TDMG0002 Icon-5 Maintenance Guide –Version: 02 –Release date: 2020-04-27

Maintenance procedure on Icon-5 analyzers

These steps must be performed by trained service engineer! Please note the following

warnings:

WARNING

Risk of personal injury. Movements of motors are controlled by limited

current. Do not override built-in safety measures, do not short circuit fuses

BIOHAZARD

Risk of biological infection, contamination

WARNING

The analyzer should only be operated without covers with extreme

caution, moving parts can cause injury. High Voltage board HVDCDC

produces 180VDC.

Service marked components only when the power source is disconnected.

WARNING

Risk of personal injury. The ceramic shear valve has a sharp needle

installed. Avoid touching the needle

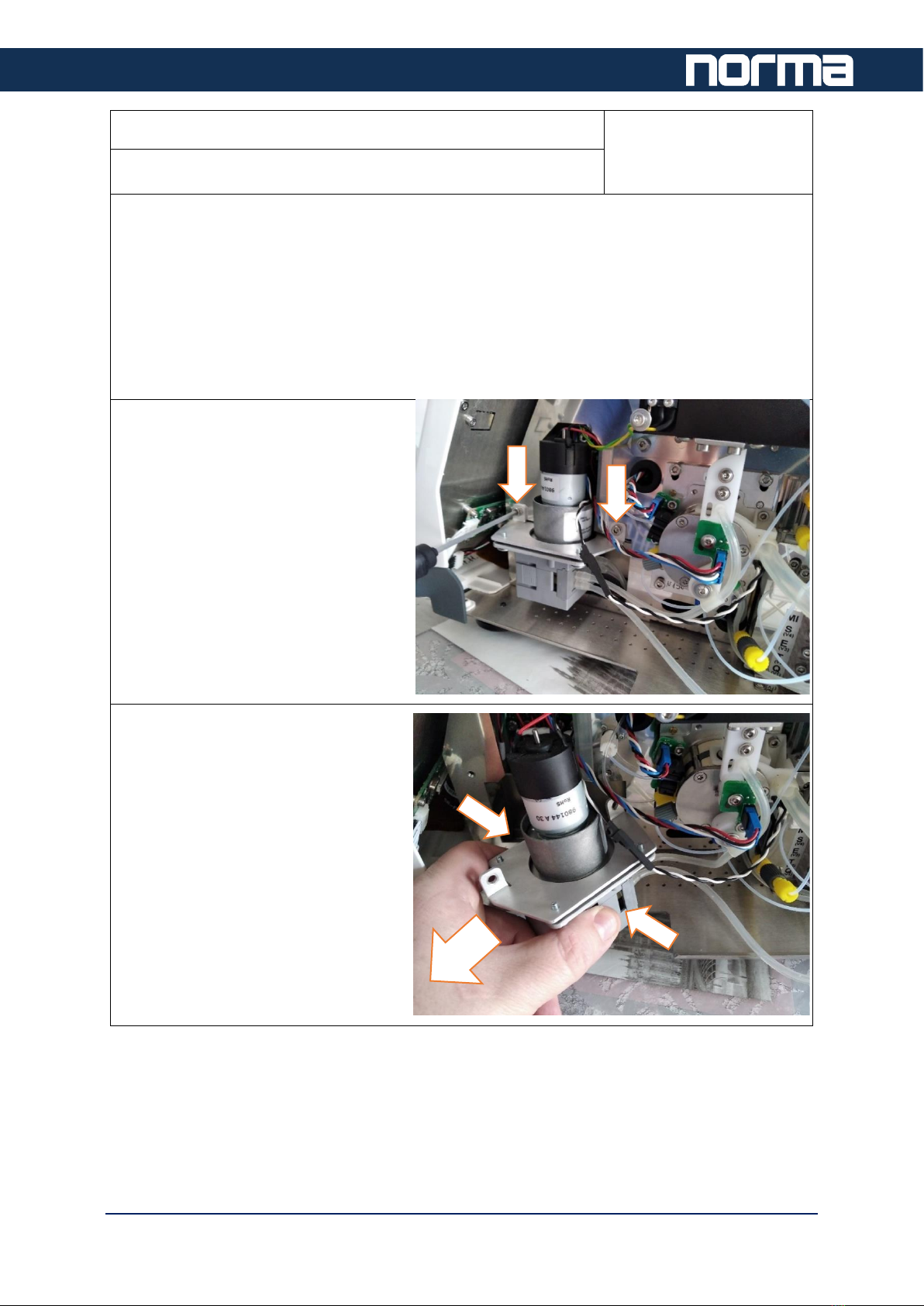

To prepare the Icon-5 for the maintenance, please, shut down the analyzer and pinch

the reagent pickup tubes using the clamps provided in the reagent pickup tube set,

and remove both side covers to get easy access to the inner components.