2 - 23

目 錄

1應用範圍.................................................................................................................3

2-1 安全措施........................................................................................................... 3

2-1.1 安裝前........................................................................................................ 3

2-1.2 加油之前.................................................................................................... 3

2-1.3 電子控制器的安全措施............................................................................4

2-1.4 發生故障時................................................................................................ 4

2-2 注油機組成元件............................................................................................... 4

2-3 產品標籤........................................................................................................... 5

2-4.1 安裝注油機................................................................................................ 6

2-4.2 加入油料..................................................................................................... 6

2-4.3 油管接法.................................................................................................... 6

2-4.4 安裝電源和警報器....................................................................................7

3使用說明..................................................................................................................8

3-1 顯示與控制面板................................................................................................ 8

3-2 潤滑時間............................................................................................................ 8

3-3 間歇時間............................................................................................................ 8

3-4 強制潤滑............................................................................................................ 9

3-5 補充油料............................................................................................................ 9

4保養 .......................................................................................................................9

5故障排除.................................................................................................................10

6保證 .......................................................................................................................11

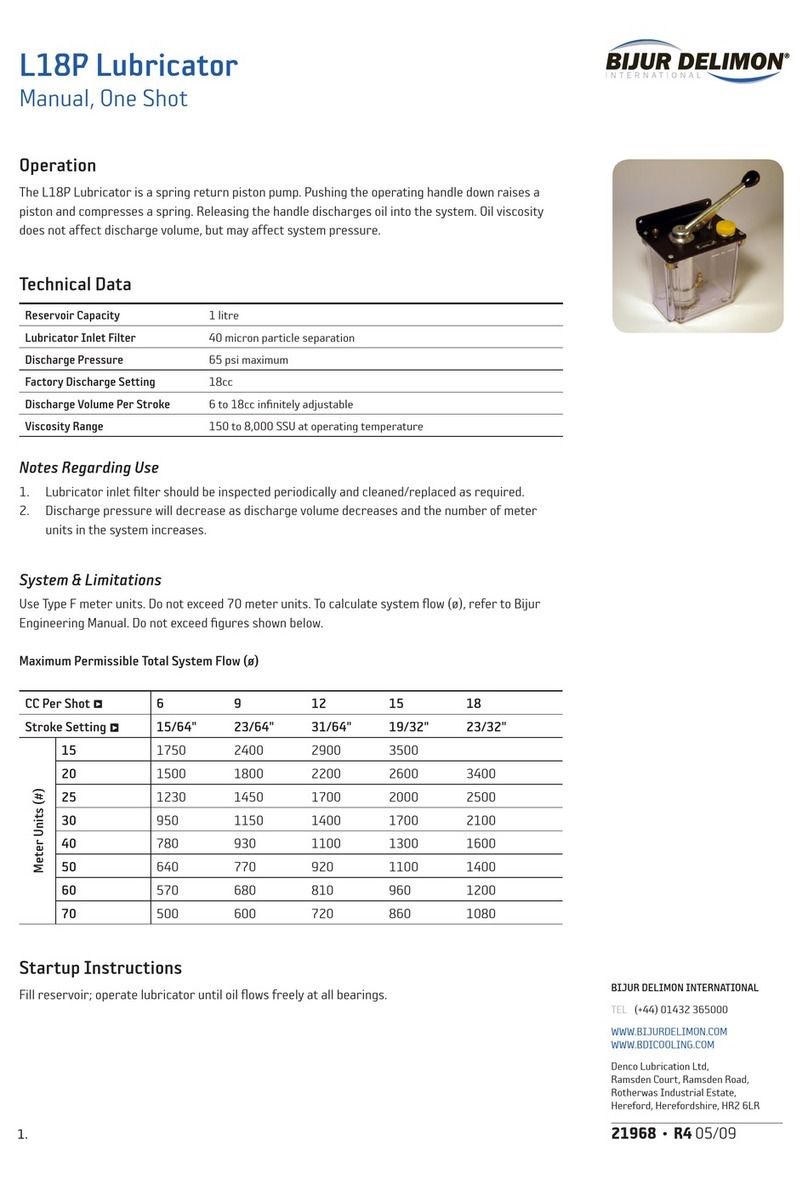

7技術資料.................................................................................................................11

7-1 規格 .............................................................................................................. 11

8聯繫方式..................................................................................................................23