VERS. 2023.03.15 CFP13 W B _MAN_ EN

7

1.2 Machine plate

Important data can be found on the following plate located on the machine:

1.3 Safety instructions for particular operating phases

Before starting the work

•Before commencing work, make yourself familiar with the working environment at the place of

use. The working environment includes: obstacles in the area of work and manoeuvre, the

firmness of the floor, necessary protection at the site relating to public thoroughfares and the

availability of help in the event of accidents.

•Plate compactors must only be used for compaction jobs observing safety and operating

instructions.

•People who work with plate compactors must know everything regarding safety instructions.

•Do not take drugs or drink alcohol before using plate compactors.

•Always wear appropriate protective clothes (ear protections, gloves, protecting shoes and

helmet).

•Do not alterate the operation devices of the plate compactor.

•Do not leave control elements during compaction.

•Store the compactor with engine off in a safe place.

•Do not smoke when using compactor. Keep the compactor out of open flames.

•Always wear appropriate protective clothes.

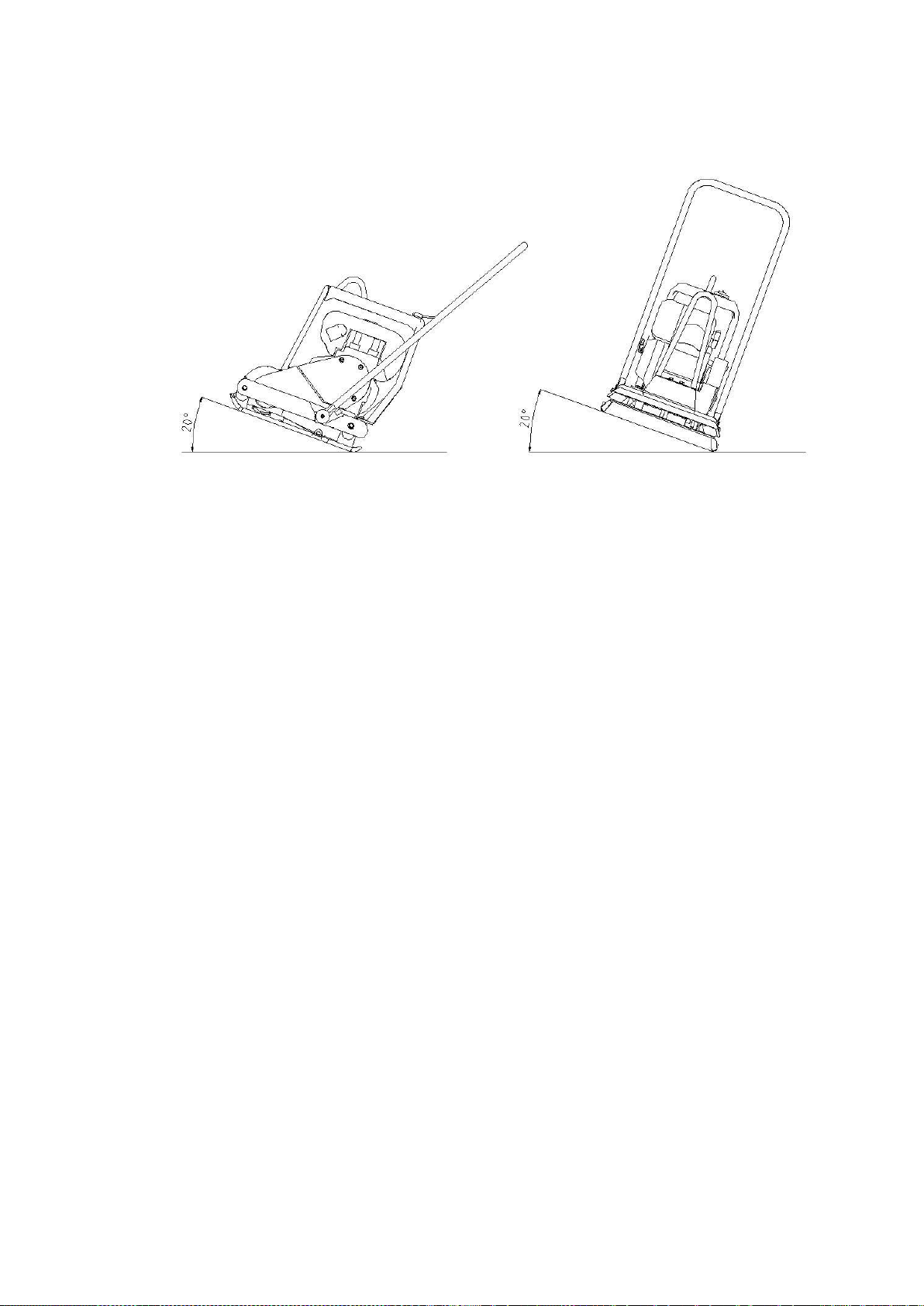

•When the work area is near slopes, the compactor could turn over.

•When you use compactor in reverse and in a narrow place, the operator must be sideways

from the handle in order to avoid stumbling.

•Always operate in safe conditions in order to avoid accidents.

•Always operate in maximum stability conditions.

•Use transport wheels only for movements in yard. In all the other situations they must be

removed.

•Always make sure of the proper functioning of the safety and control devices.

•If there are any problems, stop immediately the machine and inform the person responsible of

the yard.

•Attention is drawn to the use of BS2092 safety goggles in conformity with specified Processes

No.8 of the Protection of Eyes Regulation 1974, Regulation 2(2) Part 1. and additional dusk

mask for dry cutting (only in exceptionally cases).