5

the equipment. Use proper code agency listed conduit and

a conduit connector for connecting the supply wires to the

unit. Use of rain tight conduit is recommended.

• 208/230 Volt units are shipped from the factory wired for

230 volt operation. For 208V operation, remove the lead

from the transformer terminal marked 240V and connect

it to the terminal marked 208V.

• Optional equipment requiring connection to the power or

control circuits must be wired in strict accordance of the

NEC (ANSI/NFPA 70), applicable local codes, and the

instructions provided with the equipment.

Grounding

WARNING:

The unit cabinet must have an uninterrupted or

unbroken electrical ground to minimize personal

injury if an electrical fault should occur. Do not

use gas piping as an electrical ground!

This unit must be electrically grounded in accordance with

local codes or, in the absence of local codes, with the National

Electrical Code (ANSI/NFPA 70) or the CSA C22.1 Electrical

Code. Use the grounding lug provided in the control box for

grounding the unit.

Comfort AlertTM Diagnostics Module

(Select Models Only)

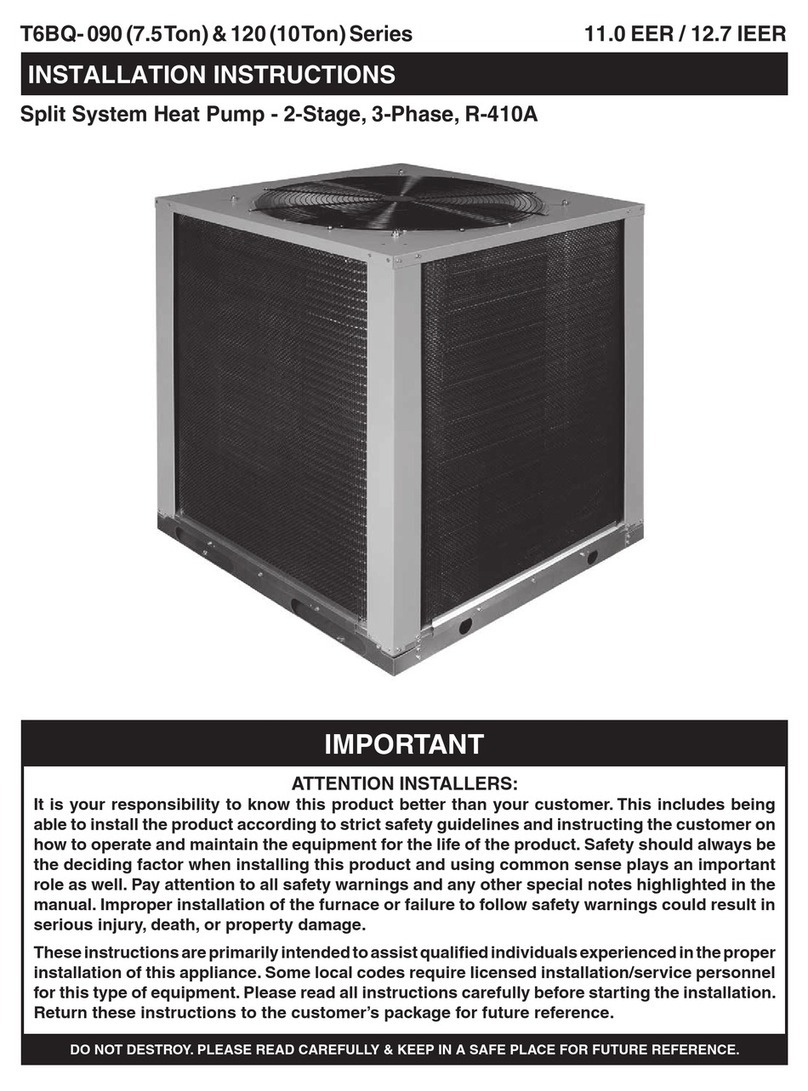

The Comfort AlertTM Diagnostics Module (Figure 2) is a

breakthrough innovation that troubleshoots heat pump and

air conditioning system failures and accurately detects the

cause of electrical and system related failures without any

sensors. The module installs easily in the electrical box of the

outdoor unit near the compressor contactor. By monitoring

and analyzing data from the Copeland scroll compressor and

the thermostat demand, the module can accurately detect

the cause of electrical and system related failures without

any sensors. A flashing LED indicator communicates the

ALERT code and a diagnostic key is also imprinted on the

side of the module to quickly direct the technician to the root

cause of a problem.

Figure 2. Comfort AlertTM Diagnostics Module

POWER LED

(Green)

TRIP LED

(Red)

ALERT LED

(Yellow)

Key

NOTE: This module does not provide safety protection! The

Comfort AlertTM Diagnostics Module is a monitoring device

and cannot control or shut down other devices.

24 VAC Power Wiring

The Comfort AlertTM module requires a constant nominal

24 VAC power supply. The module cannot be powered by

the Cterminal on a defrost board or other control board

without experiencing nuisance alerts. NOTE: The wiring to

the module’s R& Cterminals must be routed directly from

the indoor unit or thermostat.

If the constant 24 VAC (Rwire) is not present in the outdoor

unit, use one of the spare wires in the thermostat cable to

bring power to the module. Connect the other end of the

spare wire to Rat the indoor unit or thermostat.

Thermostat Demand Wiring

The Comfort AlertTM module requires a thermostat demand

signal to operate properly. The thermostat demand signal

input (labeled Yon the module), should always be connected

to the compressor contactor coil. NOTE: When the coil is

energized, the demand signal input is 24 VAC. When the

coil is not energized, the demand signal input should be less

than 0.5 VAC.

NOTES:

• Factory installed modules have different thermostat demand

signal wiring. Always follow manufacturer wiring instructions

when replacing the module.

• After the thermostat demand signal is connected, verify

that 24 VAC across Y & C when demand is present.

Interpreting the Diagnostic LED’s

When an abnormal system condition occurs, the Comfort

AlertTM module displays the appropriate ALERT and/or TRIP

LED will flash a number of times consecutively, pause and

then repeat the process. To identify a Flash Code number,

count the number of consecutive flashes.

Each time the module powers up, the last ALERT Flash Code

that occurred prior to shut down is displayed for one minute.

The module will continue to display the LED until the condition

returns to normal or if 24 VAC power is removed from the

module. See Table 1 (page 11) for flash code identification

or Table 2 (page 12) for module wiring troubleshooting.

LED Description

• POWER LED (Green): indicates voltage is present at the

power connection of the module.

• ALERT LED (Yellow): communicates an abnormal

system condition through a unique flash code.

NOTE: The ALERT LED will flash consecutively, pause

and then repeat the process. The number of consecutive

flashes, referred to as the Flash Code, correlates to a

particular abnormal condition. Detailed descriptions of

these ALERT Flash Codes are listed in Table 1 (page

11) and Table 2 (page 12).

• TRIP LED (Red): indicates a demand signal is received

from the thermostat, but current to the compressor is not

detected by the module. The TRIP LED typically indicates

if the compressor protector is open or the compressor has

no power.

The scroll compressor’s R (run), C(common), and S(start)

wires are routed through the holes in the Comfort AlertTM

module marked R, C, & S.NOTE: The common wire does

not need to be routed through the module for it to operate.