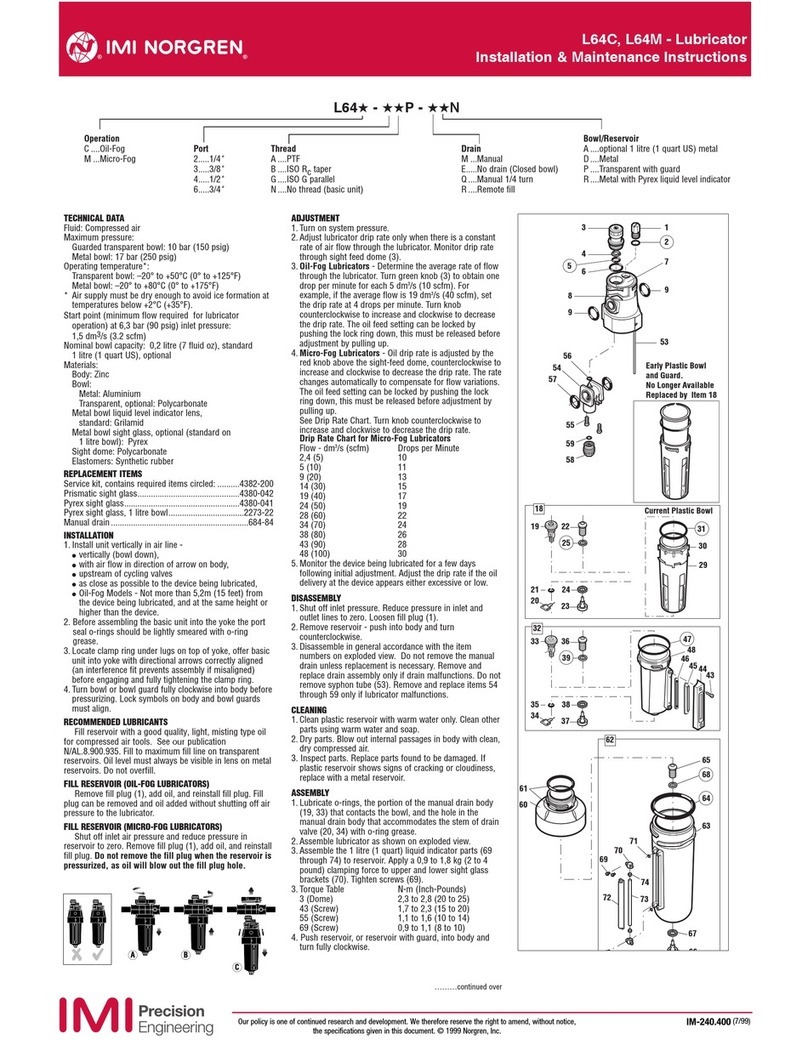

DISASSEMBLY

1. Shut off inlet pressure. Reduce pressure in inlet and

outlet lines to zero. Loosen fill plug (2).

2. Remove reservoir - push into body and turn

counterclockwise.

3. Disassemble in general accordance with the item

numbers on exploded view. Do not remove the

manual drain unless replacement is necessary.

Remove and replace drain assembly only if drain

malfunctions. Do not remove siphon tube (49).

Remove and replace items 50 thru 55 only if lubricator

malfunctions. O-ring (55) is only used on Micro-Fog

lubricators.

CLEANING

1. Clean plastic reservoir with warm water only. Clean

other parts using warm water and soap.

2. Dry parts. Blow out internal passages in body with

clean, dry compressed air.

3. Inspect parts. Replace parts found to be damaged. If

plastic reservoir shows signs of cracking or cloudiness,

replace with a metal reservoir.

ASSEMBLY

1. Lubricate o-rings, the portion of the manual drain

body (18, 28, 37) that contacts the bowl, and the hole

in the manual drain body that accommodates the

stem of drain valve (19, 29, 38) with o-ring grease.

2. Assemble lubricator as shown on exploded view.

3. Torque Table N-m (Inch-Pounds)

2 (Fill Plug), 4 (Quick-fill cap) 1,1 to 1,6 (10 to 14)

6, 8 (Dome) 2,3 to 2,8 (20 to 25)

43 (Screw) 1,7 to 3,4 (15 to 30)

50 (Screw) 2,0 to 2,5 (18 to 22)

4. Push reservoir, or reservoir with guard, into body and

turn fully clockwise.

IM-180.400.02 (9/98)

Supersedes 4/98

© Norgren 1998