INS70085LochinvarProtoNodeStartupGuide Page5 o

48

ProtoCessor1991TarobCourtMilpitas, California 95035 USA Web:

www.ProtoCessor.com

Email:

Support@ProtoCessor.com

TABLEOFCONTENTS

1

Introduction

...................................................................................................................................................

7

1.1ProtoNodeGateway......................................................................................................................................7

2BACnet/LonWorksSetupforProtoCessorProtoNode

FPC‐N34/FPC‐N35.......................................................

7

2.1RecordIdentification

Data

.............................................................................................................................7

2.2ConfiguringDevice

Communications

.............................................................................................................7

2.2.1SetModbusCOMsettingonallofthedevicesconnectedtotheProtoNode

..........................................7

2.2.2SetModbusRTUNode‐IDforeachofthedevicesattachedtothe

ProtoNode........................................8

2.3SelectingStoredConfigurations,SettingtheMacAddress,DeviceInstance,Node_ID,andBaud

Rate

.......9

2.3.1SelectingConfigurationFilesforDevices:“S”bankDIPSwitchesS0–

S3

................................................9

2.3.1.1BACnetMS/TPandBACnetIPDIPSwitchSettings

.........................................................................9

2.3.1.2LonWorksDIPSwitchSettings

......................................................................................................11

2.3.2BACnetMS/TP(FPC‐N34):SettingtheMACAddressBACnet

Networks................................................11

2.3.3BACnetMS/TPandBACnet/IP(FPC‐N34):SettingtheDevice

Instance.................................................12

2.3.3.1BACnetMS/TPorBACnet/IP:AssigningSpecificDeviceInstances

..............................................12

2.3.4MetasysN2andModbusTCP/IP(FPC‐N34):Settingthe

Node‐ID

.........................................................12

2.3.5BACnetMS/TP(FPC‐N34):SettingtheSerialBaudRate(DIPSwitchB0–

B3).......................................13

2.3.5.1BaudRateDIPSwitchSelection

....................................................................................................13

3InterfacingProtoNodetoDevices

................................................................................................................14

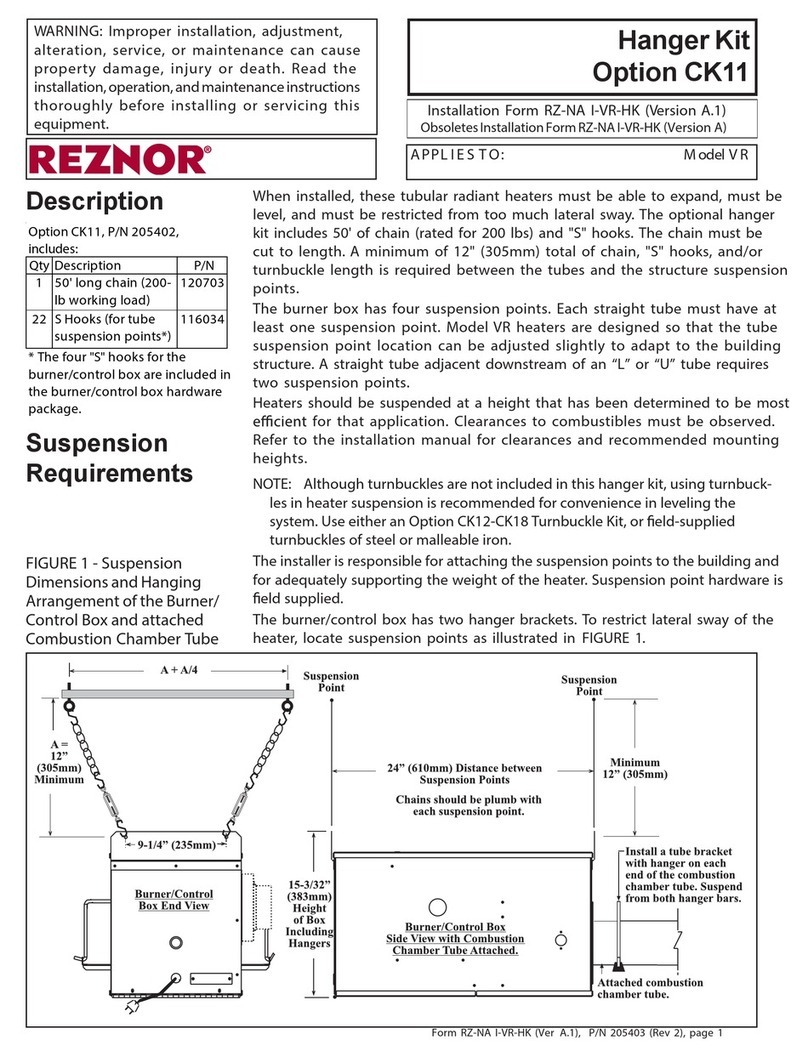

3.1ProtoNodeFPC‐N34andFPC‐N35ShowingConnection

Ports

....................................................................14

3.2DeviceConnectionstoProtoNode...............................................................................................................15

3.2.1EndofLineTerminationSwitchfortheModbusRS‐485portonthe

ProtoNode

...................................16

3.2.2Lochinvar’sArmor,SYNC/ArmorX2,Knight/KnightXL,Crest,Copper‐FinIIandFTXLLowVoltage

ModbusRTUConnectionWiringtothe

ProtoNode:

............................................................................................17

3.3BACnetMS/TPorMetasysN2(FPC‐N34):WiringFieldPorttoRS‐485

Network

........................................18

3.4LonWorks(FPC‐N35):WiringFieldPorttoLonWorksNetwork..................................................................19

3.5ConnectingPowerto

ProtoNode

.................................................................................................................20

4

ACnet/IPandModbusTCP/IP:ChangetheProtonodeIP

Address..............................................................

21

4.1ConnectthePCtoProtoNodeviathe Ethernet

Port

...................................................................................21

4.2BACnetMS/

PandBACnet/IP:Setting Node

Offset to Assign Specific Device Instances.........................22

4.3AccessingtheFS

WebGUIfromthe Web Configurator ............................................................................23

4.4BACnet/IPandModbusTCP/IP:Setting IP Address for Field

Network

........................................................24

5Howtostarttheinstallationover:clearingprofiles

.....................................................................................

25

6LonWorks(FPC‐N35):CommissioningProtoNodeonaLonWorks

Network..................................................

26

6.1CommissioningProtoNodeFPC‐N35onaLonWorksNetwork...................................................................26

6.1.1InstructionstoUploadXIFFilefromProtoNodeFPC‐N35UsingFSGUIWeb

Server

.............................26

7CASBACnetExplorerforValidatingProtoNodeintheField

.........................................................................

28

7.1DownloadingtheCASExplorerandRequestinganActivationKey.............................................................28

7.2CASBACnet

Setup

........................................................................................................................................29

7.2.1CASBACnetMS/TPSetup.......................................................................................................................29

7.2.2CASBACnetBACnet/IP

Setup

.................................................................................................................29

AppendixA.Troubleshooting

..............................................................................................................................

30

AppendixA.1.ViewingDiagnostic

information

.......................................................................................................30

AppendixA.2.CheckWiringandSettings................................................................................................................31

AppendixA.3.TakeDiagnosticCaptureWiththeFieldServerUtilities...................................................................31

AppendixA.4.BACnet/IP:SettingNetwork_NumberformorethanoneProtoNodeonSubnet...........................34

AppendixA.5.LEDDiagnosticsforModbusRTUCommunicationsBetweenProtoNodeand

Devices

...................34

AppendixB.VendorInformation‐

Lochinvar

.......................................................................................................

35

AppendixB.1.SyncModbusRTUMappingstoBACnetMS/TP,BACnet/IP,MetasysN2and

LonWorks

................35

AppendixB.2.KnightModbusRTUMappingstoBACnetMS/TP,BACnet/IP,MetasysN2and

LonWorks

.............36