Norvell M1000 User manual

SPRAY TAN SYSTEM

m1000

EXPLANATION

OF SYMBOLS USED

THIS INDICATES A CONDITION

THAT WILL CAUSE SERIOUS INJURY

OR LOSS OF LIFE IF THE WARNING

IS IGNORED.

THIS INDICATES THAT A CONDITION

COULD CAUSE SERIOUS INJURY

OR LOSS OF LIFE IF THE WARNING

IS IGNORED.

THIS INDICATES A CONDITION

THAT MAY CAUSE MINOR

INJURY AND/OR EQUIPMENT/

PROPERTY DAMAGE.

Read all safety information

before operating the equipment.

Save these instructions.

M1000 SPRAY SYSTEM

#1 Rated lightweight, portable spray tanning system!

Use in a salon or on the go. Expertly crafted to deliver

a natural-looking tan and even spray passes with Norvell

Solutions. Welcome to the Norvell Family and thank you

for entrusting your beautiful glow with the world’s most

sought-after brand. Whatever the event, occasion, or

day of the week Norvell has your shade.

Please visit us at norvelluniversity.com to become certified

as a spray tanning professional artist. Inside this box is a

coupon card with information on how to activate the warranty

on your equipment and begin your online training journey

at no cost.

Thank you,

The Norvell Team

FIELD OF APPLICATION

The Norvell M1000 Pro Mobile Spray Tan System has been specifically

developed for the application of Professional Norvell liquid spray tanning

solutions. Any application other than that described in this instruction

manual is not permitted and will immediately void ALL warranty.

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS.

To reduce the risks of fire or explosion, electrical shock and the injury to

persons, read and understand all instructions included in this manual. Be

familiar with the controls and proper usage of the equipment.

• Risk of fire or explosion! Solvent and paint fumes can explode or ignite,

causing severe injury and property damage.

• Paints and solvents containing HALOGENATED HYDROCARBONS

can react explosively with aluminum. Always check the product’s label

before using these materials in the unit.

• Hazardous vapors: Paint, solvents, insecticides, and other materials may

be harmful if inhaled, causing severe nausea, fainting or poisoning.

• Make sure the room is well ventilated. Avoid all ignition sources, such as

static electricity sparks, open flames, hot objects, sparks from

connecting and disconnecting power cords, and working light switches.

• Follow the material and solvent manufacturers’ safety precautions and

warnings. Do not use liquids with flash points less than 100 degrees

Fahrenheit (38 degrees Celsius).

• Static electricity can be produced by HVLP spraying. Make sure any

electrically conductive object being sprayed is grounded to prevent

static sparking. The sprayer is grounded to prevent static sparking.

The M1000 is grounded through the electrical cord on the unit. If an

extension cord is necessary, that extension cord must be a grounded

three-pronged cord. One that is made for the appropriate voltage used.

• Do not carry the turbine while spraying.

• Keep the turbine at the maximum distance from the spraying area.

• The M1000 is not to be used by persons (including children) with

reduced physical, sensory or mental capabilities, or lack of experience

and knowledge, unless they have been given supervision and instruction.

• Children should be supervised and instructed not to play with

the equipment.

IMPORTANT SAFETY INSTRUCTIONS

Improper installation of the plug can result in the risk

of electrical shock. If repair or replacement of the

plug or cord is necessary, contact the Norvell support

team for assistance. Do not use if the plug or cord is

damaged in any way. Only use the unit with an outlet

that is properly installed in accordance with local

codes and ordinances.

• For any question regarding proper installation of the plug,

consult a qualified (licensed or certified) electrician.

• Do not modify the plug provided. If the plug does not fit

the outlet, have the proper outlet installed by a qualified

electrician.

• This product is for use on a nominal 120-volt circuit. Make

sure that the product is connected to an outlet having the

same configuration as the plug. No adapters should be used

with this product.

• Keep cords away from water. Ground fault circuit interrupter

protection should be used when cords are in wet or damp

environments.

• When using an extension cord, be sure it is in good condition

and heavy enough to meet the specifications in the chart below.

If an extension cord is needed the following wire sizes must

be used (see chart below).

SET UP AND OPERATE YOUR

NORVELL M1000 SPRAY TAN SYSTEM

• Plug the Norvell M1000 HVLP spray tan system unit into a

proper electrical outlet. Make sure that the electric service

provides the nominal 120Vac circuit used by this system.

DO NOT attempt to connect the unit to the wrong electric

current as this will not only damage your unit but also void

your warranty.

• Next, locate the male end of the air hose and connect it to

the female quick connect on the M1000 spray tan system.

— To insert the coupler, pull back on the ring of the black

coupler located on the M1000 system and connect it to

the male connector on the hose.

— Release the ring to allow the coupler to snap into place.

The hose should now be connected to the unit.

— To remove the air hose, pull back on the ring of the black

coupler and remove.

If you have just finished spraying, the connector may

be hot. Allow the M1000 HVLP unit to cool down for

about 10 minutes before disconnecting the air hose

from the HVLP unit. Use Caution!

EXTENSION CORD

LENGTH

RECOMMENDED

GAUGE

25'CORD 10, 12, OR 14 GAUGE

10 OR 12 GAUGE50'CORD

10 GAUGE100'CORD

NORVELL CUSTOMER SERVICE 888.829.2831

NORVELLTANNING.COM/PROFESSIONAL

INFO@NORVELLTANNING.COM

PREPARE THE SPRAY GUN

• Unscrew the plastic cup from the Spray Gun. Pour Norvell

sunless tanning solution into the cup. Do not fill more than

3/4 full.

• Carefully screw the cup back onto the main body

of the Spray Gun. Screw the cup on firmly but

DO NOT over tighten. Over tightening will

cause the cup to “pop” and damage the threads.

Leakage will require replacement of the cup.

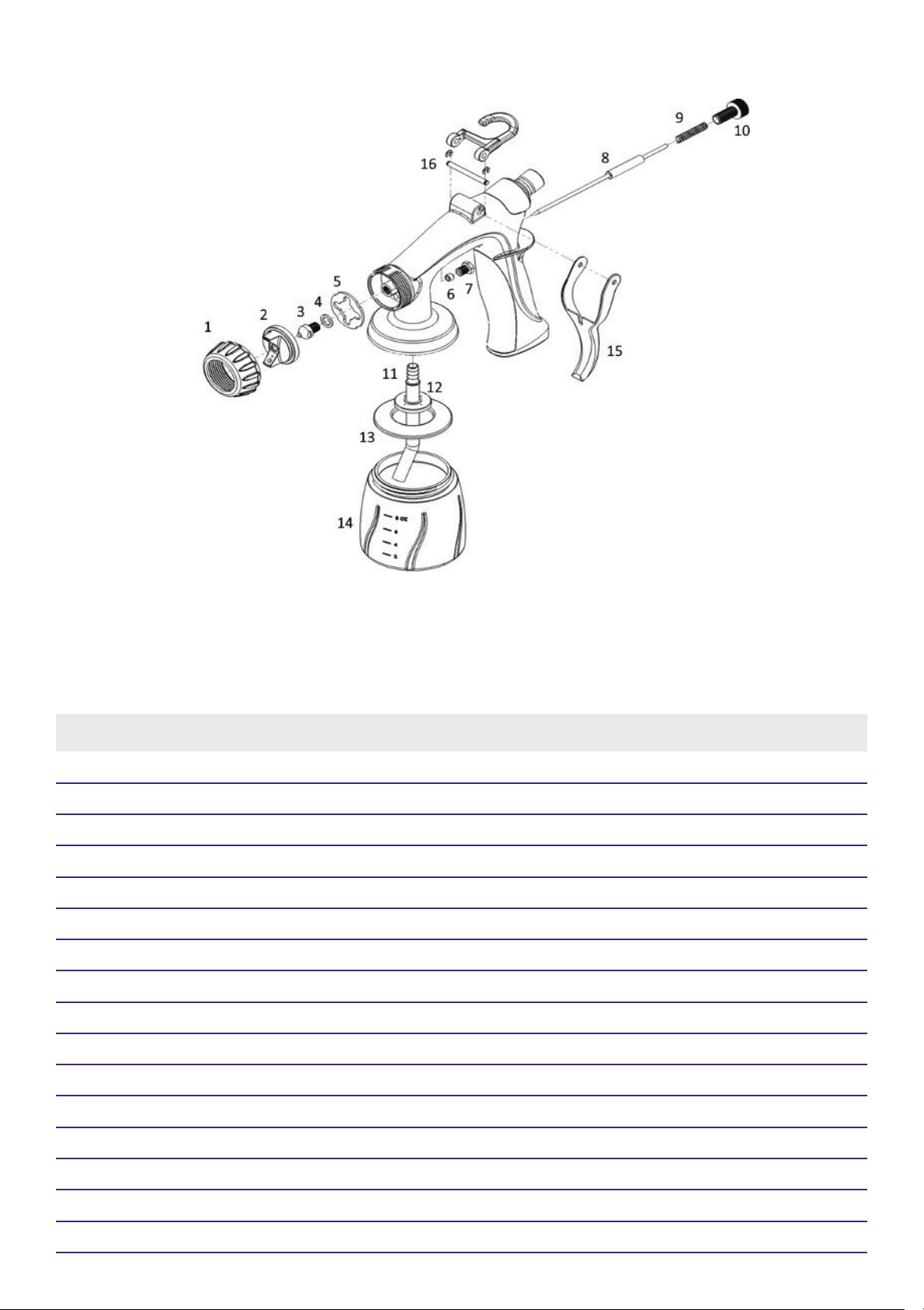

• Locate the air cap (#2) on the M1000 SPRAY GUN diagram.

Slightly turn the air cap ring (#1) counterclockwise to loosen the

air cap. Notice that you can now rotate the air cap freely.

• Look at Spray Gun Patterns diagram below. Note the position

of the air cap and the direction of the spray pattern. Pattern 1is

for spraying side to side. Pattern 2is for spraying up and down.

Pattern 3will produce a spot or circle. Patterns 1and 2are the

most common positions for applying tanning solutions.

• Turn the air cap (#2) to the position you want. Turn the air cap

ring (#1) clockwise to lock the air cap in place.

SPRAY GUN PATTERNS

• Next, position the M1000 HVLP Unit as far away as practical

and possible from the area where you will spray.

• Attach the remaining end of the hose to the M1000 HVLP

Spray Gun as follows:

— Locate the coupler at the rear top of the M1000 HVLP

Spray Gun. See SPRAY GUN diagram.

— Pull back on the collar of the black connector on the air hose.

— Push the connector over the coupler and release.

— Your Spray Gun should now be firmly attached to the

air hose.

ADJUSTING THE SPRAY GUN

• Locate the Solution Flow Screw (#10) on the M1000 SPRAY

GUN diagram.

• Turning the Solution Flow Screw clockwise reduces and will

eventually stop the flow of solution.

DO NOT over-tighten the screw as this will cause

damage to the end of the needle. Once the trigger

cannot be pulled back there is no point in tightening

the screw down more, this will only damage the end

of the needle.

• Turning the Solution Flow Screw anti or counterclockwise will

increase the flow of solution.

• In general, 1–2 full turns from the fully closed position will

provide a good solution flow. You may find that you want more

or less solution. You can adjust the Solution Flow Screw to your

desired setting.

NOTE: Opening the Solution Flow Screw more than 3turns

will not increase the solution flow and will in fact decrease the

efficiency of your Spray Gun.

• In general, hold the M1000 Spray Gun 6" (15cm) from the person

being sprayed. Moving the Spray Gun back will increase the size

of the mist pattern. Moving the Spray Gun closer will decrease the

size of the mist pattern. The further away you hold the Spray Gun,

the more you will need to increase the solution flow thus causing

abnormal amounts of airborne solution (overspray).

• Holding the Spray Gun closer to the person being sprayed along

with a minimum flow of solution will provide the best results, no

streaks or running solution and virtually no mist in the spray area.

• Be sure to move the Spray Gun at a slow, steady speed keeping

the distance of the Spray Gun the same throughout the

application. This will ensure perfect results. It is actually very

easy. Practice a few times and you will be an expert.

• It is best to hold the Spray Gun in a vertical position when

spraying. If you want to change the direction of the mist pattern,

rotate the position of the air cap rather than turning the Spray

Gun on its side.

• Always hold or store the Spray Gun in a vertical position. A slot in

the M1000 HVLP Turbo Unit is provided to hold and store the

Spray Gun. It is a good habit to use it when you are not spraying.

Spray across

from side

to side

Spray up

& down or

vertical

(preferred)

Spray in small

spot or circle

(contouring)

AIRCAP

POSITION PATTERN PURPOSE

DIAGRAM #

NORVELL M1000 SPRAY GUN PARTS LIST AND DIAGRAM

PART # DESCRIPTION

1202134 AIR CAP COLLAR

2202138 AIR CAP

3202139 NOZZLE

4202140 NOZZLE GASKET

5202133 AIR DISTRIBUTOR PLATE

6202012 NEEDLE GASKET

7202119 NEEDLE PACKING SCREW

8202137 NEEDLE

9202142 NEEDLE SPRING

10 202150 SOLUTION FLOW SCREW

11 202135 PICKUP TUBE

12 202136 PICKUP TUBE DISC

13 202145 CUP GASKET

14 202144 SOLUTION CUP

15 NA TRIGGER

16 NA TRIGGER PIN

M1000 Filter

Filter Cartridge Location

Removed Filter

FPO PIC

START SPRAYING

• The ON/OFF switch is located on the M1000 HVLP Spray

Tan Unit. Turn it on when ready.

• Open the Solution Flow Screw slowly.

• Set the mist pattern you wish to use by adjusting the air cap

to the desired position. Refer to Spray Gun Patterns.

• Direct the Spray Gun to the area of the body that you want

to start spraying.

• Pull back on the trigger (#15) and move the Spray Gun as noted

in the diagram below. Do not wave the Spray Gun back and

forth in front of your client by bending your wrist. Rather, keep

your wrist straight and move your entire arm. Movement should

be steady, even, and deliberate, always keeping your distance

the same.

MAINTENANCE

NORVELL M1000 HLVP SPRAY TAN SYSTEM

• The only maintenance necessary on the M1000 HVLP unit is

cleaning and/or changing the filter element. The filter should be

removed and rinsed out at least once every 30 days or after a

total of 30 sessions. The filter housing and filter are located on

the underside of the M1000 HVLP Unit.

• To clean or replace the filter, pull the tab on the filter housing

and remove the housing from the M1000 HVLP unit.

• Pull the filter out of the filter housing to clean or replace it.

AIR HOSE

• Wipe the air hose daily with a damp cloth and store in a clean

dry place.

SPRAY GUN

• It is important to clean your Spray Gun daily.

• At the end of the day or when the equipment will not be used

any more, disconnect the Spray Gun from the air hose.

• Carefully unscrew the cup. If there is remaining solution, either

close the cup with a cup lid, or pour the remaining

solution into a proper storage container.

• Rinse the cup under warm running water until clean.

• Fill the cup about 1 /4 full with water. Reconnect Spray Gun to

Air Hose. Turn on the M1000 HVLP Unit. Direct the Spray Gun

to a safe area and spray the clean warm water through the Spray

Gun until the cup is empty.

• Turn off the M1000 HVLP Unit. Disconnect the Spray Gun.

Unscrew the cup.

• Wipe all exposed areas dry.

• Unscrew and remove the Air Cap Collar (#1). Rinse the threads

under warm running water. Wipe clean the threads and dry.

Add a small amount of Spray Gun lube to the threads.

• Remove the Air Cap (#2). Rinse under warm running water.

Wipe clean and dry.

• If necessary, remove Air Distributor Plate (#5). Rinse under

warm running water. Wipe clean, dry, and lubricate with Spray

Gun lube.

• Reinstall the three pieces you just removed by reversing the

removal procedure. Your Spray Gun should be ready for the

next use. Store the Spray Gun in the holder on the M1000

HVLP Unit.

• The Solution nozzle (#3) can be removed for additional

cleaning if necessary. Be careful. There is a Solution nozzle

gasket (#4) around the threads of the Solution nozzle. Be sure

to reinstall or leakage will occur. Removal of the Solution nozzle

is not necessary on a daily basis. You should, however, remove it

once a week and rinse under running water. The Solution nozzle

can be easily removed with an adjustable wrench or spanner or

the wrench provided in the Spray Gun Repair Kit. Place the tip

of your adjustable wrench or spanner on the two flat areas of

the nozzle and twist counterclockwise.

• The Solution needle (#10) can also be removed for additional

maintenance. To remove: Turn the Solution Flow Screw anti

or counterclockwise until it comes out of the Spray Gun.

Be careful when removing the Solution Flow Screw as there

is a small spring (#9) around the needle. Do not lose it. This is

important to the operation of the Spray Gun. Set the spring

aside and pull the trigger all the way back until you can grab the

needle with your fingertips and pull it out from the back

of the Spray Gun. Once removed, rinse under warm running

water, clean and dry. Reinstall reversing the removal procedure.

NOTE: Occasionally it is necessary to lubricate the needle (#10)

where it slides through the gland nut (#7). Simply rub a few

drops of Spray Gun lube around the needle shaft and reinsert

into the back of the Spray Gun.

TROUBLESHOOTING

1. The M1000 HVLP unit is turned ON and air is blowing out

of the M1000 Spray Gun. This is correct. Air blows constantly

when the HVLP unit is ON.

2. The M1000 HVLP unit is turned ON but the unit is not

operating or blowing air. Check that the unit is plugged in

to a proper electrical source. Be sure there is power at the

electrical source. If there is no problem with the electrical

supply, please call Norvell

technical support.

3. The M1000 HVLP unit is turned ON and the trigger is

pulled back, but no solution comes out. Check that the cup

is screwed firmly to Spray Gun. Check that there is no solution

bubbling or leaking around the cup. Turn M1000 HVLP unit

OFF. Unscrew cup. Be sure that Solution Tube and Disc (#14) is

connected and has not come loose. Locate the two small holes in

the Disc around the Solution tube. Be sure that these two small

holes are not clogged with dried solution. To clean, carefully

insert a pin through each hole ensuring that they are clear. Turn

M1000 HVLP Turbo unit OFF. Remove the Air Cap Collar (#1),

the Air Cap (#2) and the Air Distributor Plate (#5). Remove

Solution nozzle (#3) with an adjustable wrench or spanner. There

is a Solution nozzle gasket (#4) on the Solution nozzle. Do not

lose it. Rinse Solution Nozzle under running water and check for

dried solution that may have blocked the hole. Reinstall Solution

Nozzle Gasket. Reinstall the nozzle assembly. Try spraying again.

If you still have a problem, please call Norvell technical support.

4. There is solution leaking in front of the trigger. With a wrench,

tighten Solution Needle Packing Screw (#7). Do not over tighten.

This can cause Solution needle to stick and not spring back. Try

spraying again. If leaking continues the Solution Needle Packing

needs to be replaced. Remove Solution Needle Packing Screw

(#7). Pry out the Solution Needle Spring (#9). Replace. Reinstall

Solution Needle Packing Screw. Tighten all the way, and then back

off slightly. (1/8 turn) Test spray gun for leakage. If you still have

a problem, please call Norvell technical support.

5. Solution is spraying out of the nozzle without the trigger being

pulled. Immediately turn M1000 HVLP unit OFF and disconnect

spray gun from air hose. Slightly adjust (loosen) Solution Needle

Packing Screw (#7). Test to see if problem is resolved. Check

to see that Needle Spring is installed. (#9). Remove Solution Flow

Screw (#10). Look for Needle Spring around the back of the

Solution Needle. (See diagram). If lost, call for a replacement.

Check Solution nozzle. Remove and clean using item 4, above.

6. Solution is leaking out around the top of the cup. Make sure

that the cup has been screwed firmly to the body of the Spray

Gun. Make sure the threads around the cup are clean and the

threads inside the cup top assembly are clean. Replace the

Cup Gasket (#13) by prying out the old gasket and firmly

pressing a new gasket into position.

WARRANTY AND TECHNICAL SUPPORT

For all technical questions please call Norvell, A Division of Sunless, Inc. at

855.450.3500. For spraying technique and certification visit norvelluniversity.com.

TECHNICAL SUPPORT

Available Monday–Friday | 8AM–4:30PM, CST.

Norvell

855.450.3500

norvelltanning.com

Norvell, A Division of Sunless, Inc.

MAINTENANCE VIDEOS

We have created a series of videos to help you properly care for your Norvell

equipment. These can be found at:

norvelltanning.com

youtube.com/user/NorvellSunless

REPAIR

Norvell has an in-house repair department to assist you if your equipment is in or out

of warranty. Contact Norvell for instructions in utilizing this support.

Available Monday–Friday | 8AM–4:30PM, CST.

855.450.3500

The Norvell Mobile M1000 Turbine is warranted by Norvell for a total period of one (1)

year from the ORIGINAL date of purchase by the ORIGINAL PURCHASER. Proof of

purchase should be included and all SHIPPING CHARGES to be pre-paid when sending

back to Norvell for repair.

Norvell, upon examination of the machine/equipment, will replace or repair, at their

discretion, defects in material or workmanship. The warranty covers manufacture

defects only.

This warranty does not include:

Misuse, damage, neglect, alterations, disassembled equipment or modifications,

lack of maintenance, cleaning, water damage to electrical parts and incorrect voltage

connection.

This warranty in lieu of all other express warranties, any warranty implied by law, including

but not limited to implied warranties of merchantability to fitness, is excluded to the

maximum extent permitted by law and, if not excludable, it is limited to the duration of

the express warranty.

No representative or person is authorized to extend this warranty or to create for Sunless,

Inc./Norvell, any other liability in connection with the sale of any Norvell products.

Sunless, Inc./Norvell shall not be liable for any consequential, incidental, or special

damages of any kind directly or indirectly resulting from breach of any express or

implied warranty.

DO NOT USE EQUIPMENT BEFORE READING THIS MANUAL!

This manual contains important warnings and instructions.

Call to register your warranty today.

Please read these instructions carefully and keep for your reference.

NORVELL, A DIVISION OF SUNLESS, INC.

Customer Service 888.829.2831 or 615.529.1250

norvelltanning.com/professional

Other manuals for M1000

1

Table of contents

Other Norvell Paint Sprayer manuals

Popular Paint Sprayer manuals by other brands

WAGNER

WAGNER GA 5000EAIC Translation of the original operating manual

SATA

SATA SATAjet 1000 K HVLP operating instructions

Task Force Tips

Task Force Tips Masterstream Series Instructions for installation, safe operation and maintenance

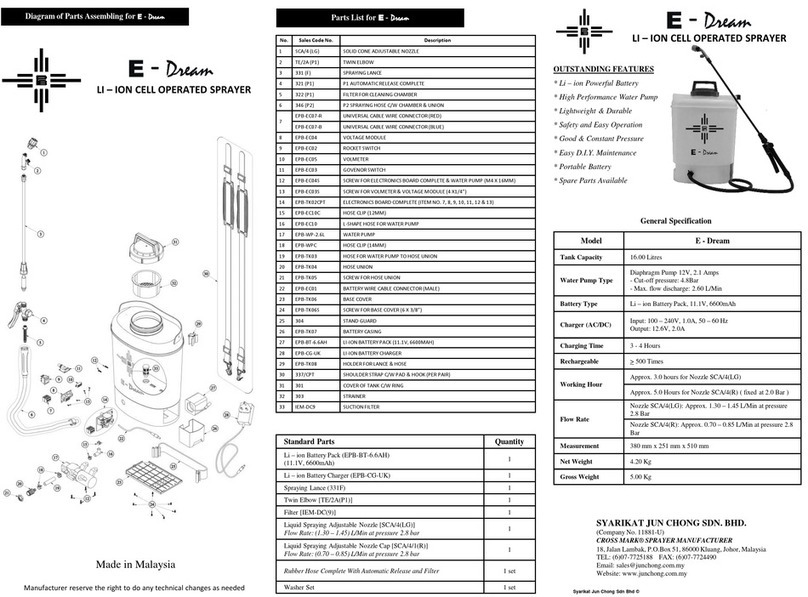

SYARIKAT JUN CHONG

SYARIKAT JUN CHONG E-Dream instruction manual

Stihl

Stihl SR 450 instruction manual

Earlex

Earlex SPRAY STATION HV3500 Operating instructions manual