1

In Canada:

The conversion shall be carried out in accordance with the requirements of the provincial

authorities having jurisdiction and in accordance with the requirements of the CAN/CSA B149.1

and CAN/CSA B149.2 Installation Code.

LA CONVERSION DOIT ÊTRE EFFECTUÉE CONFORMÉMENT AUX EXIGENCES DE L'AUTORITÉ

PROVINCIALE AYANT JURIDICTION ET AUX, CAN/CSA B149.1, ET CAN/CSA-B149.2.

*A qualified service agency is any individual, firm, corporation or company which either in person or

through a representative is engaged in and is responsible for the connection, utilization, repair or

servicing of gas utilization equipment or accessories; who is experienced in such work, familiar with all

precautions required, and has complied with all of the requirements of the authority having jurisdiction.

*Conversion acceptable for install locations 0 2,000 feet. See unit’s installation manual for procedures to

adjust above 2,000 feet.

NORITZ America Corporation

11160 Grace Avenue

Fountain Valley, CA 92708

866 766 7489

www.noritz.com

CK IM 16

Rev. 05/19

Conversion Kits: CK 82, CK 83

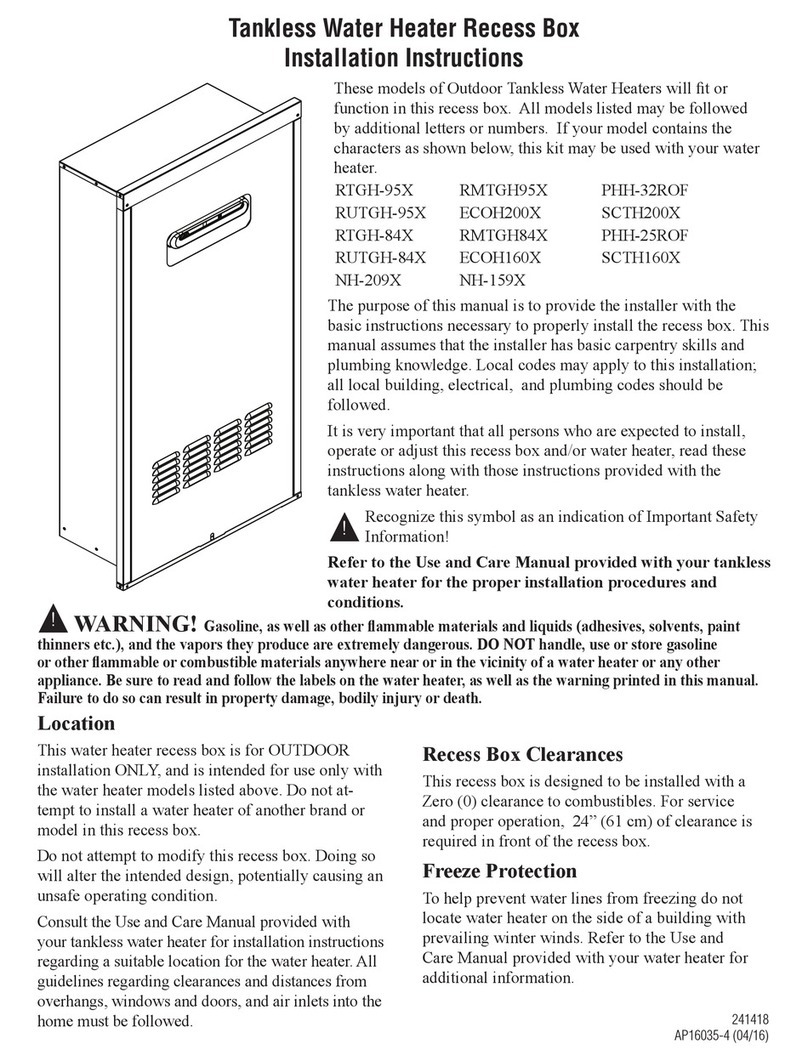

This conversion kit shall be installed by a

qualified service agency in accordance with

the manufacturer’s instructions and all

applicable codes and requirements of the

authority having jurisdiction. The information

in these instructions must be followed to

minimize the risk of fire or explosion or to

prevent property damage personal injury or

death. The qualified service agency is

responsible for the proper installation of this

kit. The installation is not proper and

complete until the operation of the converted

appliance is checked as specified in the

manufacturer’s instructions supplied with the

kit.

Cette trousse de conversion ne doit être

installée que par le représentant d'un

organisme qualifié et conformément aux

instructions du fabricant et à tous les codes et

exigences pertinents de l'autorité

compétente. Les instructions de cette

notice doivent être suivies afin de réduire au

minimum le risque d'incendie ou d'explosion

de dommage matériel de blessure ou de

mort. L'organisme qualifié

est responsable de l'installation adequate de

cette trousse. L'installation n'est pas adéquate

ni complète tant que le bon fonctionnement

de l'appareil converti n'a pas été vérifié selon

les instructions du fabricant fournies avec la