Northwest Manufacturing Powertow Supertow I Owner's manual

™

Brought to you by: Powertow ™

Supertow III … Division of Northwest Manufacturing, Inc.

Pilot’s Operating Handbook

10179 N. Navion Dr., Hayden, ID 83835 - 208-635-5352 FAX 208-635-5251

Model: SUPERTOW I, II,III

Things to know:

Keep your crate in the event there is any shipping damage to your unit.

Read this instruction manual thoroughly before attempting to load

and move your aircraft.

Your unit will need Oil & Gas - before test running the unit.

Tools handy for final assembly

½” End Wrench

Phillips Screwdriver

Wire Cutters

Thank you for choosing a Powertow, for your hangaring needs.

Customer Service is #1with our company. If you have any questions

or comments on your unit, please call us at 800-635-5565

Supertow III Setup

Handle and four cables to hook up, it’s that simple. Have a friend help you with the handle.

Pre Set-Up …Keep unit on pallet for ease of assembly.

Remove the three black bolts from frame. Located at back of frame top and bottom and set aside.

DO NOT REMOVE THE MASKING TAPE from any cables, until they have been attached.

The tape in all instances is to keep the proper pre-set adjustments in place until hook-up.

Step 1 –Lever - Before attaching the handle…

.

Step 2 - Shift Cable Attachment – Short Black Cable –Remove one nut & washer. Feed end of cable

through the upright support and attach washer and nut tightly with a Crescent Wrench. Remove tape.

.

IMPORTANT – Feed the long black cable under the wire

harness going to the engine. Let it continue under engine to front

of machine and let hang loosely for now. You can then attach the

main handle using the three black bolts. Start with the top bolt

loosely: then the bottom bolts and tighten in the same order.

Wrench is supplied to tighten bolts into threaded frame

Attach end of shift cable by

pulling back outer sleeve and slip

on to the transmission shifter

Step 3 – Brake Cable Locate cable from brake handle at top of

machine. Follow down to spring end. Line up the slots in brass fitting

in order to slip wire into bracket. Pull back the spring over the cable

and slip wire into lined up slots on support. Turn slots to keep in place

Attach the other end of the

spring clip onto transmission

brake lever. Use the 1/4” bolt

from brake lever and secure

with nut – leave room for clip

to move freely.

Supertow III Setup

Step 4

Step 5 –Throttle Cable

Step 6 -Clutch Cable

Locate Clutch Cable Attached on bottom

of frame, hanging loose with black barrel.

Connect this end of Clutch Cable up to the

top half of cable with threaded end.

Run threaded end into barrel snug against

nut. This will leave most of the screw

portion showing.Remove tape.

This barrel twist chamber adjusts the

tension of the clutch.

It’s important for the clutch to fully disengage when released. If you have this adjustment too tight, the

machine will continue to travel even when the handle is released.

“Lazy Susan” Cradle

The long black cable hooks up to the

load and release plate for the Lazy

Susan Cradle at the front end of unit.

Follow same attachment procedures as

shift cable hook-ups.

Locate the throttle control

attached to the engine and

bring it up to top of

handle. Remove the two

Phillips Screws on side of

handle and install throttle

control.

The cable will be secured

down the left side with

Nylon Ties in final step.

Supertow III Setup

Shift Cable

Lazy Susan

Release Cable

Throttle Control

Clutch Cable

Secure Clutch Cable to Handle.

Locate keeper on lower left side of handle. Remove the

10-24 Screw and attach Clutch Cable using the tab on

cable housing.

Be sure Clutch Cable is on the outside of Throttle and

Brake Cables, then secure all cables (Except Clutch) to

handle with nylon ties provided with Throttle Cable down

left side and Brake Cable under handle.

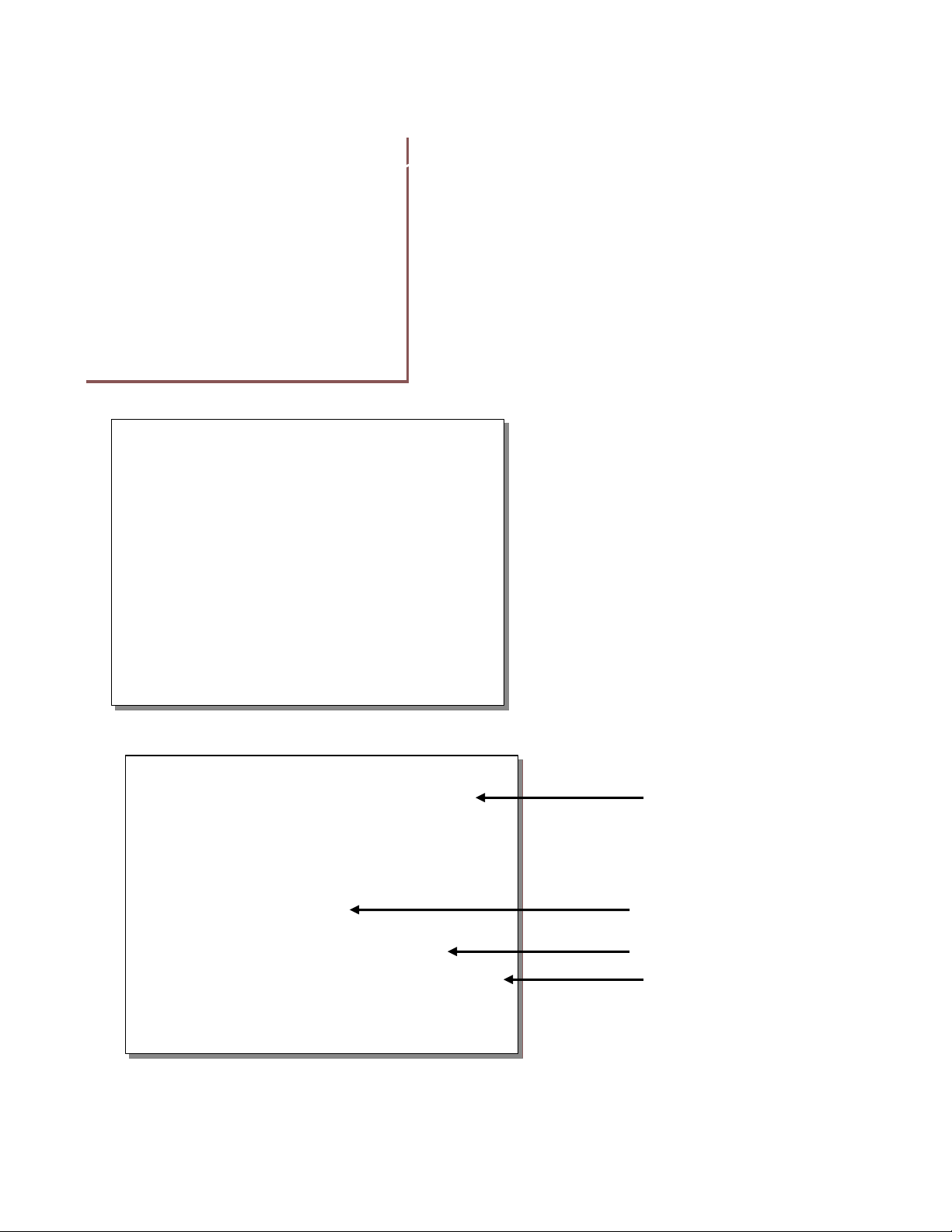

Bottom View for Reference

The two bolts next to the engine pulley are belt

guides, that create a loop around the pulley

keeping the drive belt from engaging while the

engine is running and clutch is disengaged.

There are three pulleys on the bottom of the

unit: The engine drive pulley, the large

transmission and the small clutch pulley on the

clutch arm. These pulleys need to be line

with each other. The bolt on the left side of

Clutch Arm will need to be adjusted after the

first couple hours of use. If the Clutch Arm

drops down out of alignment, it will run on the

rim of the idler pulley and spin the drive belt

off the unit.

SUPERTOW™part of the POWERTOW™ line by NW MFG

SHORT & SWEET PLEASE READ

Congratulations on your purchase of the Supertow.

As you already know, it’s a unique machine.

So let’s familiarize you with your new toy!

What’s where…?

Let’s start by standing at the rear of your tow.

On the handle, above the throttle are two lever handles.

Transmission lever

The transmission shift lever is on the right of the handle. Rocking your tow gently,

push this lever forward to its stop. A lot of force will not be required. Now ease the

lever back one click for neutral, allowing unit to freewheel, when not running. The

transmission has one speed forward and five reverse speeds.

Loading Gate lever

The lever on the left side releases the loading gate, of the “Lazy Susan Cradle” from

its locked position, when pulled back. After releasing gate, return lever back to its

original position away from you. This simple move applies to loading and

unloading.

Fingertip position is Brake lever on right side and Clutch & Go lever at left.

Ready to roll…!

Time to take the Supertow out for a solo, without your aircraft! It’s very important

to make sure the controls are all working correctly before you hook your beautiful

bird up to it … Yes a few touch and go’s...

Engine – Don’t forget the oil for the engine, it will take approximately ¾ of quart. A

splash of 100LL, no more throwing the test gas on the tarmac and we’re ready to start

up the unit. Place the throttle control in the choke or start position, push primer 3 to

4 times (if supplied), and start the engine. Move control to run position at about

medium speed. After some use you’ll know how much power is required for your

particular job. Greatest torque is developed at two-thirds throttle setting.

Out in the open, run the unit checking out all the handle controls. The clutch

operation is very important. When you release the clutch handle, the drive belt

should disengage completely, and there should be no creeping of machine. (If there

is, refer back to set-up instructions). This acts as a safety. This unit also has a brake.

However, if you continue to squeeze the clutch while trying to stop, it will weaken

the brake action. Operate the Lazy Susan load features. Running the unit for a few

minutes will break-in the engine, cables, belt and of course the operator.

Load & Go Instructions – OK…with transmission in neutral, the engine is running;

we’re ready to load your, “Winged Pride and Joy”. First time outside of hangar

please. Chock the back of the main gears. Easing the shift lever forward will

put your tow in the only forward gear. With the Lazy Susan Cradle in the unlocked

down position, line up the roller bar, to the front of your nosewheel. Gently squeeze

the clutch lever for power, while easing under the nosewheel for loading. When the

wheel rolls onto the cradle, it will hit the roller at the back of the cradle, easing the

front up into the locked position. Release clutch, as soon as it loads!!

SHOWING OFF TO YOUR FRIENDS…NOT QUITE YET!

You are now ready to move your plane. Don’t be too over zealous at trying out the

turn radius. The Lazy Susan will turn under your nosewheel. The wingspan alone is a

great deal of torque at your hands. You will have fun watching your nose gear stay

straight while making a turn.

It’s best to practice out in open first, to get the feel of the machine at different

speeds.

Remember - You have onespeed going into the hangar, and five speeds to the gas

pump. First gear in both positions is 65 feet per minute.

When you are ready to unload your plane, be sure cradle is inline with machine. (It’s

the only position for unloading). Reverse your transmission and ease the loading

gate lever back, allowing you to back out from under the nose gear. Then, push

handle forward to original position. (This will allow the cradle to “lock” for the next

time you are ready to load.)

Now here’s a good tip. Get up kind of early on Saturday morning, and get out

to the airport before the rest of the hangar bums get there. Pull your plane out of the

hangar by hand for the last time, and get it out on the apron well away from all hard

objects. Go through the above procedures until you really have it down. By the time

those guys show up, you will have become super proficient and will be able to put

on one helluva show. Should they ask, our phone number is on the decal. Ready for

another tip? Always have chock blocks of some kind anchored at the rear of your

main wheel position in the hangar to prevent inadvertent travel through the rear of

your hangar.

Last tip: If you really want to get smart, re-read this stuff after you have

actually used the machine a few times – it will be more meaningful.

Door Tracks -To get a heavy plane over door rails or ledges, a moderate amount

of speed is necessary so that the momentum of aircraft mass will help carry it

over, but smoothly. Do not jump the unit over door tracks, which result in the

nose gear turning within the Lazy Susan Cradle. This applies also to any means

of shifting the nose gear sideways in the Lazy Susan Cradle. The nose gear

should remain straight in the cradle for correct operation.

If door tracks are a problem, your shipping crate lid can be cut to fill spaces in

door tracts. There is enough wood to make additional spacers for the main gear also.

For you readers only:

How does the Lazy Susan really work?

In the correct position for loading, there are two latches, one on each side

located at the back of the Lazy Susan, as the unit drives under the nose gear; the

roller assists in moving the wheel up and onto the turn plate. The nose gear then

trips up the back plate locking it into place. You can turn the plane without turning

the yoke. The Lazy Susan turns separately from the Supertow on ball bearings,

allowing rotation.

To unload from the Susan, you simply pull the lever back. It is attached

to a rod and then to the two latches, tripping them open. You can put the unit in

reverse to back it off.

If the loading gate lever is not returned to the down position, the turn table will

not turn more than a couple inches, nor will it release the latches to unload. This

insures the plane will unload centered each time. You will not be able to unload the

plane, except in the same position as loaded. The loading gate lever is a

mechanical release; no springs to jump open accidentally.

TIP: Chock Blocks are used on mains to load. When releasing your plane in hangar,

back your plane up to the chocks leaving a space of several inches for the plane to

roll out from under the cradle and back to the chocks. After a few times of loading

and unloading your plane, you will find it to be the smoothest operation going.

THE LOCALIZER APPROACH TO HANGARING

This approach was designed specifically for the hangaring of aircraft by

one person where there is little space between wingtips and hangar door

opening. The minimums for this approach are down to 12" clearance at each

wingtip. Place the aircraft partially into the hangar, equal distance for each

wingtip from hangar door. Facing the aircraft in the same direction as it will be

hangared, mark the hangar floor indicating the exact centerline of the right main

gear tire only.

Pull the aircraft out and paint a single stripe on the centerline of the right

main only, starting approximately 10' out from hangar door and back as far as

main wheel would normally go. Only this single point of alignment needs to be

checked progressively when hangaring the aircraft to ensure clearance.

Rear main wheel chock blocks should always be anchored in position on

hangar floor to prevent inadvertent travel through rear of hangar.

MAINTENANCE RECORDS & NOTES

SUPERTOW™TROUBLESHOOTING

CHAIN IS TOO LOOSE……………………… Pillow blocks are slotted for take-up.

CHAIN BREAKS……………………………… Chain is too loose. Check sprocket alignment.

BELT SLIPPAGE WHEN

CLUTCH IS FULLY ENGAGED…………… Shorten clutch cable by turning turnbuckle at handle.

Adjust cable so clutch is fully engaged with approximately

1”of space remaining between clutch handle and

machine handle grip. Need new belt.

DRIVES WHEN NOT SQUEEZED…………. Lay a straight edge over the 8” pulley and engine pulley and

make sure they are in the exact same plane (level).

Check to make sure belt guides are in place.

Check Clutch arm and make sure it is adjusted up and not

Hanging down against the belt.

BELT SLIPS OFF PULLEY…………………. Tighten turnbuckle – check to make sure motor and

transmission pulleys are in line.

CLUTCH DOES NOT RELEASE…………… Lengthen cable at turnbuckle. Check belt guides.

See clutch cable this page. Check Clutch Arm adjustment

Make sure the arm is adjusted up not contacting the belt.

GAS UNIT: ENGINE SURGES……………… See engine manual.

ENGINE DIES UNDER LOAD……………… Check high-speed mixture adjustment.

See engine page.

EXCESSIVE NOISE UNDERNEATH UNIT… Check belt guides, “use no belt dressing”.

Loosen jam nut

and back out the

bolt part way.

Pillow blocksis slotted

for adjusting.

Supertow III Setup

CHAIN ADJUSTMENTS

After some use your chain may loosen up. Your machine may jump, experience chain noise or

grinding. You can tighten the chain in this manner. This is a unique chain tightening system.

Follow this procedure closely. Questions call 800-635-5565.

Loosen all the bolts holding down the pillow block bearings

Tighten the Adjusters bolts evenly against all three pillow blocks; until chain is comfortably

tight (Do not over tighten) Tighten jam nuts or your bolts will back out over time.

Securely tighten the bolts holding pillow block bearings. The pillow blocks are slotted also.

Last...Retighten the back bolt against pillow block and tighten jam.

Adjuster Bolt

Jam Nut

Slotted Pillow

Block Bearings

Zirk Oil Fitting

You have 3 drive chains on the “Supertow III”

Two drive chains to the tires and one from

transmission to the differential.

Start with the 2 forward drive chains. Loosen the

3 Jam Nuts from the front of pillow blocks do not

back out the bolts, just loosen the nuts.

Loosen black flat head bolt on top of handle.

Loosen 6 bolts on top of engine plate. (3 on each

side)…Turn adjusting bolts the same amount on

each side until chain is taunt between differential

and transmission. Tighten jam nuts, 6 engine bolts

and black handle bolt last

This has tightened the drive chains. Now you will need to slide the engine plate back towards

the handle to remove the chain slack from the transmission to differential. You will need to

tighten this chain also.

Adjusting Bolts

Loosen and back off

jam nut on each

adjuster bolt, located

on the inside of the

frame in front of

engine plate. Leave

the bolt touching

engine plate.

Maintenance Notes:

Zirk fittings on pillow blocks need grease once a year;

Change and check oil per engine manual

5 Speed transmissions is sealed…no lubricating required

Feel free to run 100 LL in your engine.

USE EXTREME CAUTION WHEN

OPERATING ANY POWER EQUIPMENT!

1. Do not operate this machine until you have read and

understand all instructions for proper use.

2. Do not operate unit when not running smoothly.

3. Keep hands and feet out from under towing equipment.

4. Operate in well ventilated area.

5. Do not leave a running machine unattended.

6. Do not operate electric unit in wet conditions or if cords are frayed.

7. Do not start engine when unit is in gear.

8. Hangar storage area should include anchored chocks to

control inadvertent movement of planes into hangar walls.

9. Do not change gearing to increase speed.

10. Do not move planes up any inclines...flat surface only.

11. Do not attach any device to activate throttle when both hands -

are not on throttle control.

12. Do not run engine without checking oil level.

13. Do not spill gasoline on hot engine.

14. Do not smoke when filling tank with gasoline.

15. Use caution when operating machine on icy / slippery surfaces.

16. Do not move planes in excess of speed that cannot be easily

stopped... there is no braking device on the unit.

17. Do routine maintenance to insure proper operation of unit.

18. Do not use unit if the Powertow engine is not running smoothly.

We hope you enjoy this Northwest Manufacturing product.

It was designed and built to give many years of reliable

service with proper use and routine maintenance.

GENERAL WARRANTY AND CONDITIONS

NORTHWEST MANUFACTURING, INC.

10179 N. Navion Dr., Hayden, IDAHO 83835

208-635-5352 FAX: 208-635-5251

E-mail: sales@powertow.com

Homepage: www.powertow.com 7-2009

Thank you for buying POWERTOW

™

NOTE: Adding any unauthorized third party attachments or accessories to any Powertow, Voids all

warranty and claims of responsibility by Powertow, or Northwest Mfg., its parent company. Any damage

to tow or aircraft is the responsibility of the aircraft owner and accessory manufacturer.

This manual suits for next models

2

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions