North Atlantic 75DS2 User manual

75DS2 Operations Manual

North Atlantic Industries, Inc.

11/11/2011

Rev: 2011-11-11-1000

www.naii.com

Page 1 of 43

75DS2

3U cPCI SYNCHRO/RESOLVER or

LVDT/RVDT CONVERTER

OPERATIONS MANUAL

75DS2 Operations Manual

North Atlantic Industries, Inc.

11/11/2011

Rev: 2011-11-11-1000

www.naii.com

Page 2 of 43

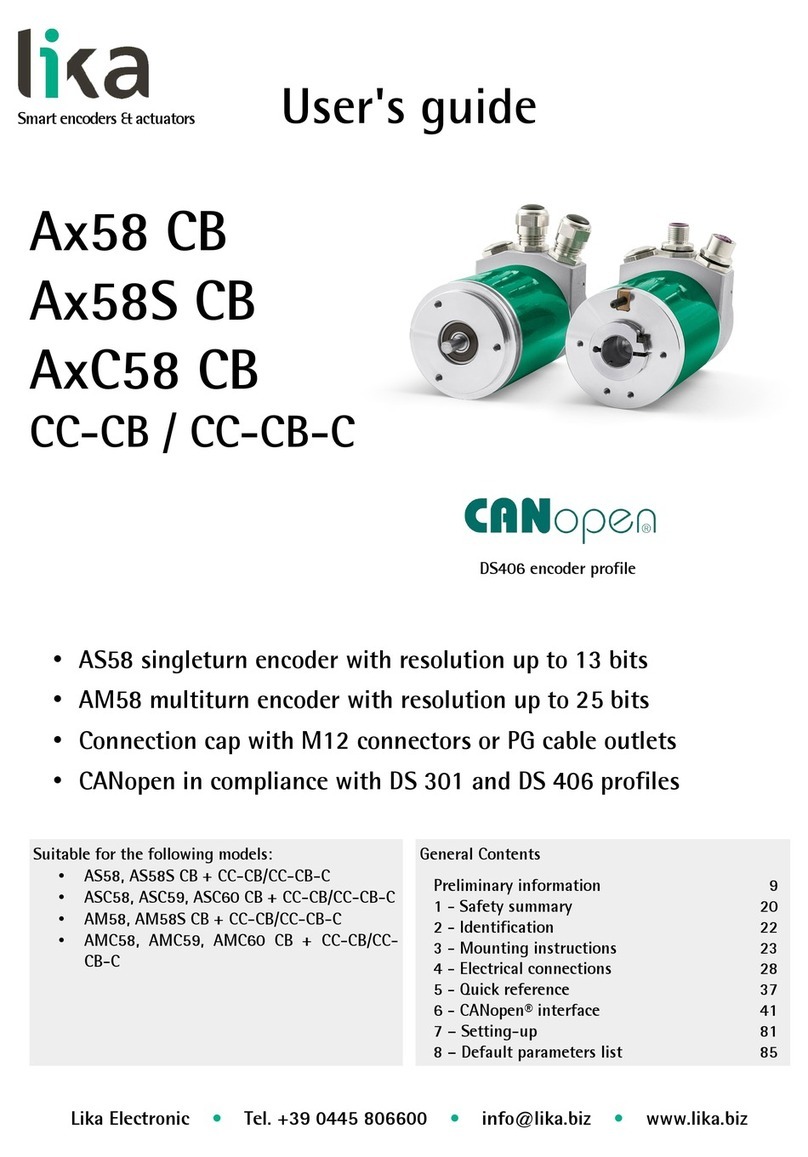

MODEL 75DS2

3U cPCI SYNCHRO/RESOLVER or LVDT/RVDT

CONVERTER

Convection Cooled

Features

1, 2, 3, or 4 Synchro/Resolver (D/S) or

LVDT/RVDT (DLV) simulation channels

1 arc-minute (0.0167°) accuracy

16 bit resolution

1.5, 2.2 or 3 VA drive capability per

synchro channel

Automatic background BIT testing

continually checks and reports the health

of each channel

Optional onboard 3 VA programmable

reference supply

Connections via front panel, rear

connector or both

Convection and conduction-cooled

Wrap-around converters for reading actual

commanded outputs

No adjustments or trimming required

Wide operating temperature range

Software support kit and drivers are

available

Conduction Cooled

Description

The 75DS2 is a 3U cPCI board which incorporates up to 4 Digital-to-Synchro/Resolver converters with

1.5, 2.2 or 3 VA drive capability; or 2 or 4 isolated DLV converters. The board features continuous

background BIT testing, reference and signal loss detection. Each channel is independent, isolated

and enables the user to ground one of the outputs without affecting performance. This model drives

passive or active loads. In addition, the card provides an optional onboard reference supply.

Automatic background BIT testing, an important feature, is always enabled and continually checks the

health of each channel. There is no need to guess or make assumptions about system performance. A

fault is immediately reported and the specific channel is identified. This diagnostic capability is of

tremendous benefit because it immediately identifies and reports a failure, without the need to shut

down the equipment for troubleshooting. Testing is totally transparent to the user, requires no external

programming, and has no effect on the standard operation of the card.

75DS2 Operations Manual

North Atlantic Industries, Inc.

11/11/2011

Rev: 2011-11-11-1000

www.naii.com

Page 3 of 43

Table of Contents

MODEL 75DS2...........................................................................................................................................................2

3U CPCI SYNCHRO/RESOLVER OR LVDT/RVDT CONVERTER..........................................................................2

FEATURES ................................................................................................................................................................2

DESCRIPTION ...........................................................................................................................................................2

SPECIFICATIONS......................................................................................................................................................6

General –for the Mother Board...............................................................................................................................................6

D/S (Module 3*, 4*) –One Isolated Digital-to-SYN/RSL Ch, 3.0 VA Output............................................................................6

D/S (Module 1*,2*) –Two Isolated Digital-to-SYN/RSL Ch, 1.5/2.2 VA Outputs.....................................................................6

DLV (Module 5*) –Two/Four Isolated DLV Simulation Ch, LVDT/RVDT Outputs...................................................................7

Reference (Module W6, W7)–Optional, Isolated, On-Board Reference Supply .....................................................................8

Product Configuration and Memory Map.................................................................................................................................9

MEMORY MAP........................................................................................................................................................................9

D/S ONE/TWO CHANNEL (MODULES 1*, 2*, 3*, 4*)............................................................................................ 10

Principle of Operation............................................................................................................................................................10

Built-In Test (BIT) / Diagnostic Capability..............................................................................................................................10

Wrap S/D Angle (Read).........................................................................................................................................................11

Measured Reference Voltage................................................................................................................................................11

Measured Signal Voltage ......................................................................................................................................................11

Signal Loss Threshold...........................................................................................................................................................11

Reference Loss Threshold ....................................................................................................................................................11

D/S Channel Frequency........................................................................................................................................................11

D/S Status, Signal Loss.........................................................................................................................................................12

D/S Wrap Select, Internal/External (Pending) .......................................................................................................................12

D/S Status, External Amplifier (Pending)...............................................................................................................................12

D/S Write Angle –Single Speed............................................................................................................................................12

D/S Write Angle –Two Speed...............................................................................................................................................12

D/S Rotation..........................................................................................................................................................................13

D/S Stop Angle......................................................................................................................................................................13

D/S Set Rotation Rate...........................................................................................................................................................13

D/S Rotation Mode, Continuous or Start/Stop.......................................................................................................................13

D/S Rotation Status...............................................................................................................................................................13

Start Rotation ........................................................................................................................................................................13

Stop Rotation.........................................................................................................................................................................13

D/S Set Reference Voltage ...................................................................................................................................................14

D/S Set Signal Voltage..........................................................................................................................................................14

D/S BIT Test Enable..............................................................................................................................................................14

D/S Status, BIT Test..............................................................................................................................................................15

Test (D2) Verify .....................................................................................................................................................................15

D/S Ratio 1/2.........................................................................................................................................................................15

D/S Output Mode...................................................................................................................................................................15

D/S Synchro / Resolver Select ..............................................................................................................................................16

D/S Torque Receiver Select..................................................................................................................................................16

D/S Trigger Source Select.....................................................................................................................................................16

D/S Trigger Slope Select.......................................................................................................................................................16

D/S Module Power Enable ....................................................................................................................................................16

D/S Output Enable.................................................................................................................................................................16

D/S Active Channel Select ....................................................................................................................................................17

D/S Status, Reference Loss..................................................................................................................................................17

D/S Status, Phase Lock Loss................................................................................................................................................17

D/S Set Phase Offset ............................................................................................................................................................17

Reference Loss Interrupt Enable...........................................................................................................................................17

Signal Loss Interrupt Enable .................................................................................................................................................18

BIT Test Fail Interrupt Enable................................................................................................................................................18

Phase Lock Loss Interrupt Enable.........................................................................................................................................18

OSC (Optional Onboard Reference Supply) Set Frequency .................................................................................................18

OSC (Optional Onboard Reference Supply) Set Voltage......................................................................................................19

Interrupt Vector......................................................................................................................................................................19

D/S (1*, 2*, 3*, 4*) (PCI) MODULE MEMORY MAP............................................................................................... 20

DLV TWO/FOUR CHANNEL (MODULE 5*)........................................................................................................... 21

Principle of Operation............................................................................................................................................................21

75DS2 Operations Manual

North Atlantic Industries, Inc.

11/11/2011

Rev: 2011-11-11-1000

www.naii.com

Page 4 of 43

Built-in Test/Diagnostic Capability.........................................................................................................................................21

Wrap LVDT Position (Read)..................................................................................................................................................21

Wrap (LVDT) Velocity............................................................................................................................................................22

DLV Channel Signal Voltage.................................................................................................................................................22

DLV Channel Excitation Voltage............................................................................................................................................22

Signal Loss Threshold...........................................................................................................................................................22

Excitation Loss Threshold .....................................................................................................................................................22

DLV Write Position ................................................................................................................................................................22

DLV Response / Filter Time ..................................................................................................................................................22

Status, Signal Loss................................................................................................................................................................23

DLV Channel Frequency.......................................................................................................................................................23

DLV Set Channel Excitation Voltage.....................................................................................................................................23

DLV Set Channel Signal Voltage...........................................................................................................................................23

DLV BIT Test Enable.............................................................................................................................................................24

Test (D2) Verify .....................................................................................................................................................................24

DLV Output Mode..................................................................................................................................................................24

DLV 2-Wire or 3/4-Wire Select..............................................................................................................................................24

DLV Module Power Enable ...................................................................................................................................................25

DLV Current ..........................................................................................................................................................................25

DLV Active Channel Select ...................................................................................................................................................25

DLV Status, Excitation Loss..................................................................................................................................................25

DLV Status, Phase Lock Loss...............................................................................................................................................25

DLV Set Phase Offset ...........................................................................................................................................................25

DLV Current Threshold..........................................................................................................................................................25

OSC (Onboard) Excitation Set Frequency.............................................................................................................................26

OSC (Onboard) Excitation Set Voltage .................................................................................................................................26

DLV Status, BIT Test.............................................................................................................................................................27

Excitation Loss Interrupt Enable............................................................................................................................................27

Signal Loss Interrupt Enable .................................................................................................................................................27

BIT Test Fail Interrupt Enable................................................................................................................................................27

Phase Lock Loss Interrupt Enable.........................................................................................................................................27

Interrupt Vector......................................................................................................................................................................28

2/4 CH DLV (5*) (PCI) MODULE MEMORY MAP.................................................................................................. 29

OPTIONAL ONBOARD REFERENCE CONTROL ................................................................................................ 30

OSC (Optional Onboard Reference Supply) Set Frequency .................................................................................................30

OSC (Optional Onboard Reference Supply) Set Voltage......................................................................................................30

PCI Memory Map...................................................................................................................................................................30

GENERAL USE REGISTER MEMORY MAP......................................................................................................... 31

MEMORY MAP......................................................................................................................................................................31

Part Number..........................................................................................................................................................................31

Serial Number........................................................................................................................................................................31

Date Code.............................................................................................................................................................................31

Revisions...............................................................................................................................................................................31

Board Ready .........................................................................................................................................................................31

Watchdog Timer....................................................................................................................................................................31

Soft Reset..............................................................................................................................................................................31

Design Version......................................................................................................................................................................31

Platform.................................................................................................................................................................................32

Model.....................................................................................................................................................................................32

Generation.............................................................................................................................................................................32

Special Spec .........................................................................................................................................................................32

Interrupt Flow for PCI/cPCI....................................................................................................................................................33

75DS2 CONNECTOR/PIN-OUT INFORMATION................................................................................................... 34

Front Panel Connectors J3, J4:.............................................................................................................................................34

Rear Panel Connectors J1, J2:..............................................................................................................................................34

Optional Onboard Reference Output.....................................................................................................................................34

NAI Synchro / Resolver Naming Convention.........................................................................................................................35

SLOT 1 D/S OR DLV.............................................................................................................................................................35

SLOT 2 D/S OR DLV.............................................................................................................................................................36

Dimensions............................................................................................................................................................................37

PART NUMBER DESIGNATION............................................................................................................................ 38

Two Channel D/S Module Code Table..................................................................................................................................40

75DS2 Operations Manual

North Atlantic Industries, Inc.

11/11/2011

Rev: 2011-11-11-1000

www.naii.com

Page 5 of 43

Single Channel D/S Module Code Table...............................................................................................................................41

2/4 Channel DLV Module Code Table...................................................................................................................................42

REVISION PAGE .................................................................................................................................................... 43

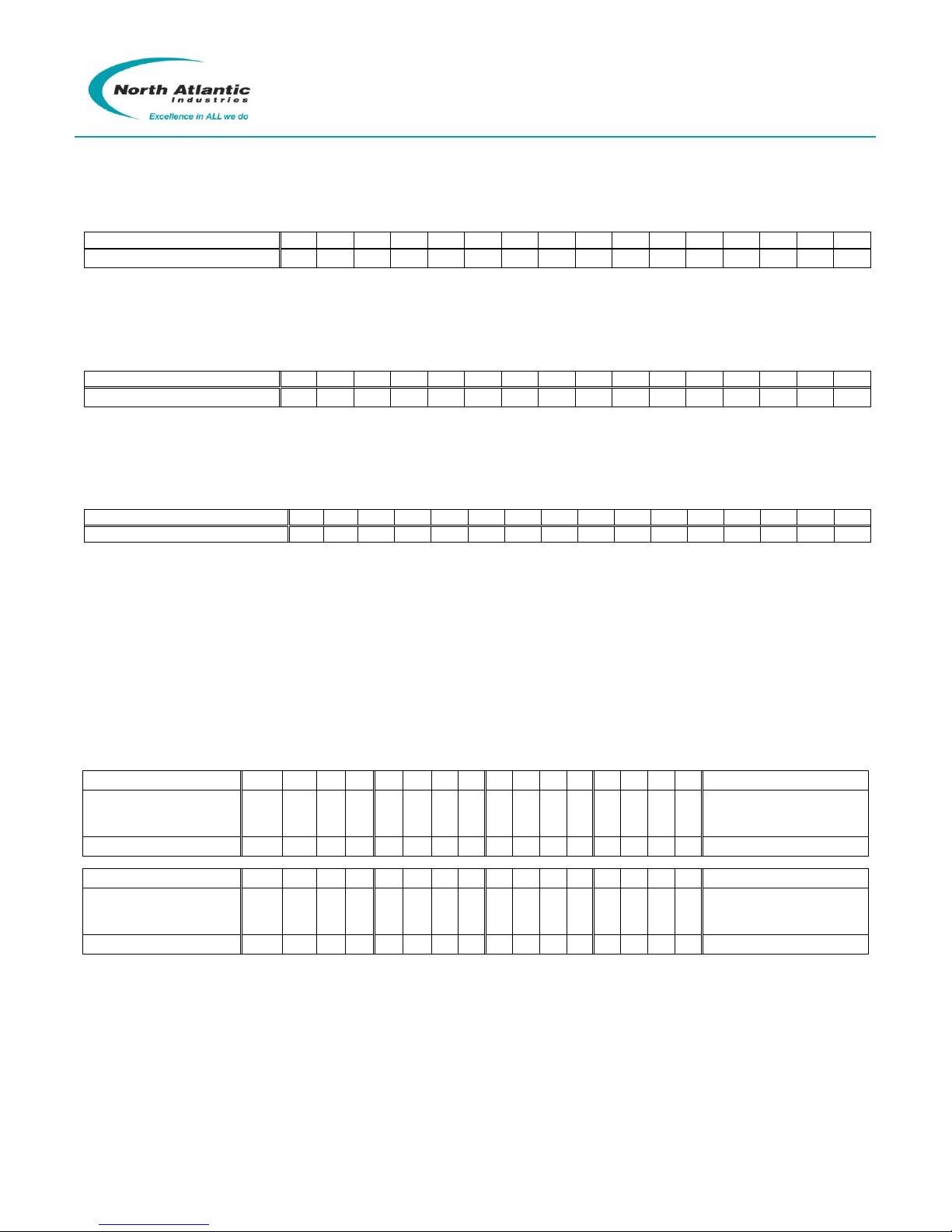

Specifications

75DS2 Operations Manual

North Atlantic Industries, Inc.

11/11/2011

Rev: 2011-11-11-1000

www.naii.com

Page 6 of 43

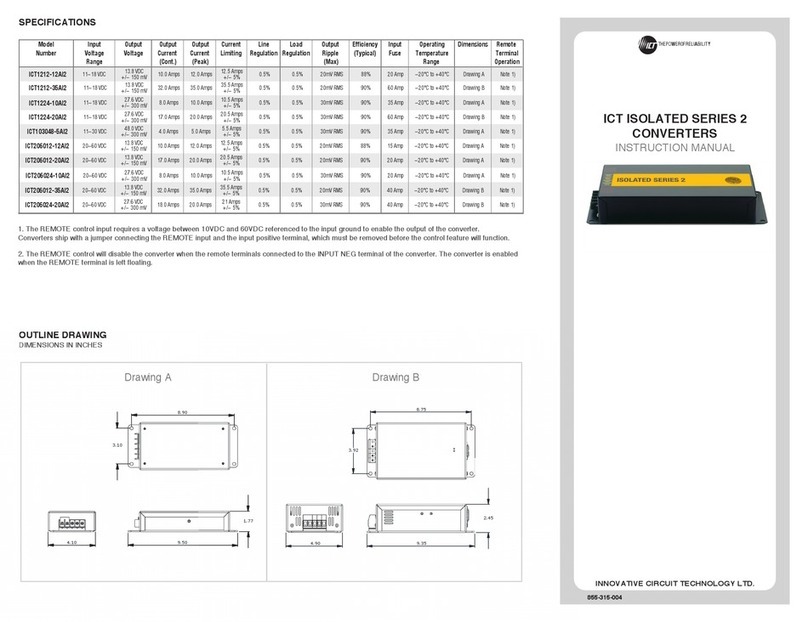

SPECIFICATIONS

General –for the Mother Board

Signal Logic Level:

Automatically supports either 5V or 3.3V CPCI bus

Power (Motherboard):

+5 VDC @ 750mA and ±12V @ 15mA, then add pwer for each individual

module

Temperature, Operating:

“C” =0°C to +70°C; “E”=-40°C to +85°C (See part number)

Storage Temperature:

-55°C to +105°C

Size:

Height -3.94” / 100 mm (3U)

Width -0.8” / 20.3 mm (4HP)

Depth –6.3” / 160 mm

Weight:

4 oz. (115 g) unpopulated,

Add weight for each module (typically 1 oz. each)

Add 2oz. (57g) for reference supply

Add 2 oz. (57g) for wedgelocks

D/S (Module 3*, 4*) –One Isolated Digital-to-SYN/RSL Ch, 3.0 VA Output

*See P/N

(Applies to each channel unless noted otherwise)

Resolution:

16 bits (.0055°)

Accuracy:

0.067º (4 arc minutes) for passive loads; 30 arc minutes for TR’s

Output Format:

Synchro or Resolver, (see part number), galvanic isolation

Output Voltage:

(See code table and part number)

Output Load:

3.0 VA max. /Channel. Short circuit protected

Output Control:

Channel output can be turned ON/OFF

Regulation (VL-L):

5% max. No load to Full load

Rotation:

Continuous rotation or programmable Start and Stop angles. 0 to 13.6 RPS with a

resolution of 0.15/sec. Step size is 16 bits (0.0055)° up to 1.5 RPS, then linearly

increases to 12 bits (0.088°) at 13.6 RPS

Reference Input Voltage:

2 to 115Vrms, Galvanic isolated. Uses @ 1 ma max/Channel

Reference Frequency:

47 Hz to 10 KHz (See part number)

Phase Shift:

0.5° max. (Between output and reference)

Programmable Phase Shift:

Programmable, ± 90with 0.1resolution

Settling Time:

Less than 100 microseconds

Module Power:

+5VDC @ 50 mA

±12VDC @ 115 mA (no-load); (Add 1.1 watts of ±12V for every VA of output).

Therefore, a 3.0 VA Load adds to ±12VDC 138 mA average, or 157 mA peak

External ±12VDC input power can be utilized

Ground:

Isolated signal and reference. Channels individually isolated from each other and

from system ground

Weight:

1.5 oz. (42g)

D/S (Module 1*,2*) –Two Isolated Digital-to-SYN/RSL Ch, 1.5/2.2 VA Outputs

*See P/N

(Applies to each channel unless noted otherwise)

Resolution:

16 bits (.0055°)

Accuracy:

±1 arc-minute (.017°) from No Load to Full Load

Output Format:

Synchro or Resolver (see part number), galvanic isolation

Output Voltage:

(See code table and part number)

Output Load:

1.5 VA @ 11.8 VLL or 28 VLL, and 2.2 VA @ 90 VLL max. per Channel

(Power reduces linearly as output voltage is reduced.) Shortcut circuit protected

Output Control:

Module outputs can be turned ON/OFF

Regulation (VL-L):

5% max. No load to Full load

Specifications

75DS2 Operations Manual

North Atlantic Industries, Inc.

11/11/2011

Rev: 2011-11-11-1000

www.naii.com

Page 7 of 43

Ratio:

Dual speed, Programmable, Set any ratio between 2 and 255

Rotation:

Continuous rotation or programmable Start and Stop angles. 0 to 13.6 RPS with

a resolution of 0.015/sec. Step size is 16 bits (0.0055)° up to 1.5 RPS, then

linearly increases to 12 bits (0.088°) at 13.6 RPS

Reference Input Voltage:

2 to 115Vrms, Galvanic isolation. Uses 1 ma max/Channel

Reference Frequency:

47 Hz to 10 KHz (See part number)

Phase Shift:

0.5° max. (between output and reference)

Programmable Phase Shift:

Programmable, ± 90with 0.1resolution

Settling Time:

Less than 100 microseconds

Module Power:

+5VDC @ 570 mA ±12VDC @ 160 mA (no-load) per channel

(Add 2.9 watts of ±12VDC for every VA of output per channel)

Therefore, a 1.5 VA Load adds to ±12V 181 mA average, or 288 mA peak per channel

External ±12V input power can be utilized

Ground:

Isolated signal and reference. Channels individually isolated from each other and

from system ground

Weight:

1.5 oz. (42 g)

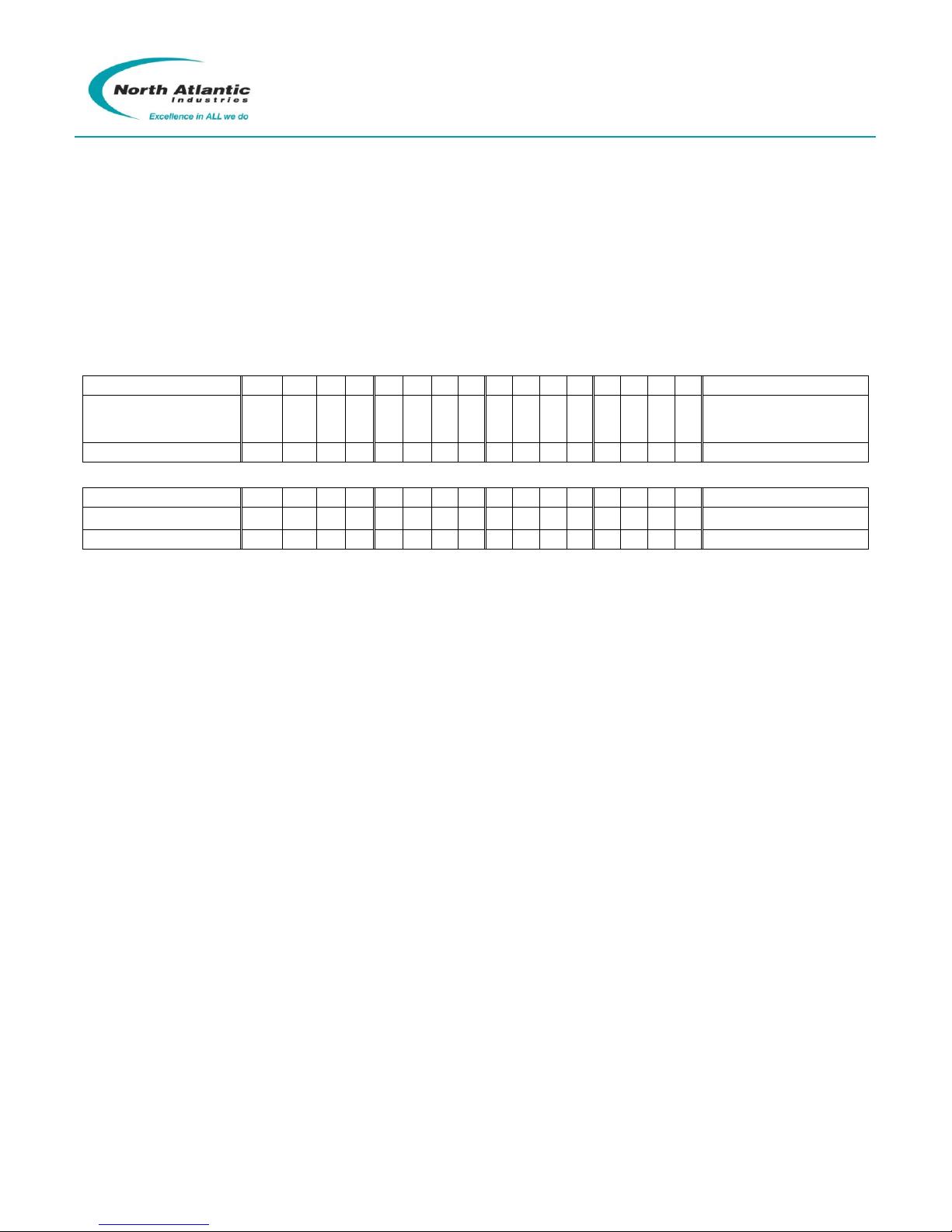

DLV (Module 5*) –Two/Four Isolated DLV Simulation Ch, LVDT/RVDT Outputs

*See P/N

(Applies to each channel unless noted otherwise)

Number of Channels:

2 (3/4-wire) / 4 (2-wire)

Resolution:

16 bits (.001526% FS)

Linearity:

0.1% FS

Output Gain:

0.1%

Output Format:

Configurable for either 3/4-wire or 2-wire.Galvanically isolated. Output voltage

is programmable fixed or ratio-metric

Output Voltage:

Programmable (See code table and part number)

Output Load:

1.5 VA max @ 11.8 VRMS or 28 VRMS (de-rates linearly as voltage is

decreased) (See code table)

Regulation (VL-L):

5% max. No load to Full load

Excitation Input Voltage:

(See part number), Galvanic isolated. Uses 1 ma max/Channel

Excitation Frequency:

47 Hz to 10 kHz (See part number)

Phase Shift (A/B):

0.5° max. (Between output and reference) (Programmable phase shift)

Settling Time:

Less than 100 microseconds

Module Power:

+5VDC @ 570 mA

±12VDC @ 160 mA (no-load) per channel. (Add 2.9 watts of ±12VDC for every

VA of output per channel). Therefore, a 1.5 VA Load adds to ±12V 181 mA

average, or 288 mA peak per channel

External ±12V input power can be utilized

Ground:

Isolated signal and excitation; Channels individually isolated from each other

and from system ground

Weight:

1.5 oz. (42g)

Specifications

75DS2 Operations Manual

North Atlantic Industries, Inc.

11/11/2011

Rev: 2011-11-11-1000

www.naii.com

Page 8 of 43

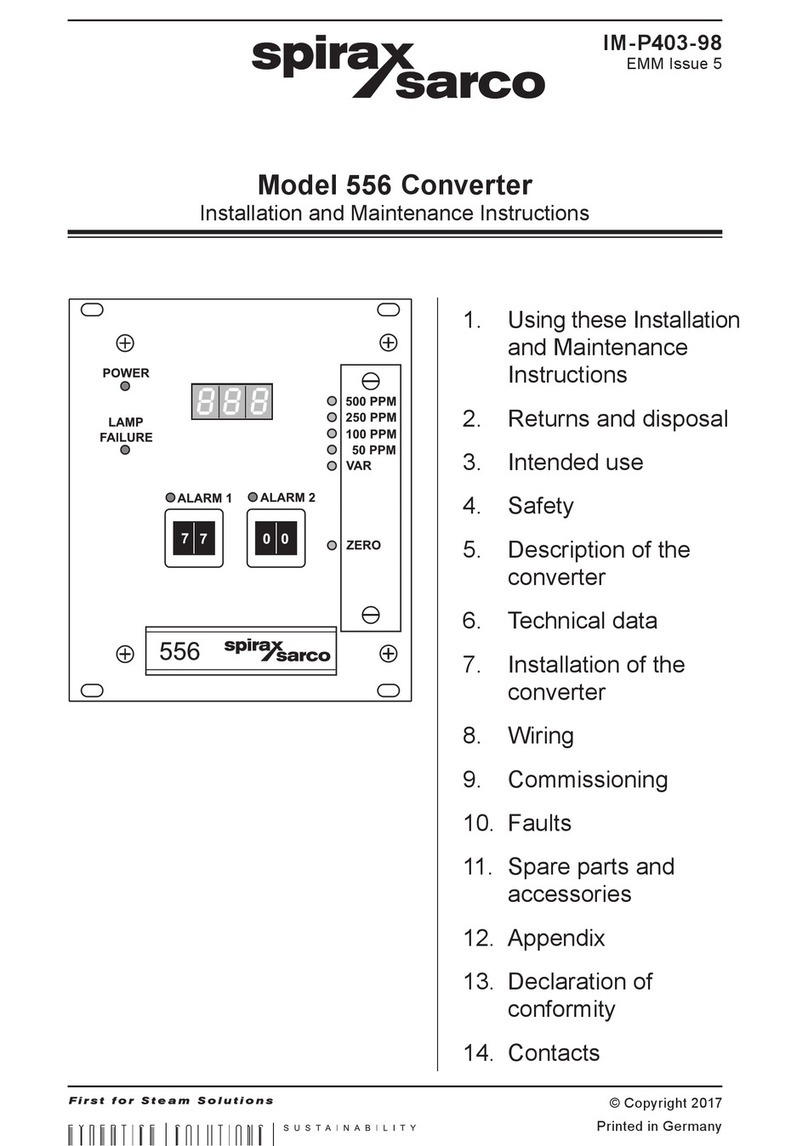

Voltage (V) Output (Programmed)

Power Output (VA)

2.0

4.0

6.0

30

25

20

15

10

Max Current ~ 420 mA

Power Derating Curves:

Voltage Range (Vrms) Max Current (mA) Power Derating

2 - 11.9 420 5 VA @ 11.8 Vrms

(Power derates linearly to 0.84 VA @ 2.0 Vrms)

12 -27.9 420 to 192 5 VA @ 26.0 Vrms (Power constant to 12.0 Vrms)

115 43 5 VA @ 115 Vrms (fixed)

5

2 - 10 V Frequency Range: 47 –15000 Hz

(5 VA max @ 15 KHz then reduces linearly to 1.5 VA @ 20 KHz 10.1 –28 V Frequency Range: 47 –10000 Hz

5VA Power Constant

Max Current ~ 420mA to 192 mA

(w/ voltage inversely proportional)

0.5

1.4

Reference (Module W6, W7)–Optional, Isolated, On-Board Reference Supply

Voltage Output:

Note: Identify voltage output option in P/N option selection

(Improved version to 5 VA introduced DOM 6/11)

Vrms to 28 Vrms, Programmable with a resolution of 0.1 V

2.0 to 10.0 Vrms / 47 Hz to 20 KHz frequency range

10.1 to 28.0 Vrms / 47 Hz to 10 KHz frequency range

or

115 Vrms fixed

115.0 Vrms / 47 Hz to 2.0 KHz frequency range

Accuracy (No Load):

2% of setting ≤ 10 KHz

5% of setting > 10 KHz

Regulation:

10% (No Load to Full Load)

Output Drive:

5 VA maximum ≤ 15 KHz

5 VA –1.5 VA (decreased linearly from 15 KHz to 20 KHz)

(See detailed description of Output Drive)

Output Protection:

Over-current (10x automatic retry; @ 1.3 sec int.; afterwards, shutdown w/ manual

reset)

Frequency:

47 Hz to 20 KHz Programmable with 0.1 Hz steps

Frequency Accuracy:

0.1% of programmed frequency or 1 Hz (whichever is greater)

THD:

2% (maximum)

Reference Output Drive:

(See detailed characterization)

Power:

+5 VDC @ 10 mA

±12 VDC @ 120 mA (Quiescent, no load, max)

Add ±12 VDC @ 40 mA for every 1 VA Load

Ground:

Output isolated from system ground

Weight:

1 oz. (28g)

Specifications

75DS2 Operations Manual

North Atlantic Industries, Inc.

11/11/2011

Rev: 2011-11-11-1000

www.naii.com

Page 9 of 43

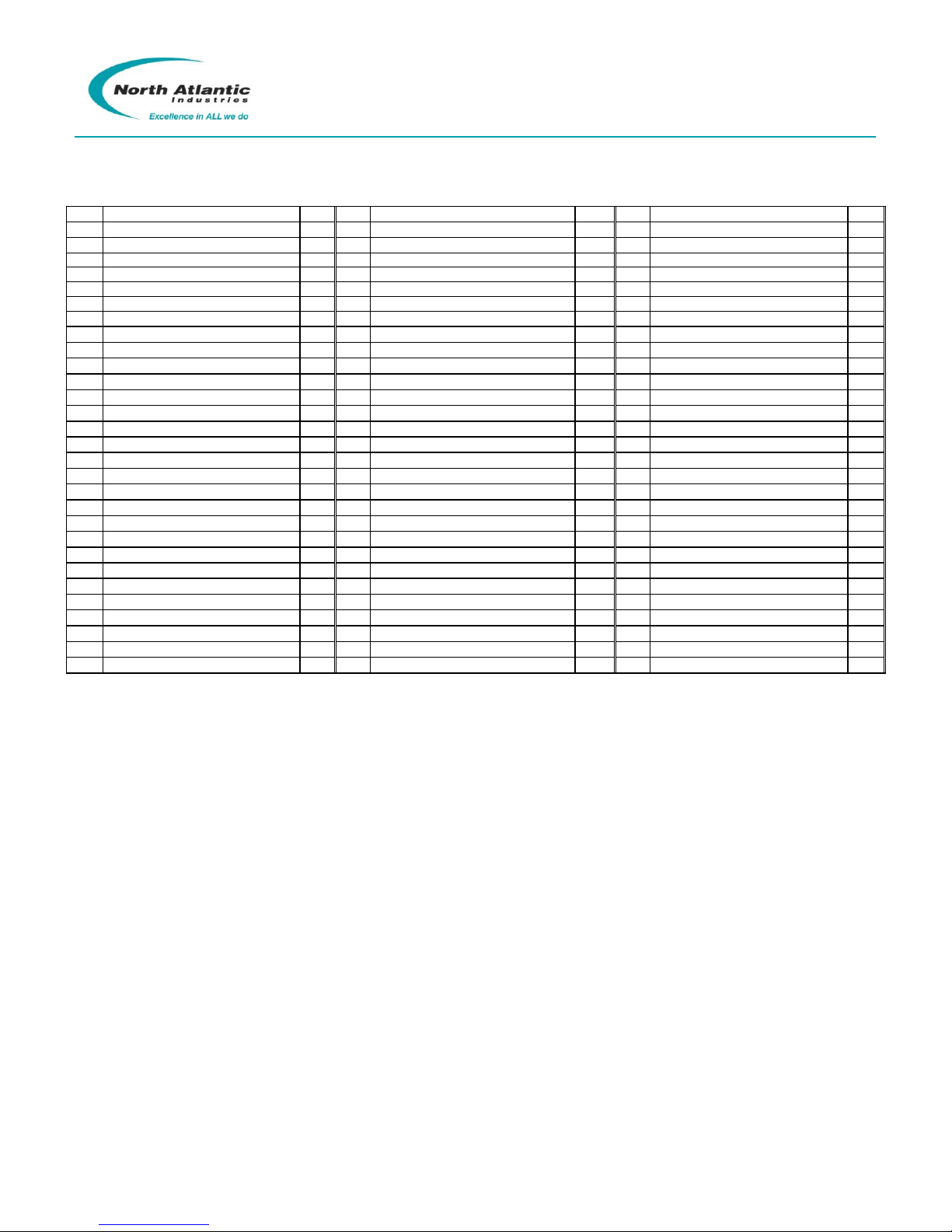

Product Configuration and Memory Map

This design provides multiple functions on a single cPCI (3U) card. When ordering, the customer selects an

assortment of up to 2 modules to populate this 2-slot “motherboard.” The memory map follows the order of

modules specified in the part number.

To address the register of any module, use the Base address to the entire card, add the Module Offset

depending upon its slot (000 or 800), and then add the Register Offset of interest (see module memory map.)

The memory map of each selected module counts from, or is superimposed over its respective module offset.

Thus, Address = Base + Module Offset + Register Offset.

For example, if a Digital I/O module were selected to populate module 1 and a Discrete I/O module were

selected to populate module 2:

Address = Base + Module 1 Offset 000 + Digital I/O register 010 = Base + 010 hex

Address = Base + Module 2 Offset 800 + Discrete I/O register 024 = Base + 824 hex

MEMORY MAP

000

Module 1 Register…

800

Module 2 Register…

3000

Unit Level General Register…

004

804

3004

008

808

3008

00C

80C

300C

010

810

3010

.

.

.

.

.

.

.

.

.

7FE

FFE

37FE

7FF

FFF

37FF

Any address NOT SPECIFIED within 4096 byte block (up to 3FFFh) is reserved.

The memory map of each module type is described hereafter:

Slot 2

Offset 800

Slot 1

Offset 000

General

Offset 3000

D/S One/Two Channel (Modules 1*, 2*, 3*, 4*)

75DS2 Operations Manual

North Atlantic Industries, Inc.

11/11/2011

Rev: 2011-11-11-1000

www.naii.com

Page 10 of 43

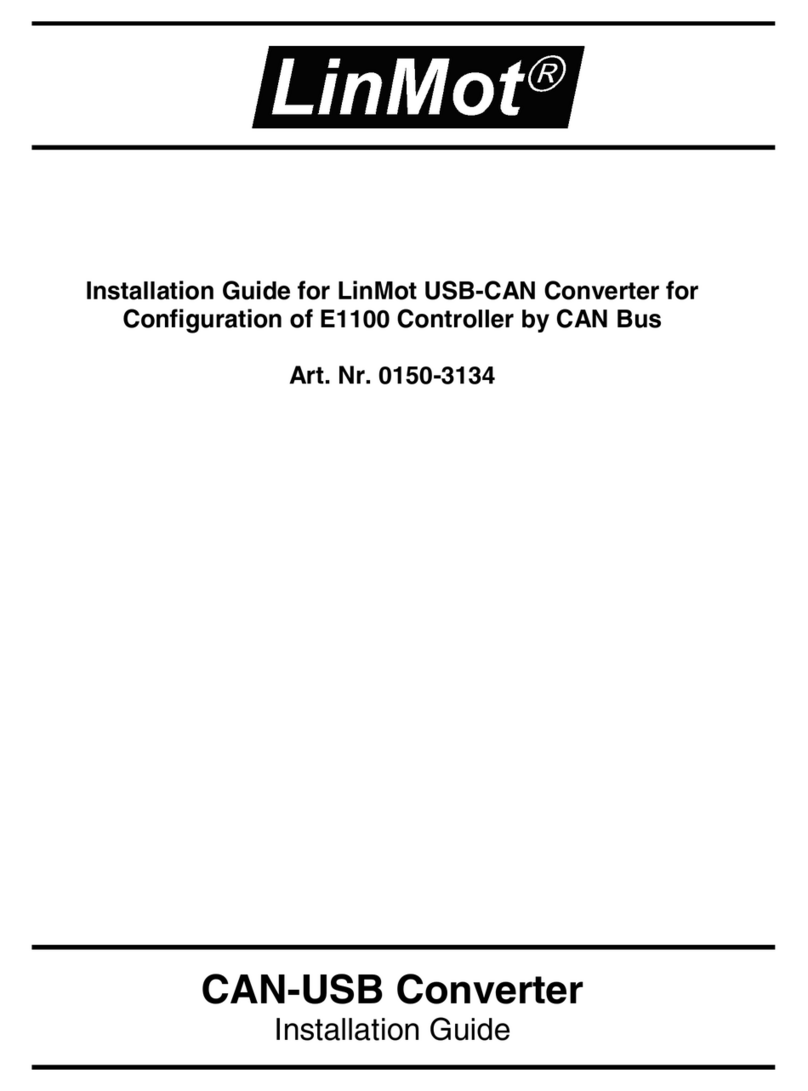

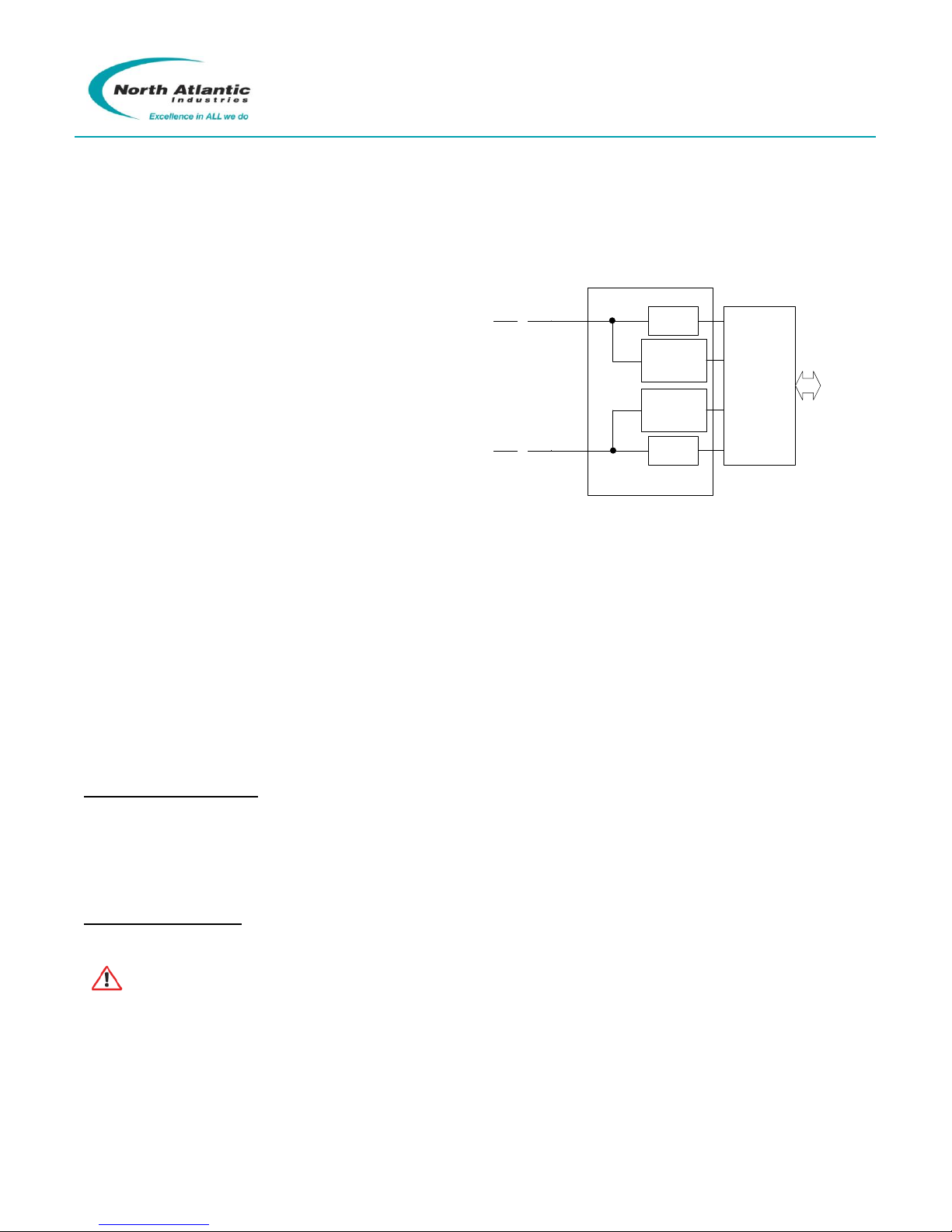

2

Wrap-Around

Test

S/D

DS 1

DS 2

State

Machine

DS Module Block Diagram

Module Bus

User Interface

Wrap-Around

Test

S/D

Signal and Reference

Isolation

1

D/S ONE/TWO CHANNEL (MODULES 1*, 2*, 3*, 4*)

(*See part number designation)

Principle of Operation

These new Digital-to-Synchro/Resolver (D/S)

modules are solid state designs that eliminate

the need for external transformers. Since these

modules operate down to 50 Hz, deleting the

previously large external transformers offers

huge space savings. The reduced size and

lower power consumption of these modules now

makes it possible to supply 10 channels on a 6U

card.

Two different modules are available within the

same package size: The first is a two-channel

1.5VA/2.2VA design that contains two separate

channels within one enclosure. The other is a

single channel 3.0VA design that will also drive

Torque Receivers. All outputs are short circuit

protected and the S2 (Z) leg can be grounded

without effecting performance. Any channel can be programmed for rotation (either continuous or with start/stop

angles). External amplifiers can be added to drive up to 30 VA with a frequency range of 50 to 400 Hz. Two-

speed (up to 1:255 ratio) outputs can be programmed (dual channel module). The processor will set a flag when it

senses that the maximum allowable misalignment of 90/gear ratio is exceeded.

New features in these modules now include a wrap capability for measuring each channel’s commanded output

angle and carrier frequency. The module’s extensive programmability now includes format selection (synchro or

resolver). A background calibration feature (pending), that is totally transparent to the operation of the channels,

constantly adjusts outputs for all load and environmental conditions. Each channel can be programmed for a

different output voltage, which can be programmed for either ratio-metric or absolute (fixed) output. Module power

ON/OFF capability provided for shutting down inactive channels.

Built-In Test (BIT) / Diagnostic Capability

Two different tests (one on-line and one off-line) can be selected:

The on-line (D2) Test initiates automatic background BIT testing that checks the output accuracy of each

channel by comparing the measured output angle to the commanded angle. Each channel is individually checked

to an accuracy of 0.2and each D/S Signal output and Reference input is continually monitored. User can

periodically clear to 00h and then read Test (D2) verification register again, after 0.1 seconds, to verify that

background bit testing is activated. Any failure triggers an Interrupt (if enabled) and the results are available in

Status Registers. The testing is totally transparent to the user, requires no external programming, has no effect on

the standard operation of the card, and can be enabled or disabled.

The off-line (D3) Test initiates a BIT test that generates and tests 24 different angles to a test accuracy of 0.2.

Results can be read from registers. External reference is required and outputs must be on. Any failure triggers an

Interrupt (if enabled). Testing requires no external programming, and can be initiated or stopped at any time.

CAUTION: Outputs must be ON and Reference supplied during this test and therefore active. Check

connected loads for possible interaction.

D/S One/Two Channel (Modules 1*, 2*, 3*, 4*)

75DS2 Operations Manual

North Atlantic Industries, Inc.

11/11/2011

Rev: 2011-11-11-1000

www.naii.com

Page 11 of 43

Wrap S/D Angle (Read)

The Wrap S/D Angle reads back the actual output signal (angle), which is used to verify that the actual output is

set to commanded angle. Read individual channels 1 or 2.

D15

D14

D13

D12

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

Wrap S/D Data () Hi

180

90

45

22.5

11.25

5.625

2.813

1.406

.703

.352

.176

.088

.044

.022

.011

.0055

Wrap S/D Data () Lo

.00274

.00137

.00068

.00034

.00017

.00008

.00004

.00002

X

X

X

X

X

X

X

X

Measured Reference Voltage

Each individual channel input signal voltage “VREF” is measured and the value reported to a corresponding read

register. The input voltage is reported to a resolution of 10 mv rms. The output is in integer decimal format. For

example, if channel 1 input REF voltage is 26.0 VRMS, the output measurement word from the corresponding

register would be 2600.

Measured Signal Voltage

Each individual channel input signal voltage “VL-L” is measured and the value reported to a corresponding read

register. The input voltage is reported to a resolution of 10 mv rms. The output is in integer decimal format. For

example, if channel 1 input signal voltage is 11.8 VRMS, the output measurement word from the corresponding

register would be 1180.

Signal Loss Threshold

Each individual channel input signal voltage “VL-L” is measured and the value reported to a corresponding read

register. The signal loss detection circuitry can be tailored to report a signal loss (at Signal Loss Status register) at

a user defined threshold. This threshold can be set to a resolution of 10 mv rms. Program the threshold by writing

the value of the voltage threshold in integer decimal format. For example, if channel 1 input signal loss voltage

threshold is to be 7 VRMS, the programmed word to the corresponding register would be 700 (2BCh).

Reference Loss Threshold

Each individual channel input reference voltage “VREF” is measured and the value reported to a corresponding

read register. The reference loss detection circuitry can be tailored to report a reference loss (at Reference Loss

Status register) at a user defined threshold. This threshold can be set to a resolution of 10 mv rms. Program the

threshold by writing the value of the voltage threshold in integer decimal format. For example, if channel 1 input

reference loss voltage threshold is to be 20 VRMS, the programmed word to the corresponding register would be

2000 (7D0h).

D/S Channel Frequency

Each individual channel Reference Frequency is measured and the value reported to a corresponding read

register. The input reference frequency is reported to a resolution of 1 Hz. The output is in integer decimal format.

For example, if channel 1 input excitation is 400 Hz, the output measurement word from the corresponding

register would be 400.

D/S One/Two Channel (Modules 1*, 2*, 3*, 4*)

75DS2 Operations Manual

North Atlantic Industries, Inc.

11/11/2011

Rev: 2011-11-11-1000

www.naii.com

Page 12 of 43

D/S Status, Signal Loss

Type: binary word

Range: N/A

Read/Write: R

Initialized Value: 0

Check the corresponding bit for a channel’s Signal Loss Status. A Signal input loss to that channel will trigger a

bit failure (=1) on a per channel basis; Passing status (=0). Signal Loss is indicated after 2 seconds. Signal input

monitoring is disabled during D3 or D0 Test. Any Signal Status failure, transient or intermittent, will latch the

Signal Status register. Reading any status bit will unlatch the entire register. Signal Status is part of background

testing and the status register may be checked or polled at any given time. When Status Interrupt is enabled,

Status Interrupt is reported through the Open Status Interrupt Vector in the General Use Memory Map.

REGISTER

D15

D14

D13

D12

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

FUNCTION

D/S Status, Signal Loss

X

X

X

X

X

X

X

X

X

X

X

X

X

X

Ch2

Ch1

CHANNEL STATUS BIT

D/S Wrap Select, Internal/External (Pending)

This register sets and determines where the wrap signal will be read from and will update in the Wrap S/D Angle

register. When set for internal, the wrap will be reading from the module output. When set for external, the wrap

will be reading from the external amplifier wrap input signals (See pin-out). “0” = internal wrap select, “1” =

external amplifier wrap select.

D15

D14

D13

D12

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

Wrap Select, Internal/External

X

X

X

X

X

X

X

X

X

X

X

X

X

X

CH2

CH1

D/S Status, External Amplifier (Pending)

This monitors the external amplifier BIT signal (See pin-out). Check the corresponding BIT status of the register

for each active channel that has the external amplifier enabled/connected. A “1” = BIT (OK), “0” = BIT (Fail)

D15

D14

D13

D12

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

Status, External Amplifier

X

X

X

X

X

X

X

X

X

X

X

X

X

X

CH2

CH1

D/S Write Angle –Single Speed

Write the desired commanded output angle. For single-speed applications (Ratio=1), write an “up to” 24-bit

integer (24-bit 2’s compliment integer) to the corresponding channel D/S Write Angle register. (ex. 330(in 16-bit

resolution) = EAABh written to Data Hi register only); 330(in 24-bit resolution) = EAAAAB –note that “EAAA” is

written to Data Hi register and “AB00” is written to Data Lo register).

WORD = (Angle (360/224)).

D15

D14

D13

D12

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

D/S Write Data () Hi

180

90

45

22.5

11.25

5.625

2.813

1.406

.703

.352

.176

.088

.044

.022

.011

.0055

D/S Write Data () Lo

.00274

.00137

.00068

.00034

.00017

.00008

.00004

.00002

X

X

X

X

X

X

X

X

Note: Writing to an Input Angle Register will stop any rotation initiated on that channel

D/S Write Angle –Two Speed

The dual channel module can automatically simulate two-speed applications (applies only to dual channel

modules). Write an “up to” 24-bit integer (24-bit 2’s compliment integer) to the corresponding channel D/S Write

Angle register to the coarse channel (channel 1). By entering a ratio in the D/S Ratio 1/2 register, the fine channel

(channel 2) will automatically output a signal proportional to the programmed coarse channel times the ratio

programmed.

D/S One/Two Channel (Modules 1*, 2*, 3*, 4*)

75DS2 Operations Manual

North Atlantic Industries, Inc.

11/11/2011

Rev: 2011-11-11-1000

www.naii.com

Page 13 of 43

D/S Rotation

Each channel may be configured for either start/stop or continuous rotation for applications that require it. In

start/stop mode, the user can program a rotational velocity and a stop angle. When triggered, either via a software

command or external pulse (selectable trigger mode), the output signal will start at the current position and

simulate rotation at the specified rotation rate and stop at the programmed stop angle. Re-initiating the trigger will

repeat the rotation. In continuous mode, the user will program a rotation rate and trigger the start of the rotation

either via software command or external trigger. Stopping rotation can be accomplished by either issuing a stop

rotation command or setting a commanded angle. Clockwise or counter-clockwise rotation is accomplished by

setting either a positive or negative 2’s complement word in the velocity register. Note: Writing to an Input Angle

Register will stop any rotation initiated on that channel.

D/S Stop Angle

May be used during implementation of D/S rotation. When the channel is set for start/stop rotation (D/S Rotation

Mode register), write the desired stop angle to this register. Write a 16-bit integer (or 16-bit 2’s compliment

integer) to the corresponding channel D/S Write Angle register. (ex. 330= EAABh).

WORD = (Angle (360/216)).

D/S Set Rotation Rate

May be used during implementation of D/S rotation. Write to the corresponding Set Rotation Rate registers (Hi

and Lo) a 2’s complement number representing the desired rotation rate, LSB = 0.015/sec.

Ex: 12 RPS = (12 x 360/0.015= 288000 = 46500h), -12 RPS = (-12 x 360/0.015= -288000 = 0xB9B00h)

Step size is 16 bits (0.0055) for up to 1.5 RPS, and then linearly decreases to 12 bits (0.088) at 13.6 RPS.

D/S Rotation Mode, Continuous or Start/Stop

For continuous rotation, set the corresponding channel bit to "0" in the Rotation Mode register. For rotation to

cease at a designated stop angle, set the bit to "1". For 2-speed applications, only the odd (coarse) channel

needs to be programmed (CH1).

D15

D14

D13

D12

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

D/S Rotation Mode

X

X

X

X

X

X

X

X

X

X

X

X

X

X

CH2

CH1

D/S Rotation Status

Check the corresponding bit of the D/S Rotation Status Register for condition of rotation (“Done”or “Not Done”)

for each channel. A ”1” means Rotation Done (output is static), “0” means Rotation Not Done (output is rotating)

on channel. Rotation monitoring is always enabled.

D15

D14

D13

D12

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

D/S Status, Rotation

X

X

X

X

X

X

X

X

X

X

X

X

X

X

CH2

CH1

Start Rotation

Implements a software command to initiate rotation (D/S Trigger Source Select Register is set for “internal”). First

set the Rotation Rate and Rotation Mode Registers for each channel that is to rotate. Then, to start rotation for the

corresponding channel, write a “1” to the corresponding channel D/S Start Rotation register.

Stop Rotation

To stop rotation for the corresponding channel, write a “1” to the corresponding channel D/S Stop Rotation

register. Channel will remain at the stopped angle until new input angles are set, or rotation is again initiated.

Note: An in-process rotation can also be stopped by commanding a new angle (D/S Write Angle).

D/S One/Two Channel (Modules 1*, 2*, 3*, 4*)

75DS2 Operations Manual

North Atlantic Industries, Inc.

11/11/2011

Rev: 2011-11-11-1000

www.naii.com

Page 14 of 43

D/S Set Reference Voltage

Utilized for setting input/output transformation ratio. Set the expected input reference voltage “VREF” to a

corresponding register. The input voltage is set with a resolution of 10 mv rms. The setting is in integer decimal

format. For example, if channel 1 expected input REF voltage is 26.0 VRMS, the set word to the corresponding

register would be 2600.

D/S Set Signal Voltage

Utilized for setting input/output transformation ratio. Set required output signal voltage “VL-L” to a corresponding

register. The output voltage is set with a resolution of 10 mv rms. The setting is in integer decimal format. For

example, if channel 1 Signal (VL-L) voltage is to be 11.8 VRMS, the set word to the corresponding register would

be 1180.

D/S BIT Test Enable

D15

D14

D13

D12

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

BIT Test Enable

X

X

X

X

X

X

X

X

X

X

X

X

D3

D2

X

X

Set bit to enable associated Built-In Self Test D2 or D3.

The on-line (D2) Test - Writing “1” to the D2 bit of the D/S Test Enable Register initiates status reporting of the

automatic background BIT testing that checks the output accuracy of each channel by comparing the measured

output angle to the commanded angle. The status bits will be set to indicate an accuracy (0.2º) problem and the

results can be read from D/S Status registers within 2 seconds and if enabled, an interrupt will be generated (See

Interrupt Register). Writing a “0” deactivates the status reporting. The testing is totally transparent to the user,

requires no external programming, and has no effect on the standard operation of this card. Note: Outputs must

be ON and Reference supplied for test to function. Card will write 55h (every 0.1 seconds) to the D/S Test

(D2) Verify register when D2 is enabled. User can periodically clear to 00h and then read the D/S Test (D2)

Verify register again, after 0.1 seconds, to verify that BIT Testing is activated. This test continuously sequences

between the channels on the card with each output being measured for approximately 180mSec. If the measured

angle has an error greater the 0.2º, a flag will be set in the appropriate register. If the input angle is stepped more

then 0.2º during a test cycle, the test cycle will not generally indicate an error. In addition, each D/S Reference

input and signal output is continually monitored. Any failure triggers an Interrupt (if enabled) and the results are

available in the D/S Signal and D/S Reference Status registers.

The off-line (D3) Test - Writing “1” to the D3 bit of the D/S Test Enable Register initiates a BIT Test that

generates and tests 24 different angles to an accuracy of 0.2. External reference is required and outputs must be

ON. The D/S Status bits will be set to indicate an accuracy problem. Results are available in the D/S Test Status

registers and if enabled, an interrupt will be generated (See Vector Interrupt Registers). Test cycle takes about 30

seconds and the D3 bit changes from “1” to “0” when test is complete. The testing requires no external

programming, and can be terminated at any time by writing a “0” to the D3 bit of the D/S BIT Test Enable register.

CAUTION: Outputs must be ON and Reference must be supplied during this test. The outputs are

therefore active. Check connected loads for possible interaction.

D/S One/Two Channel (Modules 1*, 2*, 3*, 4*)

75DS2 Operations Manual

North Atlantic Industries, Inc.

11/11/2011

Rev: 2011-11-11-1000

www.naii.com

Page 15 of 43

D/S Status, BIT Test

Check the corresponding bit of the D/S BIT Test Status Register for status of BIT (Test-Accuracy) Testing for

each “active”channel. A ”1” means Accuracy Failed; “0” means Accuracy OK. Channels that are “inactive”are

also set to “0”. The status bits will be set to indicate an accuracy (0.2º) problem and the results can be read from

D/S Status Registers within 2 seconds and, if enabled, an interrupt will be generated (See Interrupt Register).

This test continuously sequences between the channels on the card with each output being measured for

approximately 180mSec. If the measured angle has an error greater the 0.2º, a flag will be set in the appropriate

register. If the input angle is stepped more than 0.2º during a test cycle, the test cycle will not generally indicate

an error.

D/S channels, by default, are set for monitoring the channel background BIT (Built-In-Test) status reporting; “ON”

or “ACTIVE”. The front panel BIT LED illuminates (Red) if any channel reports a BIT fault. For BIT status to work

properly on an “active” channel, the D/S channel must have a valid Reference source applied and the D/S

channel power set to “ON” (so there is a valid signal being generated). If channels are not being used, it is

recommended that the channel BIT status report be turned off (or set INACTIVE). However, it should be noted

that the channel BIT status register latches the contents of a failure until read. Simply setting the channel

“INACTIVE” will not clear the BIT status register or extinguish the front panel BIT fault LED if a fault was

previously detected.

The D/S BIT Test Status register should be queried (read) to insure the register is unlatched which will enable the

BIT status register to be re-written during next status update (which, when the channel is set INACTIVE, should

clear the fault). Once this is done, the front panel BIT LED will extinguish –as long as the channels that are active

are working properly and the channels not being utilized are set INACTIVE.

Note: When D/S Wrap Select External/Internal register is set for “external”, the BIT wrap will be read from the

external amplifier wrap input signals (See pin-out). Also, the BIT tolerance will be adjusted for the amplifier

accuracy specification.

D15

D14

D13

D12

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

D/S Status, BIT Test

X

X

X

X

X

X

X

X

X

X

X

X

X

X

CH2

CH1

Test (D2) Verify

Card will write 55h at Test (D2) Verify register when (D2) is enabled, approximately every (1) second. User can

clear to 00h and then read again, after approximately (1) second, to verify that background bit testing is activated.

D/S Ratio 1/2

Utilized for automatically simulating dual speed synchro/resolver. Only applies to dual channel module. Set

desired ratio between coarse (channel 1) and fine (channel 2) channels. Enter the desired ratio, as an integer

number, in the D/S Ratio 1/2 register corresponding to the pair of channels to be used as a two-speed channel.

Example: Single speed = 1; 36:1 = integer 36. (Ratio range from 1 to 255). By entering a ratio in the D/S Ratio

1/2 register, the fine channel (channel 2) will automatically output a signal proportional to the programmed coarse

channel times the ratio programmed.

D/S Output Mode

The D/S Output Mode register is utilized for selecting either ratio-metric or absolute (fixed) mode voltages. Ratio-

metric Mode, when selected, will cause the output signal voltage of the channel to vary with the input Reference

Voltage. Fixed Mode, when selected, will cause the output signal voltage of the channel NOT to vary with the

input Reference Voltage. Set corresponding channel bit to “0” for Ratio-metric Mode. Set corresponding channel

bit to “1” for Fixed Mode.

D15

D14

D13

D12

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

D/S Output Mode

X

X

X

X

X

X

X

X

X

X

X

X

X

X

CH2

CH1

D/S One/Two Channel (Modules 1*, 2*, 3*, 4*)

75DS2 Operations Manual

North Atlantic Industries, Inc.

11/11/2011

Rev: 2011-11-11-1000

www.naii.com

Page 16 of 43

D/S Synchro / Resolver Select

As required, write a “11” or “00” (Synchro = 11; Resolver = 00) to each corresponding channel bit pair,

representing a channel commanded output format, of the Synchro/Resolver register.

D15

D14

D13

D12

D11

D10

D9

D8

D7

D6

D5

D4

CH2

D2

CH1

D0

D/S Synchro / Resolver Select

X

X

X

X

X

X

X

X

X

X

X

X

D3

D2

D1

D0

D/S Torque Receiver Select

When selected, channel will be subjected to an automatic control algorithm which minimizes torque receiver

power draw. Applies only to the single channel modules. Normal = “0”; Torque Receiver = “1”

D15

D14

D13

D12

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

D/S Torque Receiver Select

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

CH1

D/S Trigger Source Select

May be used during implementation of D/S rotation. When triggered, the D/S channel will commence rotation.

Triggering may be initiated via “internal” software command (D/S Start Rotation register) or via “external’ signal

application (see pin-out). Internal = “0x29”; External = “0x28”

D15

D14

D13

D12

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

Trigger Source Select

X

X

X

X

X

X

X

X

X

X

D

X

D

X

X

D

D/S Trigger Slope Select

May be used during implementation of D/S rotation when D/S Trigger Source Select register is set for “external”.

For rotation trigger on positive slope, set the corresponding channel bit to "0" in the Trigger Slope Select register.

For negative slope, set the bit to "1"

D15

D14

D13

D12

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

Trigger Slope Select

X

X

X

X

X

X

X

X

X

X

X

X

X

X

CH2

CH1

D/S Module Power Enable

The D/S Module Power Enable register is utilized for module channel output/power control. Set the bit,

corresponding to either channel, to enable the power output stage of the D/S channel(s). “1” = Enable; “0” =

Disabled. For dual channel modules, writing a “1” to either or both channel bits will enable and turn the output

stage power “on”. To disable, or turn off power to the output stage, all channels (both) bits must be set to “0”.

Initialized default is “00”.

D15

D14

D13

D12

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

D/S Module Power Enable

X

X

X

X

X

X

X

X

X

X

X

X

X

X

CH2

CH1

D/S Output Enable

NOTE: Single Channel D/S Only

Set the corresponding bit to “1” in the Output On/Off Register. To turn OFF channel, set corresponding bit to “0”.

Default: Set to OFF. (OFF = “0”; ON = “1”)

D15

D14

D13

D12

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

Trigger Source Select

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

CH1

D/S One/Two Channel (Modules 1*, 2*, 3*, 4*)

75DS2 Operations Manual

North Atlantic Industries, Inc.

11/11/2011

Rev: 2011-11-11-1000

www.naii.com

Page 17 of 43

D/S Active Channel Select

Allows the BIT Test Status register to be updated. For BIT status to work properly on an “active” channel, the D/S

channel must have a valid Reference source applied and the D/S channel power set to “ON” (so there is a valid

signal being generated). If channels are not being used, it is recommended that the channel BIT status report be

turned off (or set “Inactive”). Set the bit, corresponding to each channel to be monitored during BIT testing, in the

Active Channel Register for the particular D/S channel. “1” = Active; “0” = not used.

Note: Omitting this step will produce false alarms because unused channels will set faults.

D15

D14

D13

D12

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

D/S Active Channel Select

X

X

X

X

X

X

X

X

X

X

X

X

X

X

CH2

CH1

D/S Status, Reference Loss

Check the corresponding bit of the D/S Reference Status register for condition of the reference input for each

active channel. A ”1” means Reference has been lost, “0” means Reference is okay on active channels (D/S

Active Channel Select register). Channels that are inactive are also set to “0”. Reference loss is detected within 2

seconds. Reference monitoring is always enabled. Any D/S reference loss detection, transient or intermittent, will

latch the D/S Reference Status register. Reading will unlatch the register.

D15

D14

D13

D12

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

D/S Status, Reference Loss

X

X

X

X

X

X

X

X

X

X

X

X

X

X

CH2

CH1

D/S Status, Phase Lock Loss

Check the corresponding bit of the D/S Phase Lock Loss Register for condition of the phase lock between the

reference input and signal output for each active channel. A ”1” means Phase Lock Loss has occurred, “0”

means Phase Lock okay on active channels(D/S Active Channel Select Register). Channels that are inactive are

also set to “0”. (Phase Lock loss is detected within 2 seconds). Phase Lock monitoring is always enabled. Any

D/S Phase Lock Loss status failure, transient or intermittent, will latch the D/S Phase Lock Loss Status Register.

Reading will unlatch register.

D15

D14

D13

D12

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

D/S Status, Phase Lock Loss

X

X

X

X

X

X

X

X

X

X

X

X

X

X

CH2

CH1

D/S Set Phase Offset

The phase of each individual channel signal may be offset from the Reference signal. The phase may be adjusted

at a resolution of 0.1 deg / bit. Program the desired lead or lag in integer as a 2’s complement word format. For

example, if channel 1 output signal is to lead the reference signal by 1.6 degrees, program the corresponding

channel phase register to 16 (10h). If channel 1 output signal is to lag the reference signal by 1.6 degrees,

program the corresponding channel phase register to -16 (FFF0h). Phase shift range is -90 <= x <= 90.

Reference Loss Interrupt Enable

Set the bit to enable interrupts for the corresponding channel. When enabled, a reference input loss (D/S Status,

Reference) will trigger an interrupt. Default is “0” to disable interrupt on all channels. When Status Interrupt is

enabled, Status Interrupt is reported through the Reference Loss Interrupt Vector.

D15

D14

D13

D12

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

Reference Loss Interrupt Enable

X

X

X

X

X

X

X

X

X

X

X

X

X

X

CH2

CH1

D/S One/Two Channel (Modules 1*, 2*, 3*, 4*)

75DS2 Operations Manual

North Atlantic Industries, Inc.

11/11/2011

Rev: 2011-11-11-1000

www.naii.com

Page 18 of 43

Signal Loss Interrupt Enable

Set the bit to enable interrupts for the corresponding channel. When enabled, a signal input loss (D/S Status,

Signal Loss) will trigger an interrupt. Default is “0” to disable interrupt on all channels. When Status Interrupt is

enabled, Status Interrupt is reported through the Signal Loss Interrupt Vector.

D15

D14

D13

D12

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

Signal Loss Interrupt Enable

X

X

X

X

X

X

X

X

X

X

X

X

X

X

CH2

CH1

BIT Test Fail Interrupt Enable

Set the bit to enable interrupts for the corresponding channel. When enabled, a BIT Test Failure (D/S Status, BIT

Test) will trigger an interrupt. Default is “0” to disable interrupt on all channels. When Status Interrupt is enabled,

Status Interrupt is reported through the BIT Test Loss Interrupt Vector.

D15

D14

D13

D12

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

BIT Test Fail Interrupt Enable

X

X

X

X

X

X

X

X

X

X

X

X

X

X

CH2

CH1

Phase Lock Loss Interrupt Enable

Set the bit to enable interrupts for the corresponding channel. When enabled, a Phase Lock Loss (D/S Status,

Phase Lock Loss) will trigger an interrupt. Default is “0” to disable interrupt on all channels. When Status Interrupt

is enabled, Status Interrupt is reported through the Phase Lock Loss Interrupt Vector.

-

D15

D14

D13

D12

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

Phase Lock Loss Interrupt Enable

X

X

X

X

X

X

X

X

X

X

X

X

X

X

CH2

CH1

OSC (Optional Onboard Reference Supply) Set Frequency

Type: 16-bit unsigned integer

Range: 47 to 10,000 Hz

Read/Write: R/W

Initialized Value: N/A

Program Reference Frequency, where LSB is 0.01 Hz. For example: To program 400 Hz, 400 x 100= 40,000,

which equals 0x9C40. In this example, 0x0000 would be programmed in the Reference Frequency High register,

and 0x9C40 would be programmed in the Reference Frequency Low register. To program 10,000 Hz, 10,000 x

100= 1,000,000, which equals 0xF4240. In this example, 0x000F would be programmed in the Reference

Frequency High register, and 0x4240 would be programmed in the Reference Frequency Low register.

REGISTER

D15

D14

D13

D12

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

FUNCTION

327.68

163.84

81.92

40.96

20.48

10.24

5.12

2.56

1.28

0.64

0.32

0.16

0.08

0.04

0.02

0.01

approximate value

REF FREQUENCY LO

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D=DATA BIT (Hz)

REGISTER

D15

D14

D13

D12

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

FUNCTION

0

0

0

0

0

0

0

0

0

0

0

0

5242.88

2621.44

1310.72

655.36

approximate value

REF FREQUENCY HI

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D=DATA BIT (Hz)

D/S One/Two Channel (Modules 1*, 2*, 3*, 4*)

75DS2 Operations Manual

North Atlantic Industries, Inc.

11/11/2011

Rev: 2011-11-11-1000

www.naii.com

Page 19 of 43

OSC (Optional Onboard Reference Supply) Set Voltage

Type: 16-bit unsigned integer

Range: 2.0 to 28.0 Vrms, or 115 Vrms

Read/Write: R/W

Initialized Value: N/A

Program Reference Voltage, where LSB is 0.01 Vrms. For example: To program 26.1 Vrms, 26.1 x 100= 2610,

which equals 0xA32. In this example, 0x0000 would be programmed in the Reference Voltage High register, and

0x0xA32 would be programmed in the Reference Voltage Low register. To program 115 Vrms, 115 x 100=

11,500, which equals 0x2CEC. In this example, 0x0000 would be programmed in the Reference Voltage High

register, and 0x2CEC would be programmed in the Reference Voltage Low register. Note: Reference Voltage

High register always remains at 0x0000.

REGISTER

D15

D14

D13

D12

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

FUNCTION

0

0

81.92

40.96

20.48

10.24

5.12

2.56

1.28

0.64

0.32

0.16

0.08

0.04

0.02

0.01

approximate value

REF FREQUENCY LO

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D=DATA BIT (Hz)

REGISTER

D15

D14

D13

D12

D11

D10

D9

D8

D7

D6

D5

D4

D3

D2

D1

D0

FUNCTION

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

approximate value

REF FREQUENCY HI

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D

D=DATA BIT (Hz)

Interrupt Vector

The Interrupt Vector Registers store the vectors for the specific interrupts generated by the module which are

used for failure reports. If the same vector is loaded into each register, the same interrupt routine will be invoked

by all interrupts. If unique vectors are loaded into the registers, a different Interrupt Service Routine (ISR) can be

invoked by each interrupt. Write 16-bit integer (0-255).

The Signal Loss interrupt vector will be serviced when the Signal Loss status is set and the interrupt has been

enabled.

The Reference Loss interrupt vector will be serviced when the Reference Loss status is set and the interrupt

has been enabled.

The BIT interrupt vector will be serviced when the Bit (failure) status is set and the interrupt has been

enabled.

The Lock Loss interrupt vector will be serviced when the Lock Loss status is set and the interrupt has been

enabled.

D/S (1*, 2*, 3*, 4*) (PCI) MODULE MEMORY MAP

75DS2 Operations Manual

North Atlantic Industries, Inc.

11/11/2011

Rev: 2011-11-11-1000

www.naii.com

Page 20 of 43

D/S (1*, 2*, 3*, 4*) (PCI) MODULE MEMORY MAP

000

Wrap S/D Angle Lo CH1

R

140

D/S Set Reference Volt Lo CH1

W/R

1E8

D/S Set Phase Offset CH1

W/R

004

Wrap S/D Angle Hi CH1

R

144

D/S Set Reference Volt Hi CH1

W/R

1EC

D/S Set Phase Offset CH2

W/R

008

Wrap S/D Angle Lo CH2

R

148

D/S Set Reference Volt Lo CH2

W/R

1F4

D/S Rotation Status CH1/2

R

00C

Wrap S/D Angle Hi CH2

R

14C

D/S Set Reference Volt Hi CH2

W/R

330

OSC Set Voltage Lo

W/R

064

Measured Reference Voltage CH1

R

160

D/S Set Signal Volt Lo CH1

W/R

334

OSC Set Voltage HI

W/R

068

Measured Reference Voltage CH2

R

164

D/S Set Signal Volt Hi CH1

W/R

338

OSC Set Frequency Lo

W/R

070

Measured Signal Voltage CH1

R

168

D/S Set Signal Volt Lo CH2

W/R

33C

OSC Set Frequency Hi

W/R

074

Measured Signal Voltage CH2

R

16C

D/S Set Signal Volt Hi CH2

W/R

3A0

Start Rotation CH1

W

080

Signal Loss Threshold CH1

W/R

178

D/S Status, External Amplifier

R

3A4

Start Rotation CH2

W

084

Signal Loss Threshold CH2

W/R

17C

D/S Wrap Select, Internal/External

W/R

3B0

Stop Rotation CH1

W

08C

Reference Loss Threshold CH1

W/R

3B4

Stop Rotation CH2

W

090

Reference Loss Threshold CH2

W/R

180

D/S BIT Test Enable

W/R

184

D/S Ratio 1/2

W/R

700

D/S Status, BIT Test

R

098

Channel 1 Frequency

R

188

D2 Test Verify

W/R

704

Reference Loss Interrupt Enable

W/R

09C

Channel 2 Frequency

R

18C

D/S Output Mode

W/R

708

Signal Loss Interrupt Enable

W/R

0B0

Status, Signal Loss

R

190

D/S Rotation Mode

W/R

70C

BIT FAIL Interrupt Enable

W/R

198

D/S Synchro/Resolver Select

W/R

710

Phase Lock Loss Interrupt Enable

W/R

0C0

D/S Write Angle Lo CH1

W/R

19C

D/S Torque Receiver Select

W/R

0C4

D/S Write Angle Hi CH1

W/R

768

Module Design Version

R

0C8

D/S Write Angle Lo CH2

W/R

1A0

D/S Trigger Source Select CH1

W/R

76C

Module Design Revision

R

0CC

D/S Write Angle Hi CH2

W/R

1A4

D/S Trigger Source Select CH2

W/R

770

Module DSP Revision

R

0E4

D/S Stop Angle CH1

W/R

1AC

D/S Trigger Slope Select

W/R

774

Module FPGA Revision

R

0E8

D/S Stop Angle CH2

W/R

1B0

D/S Output Enable (1 CH only)

W/R

778

Module ID Revision

R

100

D/S Set Rotation Rate Lo CH1

W/R

1C0

D/S Module Power Enable

W/R

7C0

Vector Interrupt BIT Fail

W/R

104

D/S Set Rotation Rate Hi CH1

W/R

1C8

D/S Active Channel Select

W/R

7C4

Vector Interrupt REF Loss

W/R

108

D/S Set Rotation Rate Lo CH2

W/R

1CC

D/S Status, Reference Loss

R

7C8

Vector Interrupt Signal Loss

W/R

10C