4

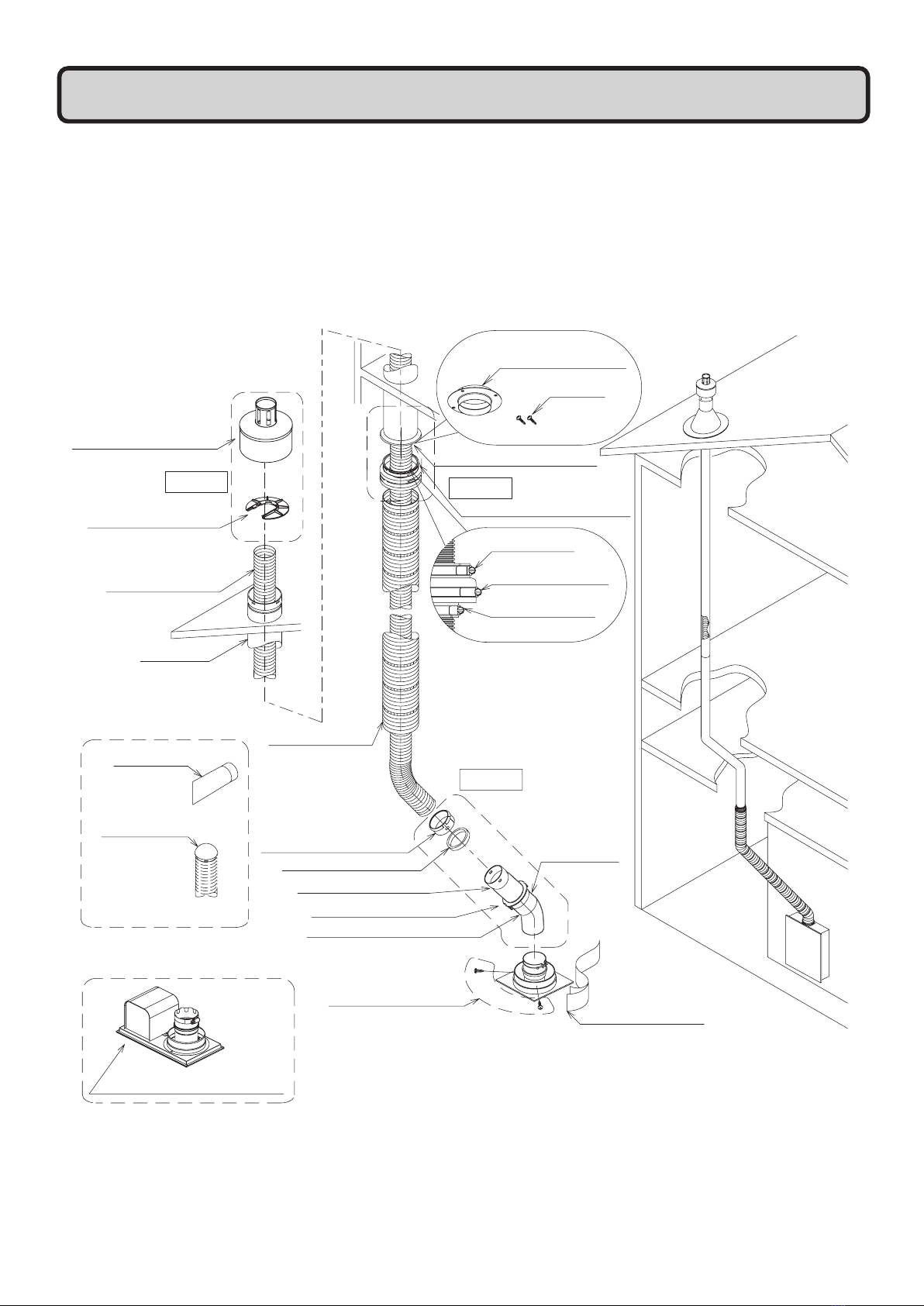

• Flex Vent 2" Kit is designed only for installation inside of B-Vent wall. Do not use it for other installation method.

Also do not use it outdoor.

• Only approved for use with the designated B-Vent manufactures.

• If the Rain Cap and B-Vent itself are damaged by corrosion, it must be replaced with new ones.

• Before installation, make sure no nails or screws have penetrated the inner B-Vent wall where the flexible vent will be

installed. Those obstructions may damage the flexible vent and may result in fires, property damage or exposure to Carbon

Monoxide.

• Do not reuse the flexible vent once it has been installed, removal of the vent may have caused damage to the flexible

vent.

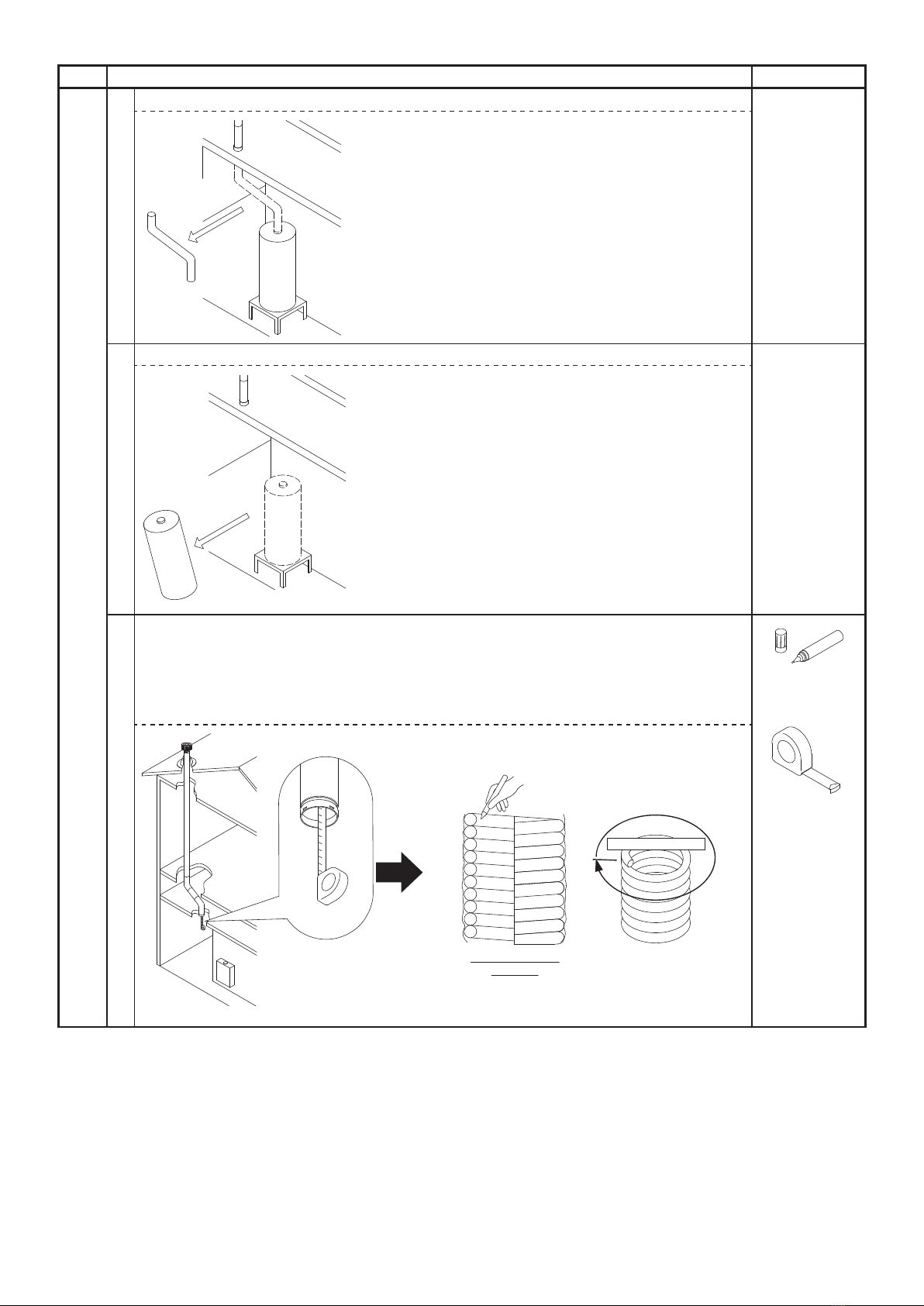

• Keep Flex vent at a temperature greater than 40°F (5°C).

Material temperature is not less than 40°F (5°C) during installation.

Damage will occur if handled or installed at lower temperatures.

• If the temperature if below 40°F (5°C) it's recommended that you store the

Flex Vent

in a warm room or car for 30 minutes.

If you find that the Flex Vent is still stiff, you may need to use a hair dryer and warm both ends of the vent to prevent breakage.

• Make sure components are kept under these following conditions.

* Clean and dry place.

* Above 40°F (5°C)

* Keep out of direct sunlight.

• Minimum bend radius should be more than 7 inch.

• Handle the flexible vent carefully.

Dropping, Crushing and Stacking may cause damage, and may result in fires, property damage or exposure to Carbon

Monoxide.

• Flex Vent 2" Kit cannot be painted.

• Avoid places where open flame are common, such as those where gasoline, benzene and adhesives are handled, or places in

which corrosive gases (ammonia, chlorine, sulfur, ethylene compounds, acids) are present.

• Avoid installation in places where dust or debris will accumulate.

Dust may block the air-supply opening, causing the performance of the device fan to drop and incomplete combustion may

occur as a result.

• Avoid installation in places where special chemical agents (e.g., hair spray or spray detergent) are used.

• For your safety, do not attempt to work on a rooftop until safety precautions have been identified and proper fall safety

measures have been taken, including the use of ladders or stairways, and personal protective equipment (PPE).

• Installation in windy or wet conditions require additional precautions. Follow local safety regulations.

40°F

(5°C)

r>7 inch

3.General Safety

• If similar flexible vent has already been installed, it must be replaced with this designated new Flex Vent Kit.

Checkup