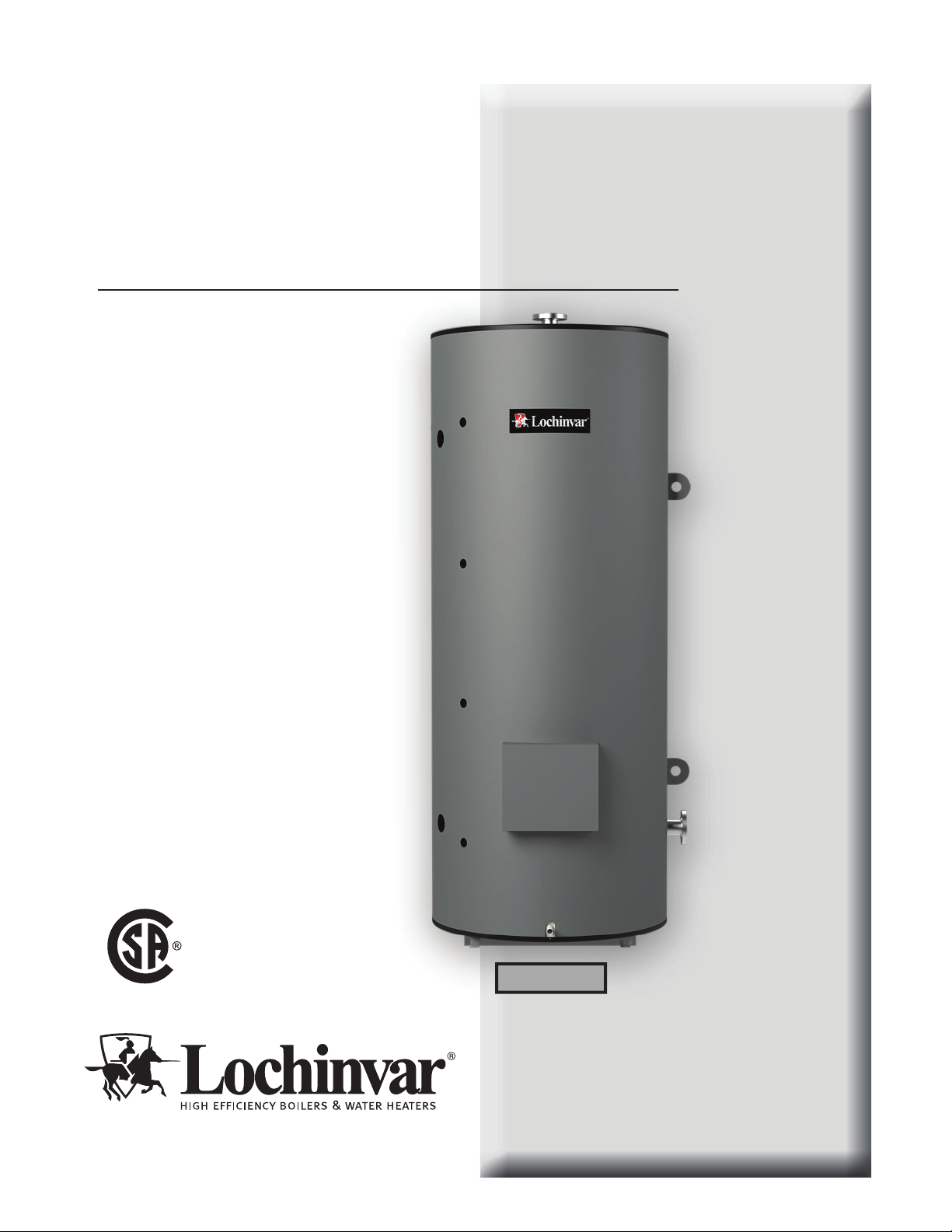

Storage Tank Installation and Operation Manual

4

Tanks with a round sheet metal jacket are insulated with a 5"

thick foam mixture that has an R value of R-30. These tanks

are for indoor installation only.

All jacketed storage tanks meet the energy efficiency

requirements of the latest edition of ASHRAE 90.1.

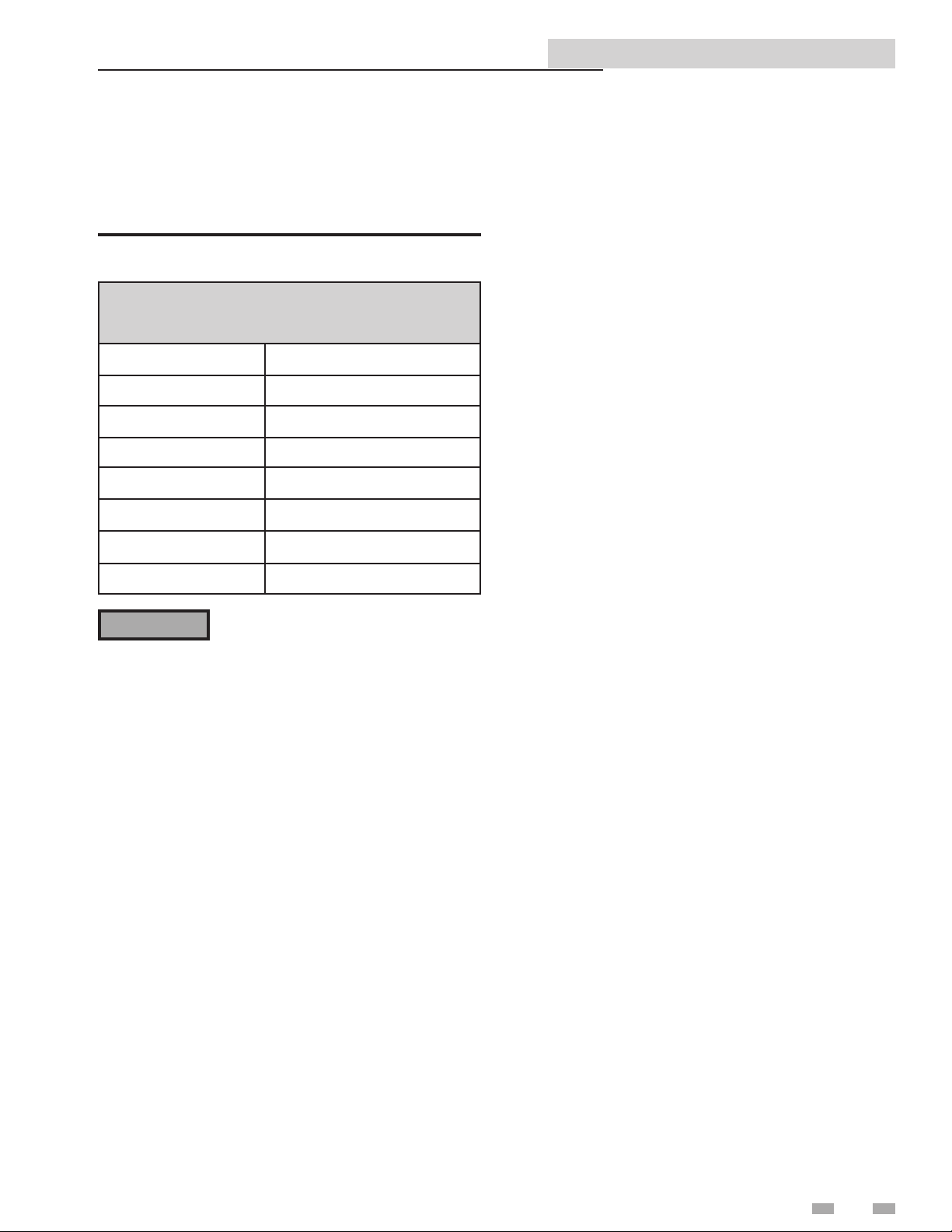

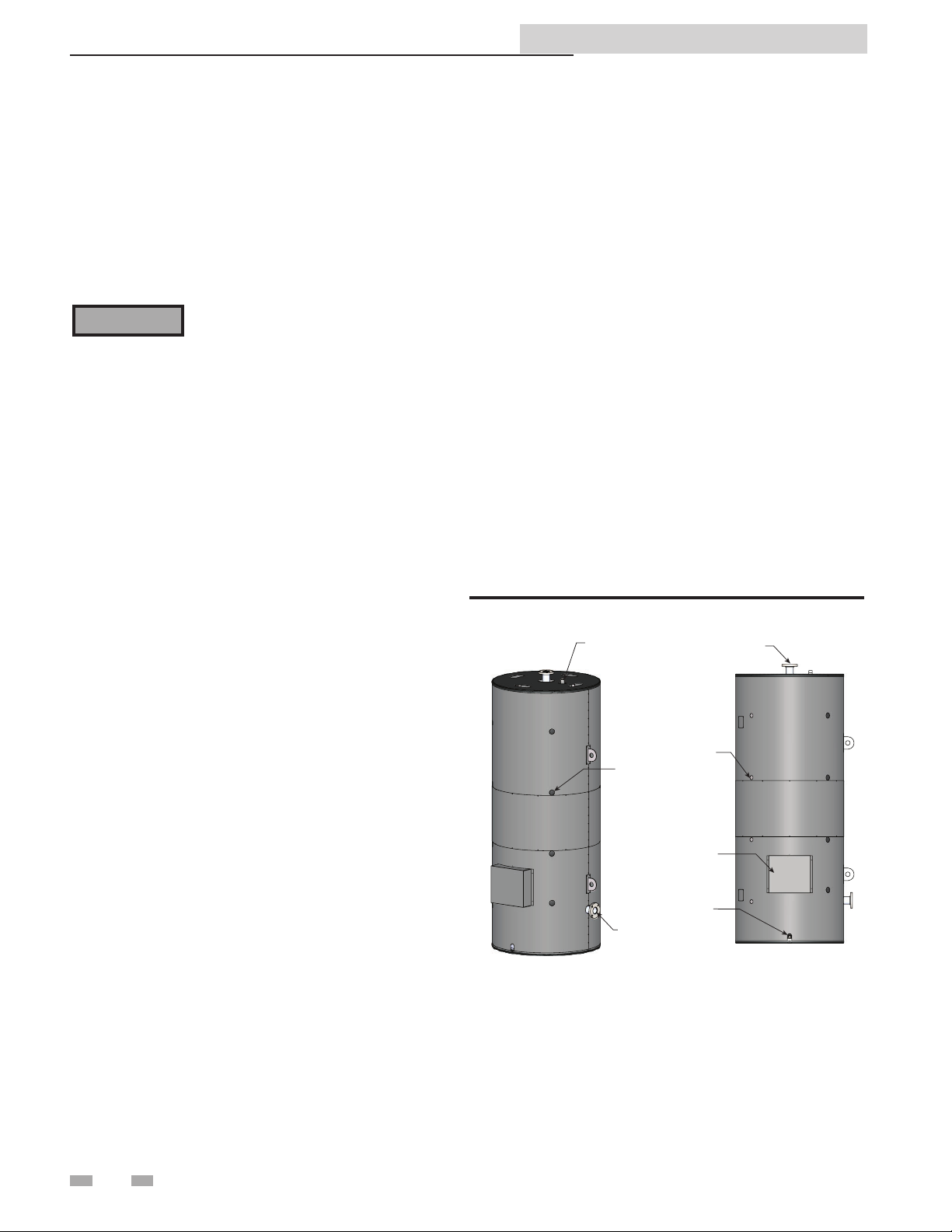

Relief Valve Tapping -- A tapping is provided for the

installation of a field supplied ASME safety relief valve.

Return / Cold Water Supply Tapping -- Lochinvar Heat

Pump Storage Tanks will have one (1) tapping designed to

return cold water back to the heater during the charge cycle

and will allow cold water in during the discharge cycle.

Hot Water Supply / Outlet Tapping -- A Hot Water Supply

/ Outlet Tapping is positioned on the top of the tank for

connection to the hot side of a mixing valve.

Drain -- A tapping or drain pipe will be connected to a low

point on the tank for drainage.

Aquastat Bulbwell -- Lochinvar Heat Pump Storage Tanks

are provided with four (4) super bulbwells for control sensors.

Five-Year Limited Tank Warranty -- Provides warranty

protection against tank failure (see warranty for details).

One-Year Limited Warranty -- Parts and accessories (see

warranty for details).

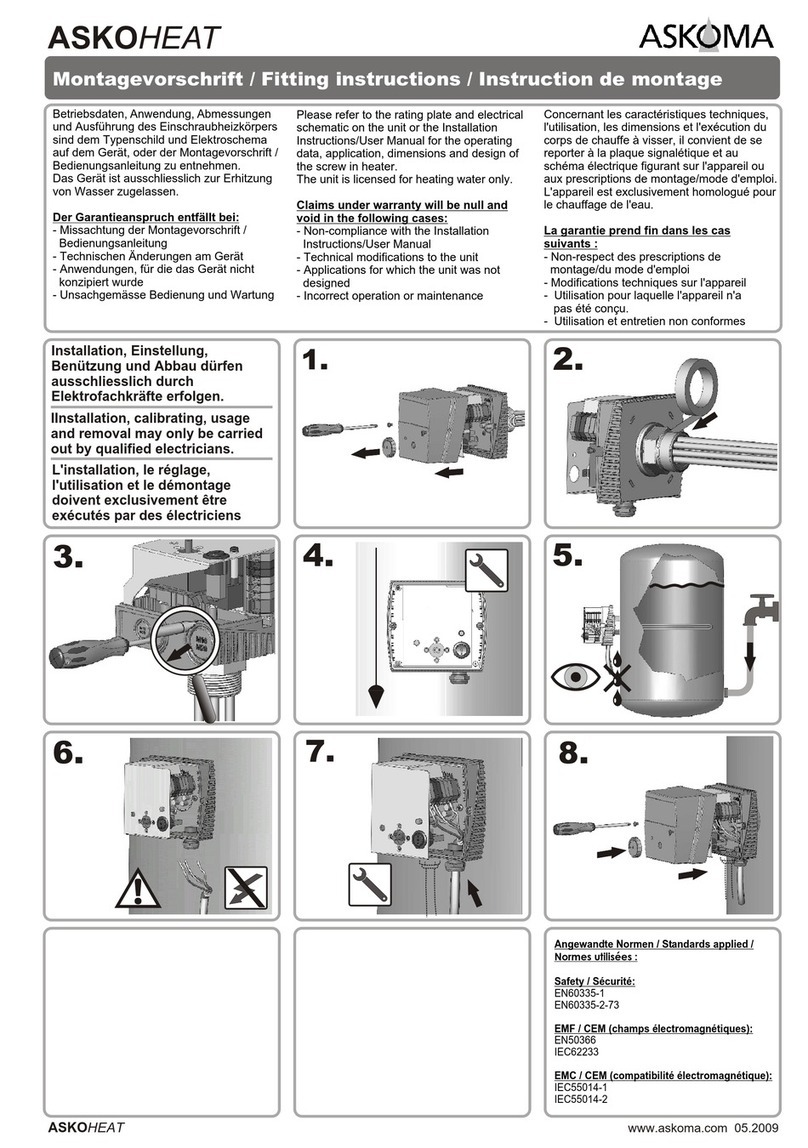

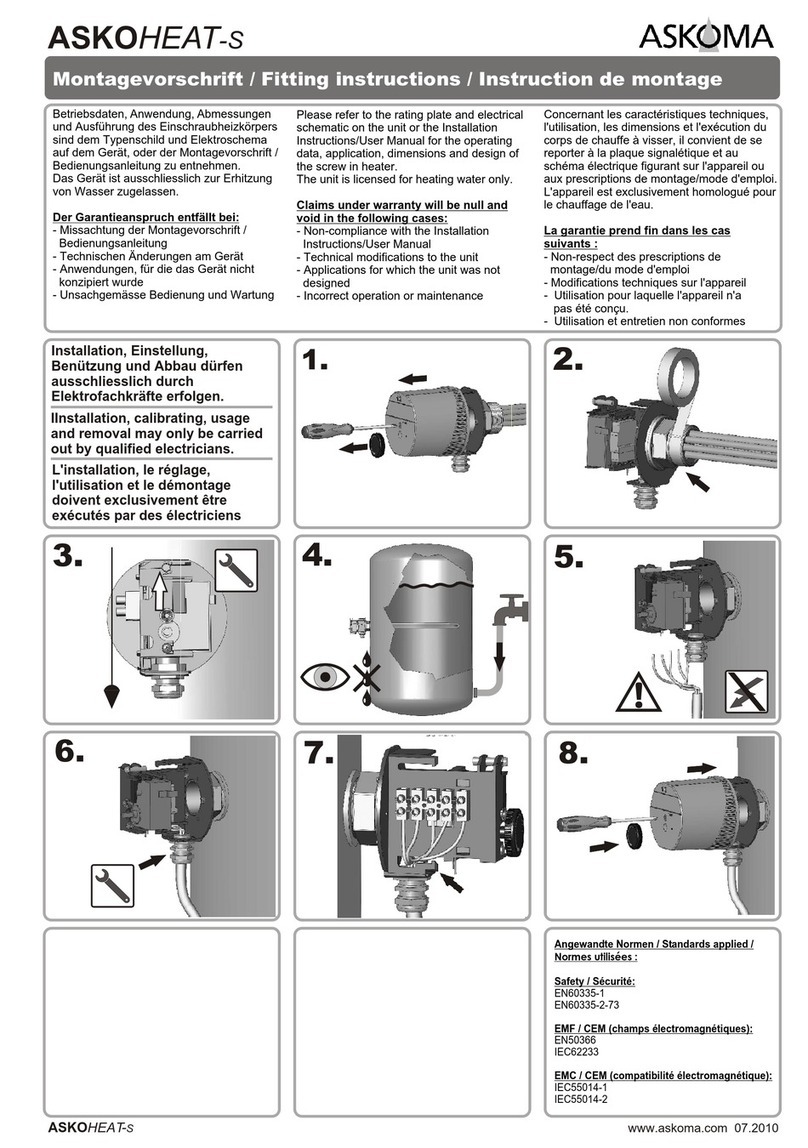

Areas of potential danger:

1. All water lines, joints, and valves.

2. All power connections and cables.

3. If the unit has been in operation, allow

the water in the heater and all

components and surfaces (tank surface,

water piping, etc.,) to cool before

starting the procedure.

4. Assure that all power to associated water

heating equipment has been shut off

and disconnected before attempting

any procedures.

5. Assure that all incoming and outgoing

water lines have been shut off at the

manual shutoff valves.

ᘐWARNING Heated water presents situations that can be

very dangerous due to the fact they are under

pressure and at very high temperatures.

To avoid possible injury or death, use

common sense and follow all accepted and

recommended procedures when performing

installation, operation, and maintenance

procedures.

The combination of electricity and water can

pose a very dangerous situation. Assure that

all power has been shut off / disconnected

before attempting any installation or

maintenance procedures.

1 General information

Transporting and unpacking the unit

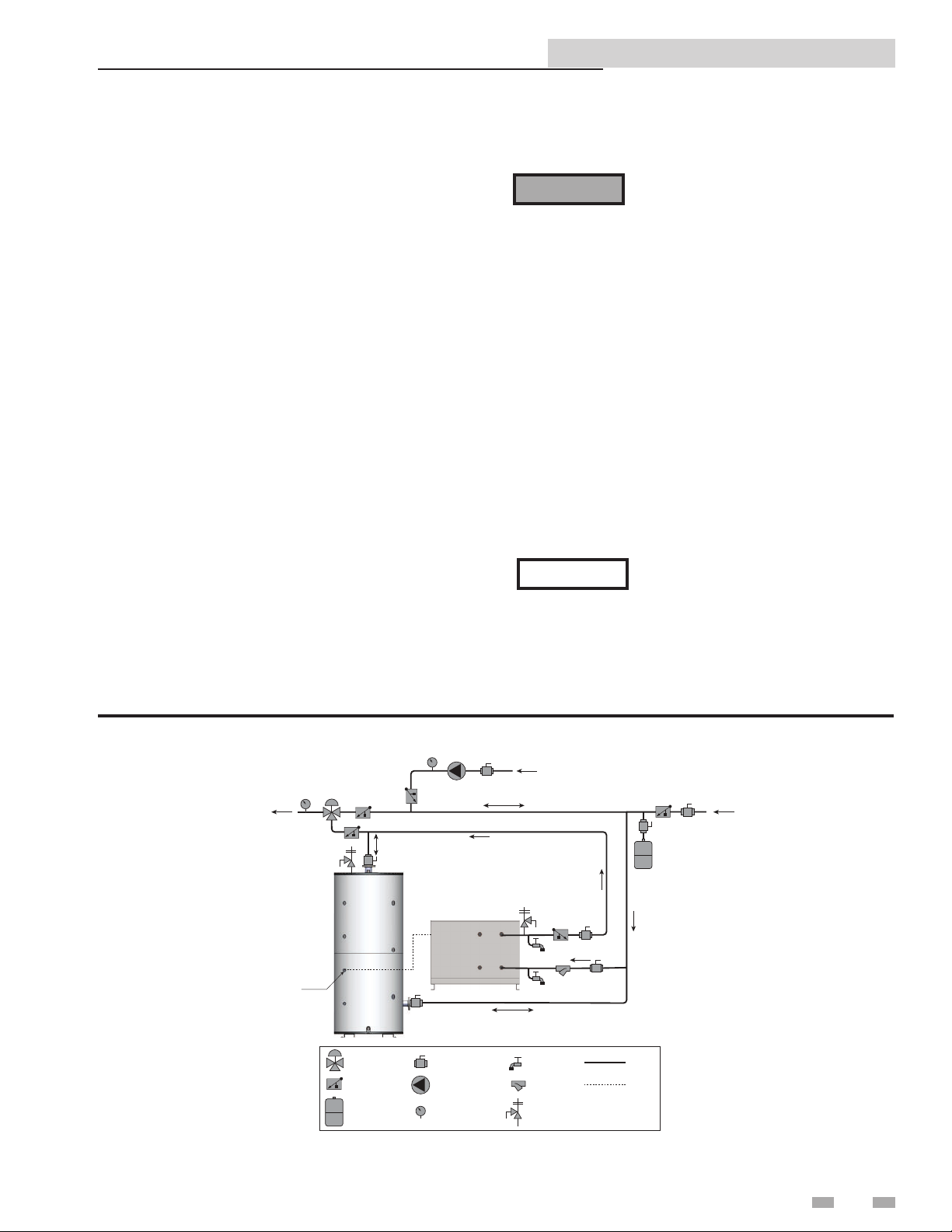

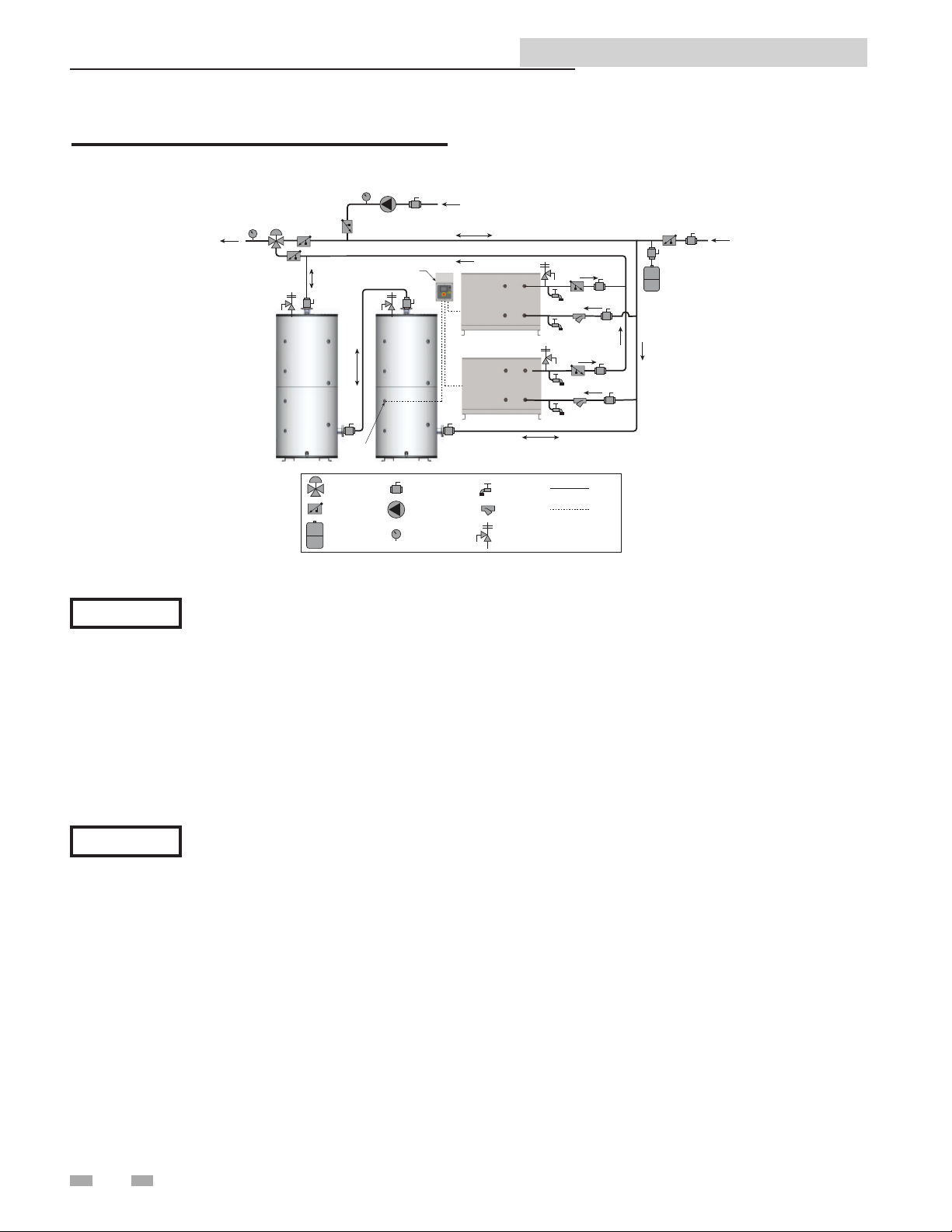

Each Heat Pump Storage Tank is fitted with lay-down shipping

legs and crated in the horizontal orientation. Crating provides

protection during shipping and a safe means in which to lift and

move the unit with a fork lift.

Remove the crate top and sides but leave the bolted bases in

place until after the unit is lifted into the vertical position.

After the top and sides are removed, the unit should be carefully

examined to assure the tank has not been damaged during

shipping. If any evidence of damage is detected that could affect

the safe operation of the unit, contact Lochinvar, LLC., or your

authorized sales representative, to report the damage and to

receive instructions on how to proceed.

After the unit and all components have been inspected for

damage, it is suggested that all optional or independent pressure

and temperature control components be checked to assure that

they meet or exceed design specifications. If any discrepancy

is found, contact Lochinvar, LLC., or your authorized

representative, before proceeding with the installation.

ᘐWARNING

ᘐWARNING