Norgren L64C Installation and operating instructions

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document. (1999 - I&M8074d) © 2020 IMI International s.r.o. 4/19

I&M/en 8.240.400.1

L64C, L64M Lubricator

Installation & Maintenance Instructions

Thread

A PTF

B ISO Rc taper

G ISO G parallel

N No thread (basic

unit)

L64H- HHP - HHN

Port

2 1/4“

3 3/8“

4 1/2“

6 3/4“

Operator

C Oil-Fog

M Micro-Fog

Drain

M Manual

E No drain (Closed Bowl)

Q Manual 1/4 turn

R Remote ill

Bowl/Reservoir

A optional 1 litre (1 quart US) metal

D Metal

P Transparent with guard

R Metal with Pyrex liquid level

indicator

TECHNICAL DATA

Fluid: Compressed air

Maximum pressure:

Guarded transparent bowl: 10 bar (150 psig)

Metal bowl: 17 bar (250 psig)

Operating temperature*:

Transparent bowl: –20° to +50°C (0° to +125°F)

Metal bowl: –20° to +80°C (0° to +175°F)

* Air supply must be dry enough to avoid ice formation at

temperatures below +2°C (+35°F).

Start point (minimum low required for lubricator

operation) at 6,3 bar (90 psig) inlet pressure:

1,5 dm3/s (3.2 scfm)

Nominal bowl capacity: 0,2 litre (7 luid oz), standard

1 litre (1 quart US), optional

Materials:

Body: Zinc

Bowl:

Metal: Aluminium

Transparent, optional: Polycarbonate

Metal bowl liquid level indicator lens, standard: Grilamid

Metal bowl sight glass, optional (standard on 1 litre

bowl): Pyrex

Sight dome: Polycarbonate

Elastomers: Synthetic rubber)

REPLACEMENT ITEMS

Service kit, contains required items circled: ..........4382-200

Prismatic sight glass...................................................4380-042

Pyrex sight glass...........................................................4380-041

Pyrex sight glass, 1 litre bowl.....................................2273-22

Manual drain .................................................................684-84

INSTALLATION

1. Install unit vertically in air line -

• vertically (bowl down),

• with air flow in direction of arrow on body,

• upstream of cycling valves

• as close as possible to the device being lubricated,

• Oil-Fog Models - Not more than 5,2m (15 feet) from the

device being lubricated, and at the same height or higher

than the device.

2. Before assembling the basic unit into the yoke the port

seal o-rings should be lightly smeared with o-ring grease.

3. Locate clamp ring under lugs on top of yoke, offer basic

unit into yoke with directional arrows correctly aligned

(an interference fit prevents assembly if misaligned)

before engaging and fully tightening the clamp ring.

4. Turn bowl or bowl guard fully clockwise into body before

pressurizing. Lock symbols on body and bowl guards

must align.

RECOMMENDED LUBRICANTS

Fill reservoir with a good quality, light, misting type oil for

compressed air tools. See our publication N/AL.8.900.935.

Fill to maximum ill line on transparent reservoirs. Oil level

must always be visible in lens on metal reservoirs. Do not

overill.

FILL RESERVOIR OILFOG LUBRICATORS

Remove ill plug (1), add oil, and reinstall ill plug. Fill plug

can be removed and oil added without shutting off air

pressure to the lubricator.

FILL RESERVOIR MICROFOG LUBRICATORS

Shut off inlet air pressure and reduce pressure in reservoir

to zero. Remove ill plug (1), add oil, and reinstall ill plug. Do

not remove the ill plug when the reservoir is

pressurized, as oil will blow out the ill plug hole.

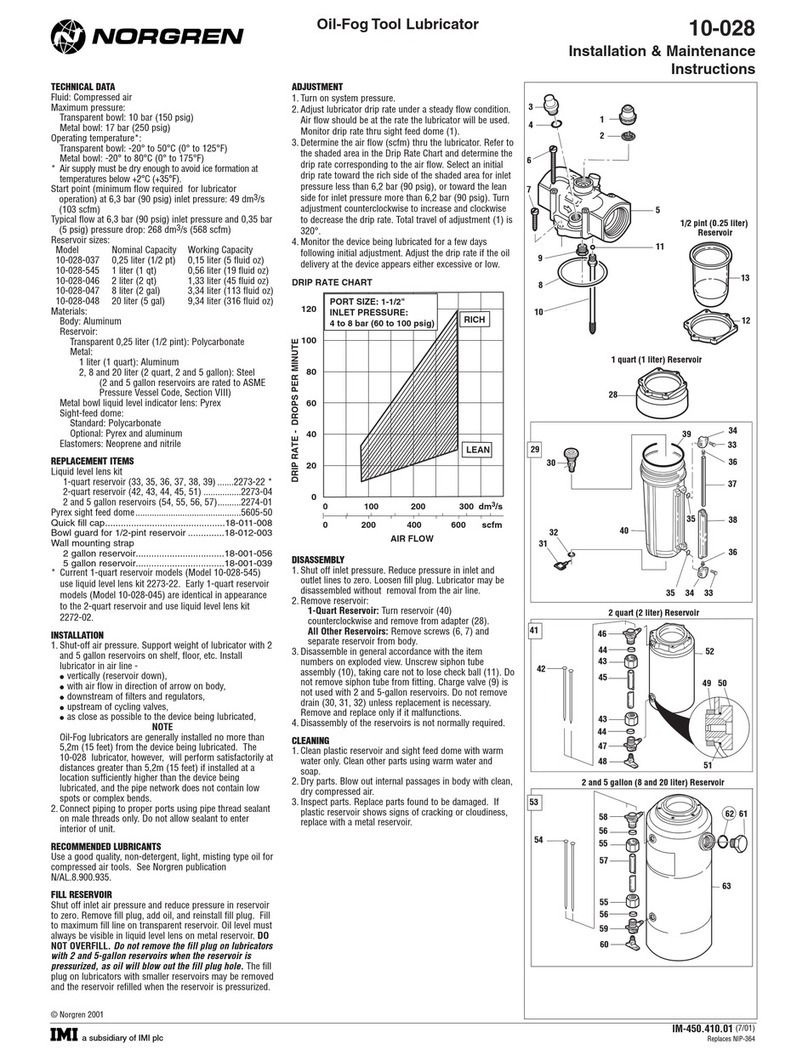

ADJUSTMENT

1. Turn on system pressure.

2. Adjust lubricator drip rate only when there is a constant

rate of air flow through the lubricator. Monitor drip rate

through sight feed dome (3).

3. Oil-Fog Lubricators - Determine the average rate of flow

through the lubricator. Turn green knob (3) to obtain one

drop per minute for each 5 dm3/s (10 scfm). For example, if

the average flow is 19 dm3/s (40 scfm), set the drip rate at

4 drops per minute. Turn knob counterclockwise to increase

and clockwise to decrease the drip rate. The oil feed setting

can be locked by pushing the lock ring down, this must be

released before adjustment by pulling up.

4. Micro-Fog Lubricators - Oil drip rate is adjusted by

the red knob above the sight-feed dome, counterclock-

wise to increase and clockwise to decrease the drip rate.

The rate changes automatically to compensate for flow

variations. The oil feed setting can be locked by pushing

the lock ring down, this must be released before adjust-

ment by pulling up. See Drip Rate Chart. Turn knob

counterclockwise to increase and clockwise to decrease

the drip rate.

Drip Rate Chart for Micro-Fog Lubricators

Flow - dm3/s (scfm) Drops per Minute

2,4 (5) 10

5 (10) 11

9 (20) 13

14 (30) 15

19 (40) 17

24 (50) 19

28 (60) 22

34 (70) 24

38 (80) 26

43 (90) 28

48 (100) 30

5. Monitor the device being lubricated for a few days

following initial adjustment. Adjust the drip rate if the oil

delivery at the device appears either excessive or low.

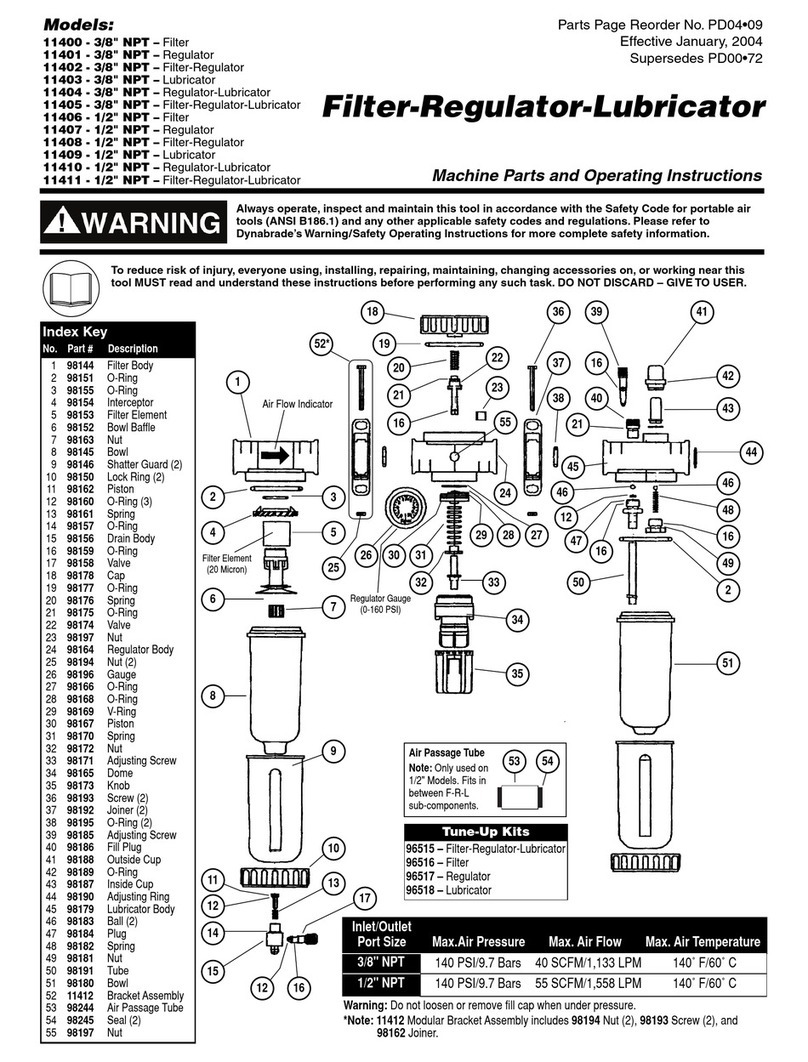

DISASSEMBLY

1. Shut off inlet pressure. Reduce pressure in inlet and outlet

lines to zero. Loosen fill plug (1).

2. Remove reservoir - push into body and turn counterc-

lockwise.

3. Disassemble in general accordance with the item num-

bers on exploded view. Do not remove the manual drain

unless replacement is necessary. Remove and replace

drain assembly only if drain malfunctions. Do not remove

syphon tube (53). Remove and replace items 54 through

59 only if lubricator malfunctions.

ADJUSTMENT

1. Turn on system pressure.

2. Adjust lubricator drip rate only when there is a constant

rate of air flow through the lubricator. Monitor drip rate

through sight feed dome (3).

3. Oil-Fog Lubricators - Determine the average rate of flow

through the lubricator. Turn green knob (3) to obtain one

drop per minute for each 5 dm3/s (10 scfm). For

example, if the average flow is 19 dm3/s (40 scfm), set

the drip rate at 4 drops per minute. Turn knob

counterclockwise to increase and clockwise to decrease

the drip rate. The oil feed setting can be locked by

pushing the lock ring down, this must be released before

adjustment by pulling up.

4. Micro-Fog Lubricators - Oil drip rate is adjusted by the

red knob above the sight-feed dome, counterclockwise to

increase and clockwise to decrease the drip rate. The rate

changes automatically to compensate for flow variations.

The oil feed setting can be locked by pushing the lock

ring down, this must be released before adjustment by

pulling up.

See Drip Rate Chart. Turn knob counterclockwise to

increase and clockwise to decrease the drip rate.

Drip Rate Chart for Micro-Fog Lubricators

Flow - dm3/s (scfm) Drops per Minute

2,4 (5) 10

5 (10) 11

9 (20) 13

14 (30) 15

19 (40) 17

24 (50) 19

28 (60) 22

34 (70) 24

38 (80) 26

43 (90) 28

48 (100) 30

5. Monitor the device being lubricated for a few days

following initial adjustment. Adjust the drip rate if the oil

delivery at the device appears either excessive or low.

DISASSEMBLY

1. Shut off inlet pressure. Reduce pressure in inlet and

outlet lines to zero. Loosen fill plug (1).

2. Remove reservoir - push into body and turn

counterclockwise.

3. Disassemble in general accordance with the item

numbers on exploded view. Do not remove the manual

drain unless replacement is necessary. Remove and

replace drain assembly only if drain malfunctions. Do not

remove syphon tube (53). Remove and replace items 54

through 59 only if lubricator malfunctions.

CLEANING

1. Clean plastic reservoir with warm water only. Clean other

parts using warm water and soap.

2. Dry parts. Blow out internal passages in body with clean,

dry compressed air.

3. Inspect parts. Replace parts found to be damaged. If

plastic reservoir shows signs of cracking or cloudiness,

replace with a metal reservoir.

ASSEMBLY

1. Lubricate o-rings, the portion of the manual drain body

(19, 33) that contacts the bowl, and the hole in the

manual drain body that accommodates the stem of drain

valve (20, 34) with o-ring grease.

2. Assemble lubricator as shown on exploded view.

3. Assemble the 1 litre (1 quart) liquid indicator parts (69

through 74) to reservoir. Apply a 0,9 to 1,8 kg (2 to 4

pound) clamping force to upper and lower sight glass

brackets (70). Tighten screws (69).

3. Torque Table N-m (Inch-Pounds)

3 (Dome) 2,3 to 2,8 (20 to 25)

43 (Screw) 1,7 to 2,3 (15 to 20)

55 (Screw) 1,1 to 1,6 (10 to 14)

69 (Screw) 0,9 to 1,1 (8 to 10)

4. Push reservoir, or reservoir with guard, into body and

turn fully clockwise.

TECHNICAL DATA

Fluid: Compressed air

Maximum pressure:

Guarded transparent bowl: 10 bar (150 psig)

Metal bowl: 17 bar (250 psig)

Operating temperature*:

Transparent bowl: –20° to +50°C (0° to +125°F)

Metal bowl: –20° to +80°C (0° to +175°F)

* Air supply must be dry enough to avoid ice formation at

temperatures below +2°C (+35°F).

Start point (minimum flow required for lubricator

operation) at 6,3 bar (90 psig) inlet pressure:

1,5 dm3/s (3.2 scfm)

Nominal bowl capacity: 0,2 litre (7 fluid oz), standard

1 litre (1 quart US), optional

Materials:

Body: Zinc

Bowl:

Metal: Aluminium

Transparent, optional: Polycarbonate

Metal bowl liquid level indicator lens,

standard: Grilamid

Metal bowl sight glass, optional (standard on

1 litre bowl): Pyrex

Sight dome: Polycarbonate

Elastomers: Synthetic rubber

REPLACEMENT ITEMS

Service kit, contains required items circled: ..........4382-200

Prismatic sight glass..............................................4380-042

Pyrex sight glass....................................................4380-041

Pyrex sight glass, 1 litre bowl..................................2273-22

Manual drain ..............................................................684-84

INSTALLATION

1. Install unit vertically in air line -

●vertically (bowl down),

●with air flow in direction of arrow on body,

●upstream of cycling valves

●as close as possible to the device being lubricated,

●Oil-Fog Models - Not more than 5,2m (15 feet) from

the device being lubricated, and at the same height or

higher than the device.

2. Before assembling the basic unit into the yoke the port

seal o-rings should be lightly smeared with o-ring

grease.

3. Locate clamp ring under lugs on top of yoke, offer basic

unit into yoke with directional arrows correctly aligned

(an interference fit prevents assembly if misaligned)

before engaging and fully tightening the clamp ring.

4. Turn bowl or bowl guard fully clockwise into body before

pressurizing. Lock symbols on body and bowl guards

must align.

RECOMMENDED LUBRICANTS

Fill reservoir with a good quality, light, misting type oil

for compressed air tools. See our publication

N/AL.8.900.935. Fill to maximum fill line on transparent

reservoirs. Oil level must always be visible in lens on metal

reservoirs. Do not overfill.

FILL RESERVOIR (OIL-FOG LUBRICATORS)

Remove fill plug (1), add oil, and reinstall fill plug. Fill

plug can be removed and oil added without shutting off air

pressure to the lubricator.

FILL RESERVOIR (MICRO-FOG LUBRICATORS)

Shut off inlet air pressure and reduce pressure in

reservoir to zero. Remove fill plug (1), add oil, and reinstall

fill plug. Do not remove the fill plug when the reservoir is

pressurized, as oil will blow out the fill plug hole.

………continued over

L64★ - ★★P- ★★N

Port

2.....1/4"

3.....3/8"

4.....1/2"

6.....3/4"

Thread

A ....PTF

B ....ISO Rctaper

G ....ISO G parallel

N ....No thread (basic unit)

Bowl/Reservoir

A ....optional 1 litre (1 quart US) metal

D ....Metal

P ....Transparent with guard

R ....Metal with Pyrex liquid level indicator

Operation

C ....Oil-Fog

M ...Micro-Fog

Drain

M ...Manual

E.....No drain (Closed bowl)

Q ....Manual 1/4 turn

R ....Remote fill

AB

C

48

32

47

Current Plastic Bowl

18

31

30

29

43

44

4645

36

38

37

39

33

35

34

56

54

58

59

67

66

72 73

70

74

63

69

71

65

68

64

62

55

57

1

2

9

53

3

4

5

9

6

8

7

22

24

23

25

19

21

20

61

60

Early Plastic Bowl

and Guard.

No Longer Available

Replaced by Item 18

L64C, L64M - Lubricator

Installation & Maintenance Instructions

IM-240.400 (7/99)

Our policy is one of continued research and development. We therefore reserve the right to amend, without notice,

the specifications given in this document. © 1999 Norgren, Inc.

ADJUSTMENT

1. Turn on system pressure.

2. Adjust lubricator drip rate only when there is a constant

rate of air flow through the lubricator. Monitor drip rate

through sight feed dome (3).

3. Oil-Fog Lubricators - Determine the average rate of flow

through the lubricator. Turn green knob (3) to obtain one

drop per minute for each 5 dm3/s (10 scfm). For

example, if the average flow is 19 dm3/s (40 scfm), set

the drip rate at 4 drops per minute. Turn knob

counterclockwise to increase and clockwise to decrease

the drip rate. The oil feed setting can be locked by

pushing the lock ring down, this must be released before

adjustment by pulling up.

4. Micro-Fog Lubricators - Oil drip rate is adjusted by the

red knob above the sight-feed dome, counterclockwise to

increase and clockwise to decrease the drip rate. The rate

changes automatically to compensate for flow variations.

The oil feed setting can be locked by pushing the lock

ring down, this must be released before adjustment by

pulling up.

See Drip Rate Chart. Turn knob counterclockwise to

increase and clockwise to decrease the drip rate.

Drip Rate Chart for Micro-Fog Lubricators

Flow - dm3/s (scfm) Drops per Minute

2,4 (5) 10

5 (10) 11

9 (20) 13

14 (30) 15

19 (40) 17

24 (50) 19

28 (60) 22

34 (70) 24

38 (80) 26

43 (90) 28

48 (100) 30

5. Monitor the device being lubricated for a few days

following initial adjustment. Adjust the drip rate if the oil

delivery at the device appears either excessive or low.

DISASSEMBLY

1. Shut off inlet pressure. Reduce pressure in inlet and

outlet lines to zero. Loosen fill plug (1).

2. Remove reservoir - push into body and turn

counterclockwise.

3. Disassemble in general accordance with the item

numbers on exploded view. Do not remove the manual

drain unless replacement is necessary. Remove and

replace drain assembly only if drain malfunctions. Do not

remove syphon tube (53). Remove and replace items 54

through 59 only if lubricator malfunctions.

CLEANING

1. Clean plastic reservoir with warm water only. Clean other

parts using warm water and soap.

2. Dry parts. Blow out internal passages in body with clean,

dry compressed air.

3. Inspect parts. Replace parts found to be damaged. If

plastic reservoir shows signs of cracking or cloudiness,

replace with a metal reservoir.

ASSEMBLY

1. Lubricate o-rings, the portion of the manual drain body

(19, 33) that contacts the bowl, and the hole in the

manual drain body that accommodates the stem of drain

valve (20, 34) with o-ring grease.

2. Assemble lubricator as shown on exploded view.

3. Assemble the 1 litre (1 quart) liquid indicator parts (69

through 74) to reservoir. Apply a 0,9 to 1,8 kg (2 to 4

pound) clamping force to upper and lower sight glass

brackets (70). Tighten screws (69).

3. Torque Table N-m (Inch-Pounds)

3 (Dome) 2,3 to 2,8 (20 to 25)

43 (Screw) 1,7 to 2,3 (15 to 20)

55 (Screw) 1,1 to 1,6 (10 to 14)

69 (Screw) 0,9 to 1,1 (8 to 10)

4. Push reservoir, or reservoir with guard, into body and

turn fully clockwise.

TECHNICAL DATA

Fluid: Compressed air

Maximum pressure:

Guarded transparent bowl: 10 bar (150 psig)

Metal bowl: 17 bar (250 psig)

Operating temperature*:

Transparent bowl: –20° to +50°C (0° to +125°F)

Metal bowl: –20° to +80°C (0° to +175°F)

* Air supply must be dry enough to avoid ice formation at

temperatures below +2°C (+35°F).

Start point (minimum flow required for lubricator

operation) at 6,3 bar (90 psig) inlet pressure:

1,5 dm3/s (3.2 scfm)

Nominal bowl capacity: 0,2 litre (7 fluid oz), standard

1 litre (1 quart US), optional

Materials:

Body: Zinc

Bowl:

Metal: Aluminium

Transparent, optional: Polycarbonate

Metal bowl liquid level indicator lens,

standard: Grilamid

Metal bowl sight glass, optional (standard on

1 litre bowl): Pyrex

Sight dome: Polycarbonate

Elastomers: Synthetic rubber

REPLACEMENT ITEMS

Service kit, contains required items circled: ..........4382-200

Prismatic sight glass..............................................4380-042

Pyrex sight glass....................................................4380-041

Pyrex sight glass, 1 litre bowl..................................2273-22

Manual drain ..............................................................684-84

INSTALLATION

1. Install unit vertically in air line -

●vertically (bowl down),

●with air flow in direction of arrow on body,

●upstream of cycling valves

●as close as possible to the device being lubricated,

●Oil-Fog Models - Not more than 5,2m (15 feet) from

the device being lubricated, and at the same height or

higher than the device.

2. Before assembling the basic unit into the yoke the port

seal o-rings should be lightly smeared with o-ring

grease.

3. Locate clamp ring under lugs on top of yoke, offer basic

unit into yoke with directional arrows correctly aligned

(an interference fit prevents assembly if misaligned)

before engaging and fully tightening the clamp ring.

4. Turn bowl or bowl guard fully clockwise into body before

pressurizing. Lock symbols on body and bowl guards

must align.

RECOMMENDED LUBRICANTS

Fill reservoir with a good quality, light, misting type oil

for compressed air tools. See our publication

N/AL.8.900.935. Fill to maximum fill line on transparent

reservoirs. Oil level must always be visible in lens on metal

reservoirs. Do not overfill.

FILL RESERVOIR (OIL-FOG LUBRICATORS)

Remove fill plug (1), add oil, and reinstall fill plug. Fill

plug can be removed and oil added without shutting off air

pressure to the lubricator.

FILL RESERVOIR (MICRO-FOG LUBRICATORS)

Shut off inlet air pressure and reduce pressure in

reservoir to zero. Remove fill plug (1), add oil, and reinstall

fill plug. Do not remove the fill plug when the reservoir is

pressurized, as oil will blow out the fill plug hole.

………continued over

L64★ - ★★P- ★★N

Port

2.....1/4"

3.....3/8"

4.....1/2"

6.....3/4"

Thread

A ....PTF

B ....ISO Rctaper

G ....ISO G parallel

N ....No thread (basic unit)

Bowl/Reservoir

A ....optional 1 litre (1 quart US) metal

D ....Metal

P ....Transparent with guard

R ....Metal with Pyrex liquid level indicator

Operation

C ....Oil-Fog

M ...Micro-Fog

Drain

M ...Manual

E.....No drain (Closed bowl)

Q ....Manual 1/4 turn

R ....Remote fill

AB

C

48

32

47

Current Plastic Bowl

18

31

30

29

43

44

4645

36

38

37

39

33

35

34

56

54

58

59

67

66

72 73

70

74

63

69

71

65

68

64

62

55

57

1

2

9

53

3

4

5

9

6

8

7

22

24

23

25

19

21

20

61

60

Early Plastic Bowl

and Guard.

No Longer Available

Replaced by Item 18

L64C, L64M - Lubricator

Installation & Maintenance Instructions

IM-240.400 (7/99)

Our policy is one of continued research and development. We therefore reserve the right to amend, without notice,

the specifications given in this document. © 1999 Norgren, Inc.

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document. (1999 - I&M8074d) © 2020 IMI International s.r.o.

L64C, L64M Lubricator

Installation & Maintenance Instructions

4/19

I&M/en 8.240.400.2

CLEANING

1. Clean plastic reservoir with warm water only. Clean other

parts using warm water and soap.

2. Dry parts. Blow out internal passages in body with clean,

dry compressed air.

3. Inspect parts. Replace parts found to be damaged. If

plastic reservoir shows signs of cracking or cloudiness,

replace with a metal reservoir.

ASSEMBLY

1. Lubricate o-rings, the portion of the manual drain body

(19, 33) that contacts the bowl, and the hole in the ma-

nual drain body that accommodates the stem of drain

valve (20, 34) with o-ring grease.

2. Assemble lubricator as shown on exploded view.

3. Assemble the 1 litre (1 quart) liquid indicator parts (69

through 74) to reservoir. Apply a 0,9 to 1,8 kg (2 to 4

pound) clamping force to upper and lower sight glass

brackets (70). Tighten screws (69).

Torque Table N-m (Inch-Pounds)

3 (Dome) 2,3 to 2,8 (20 to 25)

43 (Screw) 1,7 to 2,3 (15 to 20)

55 (Screw) 1,1 to 1,6 (10 to 14)

69 (Screw) 0,9 to 1,1 (8 to 10)

4. Push reservoir, or reservoir with guard, into body and turn

fully clockwise.

WARNING

These products are intended for use in industrial

compressed air systems only. Do not use these products

where pressures and temperatures can exceed those listed

under Technical Data.

Polycarbonate plastic bowls can be damaged and possibly

burst if exposed to such substances as certain solvents,

strong alkalies, compressor oils containing esterbased

additives or synthetic oils. Fumes of these substances in

contact with the polycarbonate bowl, externally or

internally, can also result in damage. Clean with warm

water only.

Use metal bowl in applications where a plastic bowl might

be exposed to substances that are incompatible with

polycarbonate.

Before using these products with luids other than air, for

non industrial applications, or for life-support systems

consult IMI Precision Engineering.

Use in potentially explosive atmospheres

Code of device according EC directive

2014/34/EU

II 2G Ex h IIC T6 Gb

II 2D Ex h IIIC T85ºC Db

• Only non-lammable gasese to be used as a medium.

• Surface temperature dependant on process luid

temperature and ambient temperature - must be below

the ignition temperature of the lammable gas or dust.

• Earth unit and/or pipework to avoid electrostatic

discharge.

• Precautions should be taken to prevent hazard from

adiabatic compression.

• Use wet cloth for cleaning.

• Protect the unit from object falling onto it.

• Avoid contact with corrosive environment.

• For servicing the unit it is recommended to carry out this

work outside of the danger zone.

• For details of ignition hazard assessment contact

Norgren.

This manual suits for next models

1

Other Norgren Lubrication System manuals

Popular Lubrication System manuals by other brands

DROPSA

DROPSA VIP4Air Series User and maintenance manual

DLS

DLS FlexxPump 1500 user guide

Graco

Graco 203-697 E Series Instructions-parts list

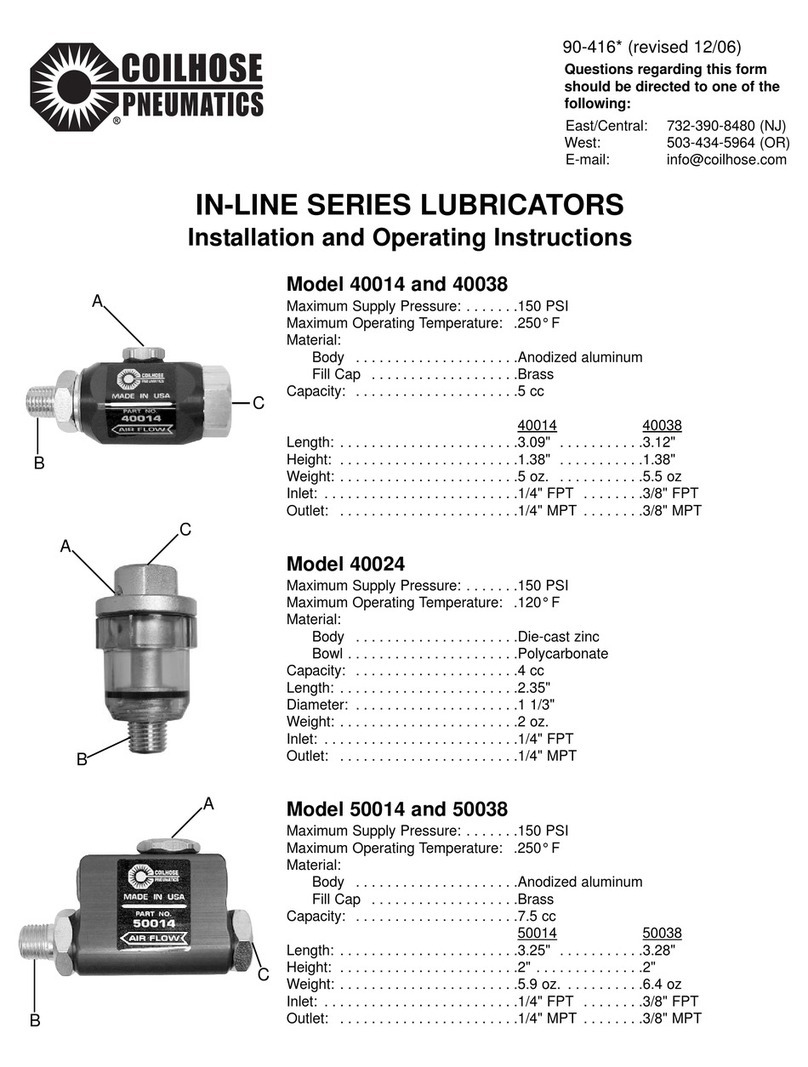

Coilhose Pneumatics

Coilhose Pneumatics IN-LINE Series Installation and operating instructions

Dynacut

Dynacut MDE Operation manual

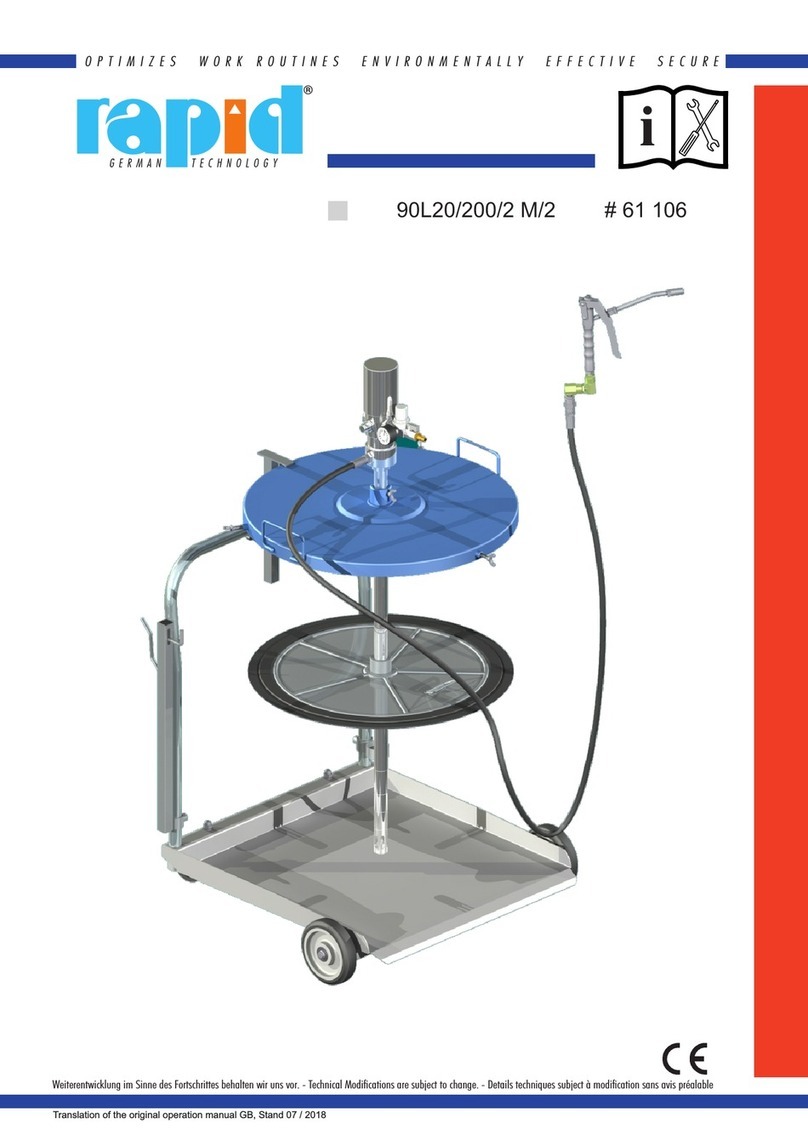

Rapid

Rapid 90 L 20/200/1 M Operation manual