Installation Sequence

Pull or Push Side Mount

Page 3

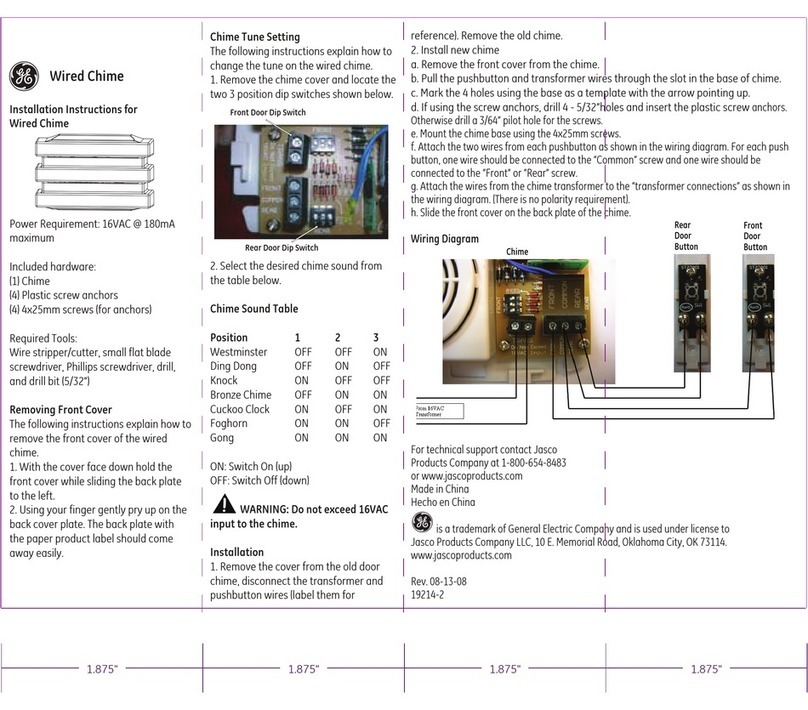

• Track Assembly

Use of the hold open assembly pack on a

non hold open device will void the

UL® listing for this product.

Remove slider assembly parts from box

# 40-7940-0050-000 for Non Hold Open or

# 40-7940-0051-000 for Hold Open

and insert into channel in the order shown.

See illustration on Page 2 or 4.

Insert end caps into ends of track prior to installing.

Place the assembled

slide track against frame with the open side down,

stop and cushion blocks toward the hinge. Move

the slider to the opposite end of the slide track.

Secure slide track with 1/4-20 flat head phillips

drive mounting screws.

• Install track to frame.

With door closed.

With door open slightly.

Rotate arm to slider and place end over stud. Push

up on arm and tap gently to seat (to prevent stud

from turning during assembly). Secure with 1/4-20 x

5/8" long truss (rounded) head phillips drive screw

with thread lock. CAUTION: Closer arm is under

spring tension and may be difficult to rotate.

Open door to the angle

you want the door to stop. With the door held at

that location, slide stop with cushion block against

slider. Tighten the stop position screw (large set

screw) with 3/16" hex wrench (from screw pack)

until secure. Release door.

(see Page 5) before installing cover.

Slide insert into unused cover slot (see

illustration on Page 2 or 4).

Install cover using screws provided.

Thread pinion cap into pinion shaft.

Do not overtighten.

Fasten cover to mounting clips

with screws provided.

• Connect arm to track.

Pull side:

Push side:

• Set door stop angle.

• Adjust closer

• Install Cover.

Full Cover:

Narrow Cover:

Full Metal Cover:

Install cover using screws

provided.

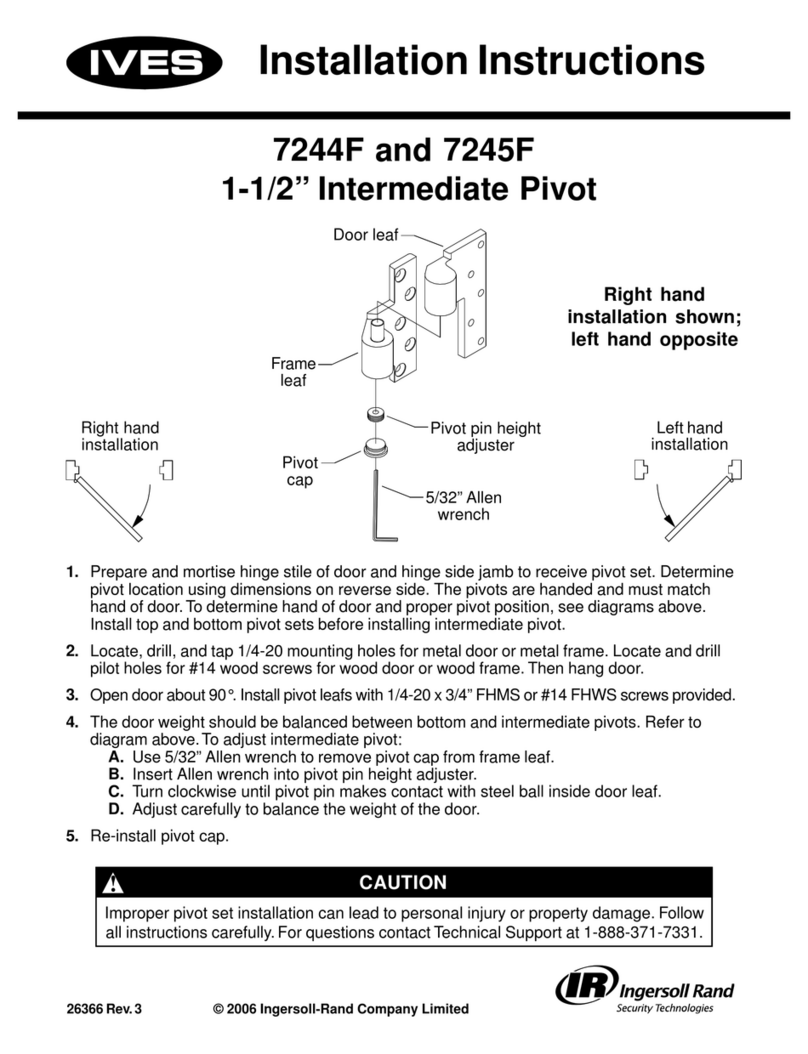

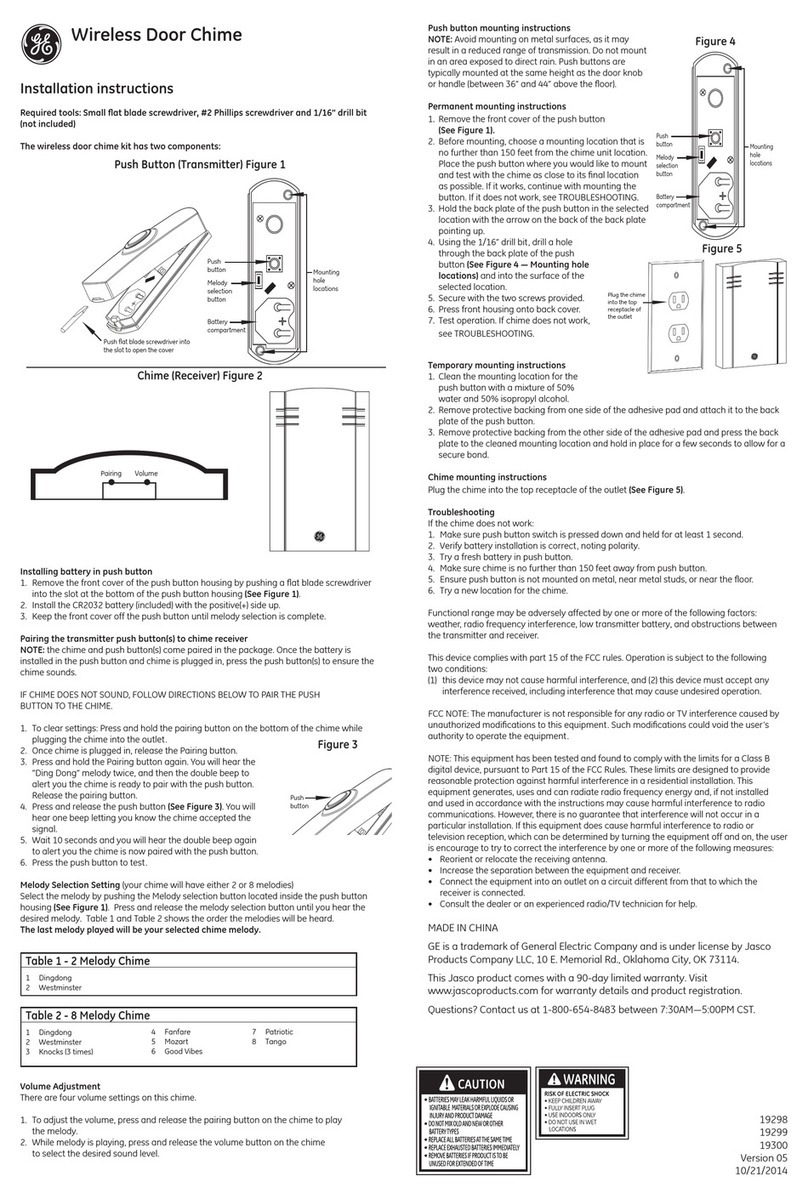

• Install arm on closer pinion-see arm indexing illustrations below.

(Top View)

Left hand

Right hand

Arm in position

Pinion Flat

Arm Indexing

PULL MOUNT

Start Here Start Here

Start Here Start Here

Reinstall Here

Rotate to Here Rotate to Here

Arm in position

Pinion Flat

Arm Indexing

PUSH MOUNT

Right hand Left hand

(Top View)

Pull mount:

Position slide arm

with counterbore

facing up and align

with pinion flat as

illustrated. Install

onto pinion.

Push mount:

With "S" & "L" valves

closed, place arm on

closer pinion shaft

with arm at a 45°

angle to frame face.

Rotate arm toward

hinge at least 50°.

Remove arm and

reinstall on pinion

with arm almost

parallel to frame

face, before pinion

shaft can rotate far

enough to create

interference with

door.

• Secure arm with washer and flat head phillips drive arm screw with

thread lock.

from

illustrations on Page 1.

on Page 2 or Page 4 to locate fastener

holes on door and frame. See "Preparation for Fasteners" chart.

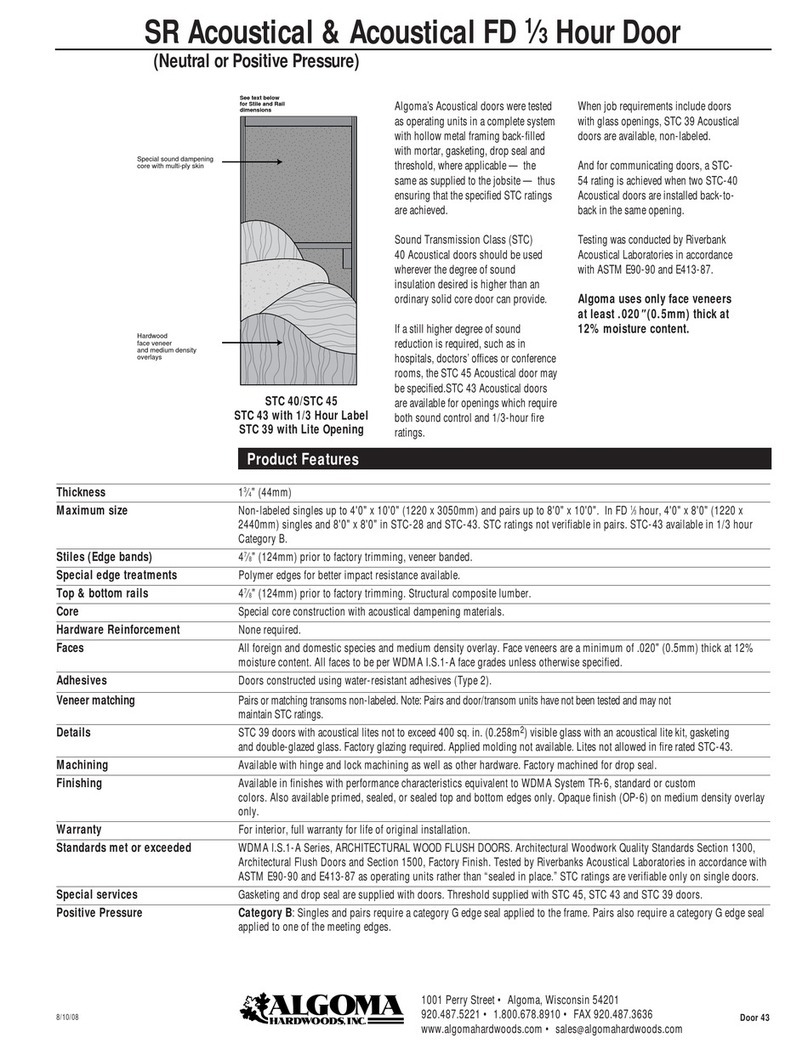

Prepare the frame for mounting track. Drill and tap holes

for 1/4-20 machine screws or #14 wood screws.

Prepare the door for mounting closer. Drill and tap (4)

holes for 1/4-20 machine screws, #14 wood screws,

3/8 diameter sex-nuts, or through bolts and grommet-nuts.

If drop plate is used (see Page 4), prepare holes for

8148/8548/8158 drop plate instead of closer.

Secure drop plate before mounting closer.

Position closer with:

- power adjustment shaft from hinge

- power adjustment shaft hinge

Secure mounting screws.

If using full metal cover, mounting clips must be slipped

under ends of closer when closer is being mounted.

Clips should project 1/4" (6 mm) from each end of closer.

Insert flat arm rod into arm tube with the

counterbore screw hole facing up. Align counterbore with the 3rd

hole in the arm tube and secure with 8-32 x 1/4 long hex socket

cap screw. See illustration on Page 2 or 4.

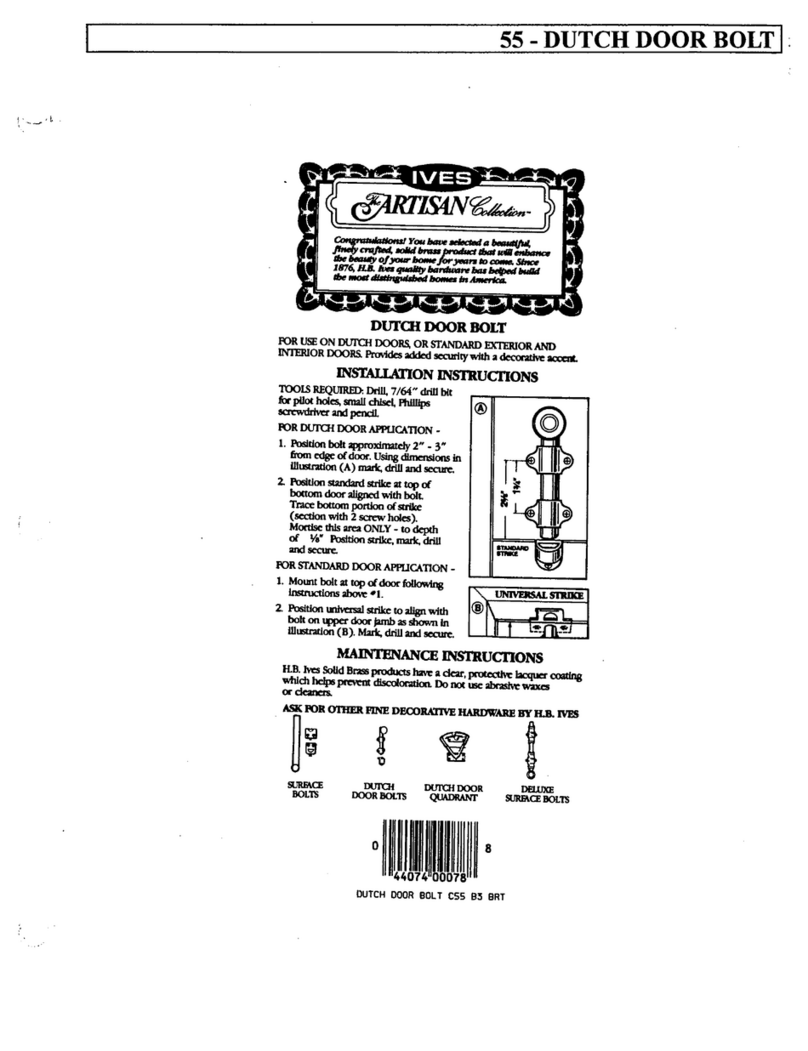

• Determine hand of door and type of installation

• Use template dimensions

Frame:

Door:

Note:

• Fasten closer to door or drop plate.

Pull side away

Push side toward

Note:

• Assemble Slide Arm.

80-9380-2212-020 (06-09)

Aluminum or

Wood

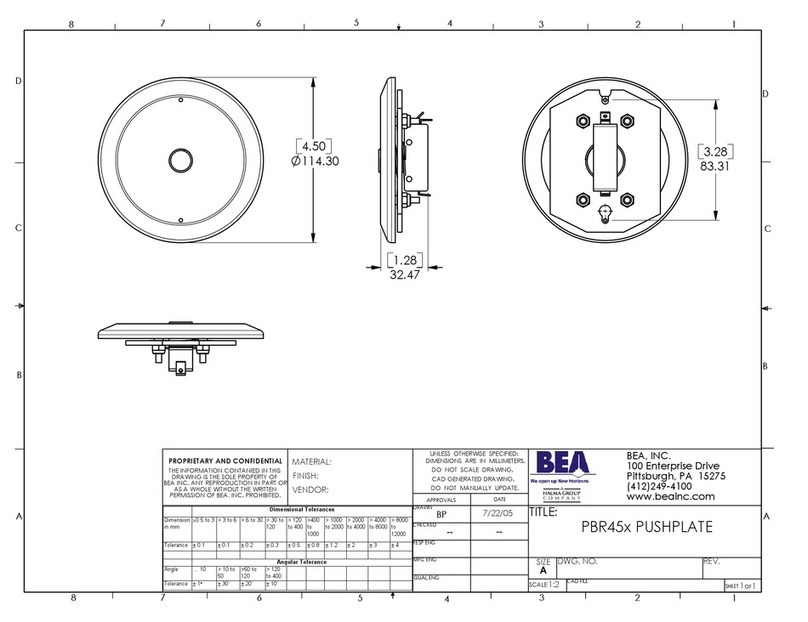

Preparation for Fasteners

Fasteners Door or Frame Drill Sizes

#14 type "A"

S.M. screw Wood 7/32" (5.56mm)

Closer: 1-1/4" (32mm)

Track: 2-3/4" (70mm)

1/4" -20 machine Metal drill: #7 (.201")

screw tap: 1/4" -20

Sex-nuts and bolts Hollow Metal 9/32" (7.00mm) through

3/8" (9.50mm) door-face

opposite to closer

3/8" (9.50mm) through

Through-bolts and 9/32" (7.00mm) through;

grommet-nuts All 3/8" (9.50mm) dia. x

3/8" (10mm) deep door-

face opposite to closer

(Optional)