Northern Industrial Tools 148830 User manual

9 " H Y D R A U L I C V E H I C L E

P O S I T I O N I N G J A C K

OWNER’S MANUAL

WARNING: Read carefully and understand all

INSTRUCTIONS before operating. Failure to follow the

safety rules and other basic safety precautions may result

in serious personal injury.

Item #148830

Page of 7

2

Thank you very much for choosing a NORTHERN TOOL + EQUIPMENT CO., INC. Product! For

future reference, please complete the owner’s record below:

Model: _______________ Purchase Date: _______________

Save the receipt, warranty and these instructions. It is important that you read the entire manual

to become familiar with this product before you begin using it.

This machine is designed for certain applications only. Northern Tool + Equipment cannot be

responsible for issues arising from modification. We strongly recommend this machine is not

modified and/or used for any application other than that for which it was designed. If you have

any questions relative to a particular application, DO NOT use the machine until you have first

contacted Northern Tool + Equipment to determine if it can or should be performed on the

product.

For technical questions please call 1-800-222-5381.

INTENDED USE

Single hydraulic vehicle jack maneuvers vehicle in any direction on 4 strong casters. Using 2 jacks

permits full 180° vehicle pivot; using 4 jacks places vehicle on a 360° rolling platform.

TECHNICAL SPECIFICATIONS & PACKING LIST

Item

Description

Size of wheel

4"

Construction

A3 steel

Width of handle

9"

GENERAL SAFETY RULES

WARNING: Read and understand all instructions. Failure to follow all instructions listed

below may result in electric shock, fire and/or serious injury.

WARNING: The warnings, cautions, and instructions discussed in this instruction

manual cannot cover all possible conditions or situations that could occur. It must be

understood by the operator that common sense and caution are factors which cannot be built into

this product, but must be supplied by the operator.

SAVE THESE INSTRUCTIONS

WORK AREA

åKeep work area clean, free of clutter and well lit. Cluttered and dark work areas can cause

accidents.

åKeep children and bystanders away while operating this jack. Distractions can cause you to

lose control, so visitors should remain at a safe distance from the work area.

Page of 7

3

åBe aware of all power lines, electrical circuits, water pipes and other mechanical hazards in

your work area, particularly those hazards below the work surface hidden from the operator’s

view that may be unintentionally contacted and may cause personal harm or property damage.

åBe alert of your surroundings. Using jacks in confined work areas may put you dangerously

close to cutting tools and rotating parts.

PERSONAL SAFETY

åStay alert, watch what you are doing and use common sense when operating this jack. Do not

use a tool while you are tired or under the influence of drugs, alcohol or medication. A moment

of inattention while operating tools may result in serious personal injury.

åDress properly. Do not wear loose clothing, dangling objects, or jewelry. Keep your hair,

clothing and gloves away from moving parts. Loose clothes, jewelry or long hair can be caught

in moving parts.

åUse safety apparel and equipment. Use safety goggles or safety glasses with side shields

which comply with current national standards, or when needed, a face shield. This applies to all

persons in the work area. Also use non-skid safety shoes, hardhat, gloves, dust collection

systems, and hearing protection when appropriate.

åDo not overreach. Keep proper footing and balance at all times.

TOOL USE AND CARE

åRead all the instructions and warnings first before attempting to operate this jack.

åDO NOT operate jack on inclined surfaces. Jack must be used on level surfaces only.

Unanticipated motion can occur as soon as jack lifts tire from surface.

åDO NOT overload jack beyond the load rating (1500 lbs. per unit)

åDO NOT start the vehicle’s engine, or drive a vehicle while the jack is in use. Jacks are

designed for hand maneuvering of vehicles only.

åDO NOT use jack to lift tires wider than 9 inches.

åDO NOT attempt to push jack over obstacles. Jack is designed to be used on level and smooth

surfaces only.

åAfter lifting, be sure to always lock the pin in place before operating. Pull the pin out after

finishing work and then release the valve.

åDo not force the tool. Tools do a better and safer job when used in the manner for which they

are designed. Plan your work, and use the correct tool for the job.

åStore idle tools. When tools are not is use, store them in a dry, secure place out of the reach of

children. Inspect tools for good working condition prior to storage and before re-use.

åUse only accessories that are recommended by the manufacturer for your model.

Accessories that may be suitable for one tool may create a risk of injury when used on another

tool.

åKeep guards in place and in working order.

åNever leave tool unattended.

OPERATION

1. Place jack on floor and press down on the pedal to release pedal lock. Pull out the lock pin

from frame.

2. Before operation, open release valve by turning the hand-wheel counterclockwise. Expand

the jack with the hand-wheel to place the rollers around the tire; position the jack so both

Page of 7

4

rollers are in contact with the tire tread. To obtain the best control of the jack while

expanding the rollers around the tire, place your left hand on top of the left side axle and

place your right hand at the center of the pedal. Close the release valve by turning the

hand-wheel clockwise to a snug-tight position; jack may now be used.

3. Install jack so that the unit is parallel to the sidewall of the tire to be lifted. Leave

approximately 3/4" of clearance between tire and jack. This is very important. If unit is

misaligned, the tire may hit the axle of the jack and not the rollers; this may damage the

jack and void the warranty.

4. To lift tire, flip the directional lever up, then place foot on pedal, depressing the pedal with

smooth, even strokes. Cycle pedal until tire is lifted from surface one inch or less. After

lifting, the lower the tire is to the ground the more stable jack will be. After lifting, be sure

to always lock the pin in place before operation. If using more than one jack, repeat

process on the other tires and maneuver the vehicles as required.

5. To release jack, pull the pin out from the frame and open the valve by turning the

hand-wheel counterclockwise slowly. Jack may be removed when rollers disengage from

the tire.

MAINTENANCE

åMaintain your jack. It is recommended that the general condition of any jack be examined

before it is used. Keep your jack in good repair by adopting a program of conscientious

repair and maintenance. Have necessary repairs made by qualified service personnel.

åCleaning. Use only soap and a damp cloth to clean your tools. Many household cleaners

are harmful to plastics and other insulation.

Page of 7

5

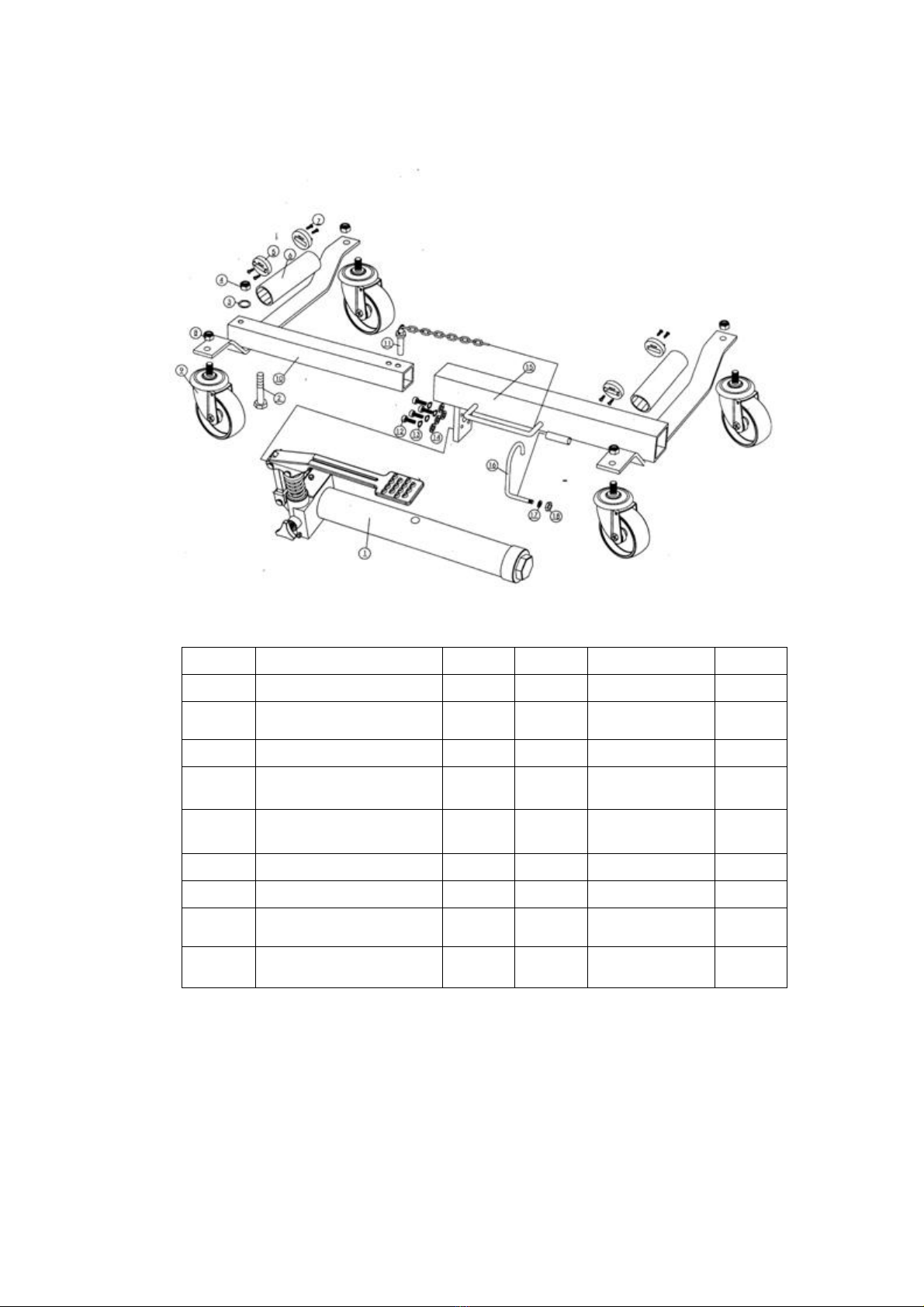

9” VEHICLE POSITIONING JACK PARTS LIST

Part#

Description

Qty.

Part#

Description

Qty.

1

Ram Assembly

1

10

Left Frame

1

2

Bolt M16*115

1

11

Lock Pin with

Chain

1

3

Flat Washer¢16

1

12

Screw M6*20

4

4

Nut M16

1

13

Lock

Washer ¢6

4

5

Roller Raceway

4

14

Flat Washer¢

6

4

6

Roller

2

15

Right Frame

1

7

Raceway Lock Screw

8

16

Hook

1

8

Lock Nut M12

4

17

Washer for

Hook

1

9

4” Swivel Caster

4

18

Nut for Hook

1

Table of contents

Popular Jack manuals by other brands

Pittsburgh

Pittsburgh 62590 Owner's manual & safety instructions

Powerbuilt

Powerbuilt 640405 Operating and maintenance instruction manual

Clarke

Clarke STRONG-ARM CTJ3000G quick start guide

Clarke

Clarke CTJ2500QLG Operating & maintenance instructions

Omega Lift Equipment

Omega Lift Equipment 18122C Operating instructions & parts manual

Pittsburgh

Pittsburgh 58816 Owner's manual & safety instructions