Norsup OceanClear LS Operation instructions

SALT CHLORINATOR

ORIGINAL MANUAL

SALZWASSER ELEKTROLYSE

ORIGINALBETRIEBSANLEITUNG

ELECTROLYSEUR DE SEL

NOTICE ORIGINALE

ELECTROLIZADOR DE SAL

MANUAL DE INSTRUCCIONES

ELETROLISADOR DE SAL

MANUAL DE INSTRUÇÕES

CENTRALINA A SALE

MANUALE DI ISTRUZIONI

UNO

|

DUO

|

PRO

EN

ES

FR

IT

DE

PT

EN

ES

FR

IT

DE

PT

SALT CHLORINATOR 4

ORIGINAL MANUAL

SALZWASSER ELEKTROLYSE 34

ORIGINALBETRIEBSANLEITUNG

ELECTROLYSEUR DE SEL 64

NOTICE ORIGINALE

ELECTROLIZADOR DE SAL 94

MANUAL DE INSTRUCCIONES

ELETROLISADOR DE SAL 124

MANUAL DE INSTRUÇÕES

CENTRALINA A SALE 154

MANUALE DI ISTRUZIONI

Google Play Store Apple Appstore

DOWNLOAD NORSUPONE APP: www.norsup.eu

45

Alterations which serve the technological progress as well as errors excepted! ORIGINAL MANUAL NORSUPWWW.NORSUP.EU Alterations which serve the technological progress as well as errors excepted!

EN

ES

FR

IT

DE

PT

SALT CHLORINATOR

Errors and technical modifications subject

to change, reproduction as well as electronic

duplication only with our written permission.

© NORSUP

Edition: 11.2020

1. FOREWORD 6

2. SAFETY GUIDELINES 6

3. FUNCTIONS PERFORMED 6

4. PACKING LIST WITH INLINE CELL 7

5. PACKING LIST WITH TCELL 8

6. INSTALLATION DIAGRAM 9

7. INSTALLATION 11

7.1. Important preliminary precautions 11

7.2. Mounting the electronics unit onto a wall 11

7.3. Installing the accessories holder 12

7.4. Installing the salt/temperature/low-water sensor 12

7.5. Installing the Pool Ground (optional) 12

7.6. Installing the pH injection heat contactor (models DUO and PRO) 13

7.7. Installing the pH probe (models DUO and PRO) 13

7.8. ORP measuring heat contactor installation (PRO) model

without the optional measuring kit 14

7.9. Installation of the ORP measuring heat contactor (PRO model)

with the optional measuring kit 15

7.10. Installing the line cell 17

7.11. Installation of the T-cell 17

7.12. Electrical connections 18

8. COMMISSIONING 20

9. ELECTRONICS UNIT INTERFACE 20

9.1. Screen 20

9.2. Indicator lights 20

9.3. Keypad 21

10. MENU STRUCTURE 1 21

11. MENU STRUCTURE 2 23

12. DETAILED INFORMATION ON THE ORP OPERATING MODE 28

13. PROBE CALIBRATION 28

13.1. Ph probe calibration 28

13.2. Calibrating the ORP probe 29

14. SHUTDOWN FOR EXTENDED PERIODS FOR WINTER 29

15. MAINTENANCE 29

15.1. Regular checks 29

15.2. Cell 30

15.3. pH probe and ORP probe 30

15.4. pH injection heat contactor 30

16. FAULTS, DIAGNOSIS AND TROUBLESHOOTING 30

17. GUARANTEE 32

CONTENTS

UNO

|

DUO

|

PRO

67

Alterations which serve the technological progress as well as errors excepted! ORIGINAL MANUAL NORSUPWWW.NORSUP.EU Alterations which serve the technological progress as well as errors excepted!

SALT CHLORINATORSALT CHLORINATOR

EN

ES

FR

IT

DE

PT

1. FOREWORD

READ, UNDERSTAND AND CAREFULLY FOLLOW ALL

OF THE INSTRUCTIONS IN THIS MANUAL BEFORE

INSTALLING AND USING THIS EQUIPMENT.

2. SAFETY GUIDELINES

2. FUNCTIONS PERFORMED

ELECTRICAL SHOCK HAZARD

To avoid the risk of injury or accident, install the

equipment out of reach of children and anyone

not authorised to operate and handle the

equipment.

Ensure that the equipment room in which the

equipment is installed complies with the standards

in force in the country of installation, at the time of

commissioning the equipment. If in doubt, contact

a qualified electrician. This equipment must also

be installed by an authorised, qualified person in

accordance with the electrical codes in force in the

country of installation at the time of installation.

The installation must also comply in all respects

with the technical specifications given in this manual

and in any document supplied with the appliance.

The equipment’s electrical cables must be

protected against any accidental damage. A

damaged cable must be replaced immediately,

using only a cable identical to the original. Never

cut or extend the electrical cables.

Only authorised, qualified people may work on the

equipment in case of failure or to perform maint-

enance. Always disconnect the power supply before

carrying out any technical work on the equipment.

Do not modify the equipment. Any modification of

the equipment can lead to risks to people as well

as the environment, and result in the deterioration

of the equipment.

ATTENTION

The detailed safety instructions in this manual are

not exhaustive. They detail the most common

risks encountered when installing and using this

equipment. Caution and common sense are

required when installing and using the equipment.

Model Chlorine

product-

ion via

electrolysis

pH

regulation

Regulation of

chlorine pro-

duction with

ORP probe

UNO

DUO

PRO

Electronics unit

1x

Controller mounting

kit for electronics unit

(wall mount + screws

+ plastic anchors)

1x

In-line cell

1x

Nut

2x

Restrictor

2x

Collar

2x

Seal

2x

Power cable for

electronics unit

1x

Power cable

for cell

1x

Accessories

holder

(equipped with

2 reducers

and 5 caps)

1x

Salt/

temperature

/low-water

sensor

1x

Analysis kit

(test strips

+ reference

card)

1x

UNO model

Pool Ground (optional)

1x

DUO model

This packing list also includes the items below.

pH probe

1x

Filter with

ballast

1x

Injection

connector

1x

Probe

connector

1x

Stopper

1x

Semi-flexible

tubing

1x

pH calibration

kit (pH 7

solution + pH

10 solution)

1x

PRO model

This packing list also includes the two sets of items below.

ORP probe

1x

ORP calibration solution

1x

Saddle clamp

(in kit)

1x

Probe connector

1x

Measuring

chamber

1x

Valve

2x

Controller

mounting kit for

the measuring

chamber (screws +

plastic anchors)

1x

Fitting

2x

Saddle clamp

(in kit)

2x

Semi-flexible

tubing

1x

Sealing tape

1x

Measuring kit (optional):

4. PACKING LIST WITH INLINE CELL Non-binding images

• In this manual, the pictograms opposite

indicate a WARNING, or a NOTE OF CAUTION,

accompanied by instructions to be followed

to the letter.

• Failure to comply with these instructions

may result in significant risk of damage to

the equipment and/or serious injury to people.

THESE INSTRUCTIONS MUST BE FOLLOWED

AND COMPLIED WITH.

89

Alterations which serve the technological progress as well as errors excepted! ORIGINAL MANUAL NORSUPWWW.NORSUP.EU Alterations which serve the technological progress as well as errors excepted!

SALT CHLORINATORSALT CHLORINATOR

EN

ES

FR

IT

DE

PT

Electronics unit

1x

Controller mount-

ing kit for electro-

nics unit (wall

mount + screws +

plastic anchors)

1x

T-cell

1x

ower cable for

electronics unit

1x

Power cable

for cell

1x

Accessories

holder

(equipped with

2 reducers

and 5 caps)

1x

Salt/temper-ature

/low-water

sensor

1x

Analysis kit (test strips +

reference card)

1x

UNO model

Pool Ground (optional)

1x

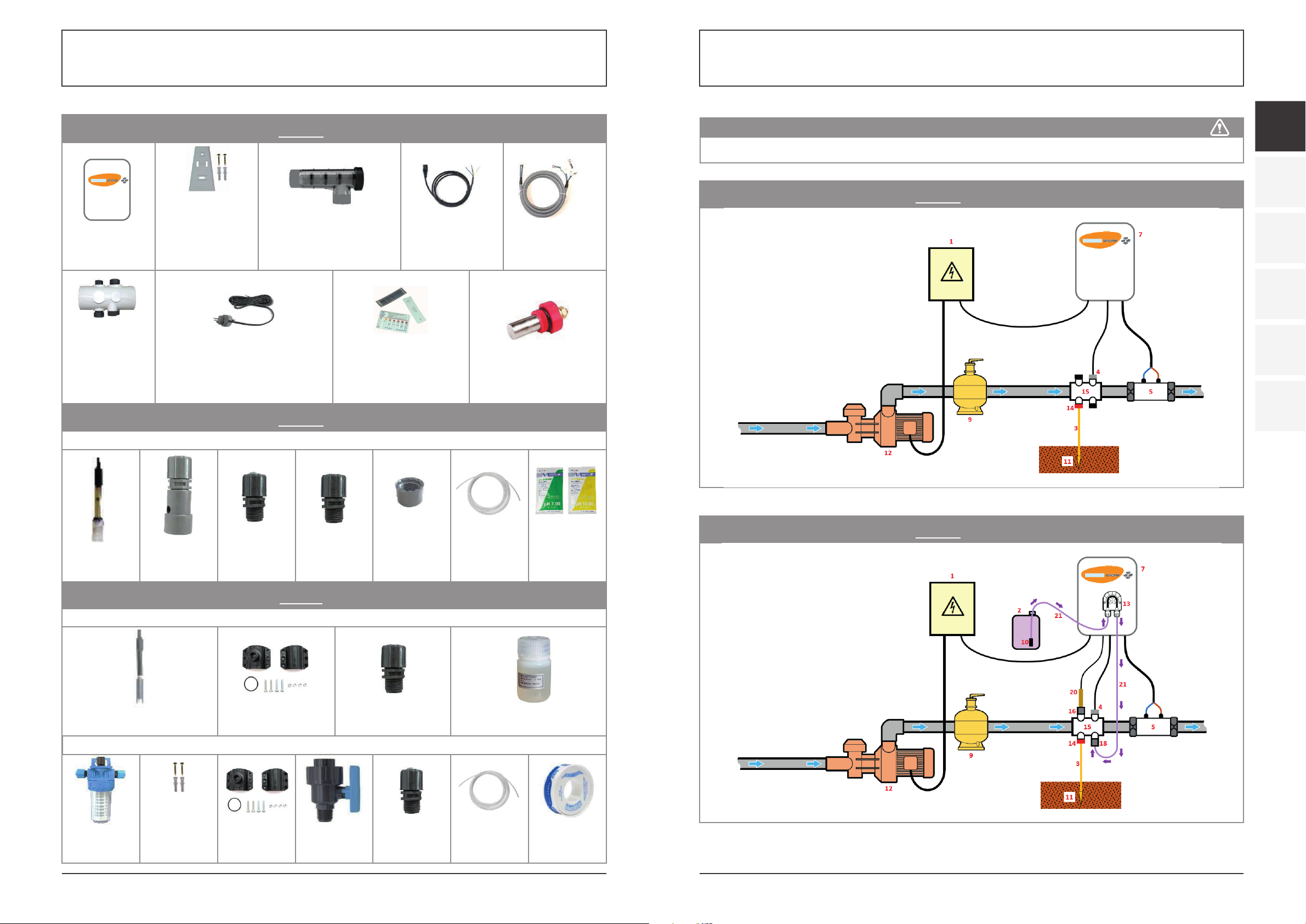

6. INSTALLATION DIAGRAM

ATTENTION

The pH corrector drum must be installed a safe distance away from any electrical device or any other chemicals.

UNO model

DUO model

DUO model

This packing list also includes the items below.

pH probe

1x

Filter with

ballast

1x

Injection

connector

1x

Probe

connector

1x

Stopper

1x

Semi-

flexible

tubing

1x

pH calibration

kit (pH 7

solution + pH

10 solution)

1x

PRO model

This packing list also includes the two sets of items below.

ORP probe

1x

ORP calibration solution

1x

Saddle clamp

(in kit)

1x

Probe connector

1x

Measuring

chamber

1x

Valve

2x

Controller

mounting kit for

the measuring

chamber (screws

+ plastic anchors)

1x

Fitting

2x

Saddle clamp

(in kit)

2x

Semi-flexible

tubing

1x

Sealing tape

1x

Measuring kit (optional):

5. PACKING LIST WITH TCELL Non-binding images

10 11

Alterations which serve the technological progress as well as errors excepted! ORIGINAL MANUAL NORSUPWWW.NORSUP.EU Alterations which serve the technological progress as well as errors excepted!

SALT CHLORINATORSALT CHLORINATOR

EN

ES

FR

IT

DE

PT

PRO model

with the optional measuring kit:

1: Electrical power supply (not provided)

2: pH corrector container (not provided)

3: Copper cable (not provided)

4: Salt/temperature/low-water sensor

5: In-line cell

5-A: Alternative assembly for T-cell

6: Measuring chamber

7: Electronics unit

8: Saddle clamp

9: Filter (not supplied)

10: Filter with ballast

11: Ground rod (not provided)

12: Filtration pump (not provided)

13: Peristaltic pump

14: Pool Ground (optional)

15: Accessories holder

16: Probe connector

17-A: Fitting

17-B: Fitting

18: Injection connector

19: ORP probe

20: pH probe

21: Semi-flexible tubing

22: Valve

7. INSTALLATION

7.1. IMPORTANT PRELIMINARY PRECAUTIONS

• The treatment capacity of the equipment must be

appropriate for the volume of the pool to be treated,

the number of people using the pool, the presence

of nearby equipment (overflow, reflecting pool, slide,

etc.) and the weather conditions where the equipment

is installed.

• Use water from the mains water supply. Do not use

water of natural origin (rainwater, run-off, ponds,

lakes or boreholes), as this may cause premature

deterioration of the electrolytic cell. • Do not use any

anti-algae products containing copper or other

metals, as this may cause premature deterioration of

the electrolytic cell.

• Check that the filtration pump and filter are in good

condition and working correctly. Also check the flow

rate of the filtration pump, the capacity of the filter, and

the outer diameter of pipework (either 50 or 63 mm).

• The equipment must be installed in a closed, dry and

sufficiently ventilated room which is protected from

water sprays and UV rays. The temperature inside

this room must not exceed 40°C.

→ If these premises are located in a country with a hot

and humid climate, they must be air conditioned.

→ If these premises are located in a country with a

temperate climate, they must be equipped with

forced ventilation.

• Determine where exactly each component will be

positioned, taking into account its size and the length

of its power cables. Also anticipate extra space around

the equipment, in order to facilitate access for

maintenance.

• The pH corrector drum must be installed a safe

distance away from any electrical device or any other

chemicals. Failure to follow these instructions may

lead to abnormal oxidation of the metal parts,

possibly resulting in complete device failure.

• Be very careful to ensure that the various components

are correctly positioned in relation to each other in

accordance with the fluid direction, as indicated in the

installation diagram. Install the cell and accessories

holder in a horizontal position first, then all other

devices for water treatment, cleaning or heating

(just before flow out into the pool). To protect property

and people, the cell and accessories holder must be

installed in series (and not in parallel), and the cell

must be positioned just after the accessories holder.

If constraints concerning the filtration heat contactor

make it necessary to install components in a way

that differs from the installation diagram, ensure

that this assembly is approved by a professional. You

must also install the flow sensor (see the overview of

the “Sensor settings” menu in chapter 11). The same

applies when intentionally deciding to install

components in a different way, for example in

order to position the cell and accessories holder

in a bypass configuration.

• A sufficient flow of water must be maintained in

the cell when connected to a power supply. If the

filtration pump has a variable flow, you must install

a flow sensor so that electrolysis automatically stops

when flow is insufficient. The electronics unit is fitted

with a socket to connect a flow sensor. Enable the

flow sensor function (see the description of the

„Sensor Parameters“ menu in chapter 11).

• All probes must be installed vertically and on the

level (not tilted) to ensure proper operation.

• The water pressure in the cell must not exceed 3 bar.

All hydraulic components installed must be able to

tolerate water pressures likely to be encountered as

part of normal use. There should be no leakage from

any part, including pipework.

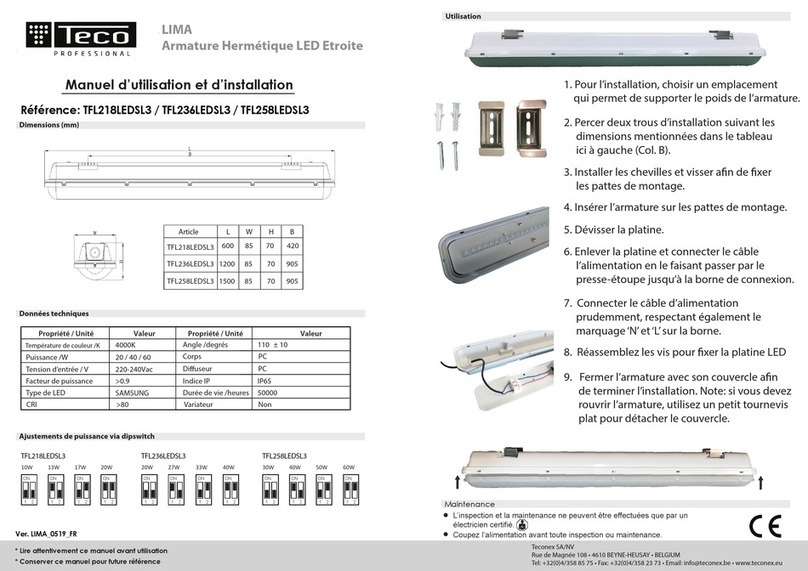

7.2. MOUNTING THE ELECTRONICS UNIT

ONTO A WALL

1) Attach the wall mount to the wall using the screws

and plastic anchors provided, following the diagrams

below:

2) Slide the electronics unit downwards onto the wall

mount.

ATTENTION

Before installing the equipment, the following

instructions must be followed:

FRONT VIEW SIDE VIEW

12 13

Alterations which serve the technological progress as well as errors excepted! ORIGINAL MANUAL NORSUPWWW.NORSUP.EU Alterations which serve the technological progress as well as errors excepted!

SALT CHLORINATORSALT CHLORINATOR

EN

ES

FR

IT

DE

PT

7.6. INSTALLING THE PH INJECTION HEAT

CONTACTOR MODELS DUO AND PRO

1) Place the pH corrector container 2as close as

possible to the equipment room’s internal

ventilation and as far away as possible from any

electrical device.

2) Connect the ballasted filter 10 to the peristaltic

pump 13, with the semiflexible tubing 21 to be cut

to the right size (see photos Aand B).

3) Insert the ballasted filter 10 at the bottom of

container 2.

4) With the use of Teflon tape (not supplied), screw

the injection connector 18 into the accessories

holder 15 and tighten by hand.

5) Connect the injection connector 18 to the peristaltic

pump 13, with the semi-flexible tubing, 21 to be cut

as needed.

7.7. INSTALLING THE PH PROBE MODELS DUO AND

PRO

1) Check that the probe bulb is properly immersed in

the solution inside the storage vial.

If this is not the case:

a) Remove the storage vial from the probe (see

photo below), and keep it for wintering.

b) Rinse the bulb with tap water.

c) Soak the probe for 30 minutes in tap water or

in a suitable KCl solution (saturated potassium

chloride).

d) Move directly to stage 3).

2) Remove the storage vial from the probe, and keep

it for wintering.

7.3. INSTALLING THE ACCESSORIES HOLDER

1) Remove the 5 stoppers and 2 reducers from the

accessories holder.

2) Following the image and instructions shown

opposite, install the accessories holder with or

without the 2 reducers (depending on the diameter

of the pipe).

3) Depending on the elements to be connected to the

accessories holder, screw back up and tighten by

hand the plug(s) required in the accessory holder,

using sealing tape (not supplied).

7.4. INSTALLING THE SALTTEMPERATURE

LOWWATER SENSOR

Screw and tighten by hand the salt/temperature/

water shortage sensor 4in the accessories holder 15,

without using sealing tape.

7.5. INSTALLING THE POOL GROUND OPTIONAL

The Pool Ground is intended for functional and not

safety purposes. It enables static electricity, whatever

its source may be, to be transferred from the pool

water to the ground. In some cases, static electricity

can stimulate the oxidation of metal parts in contact

with pool water. Static electricity can also disturb the

working of probes, which can lead to the equipment

as a whole not working correctly.

1) Without applying Teflon tape, screw in and tighten

the Pool Ground by hand 14 into the accessories

holder 15.

2) Connect the pool earthing device 14 to a ground

rod 11 (not supplied) using a copper cable without

isolating sleeve 3(not supplied).

3) Insert the whole ground rod 11 into the ground.

ATTENTION

• You must comply with the specifications of

installation standards in the country and at the time

of the installation.

• The ground rod should be sited at a distance and

unaffected by any other electrical ground device/rod.

• The ground rod must be at least 1.5 m long.

• The ground into which the ground rod is inserted

should be as wet as possible, and have a resistance

of less than 20 Ω.

ATTENTION

Following image C(exploded view of the injection

connector 18), respect the direction of assembly of

the parts, and in particular the direction of the arrow

engraved on the fitting. Failure to follow these

instructions can lead to the peristaltic pump being

damaged.

ATTENTION

The life of the pH probe depends primarily on the

strict observance of all the instructions provided in

this manual.

ATTENTION

Never touch the bulb of the probe.

14 15

Alterations which serve the technological progress as well as errors excepted! ORIGINAL MANUAL NORSUPWWW.NORSUP.EU Alterations which serve the technological progress as well as errors excepted!

SALT CHLORINATORSALT CHLORINATOR

EN

ES

FR

IT

DE

PT

4) With the use of sealing tape (not supplied), screw

the probe connector 16 into the saddle clamp 8

and tighten by hand, as shown in the photo

opposite.

5) Loosen nut Awithout removing it.

6) Insert probe 19 into probe holder 16 as shown in the

image opposite.

7) Tighten nut Aby hand.

7.9. INSTALLATION OF THE ORP MEASURING HEAT

CONTACTOR PRO MODEL WITH THE

OPTIONAL MEASURING KIT

1) Mount the 2 saddle clamps 8on the pipe, as shown

in the image opposite.

2) Drill the top of the pipe through the hole of the

saddle clamps (see arrow opposite), taking care not

to damage the tapping.

3) Check that there are no air bubbles inside the bulb.

If this is not the case, shake the probe by holding the

bulb downwards until the air bubble has risen into the

body of the probe.

4) Following the image and the instructions shown

opposite:

a) With the use of sealing tape (not supplied), screw

the probe connector 16 into the accessories

holder 15 and tighten by hand.

b) Loosen nut Awithout removing it.

c) Insert pH probe 20 into probe holder 16.

d) Tighten nut Aby hand.

7.8. ORP MEASURING HEAT CONTACTOR INSTAL

LATION PRO MODEL WITHOUT THE OPTIONAL

MEASURING KIT

1) Mount the saddle clamp 8on the pipe, as shown in

the image opposite.

2) Drill the top of the pipe through the hole of the

saddle clamp (see arrow opposite), taking care not

to damage the tapping.

3) Remove the storage vial from ORP probe 19.

ATTENTION

• Do not push the probe as far as the stop-point

of the pipe. Place the probe halfway up accessories

holder 15.

• The probe must be installed:

- after the filter and before any treatment device,

- on the top of the pipe,

- vertically, and on the level (not tilted).

ATTENTION

Do not push the probe as far as the stop-point of the

pipe. Place the probe halfway up the pipe.

16 17

Alterations which serve the technological progress as well as errors excepted! ORIGINAL MANUAL NORSUPWWW.NORSUP.EU Alterations which serve the technological progress as well as errors excepted!

SALT CHLORINATORSALT CHLORINATOR

EN

ES

FR

IT

DE

PT

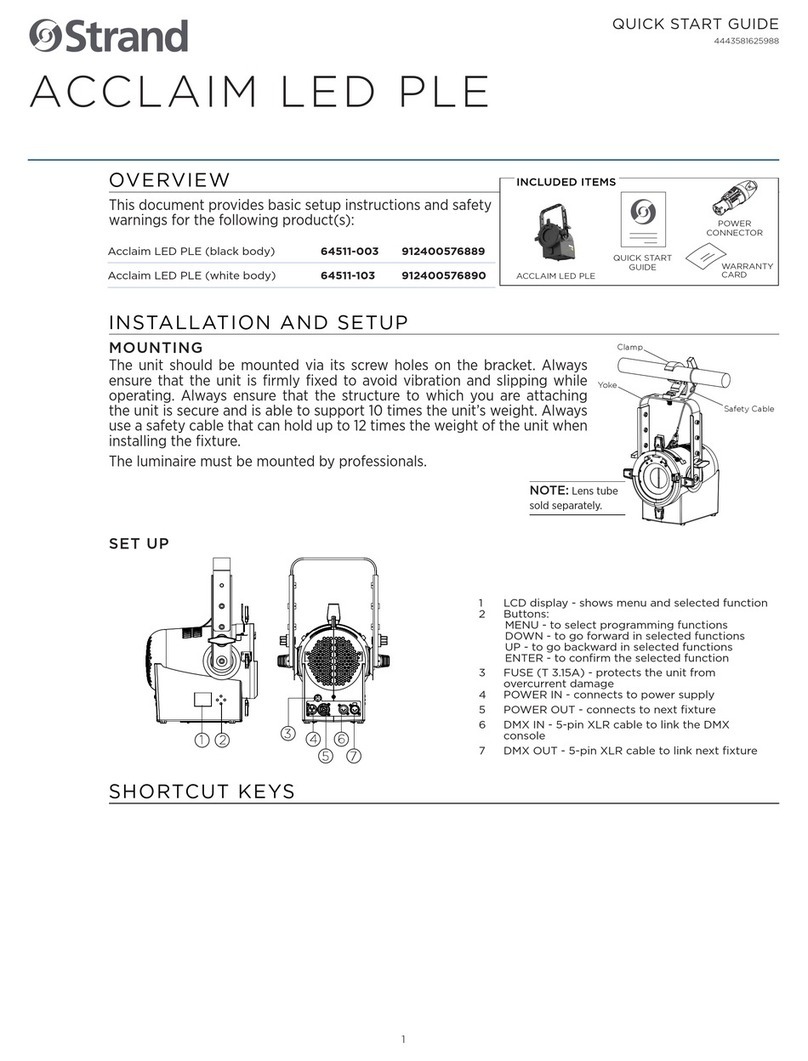

7.10. INSTALLING THE LINE CELL

1) If pipe Ahas an outer diameter of 50 mm, cut the

pipe to a length of 248 mm.

If pipe A has an outer diameter of 63 mm, cut the

pipe to a length of 232 mm.

2) Fully disassemble the cell following the above

exploded diagram.

3) Rub down all bonding surfaces with sand

paper: pipes A, reducers C, collars D.

4) Slide each nut Bonto the end of each

pipe A.

5) Glue together each set of [pipe A-

reducer C- collar D].

6) Wait for the glue to dry completely.

7) Place each seal Einside each collar D.

8) Attach cell Fwith the 2 nuts B.

7.11. INSTALLATION OF THE TCELL

1) Fully disassemble the cell following the exploded

diagram above.

2) Rub down all bonding surfaces with sand paper:

pipes A, reducers B, sleeve C.

3) Glue together the unit comprising

[pipes A- reducers B- sleeve C].

4) Wait for the glue to dry completely.

5) Place seal Dall the way into electrode E.

6) Slide electrode Einto sleeve C, with the plates of

the electrode aligned as in the above diagram.

7) Screw nut Fonto sleeve C.

3) Prepare the 2 connectors 17-A and 17-B following

the direction of assembly of the parts shown below.

4) Mount the 2 connectors 17-A/17-B and the 2 valves

22 in the 2 saddle clamps 8in accordance with the

image shown opposite, using Teflon tape.

5) Fix measuring chamber 6to the wall using the

screws and plastic anchors provided.

6) Connect measuring chamber 6to the 2 connectors

17-A and 17-B, with the semi-flexible tubing 21 cut

to the right size.

7) Remove the storage vial from ORP probe 19.

8) Loosen nut A(see the image shown opposite)

without removing it.

9) Insert the probe 19 into the measuring chamber 6

as in the photo below.

10) Tighten nut Aby hand.

ATTENTION

Respect the direction of the arrow engraved on

each fitting.

ATTENTION

Do not invert the connectors 17-A and 17-B

during assembly: observe the installation

diagram shown on the previous page,

following the direction of the water flow.

ATTENTION

Screw on and tighten nuts Bby hand.

ATTENTION

Tighten nut Fby hand.

18 19

Alterations which serve the technological progress as well as errors excepted! ORIGINAL MANUAL NORSUPWWW.NORSUP.EU Alterations which serve the technological progress as well as errors excepted!

SALT CHLORINATORSALT CHLORINATOR

EN

ES

FR

IT

DE

PT

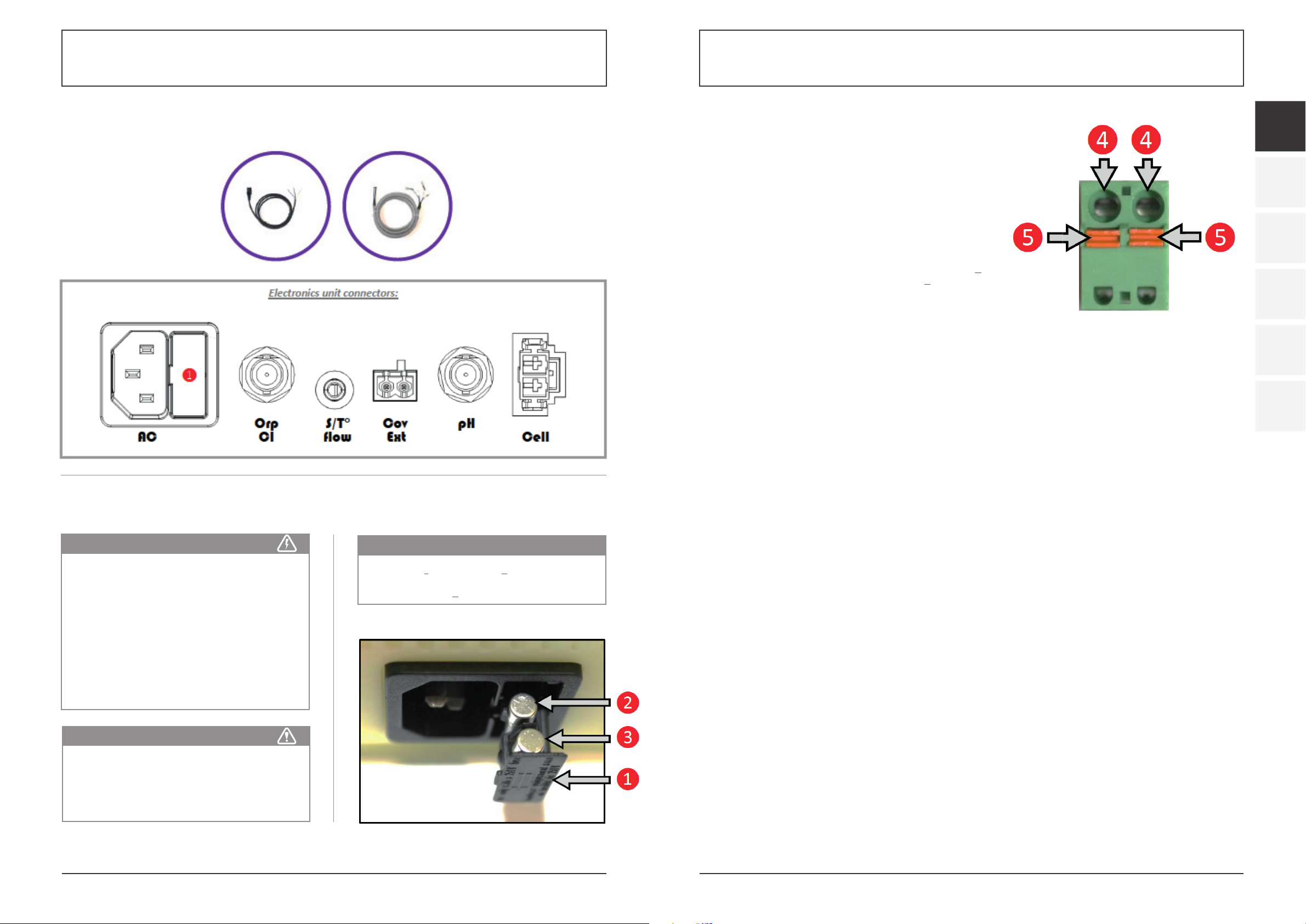

ORP CL:

ORP probe connection.

ST° FLOW:

- Connection for salt/temperature/low-water sensor.

- It is also possible to connect a flow sensor.

→ To connect a flow sensor, use the adaptor supplied with it.

COV EXT:

Connection for a flap position switch.

→ Use the connector below provided:

Directly insert the cables of the position switch into terminals 4.

(To remove the cables, apply pressure to the strips 5using a flathead screwdriver.)

PH:

pH probe connection.

CELL: Connection for the cell using the corresponding power cable.

7.12. ELECTRICAL CONNECTIONS

ATTENTION

Permanently connect the electronics unit to the

electrical unit, by linking it to the filtration pump

contactor. (Reminder: A sufficient flow of water

must be maintained in the electrolytic cell when

connected to a power supply).

NOTE

The drawer 1contains a fuse 2(6.3 A time-delay

fuse - 5 x 20 mm, as well as a compartment to

store a spare fuse 3(not provided):

ATTENTION

• Before connecting the power cable to the

electronics unit, make sure that the electrical

installation complies with the standards and

regulations in force in the country of installation.

• The connection must be carried out by a qualified

electrician.

• Do not use an extension cord.

• Do not connect the electronics unit to an

electrical outlet.

• Disconnect the power supply at the circuit

breaker beforehand and make sure that the

power supply is switched off using suitable tools.

AC: Power cable connection for electronics unit (220 V

- 50/60 Hz).

20 21

Alterations which serve the technological progress as well as errors excepted! ORIGINAL MANUAL NORSUPWWW.NORSUP.EU Alterations which serve the technological progress as well as errors excepted!

SALT CHLORINATORSALT CHLORINATOR

EN

ES

FR

IT

DE

PT

9.3. KEYPAD

10. MENU STRUCTURE 1

8. COMMISSIONING

→ All of the below steps are to be carried out when

installing the equipment for the first time, and at the

start of each new season.

1) Make sure that the electronics unit is turned off (for

how to do this see the following page).

2) Spread 5 kg of salt* per m3 around the inner edges

of the pool (depending on its volume). * High purity

salt tablets conforming to the EN 16401 standard,

quality A (free of flow agents and anti-caking

agents).

3) Run the filtration pump until the salt poured into the

pool is completely dissolved.

4) Check the water quality parameters and if necessary

make the manual adjustments, following the below

table:

5) Program and switch on the filtration pump using

the table below:

Achieving and maintaining free chlorine levels

between 0.5 and 1 ppm:

6) Measure free chlorine levels with a testing kit.

7) • If free chlorine levels are below 0.5 ppm:

a) Set filtration to „AUTO“.

b) Turn on the electronics unit (for how to do this see

the following page).

c) Set the production value to 100% (for how to do

this see page 23 or 25, depending on the model).

d) Wait until free chlorine levels reach between 0.5

and 1 ppm.

• If free chlorine levels are between 0.5 and 1 ppm:

Turn on the electronics unit ( see the following

page for instructions).

• If free chlorine levels are above 1 ppm:

a) Keep the electronics unit turned off (or turn it

off).|b) Wait until free chlorine levels reach between

0.5 and 1 ppm.

c) Turn on the electronics unit (see the following

page for instructions).

8) Adjust the production setpoint (see page 23 or 25

depending on the model to carry out this operation)

so that the free chlorine level stays between 0.5 and 1

ppm. Several adjustment tests may need to be

carried out, in order to determine an appropriate

value for the production setpoint.

→ Heavy use of the pool, incorrect inclination of the

nozzles of the basin (these must be tilted slightly

downwards), or a tree-filled environment are

decisive factors that strongly influence the free

chlorine level. In this case, increase the production

setpoint, if necessary, to maintain the free chlorine

level between 0.5 and 1 ppm.

9. ELECTRONICS UNIT INTERFACE

9.1. SCREEN

- If display flashing: information awaiting confirmation.

- If display fixed: information confirmed.

9.2. INDICATOR LIGHTS

- Solid green LED: production indicator.

- Flashing red LED: alarm indicator.

ATTENTION

All of the following steps must also be regularly

carried out once the pool is in use.

General visual state clear, free from algae

or sediment

Temperature above 15 °C

Potential of hydrogen (pH) between 7.0 and 7.4

Stabilizer levels

(cyanuric acid) below 30 ppm (mg/l)

Alkali content (AC) between 80 ppm and

120 ppm

Water hardness (WH) less than 60°f

Salt levels 5 kg/m3(depending on

its volume)

WATER

TEMPERATURE °C

HOURS OF FILTRATION

PER DAY H

16 8

18 9

20 10

22 11

24 12

26 14

28 17

30 20

>30 24

→ These figures should only be used as a guide.

They should be adjusted if necessary in order to

optimise filtration.

Switching the electronics unit on/off

→ Press and hold this key to turn on and off.

→ Production, with or without ORP

control, starts automatically 2 minutes

after switching on.

→ When turning off, the screen then the

green LED will also turn off.

→ If an alarm has been triggered, first

press on C when turning off.

BOOST BOOST BOOST BOOST BOOST BOOST BOOST BOOST Launches Boost mode.

MENU MENU MENU MENU MENU MENU MENU MENU Access to the menu structure 2

(see chapter 11).

C C

- Back to previous menu.

- Cancels command.

- Browsing the menu structures.

- Command confirmation.

- Browsing the menu structures.

- Value selection.

Com-

mand

key

(reference

pictogram

in this

manual)

Equivalent key

(Each column below corresponds to a keyboard visual) Function

Display / Navigation

* Initial display by default/upon connection of the unit to a power supply, after a few seconds.

22 23

Alterations which serve the technological progress as well as errors excepted! ORIGINAL MANUAL NORSUPWWW.NORSUP.EU Alterations which serve the technological progress as well as errors excepted!

SALT CHLORINATORSALT CHLORINATOR

EN

ES

FR

IT

DE

PT

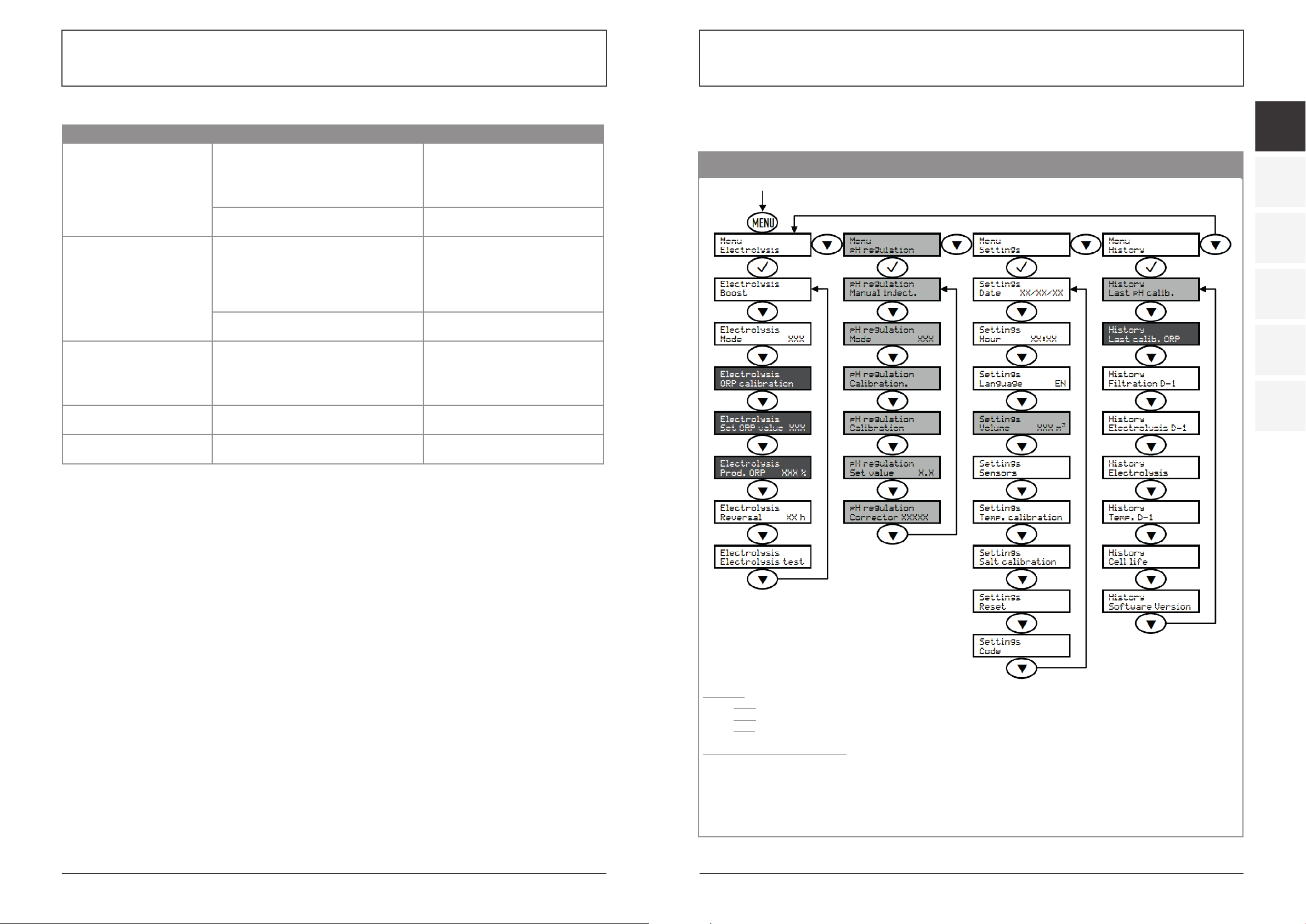

Display / Navigation

Caption :

Model UNO : white.

Model DUO : white + light grey.

Model PRO : white + light grey + dark grey.

To access a menu / set a value :

1) Press .

2) Press or to reach the desired value or data.

3) Press to confirm.

4) Press C x times to return to the initial display.

MENU FUNCTION NAVIGATION

PROD. XXX %

Displays the set production value.

→ The dot immediately after ‘PROD‘ displays

when the equipment produces chlorine

(additionally indicated by the green light on

the interface).

_

Allows you to set the production value. Press or to attain the desired

value (no confirmation needed).

PROD. XXX %

pH X.X

Displays the set production value and pH

measurement.

→ The dot immediately after ‘PROD‘ displays

when the equipment produces chlorine

(additionally indicated by the green light on

the interface).

_

Allows you to set the production value. Press or to attain the desired

value (no confirmation needed).

ORP. XXX mV

pH X.X

Displays the ORP and pH measurements.

→ The dot immediately after ‘ORP‘ displays

when the equipment produces chlorine

(additionally indicated by the green light on

the interface).

_

Salt levels

X.X g/L

Displays the salt level measurement. _

Temperature

XX °C

Displays the water temperature. _

11. MENU STRUCTURE 2

24 25

Alterations which serve the technological progress as well as errors excepted! ORIGINAL MANUAL NORSUPWWW.NORSUP.EU Alterations which serve the technological progress as well as errors excepted!

SALT CHLORINATORSALT CHLORINATOR

EN

ES

FR

IT

DE

PT

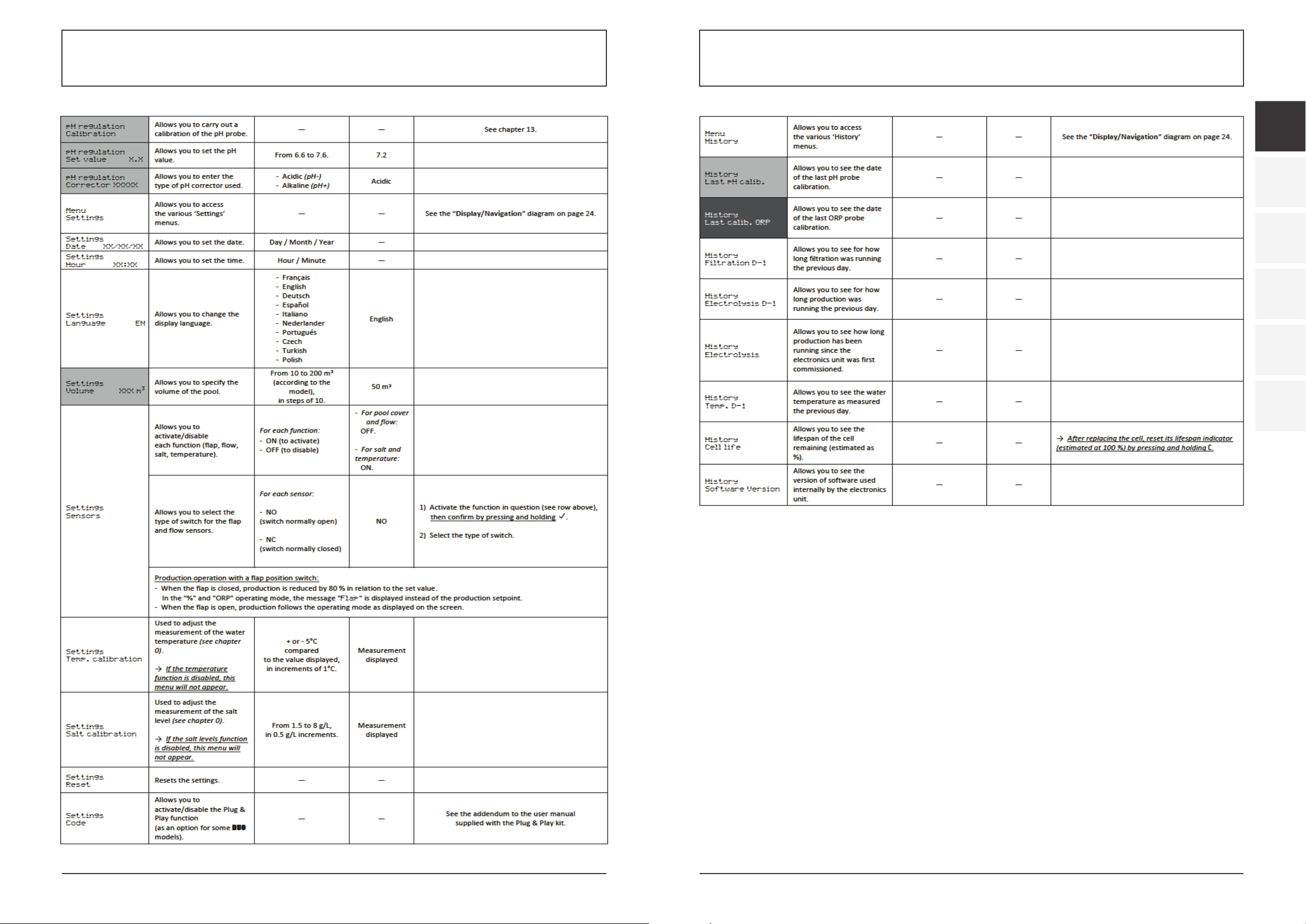

26 27

Alterations which serve the technological progress as well as errors excepted! ORIGINAL MANUAL NORSUPWWW.NORSUP.EU Alterations which serve the technological progress as well as errors excepted!

SALT CHLORINATORSALT CHLORINATOR

EN

ES

FR

IT

DE

PT

28 29

Alterations which serve the technological progress as well as errors excepted! ORIGINAL MANUAL NORSUPWWW.NORSUP.EU Alterations which serve the technological progress as well as errors excepted!

SALT CHLORINATORSALT CHLORINATOR

EN

ES

FR

IT

DE

PT

13.2. CALIBRATING THE ORP PROBE

1) Open the „ORP calibration solution“ vial.

2) Turn off the filter (and therefore the electronics

unit).

3) If the probe is already installed:

a) Remove the probe from the probe connector,

without disconnecting it.

b) Remove the probe holder nut and replace it with

the stopper provided.

If the probe is not already installed:

Connect the probe to the electronics unit.

4) Turn on the electronics unit.

5) Go to the „ORP Electrolysis Calibration“ menu (see

chapter 11).

6) Navigate through the menus following the below

instructions:

14. SHUTDOWN FOR EXTENDED PERIODS

FOR WINTER

1) Turn off the complete filtration equipment.

2) Drain the pH injection heat contactor.

PH PROBE AND ORP PROBE:

3) Equip yourself with:

- the storage vial initially mounted on the probe

(see visuals in chapters 7.7 and 7.8),- the cap

supplied (see visual in chapter 4),

- a container filled with 10% hydrochloric acid (for

the removal of scale),

- a container filled with 2.6% bleach (for the

removal of organic matter),

- a suitable KCl solution (for the preservation of the

probe).

4) Disconnect the probe.

5) Remove the probe from the probe holder.

6) Soak the probe for 1 hour in the container of

hydrochloric acid.

7) Rinse the probe with tap water, without wiping it

afterwards.

8) Soak the probe for 1 hour in the container of bleach.

9) Rinse the probe with tap water, without wiping it

afterwards.

10) Place the probe on a clean surface.

11) Fill the storage vial with KCl solution.

12) Insert the probe head into the storage vial.

13) Tidy away and store the probe in a warm, dry place,

positioning it vertically, with the bulb facing

downwards.

14) Remove the nut from the probe holder and re-

place it with the cap provided, using sealing tape.

PROPERTIES AND CONDITIONS OF USE OF THE CELL:

• When the water temperature descends below 15°C,

its chemical properties cause premature wear to the

cell. In this situation, turn off the electronics unit.

• The water in the cell must not freeze under any

circumstances.

• Provided the cell is not connected to a power supply,

leaving it installed on the pipework poses no risk of

deterioration. In this instance, carry out a suitable

chemical treatment, preferably without the use of

stabilisers.

15. MAINTENANCE

15.1. REGULAR CHECKS

• Carry out steps 4to 8in chapter 8 regularly.

• Ensure that the bulb of the pH probe is always

immersed, either in water or in a suitable KCl

solution.

12. DETAILED INFORMATION ON THE ORP

OPERATING MODEL

The amount of chlorine required can vary depending

on several conditions:

- Covered pool (by sheeting, cover or panels)

→ Small amount of chlorine required (due to absence

of UV), but risk of excessive chlorine levels due to

continual production.

- Sudden rise in the number of people using the pool

→ Very large amounts of chlorine needed, but on a

temporary basis.

- Indoor pool or sheltered pool

→ Reduced need for chlorine (because of low exposure

to external pollution), but which tends to increase de

pending on the frequency of use of the swimming pool.

Given this range of possible circumstances, it is

necessary to manage chlorine production according to

requirements.The ORP operating mode allows you to

react to each of these situations.

The ORP measurement (in mV), reflecting the

oxidation (or reduction) potential of the water, is a

major indicator of the pool’s water quality. According to

the WHO, an ORP measurement of 650 mV guarantees

disinfected water that is itself capable of disinfecting.

Despite the use of this value as a reference, this can

only be on a theoretical level, because ORP

measurements can easily vary depending on the

following parameters:

- The pH

- The type of chlorine (stabilised or non-stabilised)

- The presence of dissolved elements that can affect

the water (metals, phosphates, surfactants)

- The cleanliness of the filter

- The presence of stray currents

- presence of flocculants (as a deposit on the probes).

→ The ORP measurement:

- is not a measurement of free chlorine levels.

- varies according to free chlorine levels and all

elements in the water.

NECESSARY PREREQUISITES FOR THE ORP

OPERATING MODE:

- The pH regulation

- Stabilizer level between 20 and 30 ppm

- Grounding of pipework into which the probes are

installed (with the Pool Ground)

- No use of water from boreholes

- Installation of the ORP probe at least 30 cm before

the cell

- Balanced water profile (free chlorine levels at 1 pmm,

and pH at 7.2)

- ORP setpoint adjusted according to the ORP

measurement displayed (a value between 500 and

700 mV can be considered as correct)

→ When using a chemical (flocculant, waterline

cleaning, sequestrant), check the ORP measurement

before and after use of this product. If the ORP

measurement drops sharply, stop the ORP check for

a few days, until the effects of the product on the

ORP measurement disappear.

→ Influence of chloramines on the ORP measurement:

as chloramine levels tend to increase, the ORP

measurement tends to decrease.

→ The use of sulphates is permitted, provided they

remain at levels below 360 ppm.

→ The use of copper sulphates is strictly forbidden.

13. PROBE CALIBRATION

→ The original pH probe is already calibrated. It is

therefore not necessary to carry out calibration of

the pH probe when putting the equipment into

service for the first time.

13.1. PH PROBE CALIBRATION

1) Open the 2 „pH calibration kit“ sachets (use only

single-use standard solutions).

2) Turn off the filter (and therefore the electronics unit).

3) If the probe is already installed:

a) Remove the probe from the probe connector,

without disconnecting it.

b) Remove the probe holder nut and replace it with

the stopper provided. If the probe is not already

installed: Connect the probe to the electronics unit.

4) Turn on the electronics unit.

5) Go to the „PH regulation calibration“ menu (see

chapter 11).

6) Navigate through the menus following the

below instructions:

ATTENTION

ORP control in no case eliminates the need to

regularly check free chlorine levels.

ATTENTION

• Never store the probe in distilled water.

• Never touch the bulb of the probe.

ATTENTION

However, it is imperative to carry out a calibration

of the pH and ORP probes at the beginning of

each season when returning to service, and after

each probe replacement. ATTENTION

• The set of operations described in chapter 15

presents some risks. These operations must be

carried out by persons with the required training

and authorisation.

• Comply with all the safety instructions presented

in chapter 2.

30 31

Alterations which serve the technological progress as well as errors excepted! ORIGINAL MANUAL NORSUPWWW.NORSUP.EU Alterations which serve the technological progress as well as errors excepted!

SALT CHLORINATORSALT CHLORINATOR

EN

ES

FR

IT

DE

PT

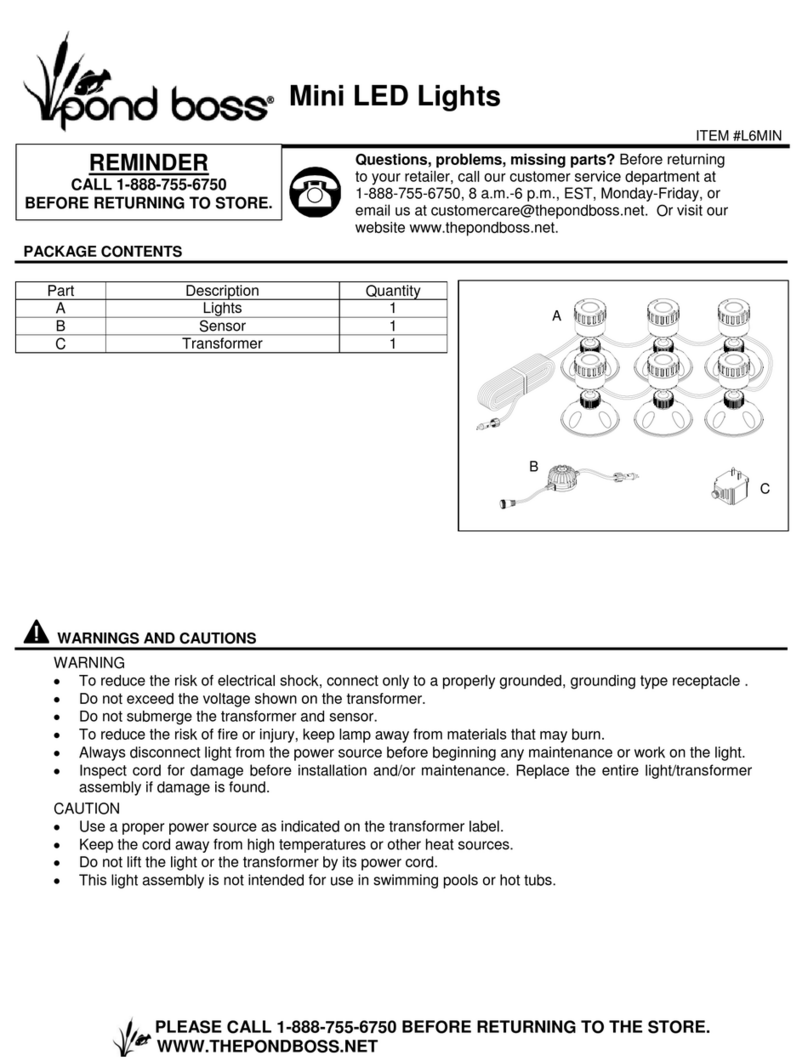

15.2. CELL

The auto-clean function helps prevent scale deposits

on the cell. However, if scale builds up despite this,

carry out manual cleaning:

1) Turn off the equipment, remove the cell (or electrode)

and check for signs of scale.

2) Use a suitable cleaning product to remove the scale.

3) Rinse and then reassemble the cell (or electrode).

4) Readjust if necessary the inversion frequency (see

the „Inversion Electrolysis“ menu in chapter 11).

15.3. PH PROBE AND ORP PROBE

→ Periodic maintenance to be carried out:

- twice/year,

- each time the equipment is put back into service,

- each time the probe is changed.

Carry out a calibration of the probe.

15.4. PH INJECTION HEAT CONTACTOR

→ Periodic maintenance to be carried out: - once/year.

→ To replace the parts below, you will need a

maintenance kit.

1) Change the hose inside the peristaltic pump (see

arrow below).

2) Change the non-return valve on the injection

connector.

16. FAULTS, DIAGNOSIS AND TROUBLESHOOTING

→ Any alarm triggered:

• will immediately be displayed on the screen.

• can be manually cleared by pressing button .

• can be disabled (except “A4 alarms - Cell Power”),

by disabling the function of the sensor related to

the fault detected (see the „Sensor Settings“ menu

in chapter 11).

→ The „pH calibration alarms“ and

„ AL - pH regulation alarms“ automatically and

immediately stop the pH regulation.

→ The alarms “A1” to “A4” automatically and

immediately stop chlorine production.

ATTENTION

• The service life of the electrolytic cell is very

closely related to observance of the instructions

and information contained in this manual.

• The replacement of a cell at the end of its life with

a compatible cell may lead to a decrease in

production and reduce the life of the equipment.

It is therefore strongly recommended to use only

an original manufacturer cell.

• Damage due to the use of a compatible cell voids

the contractual guarantee.

ATTENTION

Ensure the above parts are assembled the right

way round, paying particular attention to the

direction of the arrow marked on the fitting.

Failure to follow these instructions can lead to the

peristaltic pump being damaged.

ATTENTION

• The set of operations described in chapter 16

presents some risks. These operations must be

carried out by persons with the required training

and authorisation.

• Comply with all the safety instructions presented

in chapter 2.

Connections outside

the cleaning product

In-line cell T cell electrode

Cleaning product

Titanium plates

fully submerged

32 33

Alterations which serve the technological progress as well as errors excepted! ORIGINAL MANUAL NORSUPWWW.NORSUP.EU Alterations which serve the technological progress as well as errors excepted!

SALT CHLORINATOR

17. GUARANTEE

Before contacting your dealer, please have the

following to hand:

- your purchase invoice,

- the serial no. of the electronics unit,

- the installation date of the equipment,

- the parameters of your pool (salinity, pH, chlorine

levels, water temperature, stabilizer level, pool volume,

daily filtration time, etc.)

Every effort and all our technical experience has gone

into designing this equipment. It has been subjected

to quality controls. If, despite all the attention and

expertise involved in its manufacture, you need to

make use of our guarantee, it only applies to free

replacement of the equipment’s defective (excluding

shipping costs in both directions).

GUARANTEE PERIOD PROVEN BY DATE OF

INVOICE

Electronics unit: 2 years.

Cell: - 1 year minimum outside the European Union

(excluding warranty extension).

Cell: - 2 year minimum in the European Union

(excluding warranty extension).

Amber pH probe: 1 year.

Blue pH probe: 2 years.

ORP probe: 1 year.

Repairs and spare parts: 3 months.

The periods indicated above correspond to standard

guarantees. However, these can vary depending on the

country of installation and the distribution network.

SCOPE OF THE GUARANTEE

The guarantee covers all parts, with the exception of

wearing parts that must be replaced regularly. The

equipment is guaranteed against all manufacturing

defects within the strict limitations of normal use.

AFTERSALES SERVICES

All repairs will be performed in the workshop. Shipping

costs in both directions are at the user‘s own expense.

Any downtime and loss of use of a device in the event

of repairs shall not give rise to any claim for

compensation.

In all cases, the equipment is always sent at the user‘s

own risk. Before taking delivery, the user must ensure

that it is in perfect condition and, if necessary, write

down any reservations on the shipping note of the

carrier. Confirm with the carrier within 72 hours by

recorded letter with acknowledgement of receipt.

Replacement under guarantee shall in no case extend

the original guarantee period.

GUARANTEE APPLICATION LIMIT

In order to improve the quality of their products, the

manufacturer reserves the right to modify the

characteristics of the products at any time

without notice.

This documentation is provided for information

purposes only and is not contractually binding with

respect to third parties.

The manufacturer’s guarantee, which covers

manufacturing defects, should not be confused with

the operations described in this documentation.

Installation, maintenance and, more generally, any

servicing of the manufacturer‘s products should only

be performed by professionals. This work must also be

carried out in accordance with the current standards in

the country of installation at the time of installation.:

The use of any parts other than original parts voids the

guarantee ipso facto for the entire equipment.

The following are excluded from the guarantee:

- Equipment and labour provided by third parties when

installing the equipment.

- Damage caused by an installation not in compliance

with the instructions.

- Problems caused by modifications, accidents, misuse,

negligence of professionals or end users,

unauthorised repairs, fire, floods, lightning, freezing,

armed conflict or any other force-majeure events.

Any equipment damaged due to non-compliance with

the instructions regarding safety, installation, use and

maintenance contained in this documentation will not

be covered by the guarantee.

Every year, we make improvements to our products

and software. These new versions are compatible with

previous models. The new versions of hardware and

software cannot be added to earlier models under the

guarantee.

IMPLEMENTATION OF THE GUARANTEE

For more information regarding this guarantee,

contact your dealer or our After-Sales Service. All

requests must be accompanied by a copy of

the purchase invoice.

LEGISLATION AND DISPUTES

This guarantee is subject to French law and all

European directives or international treaties in force at

the time of the claim, applicable in France. In case of

disputes concerning its interpretation or execution, the

High Court of Montpellier (France) shall have exclusive

jurisdiction.

NOTES

34 35

Änderungen, die dem technischen Fortschritt dienen, sowie Irrtümer vorbehalten! ORIGINALBETRIEBSANLEITUNG NORSUPWWW.NORSUP.EU Änderungen, die dem technischen Fortschritt dienen, sowie Irrtümer vorbehalten!

EN

ES

FR

IT

DE

PT

SALZWASSER ELEKTROLYSE

Fehler und technische Änderungen können

nur mit unserer schriftlichen Genehmigung

geändert, reproduziert oder elektronisch

vervielfältigt werden.

© NORSUP

Auflage: 11.2020

1. VORWORT 36

2. SICHERHEITSHINWEISE 36

3. GERÄTEFUNKTIONEN 36

4. PACKLISTE MIT INLINEZELLE 37

5. PACKLISTE MIT T ZELLE 38

6. INSTALLATIONSSCHEMA 39

7. INSTALLATION 41

7.1. Wichtige Vorsichtsmaßnahmen 41

7.2. Wandmontage des Schaltkastens 41

7.3. Installation des Zubehörhalters 42

7.4. Installation der Salz / Temperatur / Durchfluss-Sonde 42

7.5. Installation des Bodenbeckens (optional) 42

7.6. Einbau der Einspritzschaltung pH (Modelle DUO und PRO) 43

7.7. Installation der pH-Sonde (Modelle DUO und PRO) 43

7.8. Installation der Redox-Messschaltung (Modell PRO), ohne optiona-

les Messkit 44

7.9. Installation der Redox-Messschaltung (Modell PRO), mit optiona-

lem Messkit 45

7.10. Installation der Zelle in der Reihe 47

7.11. Installation der T-Zelle 47

7.12. Electrical connections 48

8. INBETRIEBNAHME 50

9. SCHNITTSTELLE DES SCHALTKASTENS 50

9.1. Bildschirm 50

9.2. Kontrollleuchten 50

9.3. Tastatur 51

10. MENÜBAUM NR. 1 MENÜBAUM 51

11. MENÜBAUM NR. 2 53

12. SPEZIFIKATIONEN FÜR DIE BETRIEBSART REDOX 58

13. SONDENKALIBRIERUNG 58

13.1. Kalibrierung der pH-Sonde 58

13.2. Kalibrierung der Redox-Sonde 59

14. VERLÄNGERTE ABSCHALTUNG ÜBERWINTERUNG 59

15. INSTANDHALTUNG 59

15.1. Regelmäßige Kontrollen 59

15.2. Zelle 60

15.3. pH-Sonde und Redox-Sonde 60

15.4. pH-Wert-Injektionskreislauf 60

16. FEHLER, DIAGNOSE UND FEHLERBEHEBUNG 60

17. GARANTIE 62

EINHALT

UNO

|

DUO

|

PRO

36 37

Änderungen, die dem technischen Fortschritt dienen, sowie Irrtümer vorbehalten! ORIGINALBETRIEBSANLEITUNG NORSUPWWW.NORSUP.EU Änderungen, die dem technischen Fortschritt dienen, sowie Irrtümer vorbehalten!

SALZWASSER ELEKTROLYSESALZWASSER ELEKTROLYSE

EN

ES

FR

IT

DE

PT

Schaltkasten

1x

Befestigungskit

desSchaltkastens

(Wandhalterung +

Schrauben und Dübel)

1x

In-Line-Zelle

1x

Mutter

2x

Reduzierstück

2x

Bundbuchsen

2x

Dichtung

2x

Anschlusskabel

des Schaltkastens

1x

Anschlusskabel

der Zelle

1x

Zubehörhalter

(ausgestattet

mit 2 Reduzier-

stücken und

5 Kappen)

1x

Salz /

Temperatur /

Durch-

flussSonde

1x

Analyse-Kit

(Test streifen

+ Referenz-

karte)

1x

modell UNO

Bodenbecken (optional)

1x

modell DUO

Dieses Paket enthält auch das obige Paket.

pH-Sonde

1x

Ballastfilter

1x

Injektions-

verbindung

1x

Sonden-

träger

1x

Kappe

1x

Halbstarrer

Schlauch

1x

pH-Wert-

Eichungssatz

(pH-Wert-7-

Lösung +

pH-Wert-10-

Lösung)

1x

modell PRO

Dieses Paket enthält auch die beiden obigen Pakete.

Redox-Sonde

1x

Redox-Eichlösung

1x

Übernahmefitting

(im Kit)

1x

Sondenträger

1x

Messkammer

1x

Ventil

2x

Messkammer-

befestigungskit

(Schrauben und

Dübel)

1x

Fitting

2x

Übernahmefitting

(im Kit)

2x

Halbstarrer

Schlauch

1x

Abdichtband

1x

Messkoffer (optional):

4. PACKING LIST WITH INLINE CELL Unverbindliches Bildmaterial

1. VORWORT

LESEN, VERSTEHEN UND BEFOLGEN SIE ALLE ANWEIS-

UNGEN IN DIESEM HANDBUCH SORGFÄLTIG, BEVOR

SIE DAS GERÄT INSTALLIEREN UND BENUTZEN.

2. SICHERHEITSHINWEISE

STROMSCHLAGGEFAHR

Um das Risiko von Verletzungen oder Unfällen zu ver-

meiden, installieren Sie das Gerät außerhalb der Reich-

weite von Kindern und Personen, die nicht berechtigt

sind, das Gerät zu benutzen und zu bedienen.

Stellen Sie sicher, dass der Technikraum, in dem das

Gerät installiert werden soll, den Normen entspricht,

die im Installationsland zum Zeitpunkt der Inbetrieb-

nahme des Geräts gelten. Wenden Sie sich im Zweif-

elsfall an einen qualifizierten Elektriker. Die Installation

dieses Geräts muss von einer dazu qualifizierten

Person gemäß den zum Zeitpunkt der Installation im

Installationsland geltenden elektrischen Normen

durchgeführt werden. Die Installation muss auch in

jeder Hinsicht den technischen Spezifikationen ent-

sprechen, die in diesem Handbuch und in allen mit

dem Gerät gelieferten Dokumenten angegeben sind.

Die elektrischen Leitungen des Gerätes müssen

vor unbeabsichtigter Beschädigung geschützt

sein. Ein beschädigtes Kabel muss sofort durch ein

identisches Kabel ersetzt werden. Die Kabel

niemals durchtrennen oder verlängern.

Ausschließlich dazu qualifizierte Personen dürfen

im Fall von Störungen oder zur Wartung Eingriffe

an dem Gerät vornehmen. Vor jeglichem

technischen Eingriff am Gerät unbedingt die

Stromversorgung unterbrechen.

Das Gerät darf nicht verändert werden. Jede

Änderung an den Geräten kann zu Gefahren für

Mensch und Umwelt und zu Schäden an den

Geräten führen.

ATTENTION

Die in diesem Handbuch enthaltenen Sicherheits-

vorschriften erheben keinen Anspruch auf

Vollständigkeit. Sie nennen nur die häufigsten

Risiken, die bei der Installation und Verwendung

dieses Geräts auftreten. Gehen Sie bei jeder

Installation und jedem Gebrauch dieses Geräts

mit Vorsicht und gesundem Menschenverstand

vor.

Modell Chlor

produktion

durch

Elektrolyse

pH-Wert-

Regulierung

Produktions-

kontrolle

von Chlor mit

Redox-Sonde

UNO

DUO

PRO

• In diesem Handbuch bezeichnen die

nebenstehenden Piktogramme einen

VORSICHTS- oder sogar einen WARNHINWEIS

samt einer genau zu befolgenden Anweisung.

• Die Nichtbeachtung dieser Anweisungen kann

zu erheblichen Gefahren für das Gerät und/oder

zu schweren Verletzungen von Personen führen.

BEACHTEN UND BEFOLGEN SIE DIESE

ANWEISUNGEN.

38 39

Änderungen, die dem technischen Fortschritt dienen, sowie Irrtümer vorbehalten! ORIGINALBETRIEBSANLEITUNG NORSUPWWW.NORSUP.EU Änderungen, die dem technischen Fortschritt dienen, sowie Irrtümer vorbehalten!

SALZWASSER ELEKTROLYSESALZWASSER ELEKTROLYSE

EN

ES

FR

IT

DE

PT

Schaltkasten

1x

Befestigungskit

desSchaltkastens

(Wandhalterung

+ Schrauben und

Dübel)

1x

T-Zelle

1x

Anschlusskabel

des

Schaltkastens

1x

Anschlusskabel

der Zelle

1x

Zubehörhalter

(ausgestattet mit 2

Reduzier-

stücken und 5

Kappen)

1x

Salz / Temperatur /Durch-fluss-Sonde

1x

Analyse-Kit

(Test streifen

+ Referenz-karte)

1x

modell UNO

Bodenbecken (optional)

1x

6. INSTALLATIONSSCHEMA

ATTENTION

Der Kanister für pH-Regulierung muss ausreichend weit von elektrischen Geräten und anderen chemischen Produkten

entfernt sein.

modell UNO

modell DUO

modell DUO

Dieses Paket enthält auch das obige Paket.

pH-Sonde

1x

Ballastfilter

1x

Injektions-

verbindung

1x

Sonden-

träger

1x

Kappe

1x

Halbstarrer

Schlauch

1x

pH-Wert-

Eichungssatz

(pH-Wert-7-

Lösung +

pH-Wert-10-

Lösung)

1x

modell PRO

Dieses Paket enthält auch die beiden obigen Pakete.

Redox-Sonde

1x

Redox-Eichlösung

1x

Übernahmefitting

(im Kit)

1x

Sondenträger

1x

Messkammer

1x

Ventil

2x

Mess-

kammer-

befestigungskit

(Schrauben und

Dübel)

1x

Fitting

2x

Übernahmefitting

(im Kit)

2x

Halbstarrer

Schlauch

1x

Abdichtband

1x

Messkoffer (optional):

5. PACKLISTE MIT T ZELLE Unverbindliches Bildmaterial

Other manuals for OceanClear LS

1

This manual suits for next models

4

Table of contents

Languages:

Other Norsup Lighting Equipment manuals

Popular Lighting Equipment manuals by other brands

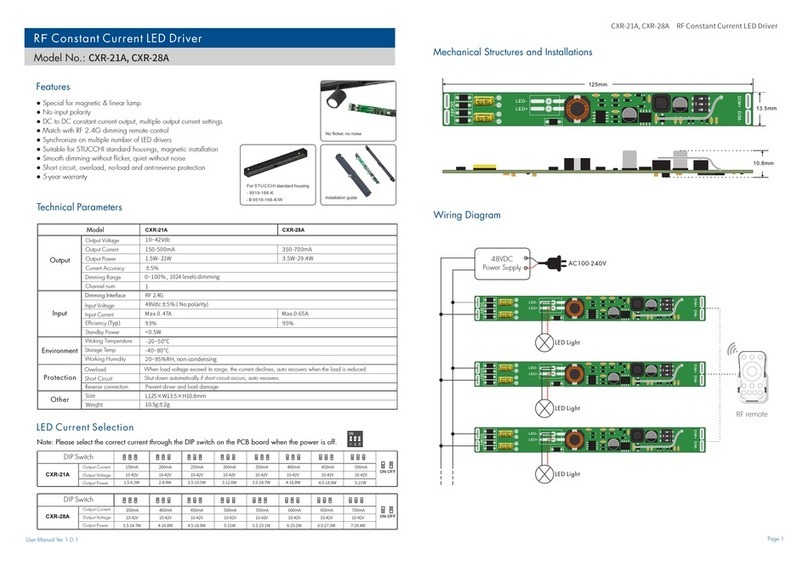

SKYDANCE

SKYDANCE CXR-21A installation instructions

Emos

Emos ZY2191 quick start guide

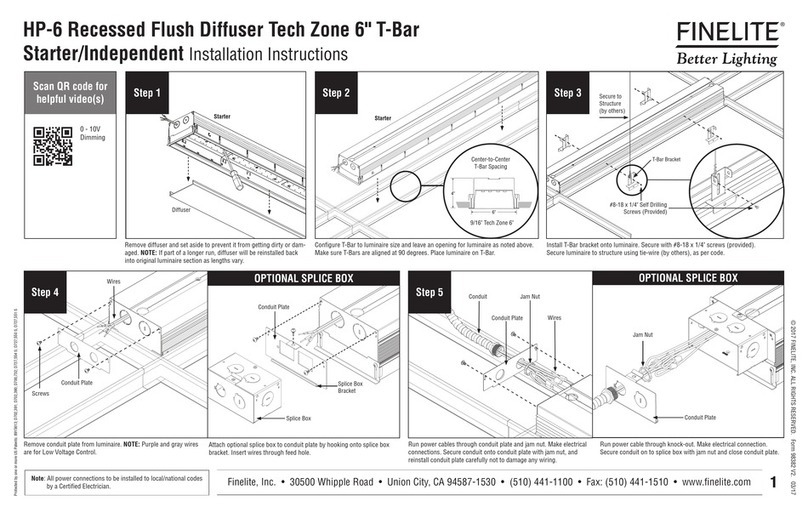

Finelite

Finelite HP-6 Recessed Flush Diffuser Tech Zone 6"... installation instructions

Barthelme

Barthelme 66000574 operating instructions

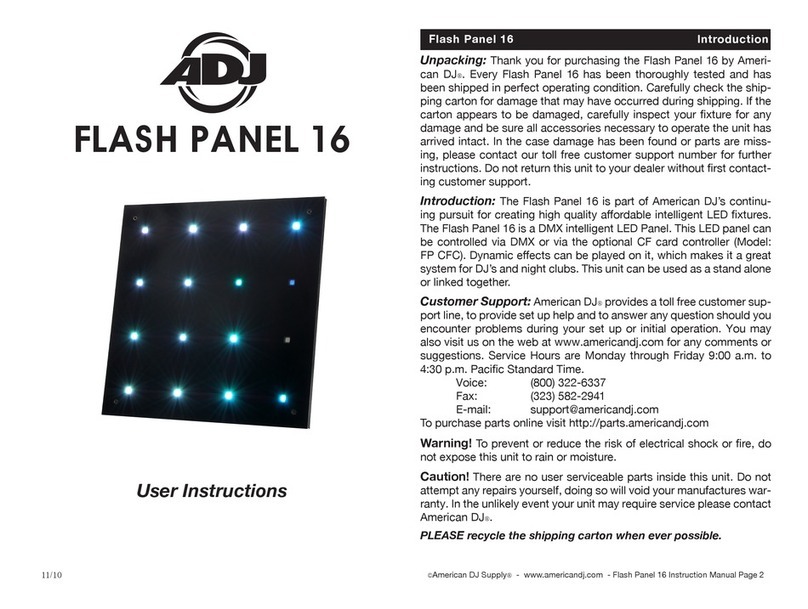

American DJ

American DJ FLASH PANEL 16 User instructions

MELINERA

MELINERA Z31656A Operation and safety notes