vi Contents

297-1001-350 Standard 02.02 August 1997

Draft: June 2, 1993

3.1.1 Maintenance records 3–1

3.1.2 Maintenance action record 3–17

3.1.3 Tools 3–17

3.2 Power plant critical limits 3–18

3.3 Power plant maintenance schedule 3–19

3.4 Power plant checks 3–20

3.5 Power plant safety checks 3–21

3.6 Power plant fuse checks 3–22

3.7 Charging equipment checks 3–22

3.8 Battery equipment checks 3–24

3.8.1 Maintenance intervals 3–24

3.8.2 Trouble conditions 3–26

3.8.3 Post connections 3–26

3.8.4 Positive plate growth 3–26

3.8.5 Post corrosion 3–27

3.8.6 Electrolyte level and temperature 3–32

3.8.7 Water analysis report 3–32

3.8.8 Avoiding battery trouble 3–33

3.9 Standby power system checks 3–34

3.10 Standby engine-alternator checks 3–35

3.11 Standby power system exercise 3–36

3.11.1 Precautions 3–36

3.11.2 Preparations 3–37

3.11.3 Procedure 3–38

3.12 Miscellaneous power plant checks 3–41

3.13 Submitting the maintenance report 3–42

4 Grounding system maintenance 4–1

4.1 Grounding system diagrams 4–1

4.2 Tools required 4–1

4.3 Building principal ground (BPG) checks 4–2

4.4 Ground resistance test 4–3

4.5 Floor ground bar (FGB) checks 4–3

4.6 Power plant grounding checks 4–4

4.7 AC grounding checks 4–4

4.7.1 AC-free DMS switch 4–4

4.7.2 Other DMS switch versions 4–5

4.8 DMS SPG checks 4–5

4.9 Framework bonding equalizer (FBE) checks 4–6

4.10 Framework ground bus checks 4–7

4.11 Logic return equalizer (LRE) checks 4–8

4.12 Logic return bar (LRB) checks 4–9

4.13 Bonding within DMS cabinets/frames 4–9

4.14 Cable entrance ground bar (CEGB) checks 4–9

4.15 Main distribution frame/protector frame checks 4–10

4.16 Cleaning corroded grounding connections 4–11

4.17 Grounding audit 4–12

List of figures

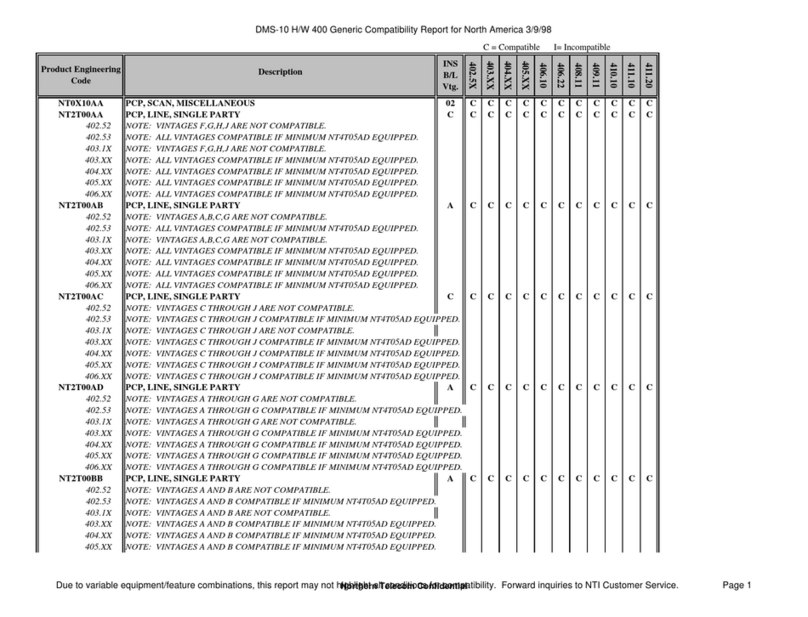

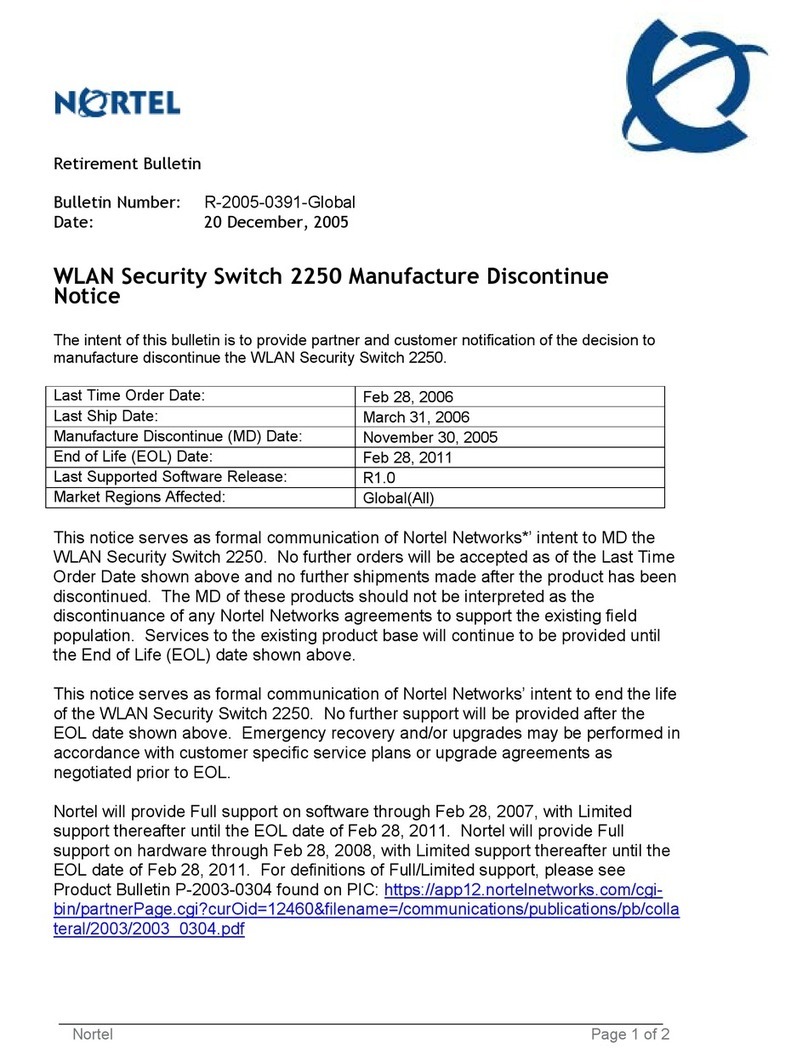

Figure 3–1 Sample pilot cell voltage and specific gravity test record 3–3