Norseman XGB Series Guide

Part No. 11110.Rev.1.04 March 2022 Printed in Canada

XGB Series

Explosion-Proof Forced Air Unit Heater

Installation, Operation, & Maintenance Instructions

Glycol Free Design

Special Notes

The following special notices highlight important

information in the installation, operation and maintenance

sections.

This symbol indicates a potentially hazardous

situation, which, if not avoided, can result in

personal injury or damage to the equipment.

This symbol indicates a potentially hazardous

situation, which, if not avoided, may be a shock

hazard.

This symbol indicates an imminently hazardous

situation, which, if not avoided, could result in

death or serious injury.

CAUTION

CAUTION

WARNING

WARNING

WARNING. Improper installation adjustment,

alteration, excessive vibration, service, or

maintenance can cause property damage,

injury or death. Read the installation, operating

and maintenance instructions thoroughly

before installing, operating or servicing this

equipment.

TABLE OF CONTENTS

A. General Information 3

A.1 Description .......................................................................................................................................... 3

A.2 Application ......................................................................................................................................... 3

A.3 Construction and Installation ............................................................................................... 3

A.4 Standard Product Features .................................................................................................... 3

A.5 Optional Features.......................................................................................................................... 3

A.6 Thermostats ...................................................................................................................................... 3

A.7 Motors .................................................................................................................................................... 3

A.8 Accesories........................................................................................................................................... 3

B. Pre-Installation 5

C. Installation and Mounting 5

C.1 Dimensions ......................................................................................................................................... 5

C.2 Mounting ............................................................................................................................................. 5

C.3 Mounting with Standard Kits ................................................................................................6

C.4 Outlet Louvres .................................................................................................................................8

C.5 Wiring.....................................................................................................................................................8

D. Options 9

D.1 Temperature Control ....................................................................................................................9

D.2 “AUTO/OFF/FAN-ONLY” (Optional)....................................................................................9

E. Normal Sequence of Operation 10

F. Maintenance 10

F.1 Motor....................................................................................................................................................... 10

F.2 Fan Blade............................................................................................................................................10

F.3 Heater Cabinet................................................................................................................................10

F.4 Overheat Protection...................................................................................................................10

F.5 Replacement Parts List..............................................................................................................11

3

General Information

A. GENERAL INFORMATION

A.1 Description

The small cabinet units are available with ratings from 3.75 to

10kW, and can be identied by their internally mounted motor.

The large cabinet units are available from 10kW up to 35kW. See

C.1 Dimensions, page5 for cabinet dimensions.

A.2 Application

Designed specically for heating industrial spaces where

potentially

explosive substances are or may be present. Typical hazardous

location environments include:

ࢦWater and Sewage Treatment Plants

ࢦOil Reneries

ࢦCompressor Stations

ࢦPulp and Paper Mills

ࢦPaint Storage Booths

ࢦCement Plants

ࢦMines

A.3 Construction and Installation

Norseman™ unit heaters use extra heavy wall nned tubular

steel heating elements to provide safe, efcient heat transfer to

the environment. The heater does not contain glycol.

In structures with high ceilings, other units may not have the

range of motion needed to direct air ow to the oor. The glycol-

free design of the XGB allows the unit to be tilted to a 30º angle

below the horizontal, with an additional 35º of airow redirection

provided by the outlet louver. For lateral airow, the entire louver

assembly can be rotated 90º.

A factory installed conduit seal provides the necessary isolation

between the supply and control housings. In Division 2, Zone 1

and Zone 2 applications, a eld installed conduit seal may not be

required.

To facilitate installation, the Norseman™ XGB explosion-proof

unit heaters feature the patented x-Max®housing with slide out

terminal block trolley for connection of the electrical supply.

A.4 Standard Product Features

See Figure 1 and Figure 2, page4.

ࢦCSA C/US Certied for hazardous locations. Small cabinet

units approved for Class I, Div 1 & 2, Group D; Class II, Div. 1 &

2, Groups E, F and G. Large cabinet units approved for Class I,

Div. 1 & 2, Groups C & D; Class II, Div. 1 & 2, Groups E, F & G.

NOTE: Class II and some atmospheric groups are not available

in every kW rating.

ࢦZone marking available.

ࢦRatings from 3.75 to 35kW.

ࢦ208 to 600V, 1 or 3 phase

ࢦLow watt density extra heavy wall tubular steel nned

heating elements with nickel plated nish

ࢦGlycol-free design allows the heater to be tilted 30º downward

ࢦRotatable outlet louvers provide 35º of additional airow

redirection

ࢦPatented x-Max®housing with track and trolley system

simplies installation and servicing

ࢦHeavy duty 16 ga. Stainless steel casing

ࢦTerminals for remote thermostat connection

ࢦDual automatic reset high limits

ࢦContactor derated for extended service life

ࢦIsolated supply connection housing eliminates the need for

conduit seals

A.5 Optional Features

ࢦBuilt-in, externally adjustable thermostat

ࢦBuilt-in disconnect

ࢦMoisture-resistant construction

ࢦ“AUTO/OFF/FAN-ONLY” switch

ࢦPilot light

ࢦManual reset high limit

A.6 Thermostats

Thermon offers a wide variety of explosion-proof thermostats to

suit most every need. Norseman™ unit heaters are available with

optional built-in, externally adjustable, bulb type thermostats

which are eld-convertible to tamper-proof. Thermostats for

remote mounting can also be provided on request.

A.7 Motors

Fractional horsepower, 1725RPM explosion-proof motor with

double shielded ball bearings and built-in thermal overload. Small

cabinet units use 1/12 hp motor approved for Class I, Group D;

Class II, Group E, F, and G. Large cabinet units use 1/2 hp motor

approved for Class I, Groups C and D; Class II, Groups E, F & G, as

standard.

A.8 Accesories

Norseman™ explosion-proof unit heaters readily adapt to

most mounting requirements. Each heater is equipped with a

basic swivel bracket that is compatible with any of the optional

mounting kits.

Optional mounting kits allow the unit to be installed on a wall

ceiling, 3" pipe, or oor stand. Each mounting conguration

provides maximum exibility for outlet ow direction. The swivel

bracket (standard on all heaters) features holes for afxing a

safety chain.

4

General Information

Edmonton Head Office & Factory

5918 Roper Road, Edmonton, Alberta, Canada T6B 3E1

P 780.466.3178 F 780.468.5904 Toll Free 1.800.661.8529

Part No. 11110 - Rev. 01

Installation, Operation & Maintenance Instructions for

NorsemanTM XGB Explosion-Proof Unit Heater

3.75 - 35kW, 60 Hz Units

1.0 GENERAL INFORMATION

DESCRIPTION

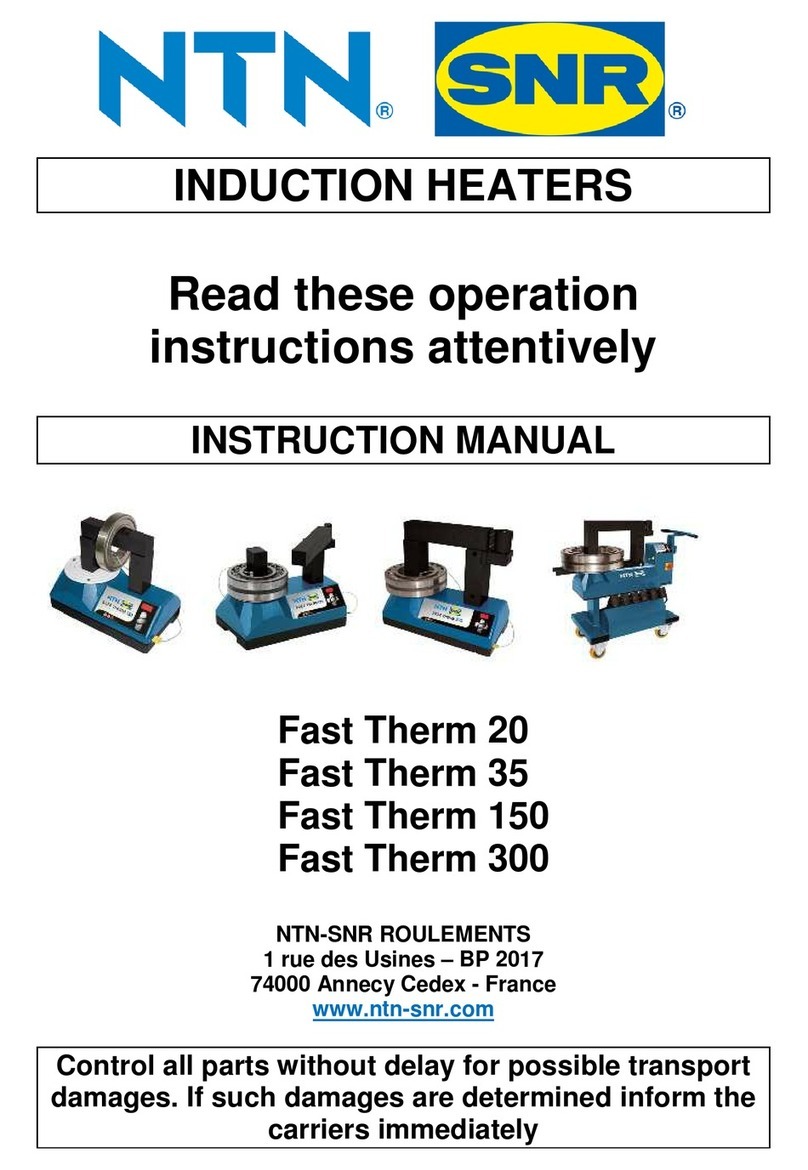

CCI Thermal’s XGB explosion-proof unit heater is the latest addition

to the NORSEMAN™ line of hazardous location heating products.

The small cabinet units are available with ratings from 3.75 – 10kW,

and can be identified by their internally mounted motor. The large

cabinet units (shown below) are available from 10kW up to 35kW.

See section 3.1 for cabinet dimensions.

APPLICATION

Designed specifically for heating industrial spaces where potentially

explosive substances are or may be present. Typical hazardous

location environments include:

• Water and Sewage Treatment Plants

• Oil Refineries

• Compressor Stations

• Pulp and Paper Mills

• Paint Storage Booths

• Cement Plants

• Mines

CONSTUCTION AND INSTALLATION

CCI Thermal’s NORSEMAN™ unit heaters use extra heavy wall

finned tubular steel heating elements to provide safe, efficient heat

transfer to the environment. The heater does not contain glycol,

decreasing maintenance costs.

Flow adjustment… in structures with high ceilings, other units may

not have the range of motion needed to direct air flow to the floor.

The glycol-free design of the XGB allows the unit to be tilted to a 30º

angle below the horizontal, with an additional 35º of airflow

redirection provided by the outlet louver. For lateral airflow, the entire

louver assembly can be rotated 90º.

No conduit seal required… a factory installed conduit seal

provides the necessary isolation between the supply and control

housings. In Division 2, Zone 1 and Zone 2 applications, a field

installed conduit seal may not be required.

Simplified wiring… to facilitate installation, the NORSEMAN™

explosion-proof unit heaters feature the patented x-Max® housing

with slide out terminal block trolley for connection of the electrical

supply.

STANDARD PRODUCT FEATURES

• CSA C/US Certified for hazardous locations. Small cabinet units

approved for Class I, Div 1 & 2, Group D; Class II, Div. 1 & 2,

Groups E, F and G. Large cabinet units approved for Class I, Div. 1

& 2, Groups C & D; Class II, Div. 1 & 2, Groups E, F & G.

Note: Class II and some atmospheric groups are not available in

every kW rating.

• Optional Zone marking available.

• Ratings from 3.75 – 35kW.

• 208 – 600V, 1 or 3 phase

• Low watt density extra heavy wall tubular steel finned heating

elements with nickel plated finish

• Glycol-free design allows the heater to be tilted 30º downward

• Rotatable outlet louvers provide 35º of additional airflow redirection

• Patented x-Max® housing with track and trolley system simplifies

installation and servicing

• Heavy duty 16 ga. Stainless steel casing

• Terminals for remote thermostat connection

• Dual automatic reset high limits

• Contactor derated for extended service life

• Isolated supply connection housing eliminates the need for conduit

seals

OPTIONAL FEATURES

• Built-in, externally adjustable thermostat

• Built-in disconnect

• Moisture-resistant construction

• “Auto/off/fan-only” switch

• Pilot light

• Manual reset high limit

THERMOSTATS

CCI Thermal offers a wide variety of explosion-proof thermostats to

suit most every need. NORSEMAN™ unit heaters are available with

optional built-in, externally adjustable, bulb type thermostats which

are field-convertible to tamper-proof. Thermostats for remote

mounting can also be provided on request.

MOTORS

Fractional horsepower, 1725 rpm explosion-proof motor with double

shielded ball bearings and built-in thermal overload. Small cabinet

units use 1/12 hp motor approved for Class I, Group D; Class II,

Group E, F, and G. Large cabinet units use 1/2 hp motor approved

for Class I, Groups C and D; Class II, Groups E, F & G, as standard.

ACCESSORIES

NORSEMAN™explosion-proof unit heaters readily adapt to most

mounting requirements. Each heater is equipped with a basic swivel

bracket that is compatible with any of the optional mounting kits.

Optional mounting kits allow the unit to be installed on a wall ceiling,

3” pipe, or floor stand. Each mounting configuration provides

maximum flexibility for outlet flow direction. The swivel bracket Figure 2 - XGB Heater Dimensions

2.0 PRE-INSTALLATION

2.1 Inspect the heater for possible damage due to shipping and

handling. Claims for shipping damages shall be placed with the

carrier.

2.2 Check the heater nameplate to ensure that the heater area

classification and temperature code are suitable for the hazardous

area classification.

2.3 Verify that the nameplate voltage, phase and wattage are as

ordered and are the same as the electrical power supply available.

DO NOT CONNECT THE XGB UNIT HEATER TO A SUPPLY

VOLTAGE OTHER THAN THAT SHOWN ON THE PRODUCT

NAMEPLATE.

3.0 INSTALLATION AND MOUNTING

The heater must be installed by qualified personnel in strict

compliance with the electrical code.

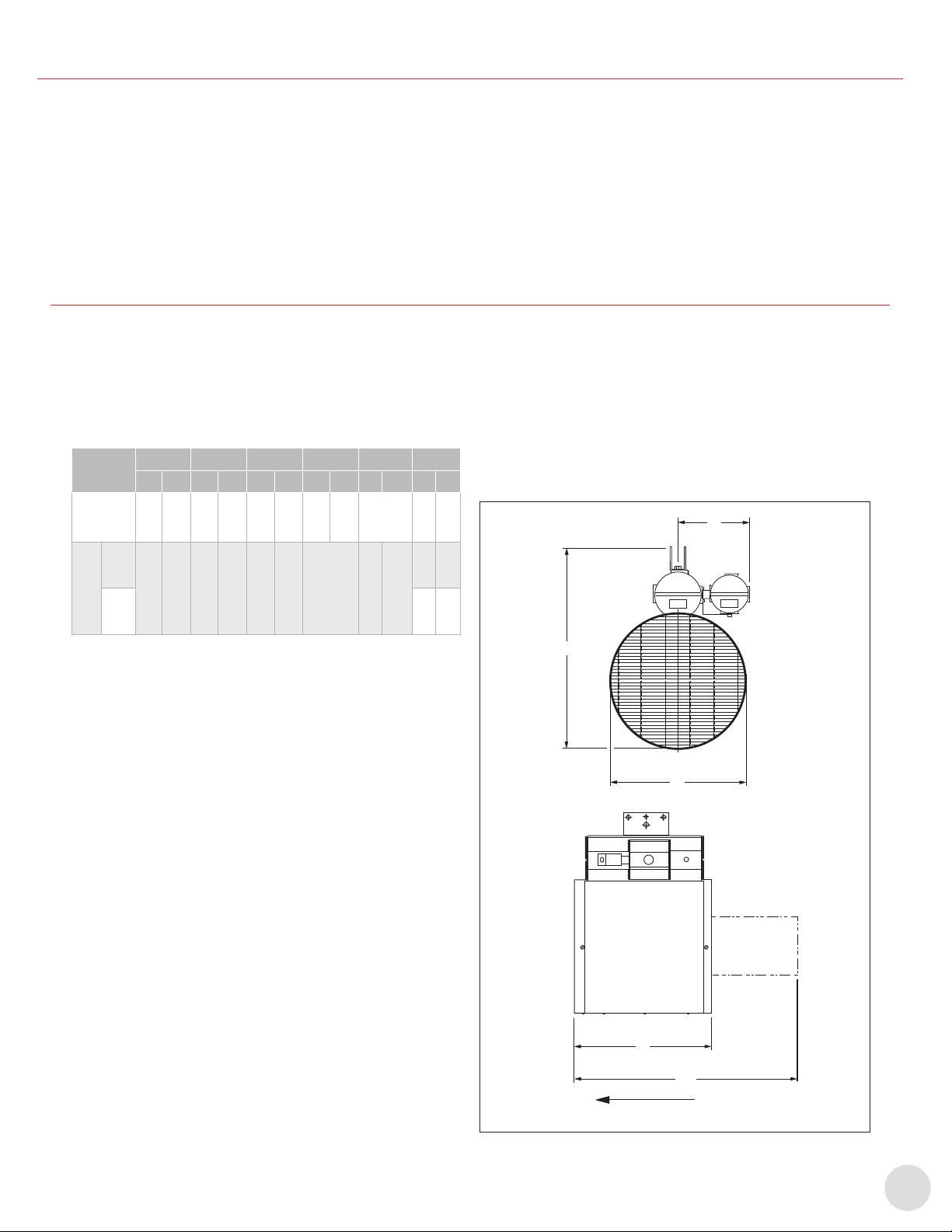

3.1 DIMENSIONS

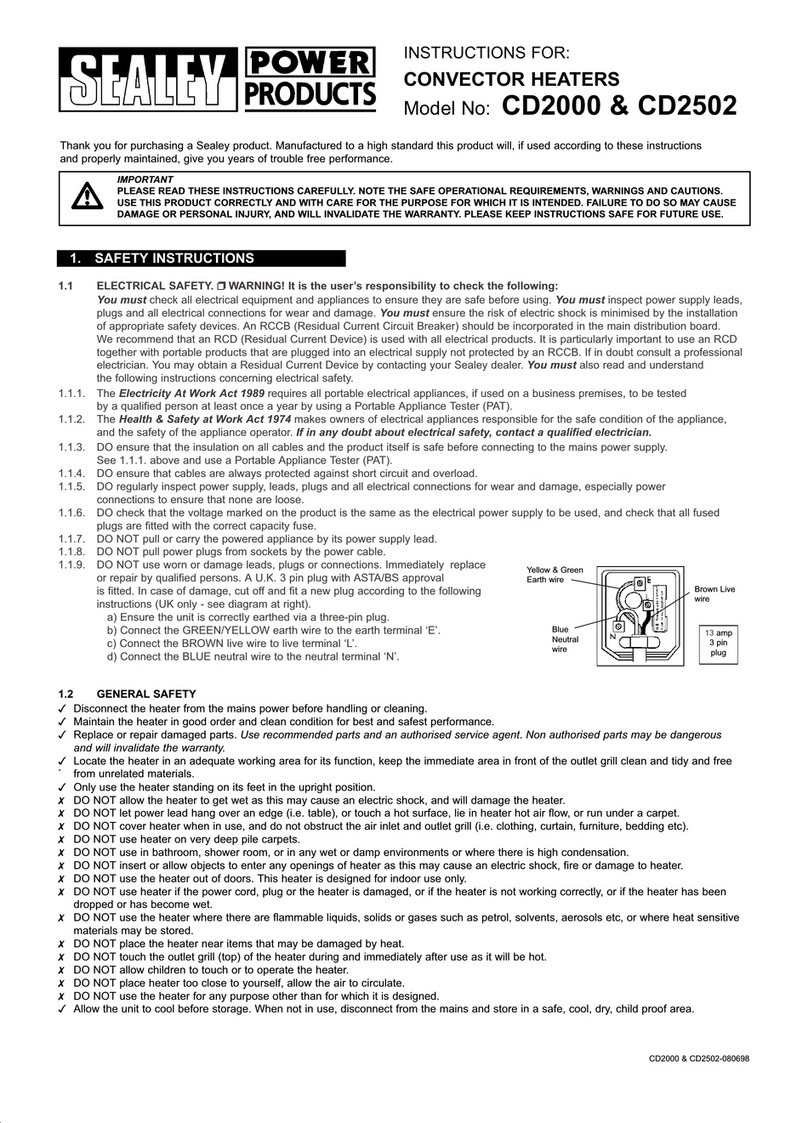

Table 1: Dimensions and Weights (See Fig. 2)

3.2 MOUNTING

3.2.1 NORSEMAN™ explosion-proof unit heaters can be mounted

to a ceiling, wall 3” pipe, or floor stand. Ensure that the mounting

surface is sufficiently strong to support the heater, which, depending

on the model, could weigh up to 185lbs, (84kg). See 3.1 for heater

dimensions and weights.

3.2.2 The heater must be positioned with a minimum 15 cm (6”) side

clearance from all surrounding surfaces and must be mounted at

least 61 cm (24”) from the floor for small cabinet units, or 2440 cm

(96”) from the floor for large cabinet units. It is best to maximize

clearances to allow freedom of rotation. Ensure that airflow into

and out of the unit is not restricted.

3.2.3 All mounting studs, bolts, nuts and other fasteners shall be

secured so that there is no possibility of loosening over prolonged

periods. Periodically inspect at regular intervals and retighten if

necessary.

3.2.4 All standard mounting kits are designed to support the heater

on its centre of gravity and to allow for 30º tilt in the vertical direction

and 360 º rotation in the horizontal. Note that horizontal rotation is

fixed after the ceiling bracket is bolted to its support.

3.2.5 For specific mounting instructions refer to the appropriate

paragraph of section 3.3.

3.2.6 If lifting with slings, take special care not to damage the casing.

3.2.7 For large cabinet units, leave the heater on the shipping skid

and use the skid as a lifting platform to facilitate installation of the

heater.

3.3 MOUNTING WITH STANDARD KITS

3.3.1 CEILING MOUNTING

a) Install the ceiling bracket to the mounting surface with the desired

orientation. Ensure that ‘LINE A” (Figure 3), a line drawn

perpendicular to the bolt holes in the mounting bar, is pointed in the

desired direction of airflow. The ceiling bracket must be secured to

the mounting surface using as many as six (but not less than two)

5/8” fasteners (not provided). Make certain that lockwashers are

used under all nuts or lag bolts.

b) Hoist the heater up to the ceiling bracket. Line up the large centre

hole in the swivel bracket with the large hole in the mounting bar.

c) Insert the 1/2” bolt and loosely secure with nut and washers

provided. Tilt the heater at the desired angle to the horizontal and

secure with the 3/8” bolt. Tighten the 1/2” bolt.

Figure 3 - Ceiling Mounting

3.3.2 WALL MOUNTING

a) Install the ceiling bracket to the wall bracket with the desired

orientation. Ensure that “LINE A” (Figure 4), a line drawn

perpendicular to the bolt holes in the mounting bar, is pointed in the

desired direction of air flow. Secure the wall bracket to the mounting

surface. The wall bracket must be secured to the mounting surface

using as many as six (but not less than four) 5/8” fasteners (not

provided). Make certain that lockwashers are used under all nuts or

lag bolts.

b) Follow steps b) and c) outlined in 3.3.1.

Figure 4 - Wall Mounting

STANDARD FEATURES, SMALL CABINET UNIT:

1) 1/12 hp explosion-proof motor

2) Inlet guard

3) Extra heavy wall tubular steel finned heating elements with

nickel plated finish

4) Patented x-Max® explosion-proof terminal housing

5) 120V control circuit includes:

• Derated magnetic contactor

• Dual automatic reset high limits

• Transformer

6) Heavy duty 16 ga. stainless steel casing

7) Outlet louver assembly

8) Swivel bracket

9) Factory installed conduit seal

10)Supply connection housing

11)Terminal block for supply wiring and thermostat connection

STANDARD FEATURES, LARGE CABINET UNIT:

1) 1/2 hp explosion-proof motor

2) Inlet wire guard

3) Extra heavy wall tubular steel finned heating elements with

nickel plated finish

4) Patented x-Max® explosion-proof terminal housing

5) 120V control circuit includes:

• Derated magnetic contactor

• Dual automatic reset high limits

• Transformer

• Fan delay relay

• Control fuse

6) Heavy duty 16 ga. stainless steel casing

7) Outlet louver assembly

8) Swivel bracket

9) Factory installed conduit seal

10)Supply connection housing

11)Terminal block for supply wiring and thermostat connection

12)Motor mount

13)Motor mount casing

3.3.3 POST MOUNTING

a) Install the ceiling bracket to the wall bracket with the desired

orientation. Ensure that “LINE A” (Figure 5), a line drawn

perpendicular to the bolt holes in the mounting bar, is pointed in the

desired direction of air flow. Secure the wall bracket to the post using

the 1/2” U-bolts, nuts and washers supplied. Make certain the

lockwashers are used under all nuts or lag bolts.

b) Follow steps b) and c) outlined in 3.3.1.

Figure 5 - Post Mounting

3.3.4 FLOOR STAND MOUNTING

a) At times adequate support for the heater may not be available

within the structure of the space to be heated. In this situation, the

floor mount stand may be desirable. Telescoping square tubing on a

support base allows the unit to be positioned at the desired height

above the floor anywhere between 1.8 m (6’) to 3 m (10’).

b) Position the base of the stand on the floor in the desired

orientation. Ensure that “LINE A” (Figure 6), a line drawn

perpendicular to the bolt holes in the mounting bar, is pointed in the

desired direction of air flow.

c) Next, the stand is to be lagged to a solid floor to prevent the unit

from toppling. Four 11/16” diameter holes are provided in the base of

the stand for this purpose.

d) Raise the mounting frame to the desired height and secure to the

base using the hardware supplied.

e) Hoist the heater up to the mounting frame.

f) Insert the 1/2” bolt and loosely secure with nut and lockwashers

provided. Tilt the heater at the desired angle to the horizontal and

secure with the 3/8” bolt. Tighten the 1/2” bolt.

Figure 6 - Floor Mounting Stand

3.4 OUTLET LOUVRES

3.4.1 A louvred grill on the heater outlet end is supplied as standard.

The louver assembly may be positioned either horizontally or

vertically for maximum flexibility.

3.4.2 Standard heaters are shipped with the louvers in the horizontal

position. To change the orientation of the louvers to vertical, remove

the three mounting screws securing the louver assembly to the

cabinet and rotate the louver 90º to the desired direction.

3.5 WIRING

CAUTION: Whenever hazardous materials are present, ensure

that the terminal housing covers, plugs, etc., are secured (but

not over-tightened) before powering the heater.

All circuits must be in the open position before removing

junction or terminal box covers.

3.5.1 The heater must be installed by qualified personnel in strict

compliance with the electrical code.

3.5.2 All heaters are factory pre-wired and ready for direct

connections to the power supply leads.

3.5.3 The heater must be individually fused, preferably with Class J

time-delay fuses for maximum safety. Unless stated otherwise in

your local code, fuse size shall be 125% of line current or next size

larger. See Table 2 for recommendations.

3.5.4 Use approved conduit and conduit seals are required by the

code for the hazardous location.

3.5.5 The NORSEMAN™ explosion-proof unit heaters are equipped

with a factory installed conduit seal between the control and supply

housings. In Division 2, Zone 1 and Zone 2 applications, a field

installed conduit seal may not be required.

3.5.6 Supply wiring connections are made by accessing the over of

the side mounted supply connection housing (terminal box). Slide

the control trolley out of the housing just enough to access the

terminal block (Figure 8).

3.5.7 Connect the power leads to terminals marked L1and L2 for

single phase and L1, L2 and L3 for three phaseheaters making certain

to leave some excess wire to ensure that the leads may slide back

into the housing with the trolley. See Figure 9 for control circuit and

Figure 10 for suggested wiring. Exercise care to avoid damage to

wires caused by threads on the housing.

Table 2: Recommended Fuse Sizes

Figure 9A - Small Cabinet XGB Wiring Schematic

Figure 9B - Large Cabinet XGB Wiring Schematic

3.5.8 Connect the ground wire to the ground connection located in

the supply connection housing; once again, making sure that the

wire is sufficiently long to slide back into the housing with the trolley.

See Figure 10.

Figure 10 - Supply Connection

3.5.9 Due to the presence of hazardous materials, ensure that

the terminal housing covers, plugs, etc., are secured (but not

over-tightened) before powering the heater.

4.0 TEMPERATURE CONTROL

4.1 BUILT-IN THERMOSTAT (OPTIONAL)

When specified, the unit comes equipped with a built-in thermostat

pre-wired to all other standard controls. Set the temperature to the

desired operating condition.

4.2 REMOTE THERMOSTAT (OPTIONAL)

Install the XT thermostat in accordance with the instruction sheet

provided. Terminals “T1” and “T2” in the heater supply housing are

provided for connection to the remote thermostat and are pre-wired

to the rest of the control circuit. Remove the jumper wire between

“T1” and “T2” and connect the thermostat to these terminals. (Refer

to Figure 9). Set the temperature to the desired operating condition.

5.0 “AUTO / OFF / FAN-ONLY” SWITCH (OPTIONAL)

If ordered, a factory installed “auto / off / fan-only” switch may be

included on the heater. The “fan-only” feature allows the heater to

cycle in a “heat” mode dictated by the controlling thermostat, even

though the fan is operating continuously.

6.0 NORMAL SEQUENCE OF OPERATION

6.1 The heater must be properly mounted and wired in accordance

with the instructions contained in this manual. The fan blade must be

free to rotate with no obstruction to air inlet or outlet areas.

6.2 Energize the heater at the rated supply voltage.

6.3 Assuming that the thermostat calls for heat, i.e. the thermostat is

set to a higher temperature that ambient:

a) The main contactor will energize the elements and the fan motor.

b) After the inlet air temperature rises to the set point of the

thermostat, the thermostat contacts will open and the main contactor

will de-energize the elements and the fan motor.

Note: The large cabinet XGB incorporates a fan delay feature in both

the “ON” and “OFF” cycles. This is a desirable feature as it allows

the heater to come to temperature before the fan operates (no cold

blasts) and to cool down the “OFF” cycle (longer life for control

components and motor). Delay “ON” is 15 - 40 seconds and delay

“OFF” is 60 -160 seconds.

6.4 The cycle described above will repeat when the ambient

temperature falls below the thermostat set point.

IMPORTANT:

THE PROPER MOTOR/FAN ROTATION, VIEWED FROM THE

REAR OF THE HEATER IS COUNTER CLOCKWISE FOR THE

SMALL CABINET UNITS AND CLOCKWISE FOR THE LARGE

CABINET UNITS, AS INDICATED BY THE FAN ROTATION

LABEL ON THE HEATER. INCORRECT ROTATION OF THE FAN

WILL CAUSE THE HEATER TO OVERHEAT AND CYCLE ON THE

HIGH LIMITS. CONSULT FACTORY IN CASE OF INCORRECT

ROTATION.

7.0 MAINTENANCE

7.1 The NORSEMAN™ explosion-proof unit heaters are designed

and constructed to operate in tough industrial applications with a

minimum of maintenance. However, some routine maintenance is

recommended to extend the life of the heater and its components.

Always disconnect the electrical supply before performing any

maintenance.

7.2 Periodically inspect the heater installation to ensure that all

connections, fittings, plugs, screws, covers, etc. are tight and free of

corrosion.

7.3 Check the inside of the cabinet and around the element fins for

dust build-up and debris, especially after seasonal shutdowns.

Clean with an air blast or vacuum. Ensure that nothing is restricting

the air flow into the unit and that the fan blade is free to rotate.

7.4 MOTOR

The motor supplied with the small cabinet units is approved for Class

1, Group D, Class II, Group E, F & G, T3B temperature code. The

motor supplied with the large cabinet units is approved for Class I,

Group C & D, Class II, Group E, F & G, T3B temperature code. All

motors have internal thermal protection to eliminate motor

overheating.

7.5 FAN BLADE

Visually inspect the fan blade to ensure it is free to rotate and

accidental damage has not occurred. If bent or damaged, a factory

balanced blade should be installed so that the rated airflow is

maintained. A damaged fan blade may not deliver the required

airflow over the elements, resulting in cycling on the high limit which

can significantly reduce the life of the contactor and the high limit.

7.6 HEATER CABINET

The XGB unit heater cabinet is stainless steel for superior corrosion

resistance. We recommend the cabinet be wiped down periodically

using a mild detergent.

7.7 OVERHEAT PROTECTION

In the event of fan failure, motor damage, excessive dust build-up or

restricted inlet airflow, the heater temperature may rise, causing the

limit controls to open, breaking the power supply to the heater. All

units are equipped with two automatic reset high limit controls.

Cycling of the high limits should not be permitted.

Should this occur, the unit should be inspected to determine the

cause of the cycling and the condition should be corrected.

8.0 REPLACEMENT PARTS LIST

The replacement parts list is included for reference only. Due to the

delicate nature of explosion-proof design, XGB unit heaters are not

field serviceable. Should any problem arise, return the unit to the

factory for service by trained personnel.

SMALL CABINET UNITS:

LARGE CABINET UNITS:

A CCI Thermal XTK thermostat kit may be purchased to replace a

broken thermostat. Refer to installation instructions provided with

the kit.

Transformers

High Limits

Motor

Contactor

Fan Blade

208V units

240V units

480V units

600V units

T2C T-Code units

T3A T-Code units

T3B T-Code units

All units

All units

10 & 7.5kW units

5 & 3.75kW units

MO250O

MO250Q

MO250S

MO250V

C12023-11

C12023-10

C12023-10

B14302-01

42CF35AF

C11028-06

C11028-05

Transformers

High Limits

Motors

Contactor

Fan Blade

Control Fuse

208V units

240V units

480V units

600V units

T2C T-Code units

T2D T-Code units

T3A T-Code units

T3B T-Code units

208 - 480V 3Ø units

240V 1Ø units

600V units

All units

All units

All units

EXA50-23

EXA50-25

EXA50-36

EXA50-39

C12023-11

C12023-11

C12023-10

C12023-12

1699

1979

2433

42CF35AF

10873

MDL-0.6

GLYCOL

FREE

DESIGN

TERMINAL BLOCK

Figure 8 - XGB Terminal Block Trolley Figure

SIDE

LOOP

TOP

1 OR 3

Ø

SUPPLY

L3

L2

L1

C

H3

H2

H1

TO HEATING

LOAD

X1

120V T1 T2 HI-LIMITS

X2 C/AUX

C NO MOTOR

REMOVE JUMPER FOR

OPTIONAL THERMOSTAT

C

M

LINE A

CEILING BRACKET

MOUNTING BAR

3/8” Flat Washer, Lock Washer, Nut

1/2” Flat Washer, Lock Washer, Nut

MOUNTING SURFACE

11/16” Dia. Mounting Holes

3/8” bolt

1/2” bolt

SWIVEL MOUNTING BRACKET SWIVEL MOUNTING BRACKET

3” PIPE (NOT INCLUDED)

WALL BRACKET

LINE A

CEILING BRACKET

MOUNTNIG BAR

1/2” U-bolt

1/2” flat washer, lock washer, nut

5/8” flatwasher, lockwasher, nut

1/2” flat washer, lock washer, nut

3/8” flat washer, lock washer, nut

5/8” bolt

1/2” bolt

3/8” bolt MOUNTING FRAME

MOUNTING BAR

3/8” flatwasher, lockwasher, nut

1/2” flatwasher, lockwasher, nut

3/8” Bolt

1/2” Bolt

SWIVEL MOUNTING BRACKET

5/8” Bolt

5/8” flatwasher,

lockwasher, nut

LINE A

MOUNTING SURFACE

11/16” dia. mounting holes

5/8” flatwasher, lockwasher, nut

WALL BRACKET

LINE A

CEILING BRACKET

5/8” Bolt

MOUNTING BAR

3/8” flatwasher, lockwasher, nut

1/2” flatwasher, lockwasher, nut

3/8” Bolt

1/2” Bolt

SWIVEL MOUNTING BRACKET

5/8” Bolt M

H1

H2

H3

TO HEATING

LOAD

REMOVE JUMPER FOR

OPTIONAL THERMOSTAT

120V HI-LIMITS

FD

C

FD

1

3

4

5

X2 T1 T2

3ØONLY

C

3ØONLY

X1

L3 L2 L1

L1

L2

L3

1 OR 3Ø

SUPPLY

AIRFLOW

C

A

B

D1

D2

Figure 1B - Large Cabinet XGB Unit Heater Components

Figure 1A - Small Cabinet XGB Unit Heater Components

Recommended

Catalog Number kW Voltage Max Line Amps Fuse Size

(Amps)

1 Ø 3 Ø 1 Ø 3 Ø

XGB038T3B 3.7 5 208 1 9 1 1 2 5 1 5

240 1 7 1 0 2 5 1 5

480 - 6 - 1 0

600 - 5 - 1 0

XGB050T3B 5 208 2 5 1 5 3 5 2 0

240 2 2 1 3 3 0 2 0

480 - 7 - 1 0

600 - 6 - 1 0

XGB075T3A 7 . 5 208 3 7 2 2 5 0 3 0

240 3 2 1 9 4 0 2 5

480 - 1 0 - 1 5

600 - 8 - 1 0

XGB100T2C 1 0 208 2 9 4 0

240 4 3 2 5 6 0 3 5

480 - 1 3 - 2 0

600 - 1 1 - 1 5

XGB100T3B 1 0 208 - 3 0 - 4 0

240 4 7 2 6 6 0 3 5

480 - 1 3 - 2 0

600 - 1 1 - 1 5

XGB150T3B 1 5 208 - 4 4 - 6 0

240 - 3 8 - 5 0

480 - 1 9 - 2 5

600 - 1 5 - 2 0

XGB200T3B 2 0 480 - 2 5 - 3 5

600 - 2 0 - 2 5

XGB225T3A 22. 5 480 - 2 8 - 3 5

600 - 2 3 - 3 0

XGB250T2D 2 5 480 - 3 1 - 4 0

600 - 2 5 - 3 5

XGB300T2D 3 0 480 - 3 7 - 5 0

600 - 3 0 - 4 0

XGB325T2D 32.5 480 - 4 0 - 5 0

600 - 3 2 - 4 0

XGB350T2C 3 5 480 - 4 3 - 6 0

600 - 3 4 - 4 5

A B C D1 D2 Weight

lbs (kg)

Small16-7/ 8 8-7/ 8 25-3-/16 17-1/ 2 - 100

Cabinet(429)(225)(640)(445)(45)

10-15 kW

Large20-1/ 8 8-7/ 8 29-1/ 4 - 31-1/ 4 145 (66)

Cabinet(511)(225)(743)(794)20-35 kW

185 (84)

Standard Features (Small Cabinet Unit)

1) 1/12 hp explosion-proof motor

2) Inlet guard

3) Extra heavy wall tubular steel nned heating elements

with

nickel plated nish

4) Patented x-Max® explosion-proof terminal housing

5) 120V control circuit includes:

–Derated magnetic contactor

–Dual automatic reset high limits

–Transformer

6) Heavy duty 16 ga. stainless steel casing

7) Outlet louver assembly

8) Swivel bracket

9) Factory installed conduit seal

10) Supply connection housing

11) Terminal block for supply wiring and thermostat

connection

Figure 1 – Small Cabinet XGB Unit Heater Components

Standard Features (Large Cabinet Unit)

1) 1/2 hp explosion-proof motor

2) Inlet wire guard

3) Extra heavy wall tubular steel nned heating elements with

nickel plated nish

4) Patented x-Max® explosion-proof terminal housing

5) 120V control circuit includes:

–Derated magnetic contactor

–Dual automatic reset high limits

–Transformer

–Fan delay relay

–Control fuse

6) Heavy duty 16 ga. stainless steel casing

7) Outlet louver assembly

8) Swivel bracket

9) Factory installed conduit seal

10) Supply connection housing

11) Terminal block for supply wiring and thermostat connection

12) Motor mount

13) Motor mount casing

Edmonton Head Office & Factory

5918 Roper Road, Edmonton, Alberta, Canada T6B 3E1

P 780.466.3178 F 780.468.5904 Toll Free 1.800.661.8529

Part No. 11110 - Rev. 01

Installation, Operation & Maintenance Instructions for

NorsemanTM XGB Explosion-Proof Unit Heater

3.75 - 35kW, 60 Hz Units

1.0 GENERAL INFORMATION

DESCRIPTION

CCI Thermal’s XGB explosion-proof unit heater is the latest addition

to the NORSEMAN™ line of hazardous location heating products.

The small cabinet units are available with ratings from 3.75 – 10kW,

and can be identified by their internally mounted motor. The large

cabinet units (shown below) are available from 10kW up to 35kW.

See section 3.1 for cabinet dimensions.

APPLICATION

Designed specifically for heating industrial spaces where potentially

explosive substances are or may be present. Typical hazardous

location environments include:

• Water and Sewage Treatment Plants

• Oil Refineries

• Compressor Stations

• Pulp and Paper Mills

• Paint Storage Booths

• Cement Plants

• Mines

CONSTUCTION AND INSTALLATION

CCI Thermal’s NORSEMAN™ unit heaters use extra heavy wall

finned tubular steel heating elements to provide safe, efficient heat

transfer to the environment. The heater does not contain glycol,

decreasing maintenance costs.

Flow adjustment… in structures with high ceilings, other units may

not have the range of motion needed to direct air flow to the floor.

The glycol-free design of the XGB allows the unit to be tilted to a 30º

angle below the horizontal, with an additional 35º of airflow

redirection provided by the outlet louver. For lateral airflow, the entire

louver assembly can be rotated 90º.

No conduit seal required… a factory installed conduit seal

provides the necessary isolation between the supply and control

housings. In Division 2, Zone 1 and Zone 2 applications, a field

installed conduit seal may not be required.

Simplified wiring… to facilitate installation, the NORSEMAN™

explosion-proof unit heaters feature the patented x-Max® housing

with slide out terminal block trolley for connection of the electrical

supply.

STANDARD PRODUCT FEATURES

• CSA C/US Certified for hazardous locations. Small cabinet units

approved for Class I, Div 1 & 2, Group D; Class II, Div. 1 & 2,

Groups E, F and G. Large cabinet units approved for Class I, Div. 1

& 2, Groups C & D; Class II, Div. 1 & 2, Groups E, F & G.

Note: Class II and some atmospheric groups are not available in

every kW rating.

• Optional Zone marking available.

• Ratings from 3.75 – 35kW.

• 208 – 600V, 1 or 3 phase

• Low watt density extra heavy wall tubular steel finned heating

elements with nickel plated finish

• Glycol-free design allows the heater to be tilted 30º downward

• Rotatable outlet louvers provide 35º of additional airflow redirection

• Patented x-Max® housing with track and trolley system simplifies

installation and servicing

• Heavy duty 16 ga. Stainless steel casing

• Terminals for remote thermostat connection

• Dual automatic reset high limits

• Contactor derated for extended service life

• Isolated supply connection housing eliminates the need for conduit

seals

OPTIONAL FEATURES

• Built-in, externally adjustable thermostat

• Built-in disconnect

• Moisture-resistant construction

• “Auto/off/fan-only” switch

• Pilot light

• Manual reset high limit

THERMOSTATS

CCI Thermal offers a wide variety of explosion-proof thermostats to

suit most every need. NORSEMAN™ unit heaters are available with

optional built-in, externally adjustable, bulb type thermostats which

are field-convertible to tamper-proof. Thermostats for remote

mounting can also be provided on request.

MOTORS

Fractional horsepower, 1725 rpm explosion-proof motor with double

shielded ball bearings and built-in thermal overload. Small cabinet

units use 1/12 hp motor approved for Class I, Group D; Class II,

Group E, F, and G. Large cabinet units use 1/2 hp motor approved

for Class I, Groups C and D; Class II, Groups E, F & G, as standard.

ACCESSORIES

NORSEMAN™explosion-proof unit heaters readily adapt to most

mounting requirements. Each heater is equipped with a basic swivel

bracket that is compatible with any of the optional mounting kits.

Optional mounting kits allow the unit to be installed on a wall ceiling,

3” pipe, or floor stand. Each mounting configuration provides

maximum flexibility for outlet flow direction. The swivel bracket Figure 2 - XGB Heater Dimensions

2.0 PRE-INSTALLATION

2.1 Inspect the heater for possible damage due to shipping and

handling. Claims for shipping damages shall be placed with the

carrier.

2.2 Check the heater nameplate to ensure that the heater area

classification and temperature code are suitable for the hazardous

area classification.

2.3 Verify that the nameplate voltage, phase and wattage are as

ordered and are the same as the electrical power supply available.

DO NOT CONNECT THE XGB UNIT HEATER TO A SUPPLY

VOLTAGE OTHER THAN THAT SHOWN ON THE PRODUCT

NAMEPLATE.

3.0 INSTALLATION AND MOUNTING

The heater must be installed by qualified personnel in strict

compliance with the electrical code.

3.1 DIMENSIONS

Table 1: Dimensions and Weights (See Fig. 2)

3.2 MOUNTING

3.2.1 NORSEMAN™ explosion-proof unit heaters can be mounted

to a ceiling, wall 3” pipe, or floor stand. Ensure that the mounting

surface is sufficiently strong to support the heater, which, depending

on the model, could weigh up to 185lbs, (84kg). See 3.1 for heater

dimensions and weights.

3.2.2 The heater must be positioned with a minimum 15 cm (6”) side

clearance from all surrounding surfaces and must be mounted at

least 61 cm (24”) from the floor for small cabinet units, or 2440 cm

(96”) from the floor for large cabinet units. It is best to maximize

clearances to allow freedom of rotation. Ensure that airflow into

and out of the unit is not restricted.

3.2.3 All mounting studs, bolts, nuts and other fasteners shall be

secured so that there is no possibility of loosening over prolonged

periods. Periodically inspect at regular intervals and retighten if

necessary.

3.2.4 All standard mounting kits are designed to support the heater

on its centre of gravity and to allow for 30º tilt in the vertical direction

and 360 º rotation in the horizontal. Note that horizontal rotation is

fixed after the ceiling bracket is bolted to its support.

3.2.5 For specific mounting instructions refer to the appropriate

paragraph of section 3.3.

3.2.6 If lifting with slings, take special care not to damage the casing.

3.2.7 For large cabinet units, leave the heater on the shipping skid

and use the skid as a lifting platform to facilitate installation of the

heater.

3.3 MOUNTING WITH STANDARD KITS

3.3.1 CEILING MOUNTING

a) Install the ceiling bracket to the mounting surface with the desired

orientation. Ensure that ‘LINE A” (Figure 3), a line drawn

perpendicular to the bolt holes in the mounting bar, is pointed in the

desired direction of airflow. The ceiling bracket must be secured to

the mounting surface using as many as six (but not less than two)

5/8” fasteners (not provided). Make certain that lockwashers are

used under all nuts or lag bolts.

b) Hoist the heater up to the ceiling bracket. Line up the large centre

hole in the swivel bracket with the large hole in the mounting bar.

c) Insert the 1/2” bolt and loosely secure with nut and washers

provided. Tilt the heater at the desired angle to the horizontal and

secure with the 3/8” bolt. Tighten the 1/2” bolt.

Figure 3 - Ceiling Mounting

3.3.2 WALL MOUNTING

a) Install the ceiling bracket to the wall bracket with the desired

orientation. Ensure that “LINE A” (Figure 4), a line drawn

perpendicular to the bolt holes in the mounting bar, is pointed in the

desired direction of air flow. Secure the wall bracket to the mounting

surface. The wall bracket must be secured to the mounting surface

using as many as six (but not less than four) 5/8” fasteners (not

provided). Make certain that lockwashers are used under all nuts or

lag bolts.

b) Follow steps b) and c) outlined in 3.3.1.

Figure 4 - Wall Mounting

STANDARD FEATURES, SMALL CABINET UNIT:

1) 1/12 hp explosion-proof motor

2) Inlet guard

3) Extra heavy wall tubular steel finned heating elements with

nickel plated finish

4) Patented x-Max® explosion-proof terminal housing

5) 120V control circuit includes:

• Derated magnetic contactor

• Dual automatic reset high limits

• Transformer

6) Heavy duty 16 ga. stainless steel casing

7) Outlet louver assembly

8) Swivel bracket

9) Factory installed conduit seal

10)Supply connection housing

11)Terminal block for supply wiring and thermostat connection

STANDARD FEATURES, LARGE CABINET UNIT:

1) 1/2 hp explosion-proof motor

2) Inlet wire guard

3) Extra heavy wall tubular steel finned heating elements with

nickel plated finish

4) Patented x-Max® explosion-proof terminal housing

5) 120V control circuit includes:

• Derated magnetic contactor

• Dual automatic reset high limits

• Transformer

• Fan delay relay

• Control fuse

6) Heavy duty 16 ga. stainless steel casing

7) Outlet louver assembly

8) Swivel bracket

9) Factory installed conduit seal

10)Supply connection housing

11)Terminal block for supply wiring and thermostat connection

12)Motor mount

13)Motor mount casing

3.3.3 POST MOUNTING

a) Install the ceiling bracket to the wall bracket with the desired

orientation. Ensure that “LINE A” (Figure 5), a line drawn

perpendicular to the bolt holes in the mounting bar, is pointed in the

desired direction of air flow. Secure the wall bracket to the post using

the 1/2” U-bolts, nuts and washers supplied. Make certain the

lockwashers are used under all nuts or lag bolts.

b) Follow steps b) and c) outlined in 3.3.1.

Figure 5 - Post Mounting

3.3.4 FLOOR STAND MOUNTING

a) At times adequate support for the heater may not be available

within the structure of the space to be heated. In this situation, the

floor mount stand may be desirable. Telescoping square tubing on a

support base allows the unit to be positioned at the desired height

above the floor anywhere between 1.8 m (6’) to 3 m (10’).

b) Position the base of the stand on the floor in the desired

orientation. Ensure that “LINE A” (Figure 6), a line drawn

perpendicular to the bolt holes in the mounting bar, is pointed in the

desired direction of air flow.

c) Next, the stand is to be lagged to a solid floor to prevent the unit

from toppling. Four 11/16” diameter holes are provided in the base of

the stand for this purpose.

d) Raise the mounting frame to the desired height and secure to the

base using the hardware supplied.

e) Hoist the heater up to the mounting frame.

f) Insert the 1/2” bolt and loosely secure with nut and lockwashers

provided. Tilt the heater at the desired angle to the horizontal and

secure with the 3/8” bolt. Tighten the 1/2” bolt.

Figure 6 - Floor Mounting Stand

3.4 OUTLET LOUVRES

3.4.1 A louvred grill on the heater outlet end is supplied as standard.

The louver assembly may be positioned either horizontally or

vertically for maximum flexibility.

3.4.2 Standard heaters are shipped with the louvers in the horizontal

position. To change the orientation of the louvers to vertical, remove

the three mounting screws securing the louver assembly to the

cabinet and rotate the louver 90º to the desired direction.

3.5 WIRING

CAUTION: Whenever hazardous materials are present, ensure

that the terminal housing covers, plugs, etc., are secured (but

not over-tightened) before powering the heater.

All circuits must be in the open position before removing

junction or terminal box covers.

3.5.1 The heater must be installed by qualified personnel in strict

compliance with the electrical code.

3.5.2 All heaters are factory pre-wired and ready for direct

connections to the power supply leads.

3.5.3 The heater must be individually fused, preferably with Class J

time-delay fuses for maximum safety. Unless stated otherwise in

your local code, fuse size shall be 125% of line current or next size

larger. See Table 2 for recommendations.

3.5.4 Use approved conduit and conduit seals are required by the

code for the hazardous location.

3.5.5 The NORSEMAN™ explosion-proof unit heaters are equipped

with a factory installed conduit seal between the control and supply

housings. In Division 2, Zone 1 and Zone 2 applications, a field

installed conduit seal may not be required.

3.5.6 Supply wiring connections are made by accessing the over of

the side mounted supply connection housing (terminal box). Slide

the control trolley out of the housing just enough to access the

terminal block (Figure 8).

3.5.7 Connect the power leads to terminals marked L1and L2 for

single phase and L1, L2 and L3 for three phaseheaters making certain

to leave some excess wire to ensure that the leads may slide back

into the housing with the trolley. See Figure 9 for control circuit and

Figure 10 for suggested wiring. Exercise care to avoid damage to

wires caused by threads on the housing.

Table 2: Recommended Fuse Sizes

Figure 9A - Small Cabinet XGB Wiring Schematic

Figure 9B - Large Cabinet XGB Wiring Schematic

3.5.8 Connect the ground wire to the ground connection located in

the supply connection housing; once again, making sure that the

wire is sufficiently long to slide back into the housing with the trolley.

See Figure 10.

Figure 10 - Supply Connection

3.5.9 Due to the presence of hazardous materials, ensure that

the terminal housing covers, plugs, etc., are secured (but not

over-tightened) before powering the heater.

4.0 TEMPERATURE CONTROL

4.1 BUILT-IN THERMOSTAT (OPTIONAL)

When specified, the unit comes equipped with a built-in thermostat

pre-wired to all other standard controls. Set the temperature to the

desired operating condition.

4.2 REMOTE THERMOSTAT (OPTIONAL)

Install the XT thermostat in accordance with the instruction sheet

provided. Terminals “T1” and “T2” in the heater supply housing are

provided for connection to the remote thermostat and are pre-wired

to the rest of the control circuit. Remove the jumper wire between

“T1” and “T2” and connect the thermostat to these terminals. (Refer

to Figure 9). Set the temperature to the desired operating condition.

5.0 “AUTO / OFF / FAN-ONLY” SWITCH (OPTIONAL)

If ordered, a factory installed “auto / off / fan-only” switch may be

included on the heater. The “fan-only” feature allows the heater to

cycle in a “heat” mode dictated by the controlling thermostat, even

though the fan is operating continuously.

6.0 NORMAL SEQUENCE OF OPERATION

6.1 The heater must be properly mounted and wired in accordance

with the instructions contained in this manual. The fan blade must be

free to rotate with no obstruction to air inlet or outlet areas.

6.2 Energize the heater at the rated supply voltage.

6.3 Assuming that the thermostat calls for heat, i.e. the thermostat is

set to a higher temperature that ambient:

a) The main contactor will energize the elements and the fan motor.

b) After the inlet air temperature rises to the set point of the

thermostat, the thermostat contacts will open and the main contactor

will de-energize the elements and the fan motor.

Note: The large cabinet XGB incorporates a fan delay feature in both

the “ON” and “OFF” cycles. This is a desirable feature as it allows

the heater to come to temperature before the fan operates (no cold

blasts) and to cool down the “OFF” cycle (longer life for control

components and motor). Delay “ON” is 15 - 40 seconds and delay

“OFF” is 60 -160 seconds.

6.4 The cycle described above will repeat when the ambient

temperature falls below the thermostat set point.

IMPORTANT:

THE PROPER MOTOR/FAN ROTATION, VIEWED FROM THE

REAR OF THE HEATER IS COUNTER CLOCKWISE FOR THE

SMALL CABINET UNITS AND CLOCKWISE FOR THE LARGE

CABINET UNITS, AS INDICATED BY THE FAN ROTATION

LABEL ON THE HEATER. INCORRECT ROTATION OF THE FAN

WILL CAUSE THE HEATER TO OVERHEAT AND CYCLE ON THE

HIGH LIMITS. CONSULT FACTORY IN CASE OF INCORRECT

ROTATION.

7.0 MAINTENANCE

7.1 The NORSEMAN™ explosion-proof unit heaters are designed

and constructed to operate in tough industrial applications with a

minimum of maintenance. However, some routine maintenance is

recommended to extend the life of the heater and its components.

Always disconnect the electrical supply before performing any

maintenance.

7.2 Periodically inspect the heater installation to ensure that all

connections, fittings, plugs, screws, covers, etc. are tight and free of

corrosion.

7.3 Check the inside of the cabinet and around the element fins for

dust build-up and debris, especially after seasonal shutdowns.

Clean with an air blast or vacuum. Ensure that nothing is restricting

the air flow into the unit and that the fan blade is free to rotate.

7.4 MOTOR

The motor supplied with the small cabinet units is approved for Class

1, Group D, Class II, Group E, F & G, T3B temperature code. The

motor supplied with the large cabinet units is approved for Class I,

Group C & D, Class II, Group E, F & G, T3B temperature code. All

motors have internal thermal protection to eliminate motor

overheating.

7.5 FAN BLADE

Visually inspect the fan blade to ensure it is free to rotate and

accidental damage has not occurred. If bent or damaged, a factory

balanced blade should be installed so that the rated airflow is

maintained. A damaged fan blade may not deliver the required

airflow over the elements, resulting in cycling on the high limit which

can significantly reduce the life of the contactor and the high limit.

7.6 HEATER CABINET

The XGB unit heater cabinet is stainless steel for superior corrosion

resistance. We recommend the cabinet be wiped down periodically

using a mild detergent.

7.7 OVERHEAT PROTECTION

In the event of fan failure, motor damage, excessive dust build-up or

restricted inlet airflow, the heater temperature may rise, causing the

limit controls to open, breaking the power supply to the heater. All

units are equipped with two automatic reset high limit controls.

Cycling of the high limits should not be permitted.

Should this occur, the unit should be inspected to determine the

cause of the cycling and the condition should be corrected.

8.0 REPLACEMENT PARTS LIST

The replacement parts list is included for reference only. Due to the

delicate nature of explosion-proof design, XGB unit heaters are not

field serviceable. Should any problem arise, return the unit to the

factory for service by trained personnel.

SMALL CABINET UNITS:

LARGE CABINET UNITS:

A CCI Thermal XTK thermostat kit may be purchased to replace a

broken thermostat. Refer to installation instructions provided with

the kit.

Transformers

High Limits

Motor

Contactor

Fan Blade

208V units

240V units

480V units

600V units

T2C T-Code units

T3A T-Code units

T3B T-Code units

All units

All units

10 & 7.5kW units

5 & 3.75kW units

MO250O

MO250Q

MO250S

MO250V

C12023-11

C12023-10

C12023-10

B14302-01

42CF35AF

C11028-06

C11028-05

Transformers

High Limits

Motors

Contactor

Fan Blade

Control Fuse

208V units

240V units

480V units

600V units

T2C T-Code units

T2D T-Code units

T3A T-Code units

T3B T-Code units

208 - 480V 3Ø units

240V 1Ø units

600V units

All units

All units

All units

EXA50-23

EXA50-25

EXA50-36

EXA50-39

C12023-11

C12023-11

C12023-10

C12023-12

1699

1979

2433

42CF35AF

10873

MDL-0.6

GLYCOL

FREE

DESIGN

TERMINAL BLOCK

Figure 8 - XGB Terminal Block Trolley Figure

SIDE

LOOP

TOP

1 OR 3

Ø

SUPPLY

L3

L2

L1

C

H3

H2

H1

TO HEATING

LOAD

X1

120V T1 T2 HI-LIMITS

X2 C/AUX

C NO MOTOR

REMOVE JUMPER FOR

OPTIONAL THERMOSTAT

C

M

LINE A

CEILING BRACKET

MOUNTING BAR

3/8” Flat Washer, Lock Washer, Nut

1/2” Flat Washer, Lock Washer, Nut

MOUNTING SURFACE

11/16” Dia. Mounting Holes

3/8” bolt

1/2” bolt

SWIVEL MOUNTING BRACKET SWIVEL MOUNTING BRACKET

3” PIPE (NOT INCLUDED)

WALL BRACKET

LINE A

CEILING BRACKET

MOUNTNIG BAR

1/2” U-bolt

1/2” flat washer, lock washer, nut

5/8” flatwasher, lockwasher, nut

1/2” flat washer, lock washer, nut

3/8” flat washer, lock washer, nut

5/8” bolt

1/2” bolt

3/8” bolt MOUNTING FRAME

MOUNTING BAR

3/8” flatwasher, lockwasher, nut

1/2” flatwasher, lockwasher, nut

3/8” Bolt

1/2” Bolt

SWIVEL MOUNTING BRACKET

5/8” Bolt

5/8” flatwasher,

lockwasher, nut

LINE A

MOUNTING SURFACE

11/16” dia. mounting holes

5/8” flatwasher, lockwasher, nut

WALL BRACKET

LINE A

CEILING BRACKET

5/8” Bolt

MOUNTING BAR

3/8” flatwasher, lockwasher, nut

1/2” flatwasher, lockwasher, nut

3/8” Bolt

1/2” Bolt

SWIVEL MOUNTING BRACKET

5/8” Bolt M

H1

H2

H3

TO HEATING

LOAD

REMOVE JUMPER FOR

OPTIONAL THERMOSTAT

120V HI-LIMITS

FD

C

FD

1

3

4

5

X2 T1 T2

3ØONLY

C

3ØONLY

X1

L3 L2 L1

L1

L2

L3

1 OR 3Ø

SUPPLY

AIRFLOW

C

A

B

D1

D2

Figure 1B - Large Cabinet XGB Unit Heater Components

Figure 1A - Small Cabinet XGB Unit Heater Components

Recommended

Catalog Number kW Voltage Max Line Amps Fuse Size

(Amps)

1 Ø 3 Ø 1 Ø 3 Ø

XGB038T3B 3. 7 5 208 1 9 1 1 2 5 1 5

240 1 7 1 0 2 5 1 5

480 - 6 - 1 0

600 - 5 - 1 0

XGB050T3B 5 208 2 5 1 5 3 5 2 0

240 2 2 1 3 3 0 2 0

480 - 7 - 1 0

600 - 6 - 1 0

XGB075T3A 7 . 5 208 3 7 2 2 5 0 3 0

240 3 2 1 9 4 0 2 5

480 - 1 0 - 1 5

600 - 8 - 1 0

XGB100T2C 1 0 208 2 9 4 0

240 4 3 2 5 6 0 3 5

480 - 1 3 - 2 0

600 - 1 1 - 1 5

XGB100T3B 1 0 208 - 3 0 - 4 0

240 4 7 2 6 6 0 3 5

480 - 1 3 - 2 0

600 - 1 1 - 1 5

XGB150T3B 1 5 208 - 4 4 - 6 0

240 - 3 8 - 5 0

480 - 1 9 - 2 5

600 - 1 5 - 2 0

XGB200T3B 2 0 480 - 2 5 - 3 5

600 - 2 0 - 2 5

XGB225T3A 22. 5 480 - 2 8 - 3 5

600 - 2 3 - 3 0

XGB250T2D 2 5 480 - 3 1 - 4 0

600 - 2 5 - 3 5

XGB300T2D 3 0 480 - 3 7 - 5 0

600 - 3 0 - 4 0

XGB325T2D 32.5 480 - 4 0 - 5 0

600 - 3 2 - 4 0

XGB350T2C 3 5 480 - 4 3 - 6 0

600 - 3 4 - 4 5

A B C D1 D2 Weight

lbs (kg)

Small16-7/ 8 8-7/ 8 25-3-/ 16 17-1/ 2 - 100

Cabinet(429)(225)(640)(445)(45)

10-15 kW

Large20-1/ 8 8-7/ 8 29-1/ 4 - 31-1/ 4 145 (66)

Cabinet(511)(225)(743)(794)20-35 kW

185 (84)

Figure 2 – Large Cabinet XGB Unit Heater Components

5

Pre-Installation

B. PRE-INSTALLATION

1. Inspect the heater for possible damage due to shipping

and handling. Claims for shipping damages shall be

placed with the carrier.

2. Check the heater nameplate to ensure that the heater

area classication and temperature code are suitable for

the hazardous area classication.

3. Verify that the nameplate voltage, phase and wattage

are as ordered and are the same as the electrical power

supply available. DO NOT CONNECT THE XGB UNIT

HEATER TO A SUPPLY VOLTAGE OTHER THAN THAT

SHOWN ON THE PRODUCT NAMEPLATE.

C. INSTALLATION AND MOUNTING

The heater must be installed by qualied personnel in strict

compliance with the electrical code.

C.1 Dimensions

Table1 – Dimensions and Weights

(See Figure 3, page5)

Cabinet

Type

A B C D1 D2 Weight

in mm in mm in mm in mm in mm lbs kg

Small

Cabinet

16

7/8 429 8

7/8 225 25

3/16 640 17

1/2 445 –100 45

Large Cabinet

10-15

kW

20

1/8 511 8

7/8 225 29

1/4 743 –31

1/4 794

145 66

20-35

kW 185 84

C.2 Mounting

1. Norseman™ explosion-proof unit heaters can be

mounted to a ceiling, wall, 3" pipe, or oor stand. Ensure

that the mounting surface is sufciently strong to

support the heater, which, depending on the model,

could weigh up to 185lbs, (84kg). Provide sufcient

stiffness to prevent excessive vibration and withstand

harsh situations such as transportable installations. See

C.1 Dimensions, page5 for heater dimensions and

weights.

2. The heater must be positioned with a minimum 15cm

(6") side clearance from all surrounding surfaces and

must be mounted at least 61cm (24") from the oor for

small cabinet units, or 2440cm (96") from the oor for

large cabinet units. It is best to maximize clearances to

allow freedom of rotation. Ensure that airow into and

out of the unit is not restricted.

3. All mounting studs, bolts, nuts and other fasteners shall

be secured so that there is no possibility of loosening

over prolonged periods. Periodically inspect at regular

intervals and retighten if necessary.

4. All standard mounting kits are designed to support the

heater on its centre of gravity and to allow for 30º tilt in

the vertical direction and 360 º rotation in the horizontal.

Note that horizontal rotation is xed after the ceiling

bracket is bolted to its support.

5. For specic mounting instructions refer to C.3,

page6.

6. If lifting with slings, take special care not to damage the

casing.

7. For large cabinet units, leave the heater on the shipping

skid and use the skid as a lifting platform to facilitate

installation of the heater.

AIRFLOW

C

A

B

D1

D2

Figure 3 – XGB Heater Dimensions

6

Installation and Mounting

C.3 Mounting with Standard Kits

1. Ceiling Mounting

1.1 Install the ceiling bracket to the mounting surface

with the desired orientation. Ensure that ‘LINE A”

(Figure 4, page6), a line drawn perpendicular

to the bolt holes in the mounting bar, is pointed in

the desired direction of airow. The ceiling bracket

must be secured to the mounting surface using as

many as six (but not less than two) 5/8" fasteners

(not provided). Make certain that lockwashers are

used under all nuts or lag bolts.

1.2 Hoist the heater up to the ceiling bracket. Line up

the large centre hole in the swivel bracket with the

large hole in the mounting bar.

1.3 Insert the 1/2" bolt and loosely secure with nut and

washers provided. Tilt the heater at the desired

angle to the horizontal and secure with the 3/8"

bolt. Tighten the 1/2" bolt.

Edmonton Head Office & Factory

5918 Roper Road, Edmonton, Alberta, Canada T6B 3E1

P 780.466.3178 F 780.468.5904 Toll Free 1.800.661.8529

Part No. 11110 - Rev. 01

Installation, Operation & Maintenance Instructions for

NorsemanTM XGB Explosion-Proof Unit Heater

3.75 - 35kW, 60 Hz Units

1.0 GENERAL INFORMATION

DESCRIPTION

CCI Thermal’s XGB explosion-proof unit heater is the latest addition

to the NORSEMAN™ line of hazardous location heating products.

The small cabinet units are available with ratings from 3.75 – 10kW,

and can be identified by their internally mounted motor. The large

cabinet units (shown below) are available from 10kW up to 35kW.

See section 3.1 for cabinet dimensions.

APPLICATION

Designed specifically for heating industrial spaces where potentially

explosive substances are or may be present. Typical hazardous

location environments include:

• Water and Sewage Treatment Plants

• Oil Refineries

• Compressor Stations

• Pulp and Paper Mills

• Paint Storage Booths

• Cement Plants

• Mines

CONSTUCTION AND INSTALLATION

CCI Thermal’s NORSEMAN™ unit heaters use extra heavy wall

finned tubular steel heating elements to provide safe, efficient heat

transfer to the environment. The heater does not contain glycol,

decreasing maintenance costs.

Flow adjustment… in structures with high ceilings, other units may

not have the range of motion needed to direct air flow to the floor.

The glycol-free design of the XGB allows the unit to be tilted to a 30º

angle below the horizontal, with an additional 35º of airflow

redirection provided by the outlet louver. For lateral airflow, the entire

louver assembly can be rotated 90º.

No conduit seal required… a factory installed conduit seal

provides the necessary isolation between the supply and control

housings. In Division 2, Zone 1 and Zone 2 applications, a field

installed conduit seal may not be required.

Simplified wiring… to facilitate installation, the NORSEMAN™

explosion-proof unit heaters feature the patented x-Max® housing

with slide out terminal block trolley for connection of the electrical

supply.

STANDARD PRODUCT FEATURES

• CSA C/US Certified for hazardous locations. Small cabinet units

approved for Class I, Div 1 & 2, Group D; Class II, Div. 1 & 2,

Groups E, F and G. Large cabinet units approved for Class I, Div. 1

& 2, Groups C & D; Class II, Div. 1 & 2, Groups E, F & G.

Note: Class II and some atmospheric groups are not available in

every kW rating.

• Optional Zone marking available.

• Ratings from 3.75 – 35kW.

• 208 – 600V, 1 or 3 phase

• Low watt density extra heavy wall tubular steel finned heating

elements with nickel plated finish

• Glycol-free design allows the heater to be tilted 30º downward

• Rotatable outlet louvers provide 35º of additional airflow redirection

• Patented x-Max® housing with track and trolley system simplifies

installation and servicing

• Heavy duty 16 ga. Stainless steel casing

• Terminals for remote thermostat connection

• Dual automatic reset high limits

• Contactor derated for extended service life

• Isolated supply connection housing eliminates the need for conduit

seals

OPTIONAL FEATURES

• Built-in, externally adjustable thermostat

• Built-in disconnect

• Moisture-resistant construction

• “Auto/off/fan-only” switch

• Pilot light

• Manual reset high limit

THERMOSTATS

CCI Thermal offers a wide variety of explosion-proof thermostats to

suit most every need. NORSEMAN™ unit heaters are available with

optional built-in, externally adjustable, bulb type thermostats which

are field-convertible to tamper-proof. Thermostats for remote

mounting can also be provided on request.

MOTORS

Fractional horsepower, 1725 rpm explosion-proof motor with double

shielded ball bearings and built-in thermal overload. Small cabinet

units use 1/12 hp motor approved for Class I, Group D; Class II,

Group E, F, and G. Large cabinet units use 1/2 hp motor approved

for Class I, Groups C and D; Class II, Groups E, F & G, as standard.

ACCESSORIES

NORSEMAN™explosion-proof unit heaters readily adapt to most

mounting requirements. Each heater is equipped with a basic swivel

bracket that is compatible with any of the optional mounting kits.

Optional mounting kits allow the unit to be installed on a wall ceiling,

3” pipe, or floor stand. Each mounting configuration provides

maximum flexibility for outlet flow direction. The swivel bracket Figure 2 - XGB Heater Dimensions

2.0 PRE-INSTALLATION

2.1 Inspect the heater for possible damage due to shipping and

handling. Claims for shipping damages shall be placed with the

carrier.

2.2 Check the heater nameplate to ensure that the heater area

classification and temperature code are suitable for the hazardous

area classification.

2.3 Verify that the nameplate voltage, phase and wattage are as

ordered and are the same as the electrical power supply available.

DO NOT CONNECT THE XGB UNIT HEATER TO A SUPPLY

VOLTAGE OTHER THAN THAT SHOWN ON THE PRODUCT

NAMEPLATE.

3.0 INSTALLATION AND MOUNTING

The heater must be installed by qualified personnel in strict

compliance with the electrical code.

3.1 DIMENSIONS

Table 1: Dimensions and Weights (See Fig. 2)

3.2 MOUNTING

3.2.1 NORSEMAN™ explosion-proof unit heaters can be mounted

to a ceiling, wall 3” pipe, or floor stand. Ensure that the mounting

surface is sufficiently strong to support the heater, which, depending

on the model, could weigh up to 185lbs, (84kg). See 3.1 for heater

dimensions and weights.

3.2.2 The heater must be positioned with a minimum 15 cm (6”) side

clearance from all surrounding surfaces and must be mounted at

least 61 cm (24”) from the floor for small cabinet units, or 2440 cm

(96”) from the floor for large cabinet units. It is best to maximize

clearances to allow freedom of rotation. Ensure that airflow into

and out of the unit is not restricted.

3.2.3 All mounting studs, bolts, nuts and other fasteners shall be

secured so that there is no possibility of loosening over prolonged

periods. Periodically inspect at regular intervals and retighten if

necessary.

3.2.4 All standard mounting kits are designed to support the heater

on its centre of gravity and to allow for 30º tilt in the vertical direction

and 360 º rotation in the horizontal. Note that horizontal rotation is

fixed after the ceiling bracket is bolted to its support.

3.2.5 For specific mounting instructions refer to the appropriate

paragraph of section 3.3.

3.2.6 If lifting with slings, take special care not to damage the casing.

3.2.7 For large cabinet units, leave the heater on the shipping skid

and use the skid as a lifting platform to facilitate installation of the

heater.

3.3 MOUNTING WITH STANDARD KITS

3.3.1 CEILING MOUNTING

a) Install the ceiling bracket to the mounting surface with the desired

orientation. Ensure that ‘LINE A” (Figure 3), a line drawn

perpendicular to the bolt holes in the mounting bar, is pointed in the

desired direction of airflow. The ceiling bracket must be secured to

the mounting surface using as many as six (but not less than two)

5/8” fasteners (not provided). Make certain that lockwashers are

used under all nuts or lag bolts.

b) Hoist the heater up to the ceiling bracket. Line up the large centre

hole in the swivel bracket with the large hole in the mounting bar.

c) Insert the 1/2” bolt and loosely secure with nut and washers

provided. Tilt the heater at the desired angle to the horizontal and

secure with the 3/8” bolt. Tighten the 1/2” bolt.

Figure 3 - Ceiling Mounting

3.3.2 WALL MOUNTING

a) Install the ceiling bracket to the wall bracket with the desired

orientation. Ensure that “LINE A” (Figure 4), a line drawn

perpendicular to the bolt holes in the mounting bar, is pointed in the

desired direction of air flow. Secure the wall bracket to the mounting

surface. The wall bracket must be secured to the mounting surface

using as many as six (but not less than four) 5/8” fasteners (not

provided). Make certain that lockwashers are used under all nuts or

lag bolts.

b) Follow steps b) and c) outlined in 3.3.1.

Figure 4 - Wall Mounting

STANDARD FEATURES, SMALL CABINET UNIT:

1) 1/12 hp explosion-proof motor

2) Inlet guard

3) Extra heavy wall tubular steel finned heating elements with

nickel plated finish

4) Patented x-Max® explosion-proof terminal housing

5) 120V control circuit includes:

• Derated magnetic contactor

• Dual automatic reset high limits

• Transformer

6) Heavy duty 16 ga. stainless steel casing

7) Outlet louver assembly

8) Swivel bracket

9) Factory installed conduit seal

10)Supply connection housing

11)Terminal block for supply wiring and thermostat connection

STANDARD FEATURES, LARGE CABINET UNIT:

1) 1/2 hp explosion-proof motor

2) Inlet wire guard

3) Extra heavy wall tubular steel finned heating elements with

nickel plated finish

4) Patented x-Max® explosion-proof terminal housing

5) 120V control circuit includes:

• Derated magnetic contactor

• Dual automatic reset high limits

• Transformer

• Fan delay relay

• Control fuse

6) Heavy duty 16 ga. stainless steel casing

7) Outlet louver assembly

8) Swivel bracket

9) Factory installed conduit seal

10)Supply connection housing

11)Terminal block for supply wiring and thermostat connection

12)Motor mount

13)Motor mount casing

3.3.3 POST MOUNTING

a) Install the ceiling bracket to the wall bracket with the desired

orientation. Ensure that “LINE A” (Figure 5), a line drawn

perpendicular to the bolt holes in the mounting bar, is pointed in the

desired direction of air flow. Secure the wall bracket to the post using

the 1/2” U-bolts, nuts and washers supplied. Make certain the

lockwashers are used under all nuts or lag bolts.

b) Follow steps b) and c) outlined in 3.3.1.

Figure 5 - Post Mounting

3.3.4 FLOOR STAND MOUNTING

a) At times adequate support for the heater may not be available

within the structure of the space to be heated. In this situation, the

floor mount stand may be desirable. Telescoping square tubing on a

support base allows the unit to be positioned at the desired height

above the floor anywhere between 1.8 m (6’) to 3 m (10’).

b) Position the base of the stand on the floor in the desired

orientation. Ensure that “LINE A” (Figure 6), a line drawn

perpendicular to the bolt holes in the mounting bar, is pointed in the

desired direction of air flow.

c) Next, the stand is to be lagged to a solid floor to prevent the unit

from toppling. Four 11/16” diameter holes are provided in the base of

the stand for this purpose.

d) Raise the mounting frame to the desired height and secure to the

base using the hardware supplied.

e) Hoist the heater up to the mounting frame.

f) Insert the 1/2” bolt and loosely secure with nut and lockwashers

provided. Tilt the heater at the desired angle to the horizontal and

secure with the 3/8” bolt. Tighten the 1/2” bolt.

Figure 6 - Floor Mounting Stand

3.4 OUTLET LOUVRES

3.4.1 A louvred grill on the heater outlet end is supplied as standard.

The louver assembly may be positioned either horizontally or

vertically for maximum flexibility.

3.4.2 Standard heaters are shipped with the louvers in the horizontal

position. To change the orientation of the louvers to vertical, remove

the three mounting screws securing the louver assembly to the

cabinet and rotate the louver 90º to the desired direction.

3.5 WIRING

CAUTION: Whenever hazardous materials are present, ensure

that the terminal housing covers, plugs, etc., are secured (but

not over-tightened) before powering the heater.

All circuits must be in the open position before removing

junction or terminal box covers.

3.5.1 The heater must be installed by qualified personnel in strict

compliance with the electrical code.

3.5.2 All heaters are factory pre-wired and ready for direct

connections to the power supply leads.

3.5.3 The heater must be individually fused, preferably with Class J

time-delay fuses for maximum safety. Unless stated otherwise in

your local code, fuse size shall be 125% of line current or next size

larger. See Table 2 for recommendations.

3.5.4 Use approved conduit and conduit seals are required by the

code for the hazardous location.

3.5.5 The NORSEMAN™ explosion-proof unit heaters are equipped

with a factory installed conduit seal between the control and supply

housings. In Division 2, Zone 1 and Zone 2 applications, a field

installed conduit seal may not be required.

3.5.6 Supply wiring connections are made by accessing the over of

the side mounted supply connection housing (terminal box). Slide

the control trolley out of the housing just enough to access the

terminal block (Figure 8).

3.5.7 Connect the power leads to terminals marked L1and L2 for

single phase and L1, L2 and L3 for three phaseheaters making certain

to leave some excess wire to ensure that the leads may slide back

into the housing with the trolley. See Figure 9 for control circuit and

Figure 10 for suggested wiring. Exercise care to avoid damage to

wires caused by threads on the housing.