NOTE: The RS-094-MK6 can be installed on existing or new water heater installations. RDT recommends that

installations be completed by a licensed plumber to ensure that all local code requirements are followed.

INSTALLATION INSTRUCTIONS

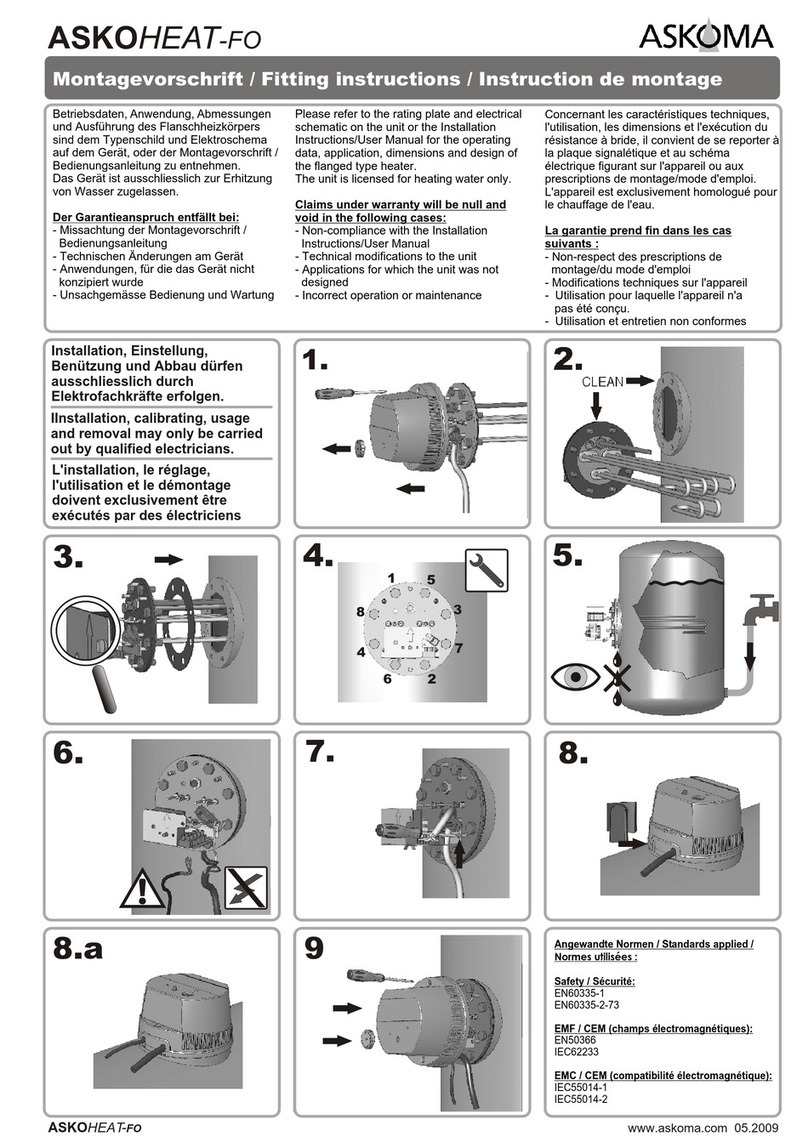

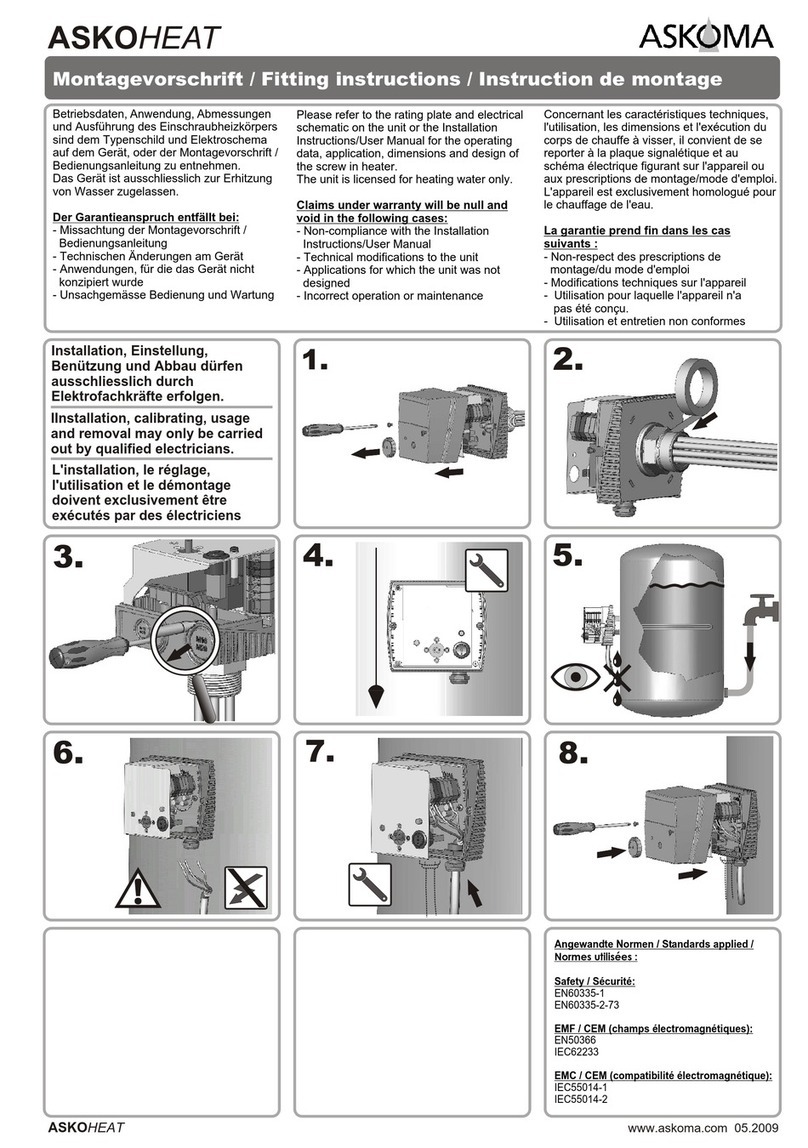

1. Turn off the water supply feed line to the water heater.

2.

Prior to installation, manually exercise the valve body to fully closed and back to fully open position by

holding it in your hand, applying a pliers to the valve stem and turning. Thread the valve body into the feed

water line after the manual shut-off. Apply pipe sealant or Teon

®

tape to the NPT threads and tighten

.

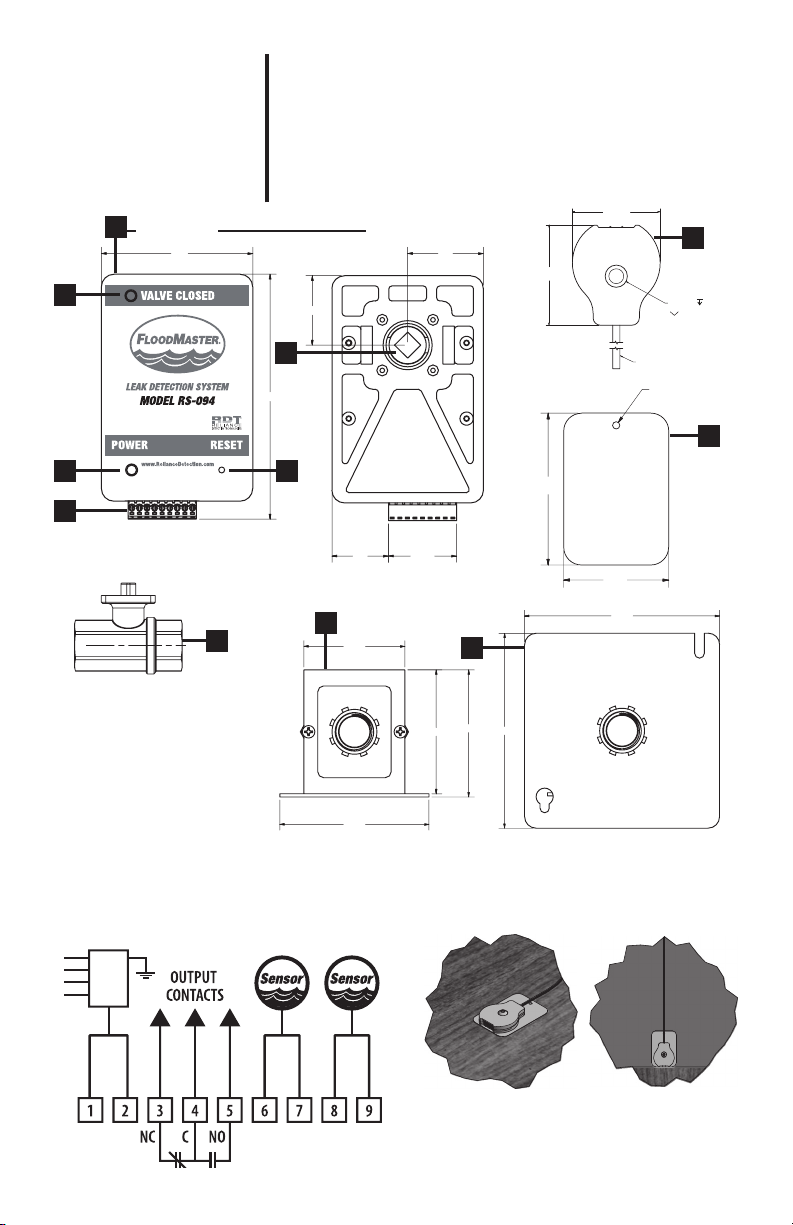

3. The receiver connector comes prewired with basic connections to the power supply and the sensor.

Using an appropriate screwdriver, make any additional electrical connections as may be desired for

output contacts or additional sensors per wiring Figure 1. (Note: additional sensors can be connected

to either 6 & 7 or 8 & 9, as wiring space allows.) Then snap the terminal wiring block into the receiver

housing at the mating slot provided.

4. Secure the valve body in one hand and snap the receiver into place on the valve body mounting pad.

(Note: Improper alignment of the valve stem may interfere with proper receiver mounting. If any resistance

is encountered, conrm the witness mark on the valve stem is in alignment with the valve ports. Use an

appropriate hand tool, such as pliers, to clamp down on the valve stem and turn in the appropriate direction

until the desired position is achieved).

5. Place the sensor(s) where water is most likely to rst accumulate (such as the drain pan or the oor next

to the tank). The sensor is magnetic and can be installed horizontally or vertically in conjunction with the

metal plate – see Figure 2.

• Clean the desired location area to ensure the surface is clean for optimum plate adhesion.

• Peel the backing off the metal plate to reveal the adhesive and stick in place.

•

Place the sensor on the plate as close as possible to the oor, allowing the magnets to secure it in place.

Note: The sensor features a through-hole that can be used to screw it onto a surface if a more permanent

installation is desired or necessary.

6. Turn off the main power. Wire the appropriate inputs to the main power source. Wire the blue and yellow

wires (24V AC output) to the plenum wire that is prewired to the power input of the contact plug. Turn on

the main power. The green “Power” indicator light on the receiver will turn on.

7. Function Test the system as follows:

• Place the sensor on a wet paper towel. The audible alarm will sound and the valve will rotate to the

closed position.

• The red “Valve Closed” LED will turn on when the valve is completely closed (approximately 45-second

cycle time). Open a hot water faucet and conrm that there is no water ow.

• Remove the sensor from the paper towel, dry the contact points, and place it back in the desired

location on the metal plate.

• Press and release the “Reset” button on the receiver to open the valve and begin the ow of water

again (approximately 45 seconds to fully re-open). The green “Power” indicator light will ash once to

indicate the reset process has begun. Open a hot water faucet and inspect for water ow.

TRANSFORMER WIRING INSTRUCTIONS

The supplied transformer has multiple input taps to accommodate different line voltages. If the existing line

voltage you have at your facility is:

120V AC – The WHITE wire from the transformer should be connected to the hot leg of the input voltage

and the black wire to the neutral leg.

208V AC – The RED wire from the transformer should be connected to the hot leg of the input voltage and

the black wire to the neutral leg.

240V AC – The ORG wire from the transformer should be connected to the hot leg of the input voltage and

the black wire to the neutral leg.

The GREEN wire in all cases must be connected to EARTH GROUND.

Each wiring combination as stated above yields the same 24V AC output across the BLUE and YELLOW wires

of the secondary winding of the transformer. See back for Transformer Mounting Instructions.