5

Shipping Restraint

The stand by generator is delivered with a

shipping restraint to prevent damage. Remove the

bolt, spacer, and yellow tag located just below the

engine starter. Failure to remove shipping restraint

may cause damage tomachine.

2.4 Installation Preparation

Prior to installation of this equipment check the

ratings of both the generator set and transfer

switch. The generatorand transfer switch voltage,

amperage, and wattage must be adequate to

handle all electrical loads that the generator and

transfer switch will power. In some instances

critical or essential electrical loads will require

“grouping” together into a separate load panel as

the generator will not be of sufficient size to carry

all electrical loads.

CAUTION •Electrical and/or building

permits may be required in your area for

installation of a Standby generator. Check

your local codes for routing of gas lines and

noise ordinance allowances.

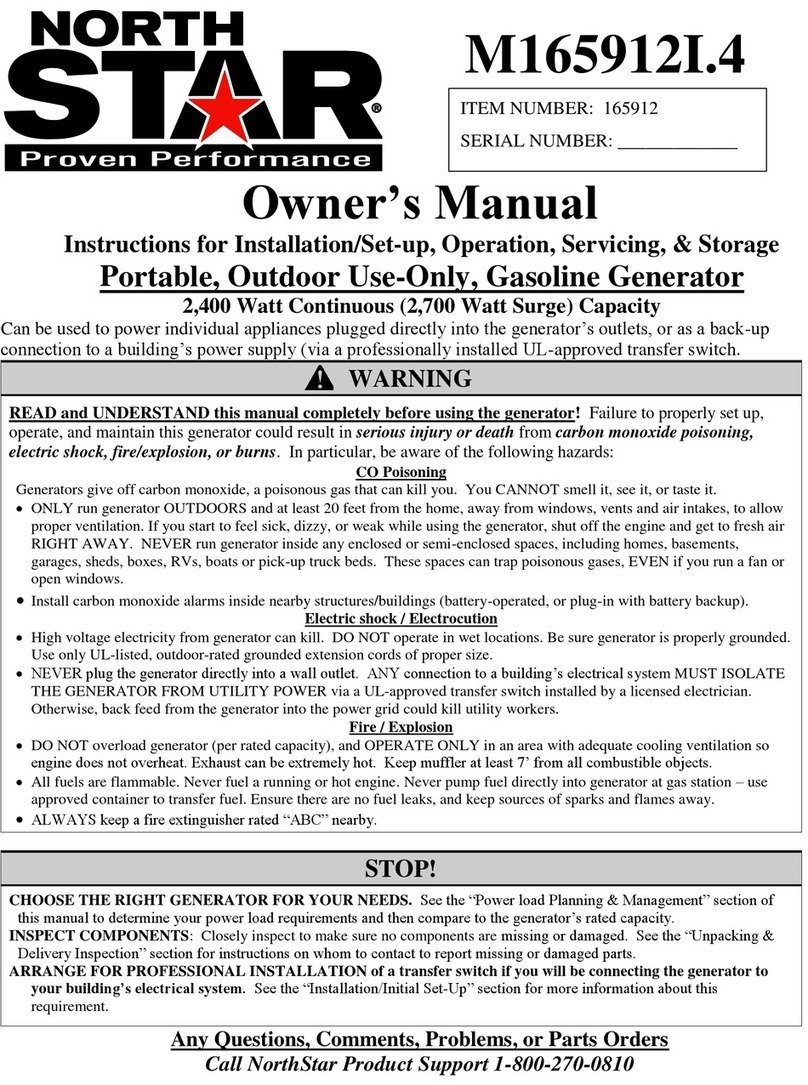

Fig. 01164 – Pallet Disassembly

The stand bygeneratorisfastenedto the shipping

palletby four 1/4” X 1.5” lagbolts. A 1/2” wrench is

required to remove the lag bolts from the pallet

(Figure 01164).

2.5 Generator Location

DANGER •Neveroperate thisgeneratorin

anenclosedarea.Exhaust gasescontain carbon

monoxide,anodorlessanddeadly poison.

DANGER •Neverinstall thegeneratorin

a locationthat exhaust gasescan seep back

into closed rooms. Gasescan seepinto closed

roomsthrough windows, doors, and floors.

Install the stand by generator set outdoors where

thereisan adequate supplyof fresh cooling air.To

help ensure trouble free operation, the following

suggestionsshould beconsidered:

1: Neverinstall the generator inareasprone to the

collectionof rainwater.

2: Never install the generator in an area that is

prone toflooding.

3: Neverlocate the generator ona roof.

4: Always locate the generator as close to the

transfer switch as possible. This will shorten the

length of electrical lead wire and conduit that is

required for the installation.

5: Always install the generator as close as

possible to the fuel source. This will help reduce

the length of pipe required for the installation.

ALWAYS consult your gas supplier, as they are

aware of laws and local codes governing the

placementof the gaspipe.

6: Always install the generator such that the air

inlets and outlets will not become blocked or

clogged with grass, leaves, litter, snow, or other

items. Clogged inlets or outlets will cause the

engine and generator to perform poorly, and

possibly resultin equipment failure.

7: Always install the generator such that there is

adequate space on all sides for servicing and

performing maintenance. A minimum of 7 feet on

all sides should be adequate. REMEMBER:

LAWS OR CODES MAY DICTATE REQUIRED

DISTANCES FROM STRUCTURES OR FUEL

SOURCES.

2.6 Sizing the Generator Mounting Slab

The stand by generator must be mounted on a

mounting pad that adequately supports the

generator housing. External isolation mounts are

not required as the generator set has vibration

isolation mounts located between the engine -

generator and thebase.

It is advisable to fasten the generator

compartment to a concrete mounting slab with a

quantity (4) of 1/4 - inch masonry type anchor

bolts. Check that the bolts are of sufficient length

to adequately secure the enclosure.

The concrete slab should extend past the

enclosure bya minimum of 3incheson all sides.

The concrete slab must be level. For further

details concerning concrete slab dimensions and

details, see FIG01168.

LAGBOLT

PALLET

FIG01164

Bolt

Space

Yello

Tag